The exhaust system component designed to reduce engine noise on a specific vehicle model, manufactured by a prominent Japanese automotive company, plays a critical role in vehicle operation. It mitigates sound produced by combustion, contributing to a quieter driving experience and compliance with noise regulations. Failure or degradation of this component typically results in increased exhaust volume and potential violations of local ordinances.

Maintaining this component in optimal condition offers multiple benefits. It ensures a more comfortable ride for occupants, minimizes noise pollution within the community, and helps maintain the resale value of the vehicle. Historically, advancements in automotive engineering have focused on improving the efficiency and longevity of these noise-reducing devices, leading to designs that are more durable and effective than earlier iterations.

This article will explore the various types of these components available, common issues that may arise, maintenance procedures, and factors to consider when selecting a replacement. Furthermore, it will delve into the installation process and potential performance upgrades.

Tips for Maintaining Optimal Exhaust System Performance

Maintaining the integrity of the exhaust system, including the sound-dampening component specific to the mid-size sedan referenced, is crucial for vehicle longevity and regulatory compliance. Adhering to these maintenance guidelines ensures optimal function and minimizes potential repair costs.

Tip 1: Routine Visual Inspections: Regularly examine the exhaust system for signs of corrosion, rust, or physical damage, particularly after operating the vehicle in harsh weather conditions or on rough terrain. Early detection of deterioration prevents small issues from escalating into major problems.

Tip 2: Prompt Addressing of Unusual Noises: Investigate any changes in exhaust tone immediately. Unusual rattling, hissing, or booming sounds can indicate leaks, damaged components, or loose connections that require professional attention.

Tip 3: Professional Exhaust System Checks: Schedule periodic inspections by a qualified mechanic. A professional assessment can identify subtle issues not readily apparent during visual inspections, such as internal corrosion or failing hangers.

Tip 4: Careful Driving Habits: Avoid driving habits that can stress the exhaust system, such as frequently traversing rough roads or aggressively accelerating the vehicle. These habits can accelerate wear and tear, reducing the lifespan of the components.

Tip 5: Adherence to Recommended Maintenance Schedules: Follow the vehicle manufacturer’s recommended maintenance schedule for exhaust system components. Replacing worn or damaged parts at the designated intervals ensures continued optimal performance.

Tip 6: Consider Quality Replacement Parts: When replacement becomes necessary, opting for high-quality, OEM-specified, or equivalent aftermarket parts is essential. Inferior components may not provide the same level of performance or longevity.

Regular maintenance and prompt attention to potential problems are critical for ensuring the efficient and quiet operation of the vehicle. Ignoring early warning signs can lead to more extensive and costly repairs.

The following sections will detail common problems, repair options, and performance upgrades available for this system.

1. Noise Reduction

The primary function of the exhaust system component installed on this Japanese-manufactured mid-size sedan is noise abatement. The effectiveness of this component directly correlates to the vehicle’s compliance with noise regulations and the overall comfort of the driving experience. Understanding the mechanisms of sound suppression within this component is vital for effective maintenance and repair.

- Internal Baffle Design

The internal configuration of baffles within the component is crucial. These baffles are strategically positioned to redirect exhaust gases, causing them to collide and interfere with each other. This interference reduces the amplitude of sound waves, resulting in a quieter exhaust note. Variations in baffle design significantly influence the frequency and intensity of the emitted sound.

- Resonance Chamber Utilization

Resonance chambers are often incorporated into the design to target specific frequencies. These chambers are tuned to resonate at particular sound frequencies, effectively canceling them out through destructive interference. The size and shape of the resonance chamber directly impact its ability to attenuate specific noise components.

- Acoustic Absorption Materials

Some designs incorporate sound-absorbing materials, such as fiberglass or steel wool, within the component’s casing. These materials absorb sound energy, converting it into heat and further reducing noise levels. The type and density of the acoustic absorption material significantly influence its effectiveness over time.

- Exhaust Gas Velocity Management

The component’s design influences the velocity of exhaust gases as they pass through the system. By controlling gas velocity, turbulence and associated noise can be minimized. Excessive turbulence can generate additional noise, while a smoother flow promotes quieter operation.

The aforementioned noise reduction methods are not mutually exclusive; rather, they are often combined to achieve optimal sound suppression within this vehicle’s exhaust system. The specific combination of techniques used will depend on factors such as engine size, vehicle model year, and applicable noise regulations. Furthermore, degradation of any of these elements contributes to elevated noise levels and may necessitate component replacement.

2. Exhaust Flow

Exhaust flow is a critical parameter directly impacting the performance and efficiency of an internal combustion engine, particularly in the context of its noise-reducing component in a mid-size vehicle produced by a Japanese manufacturer. A properly designed exhaust system optimizes the evacuation of spent gases from the engine cylinders, thereby influencing power output, fuel economy, and emissions.

- Backpressure Effects

The internal design of the noise-reducing component inevitably creates a degree of backpressure. Excessive backpressure hinders the engine’s ability to expel exhaust gases efficiently, leading to reduced horsepower and torque, particularly at higher engine speeds. Conversely, insufficient backpressure can negatively affect low-end torque and fuel economy. An optimal design balances noise reduction with minimal flow restriction. Examples include using a straight-through design with perforated cores or incorporating strategically placed resonators.

- Internal Component Geometry

The shape and size of internal passages, baffles, and chambers significantly influence exhaust flow characteristics. Sharp bends, narrow constrictions, and poorly designed expansion chambers can create turbulence and flow resistance. A well-designed component features smooth transitions, optimized cross-sectional areas, and carefully calculated chamber volumes to minimize flow losses while maintaining effective noise reduction. Performance aftermarket options often prioritize flow optimization, sometimes at the expense of sound deadening, compared to Original Equipment Manufacturer (OEM) designs.

- Material and Surface Finish

The material used in construction and the surface finish of internal components affect flow dynamics. Rough surfaces create friction and turbulence, impeding gas flow. Smoother surfaces, achieved through processes like mandrel bending and polishing, reduce friction and improve flow efficiency. Stainless steel and aluminized steel are common materials, with stainless steel offering superior corrosion resistance and potentially smoother internal surfaces over time. The material choice influences the component’s longevity and its ability to maintain consistent flow characteristics.

- Impact on Engine Performance and Efficiency

Optimizing exhaust flow directly enhances engine performance. Reducing backpressure allows the engine to breathe more freely, leading to increased horsepower and improved throttle response. A more efficient exhaust system also contributes to improved fuel economy by reducing the engine’s workload. Conversely, a poorly designed component can stifle engine performance and reduce fuel efficiency. Diagnostic tests, such as measuring exhaust backpressure with a manometer, can indicate whether the component is restricting flow excessively.

The interrelationship between noise reduction and exhaust flow necessitates a careful balance in the design and selection of the noise-reducing component. Aftermarket components often prioritize either performance or sound reduction, requiring consumers to carefully consider their priorities. Regular inspection and maintenance are crucial for ensuring that the component functions as intended, maintaining both acceptable noise levels and optimal engine performance. Degradation or damage can lead to increased backpressure, reduced efficiency, and potentially engine damage.

3. Component Material

The materials utilized in the construction of an exhaust silencing device, particularly for a specific mid-size vehicle from a Japanese automotive manufacturer, are paramount to its performance, longevity, and resistance to environmental degradation. The choice of materials directly impacts the components ability to withstand high temperatures, corrosive elements, and mechanical stresses.

- Steel Grades and Alloys

Various grades of steel, including carbon steel, aluminized steel, and stainless steel, are commonly employed. Carbon steel, while cost-effective, is susceptible to corrosion and has a shorter lifespan. Aluminized steel offers enhanced corrosion resistance due to its aluminum coating, extending its service life compared to carbon steel. Stainless steel provides the highest level of corrosion resistance, particularly against road salt and acidic exhaust gases, making it a preferred choice for durability. The specific alloy composition within stainless steel, such as 304 or 409, further influences its corrosion resistance and high-temperature strength. In regions with heavy road salt usage, stainless steel variants are often recommended to mitigate premature failure.

- Welding Techniques and Material Compatibility

The welding techniques used to join the components sections must be compatible with the chosen materials. Improper welding can compromise the structural integrity and corrosion resistance of the joints. For instance, welding stainless steel requires specialized techniques, such as gas tungsten arc welding (GTAW), to prevent sensitization and maintain its corrosion-resistant properties. Dissimilar metal welding, such as joining stainless steel to aluminized steel, can create galvanic corrosion if not executed properly, necessitating the use of specific filler metals and protective coatings.

- Internal Acoustic Packing Materials

The materials used for internal acoustic packing, such as fiberglass, steel wool, or ceramic wool, influence sound absorption characteristics and resistance to heat degradation. Fiberglass, a common choice, offers effective sound absorption but can degrade over time due to exposure to high temperatures and moisture. Steel wool provides higher temperature resistance but may be prone to corrosion in certain environments. Ceramic wool offers superior thermal stability and resistance to chemical attack, making it a premium option for long-term performance. The choice of packing material affects the components sound-dampening effectiveness and its lifespan under typical operating conditions.

- Protective Coatings and Treatments

Protective coatings and surface treatments enhance the corrosion resistance and durability of the component. Coatings such as ceramic-based paints, zinc-rich primers, or aluminized coatings provide a barrier against corrosive elements and high temperatures. These coatings help prevent rust formation and extend the components service life. The application process and quality of the coating are critical to its effectiveness. Regular inspections for coating damage and prompt repairs can prevent localized corrosion and extend the overall lifespan of the exhaust silencing device.

The careful selection and application of appropriate materials are crucial for ensuring the reliability and longevity of this exhaust system component. Material choices must consider the vehicle’s operating environment, the desired level of performance, and the anticipated service life. Understanding the properties of different materials and their compatibility with welding and coating processes is essential for informed maintenance and replacement decisions.

4. Corrosion Resistance

Corrosion resistance is a paramount attribute for the exhaust silencing component in a mid-size vehicle manufactured by a Japanese automotive company, directly influencing its longevity and performance under diverse environmental conditions. The exhaust system operates in a harsh environment, exposed to high temperatures, moisture, road salts, and acidic exhaust gases, making robust corrosion protection essential.

- Material Selection and Grade

The choice of materials, particularly the grade of steel used, significantly impacts corrosion resistance. Stainless steel, especially grades 304 and 409, provides superior resistance compared to aluminized steel or carbon steel. The presence of chromium and nickel in stainless steel forms a passive oxide layer that protects the underlying metal from corrosion. In regions with heavy road salt usage, selecting a stainless steel component can substantially extend its lifespan. Using dissimilar metals can induce galvanic corrosion, so engineers choose wisely.

- Protective Coatings and Surface Treatments

Protective coatings, such as aluminized coatings or ceramic-based paints, create a barrier against corrosive elements. These coatings prevent direct contact between the metal substrate and the surrounding environment. The effectiveness of the coating depends on its application process, thickness, and adherence to the metal surface. Regular inspections for coating damage are essential to prevent localized corrosion. Self-sacrificing (anodic) coatings such as zinc are used in certain applications for optimal protection.

- Welding Techniques and Joint Integrity

Welding processes can compromise corrosion resistance if not executed correctly. Improper welding can lead to sensitization in stainless steel, reducing its chromium content and increasing its susceptibility to corrosion. Proper welding techniques, such as gas tungsten arc welding (GTAW) with appropriate filler metals, are crucial for maintaining joint integrity and corrosion resistance. Crevice corrosion may occur with gaps in welds or seals.

- Internal Design and Moisture Management

The internal design influences moisture accumulation and corrosion rates. Designs that promote rapid water drainage minimize the time of exposure to corrosive fluids. Condensation within the component can accelerate corrosion, particularly in areas with stagnant airflow. Internal baffles and chambers should be designed to prevent moisture trapping. Drainage holes are typically integrated to facilitate water removal.

In summation, corrosion resistance is not a singular property but rather a combination of material selection, protective measures, welding techniques, and design considerations. The effectiveness of these factors determines the durability and long-term performance of this exhaust component. Ignoring corrosion resistance considerations can lead to premature failure, increased noise levels, and potential safety hazards.

5. Model Compatibility

Model compatibility is a critical consideration when addressing the exhaust silencing component of a specific vehicle, such as a mid-size sedan from a Japanese automotive manufacturer. The consequences of selecting an incompatible component range from installation difficulties to compromised vehicle performance and potential system damage. This stems from the nuanced design differences between model years and trim levels, which necessitate precise dimensional and functional matching. For example, a component designed for a 2010 model may not properly fit or function on a 2015 model due to changes in chassis design, exhaust routing, or engine specifications.

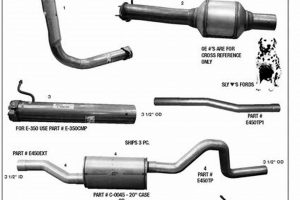

The proper selection of a compatible exhaust silencing component directly impacts several key areas. First, it ensures a secure and leak-free installation, preventing exhaust leaks that can lead to decreased fuel economy, increased emissions, and elevated noise levels. Second, it guarantees that the component aligns with existing exhaust hangers and mounting points, minimizing stress on the exhaust system and preventing premature wear. Third, it ensures that the component’s backpressure characteristics are compatible with the vehicle’s engine management system, maintaining optimal engine performance. Aftermarket components are often advertised as fitting multiple model years. However, careful verification of compatibility with the specific vehicle is essential to avoid potential problems.

In conclusion, model compatibility is an indispensable aspect of selecting a suitable replacement. Overlooking this factor can result in a cascade of negative consequences, ranging from installation headaches to significant performance and emissions issues. Vehicle owners should consult reliable parts catalogs, verify part numbers, and, when in doubt, seek professional advice to ensure the chosen component is specifically designed and validated for their vehicle. Choosing carefully avoids costly mistakes and ensures the vehicle operates as intended.

6. Installation Complexity

The level of difficulty associated with the replacement of the exhaust silencing component in a mid-size vehicle from a Japanese manufacturer varies considerably, depending on factors such as vehicle model year, existing exhaust system condition, and the skill level of the installer. Understanding this complexity is crucial for both do-it-yourself enthusiasts and professional mechanics.

- Accessibility of Mounting Points

The ease of accessing mounting bolts and hangers significantly affects the installation process. Rust, corrosion, and the presence of heat shields can obstruct access and require specialized tools or techniques. Limited clearance around the exhaust system may necessitate the removal of other components to gain sufficient working space. Some model years may have mounting points that are more difficult to reach than others due to chassis design.

- Condition of Existing Hardware

The state of the existing mounting bolts, nuts, and hangers plays a crucial role in the ease of removal. Severely corroded or seized hardware can require the use of penetrating oils, heat, or specialized extraction tools, significantly increasing the time and effort required for the replacement. In some cases, the existing hardware may need to be cut or broken off, further complicating the process.

- Need for Specialized Tools

Certain installations may require specialized tools, such as an exhaust hanger removal tool, oxygen sensor socket, or torque wrench. Accessing difficult-to-reach bolts or properly tightening fasteners to the manufacturer’s specifications often necessitates these tools. The absence of these tools can prolong the installation process and potentially damage components.

- Potential for Exhaust System Modification

In some cases, the replacement component may not perfectly align with the existing exhaust system, requiring minor modifications such as cutting, welding, or bending pipes. Such modifications demand specialized skills and equipment and can significantly increase the complexity of the installation. Aftermarket components, in particular, may require adjustments for proper fitment.

Therefore, the installation of this exhaust component can range from a relatively straightforward task to a complex undertaking requiring specialized skills and tools. Assessing the condition of the existing exhaust system and possessing the necessary tools and knowledge are essential for a successful installation. When in doubt, seeking professional assistance is recommended to avoid potential damage to the vehicle or injury to the installer.

7. Regulatory Compliance

The exhaust silencing device in a mid-size vehicle produced by a Japanese automotive manufacturer is subject to various noise emission standards mandated by federal, state, and local regulations. These regulations establish maximum permissible noise levels that vehicles must meet during operation. The component must effectively reduce engine noise to comply with these limits. Failure to meet these standards can result in fines, vehicle inspection failures, and restrictions on vehicle usage. For example, many states conduct roadside noise checks and issue citations for vehicles exceeding established decibel limits. Tampering with or removing the silencing device to increase exhaust volume is a common violation.

The design and performance characteristics of the aforementioned component are directly influenced by these regulatory requirements. Manufacturers must engineer these parts to achieve a balance between effective noise reduction, minimal exhaust flow restriction, and durability, all while adhering to legal noise limits. Changes to the component, such as modifications to the internal baffling or the use of less restrictive materials, can compromise noise reduction and lead to non-compliance. Aftermarket components are also subject to regulatory scrutiny and must be certified to meet applicable noise standards. The installation of non-compliant components can expose vehicle owners to legal penalties.

Adherence to noise emission regulations is crucial for maintaining environmental quality and public health. Excessive vehicle noise contributes to noise pollution, which can have adverse effects on human health and well-being. By ensuring compliance with noise standards, manufacturers and vehicle owners contribute to a quieter and more livable environment. The understanding of this exhaust system component is essential for promoting responsible vehicle ownership and mitigating the negative impacts of noise pollution.

Frequently Asked Questions

This section addresses common inquiries regarding the exhaust silencing component specific to the Nissan Altima, providing concise and informative answers.

Question 1: What are the primary indicators of a failing exhaust silencing component on a Nissan Altima?

Increased exhaust noise, rattling sounds emanating from under the vehicle, reduced fuel efficiency, and a failed emissions test are common indicators of potential failure. A visual inspection may reveal rust, corrosion, or physical damage to the component.

Question 2: How frequently should the exhaust silencing component on a Nissan Altima be inspected?

A visual inspection of the exhaust system, including the silencing component, is recommended at least annually or during routine maintenance intervals, such as oil changes. More frequent inspections may be warranted in regions with harsh winter conditions or extensive road salt usage.

Question 3: What is the typical lifespan of the exhaust silencing component on a Nissan Altima?

The lifespan varies depending on factors such as driving conditions, climate, and material quality. However, a properly maintained component can typically last between 5 and 7 years, or 80,000 to 120,000 kilometers.

Question 4: Can an aftermarket exhaust silencing component negatively impact the performance of a Nissan Altima?

Yes. While some aftermarket components may offer enhanced performance, others can reduce engine efficiency if not properly matched to the vehicle’s specifications. Selecting a component with appropriate backpressure characteristics is crucial.

Question 5: Is it possible to repair a damaged exhaust silencing component on a Nissan Altima, or is replacement always necessary?

Minor damage, such as small holes or cracks, may be repairable through welding. However, extensive damage, significant corrosion, or internal degradation typically necessitates replacement to ensure proper noise reduction and exhaust flow.

Question 6: What is the approximate cost associated with replacing the exhaust silencing component on a Nissan Altima?

The cost varies depending on the type of component (OEM vs. aftermarket), material, and labor rates. Generally, expect to spend between $200 and $500 for parts and labor, but obtain estimates from qualified mechanics for accurate pricing.

Understanding these common concerns helps owners make informed decisions regarding maintenance and repair. Neglecting a malfunctioning component can result in increased noise pollution, reduced vehicle performance, and potential legal ramifications.

The subsequent section will provide guidance on selecting a suitable replacement.

Muffler Nissan Altima

The foregoing examination has detailed the critical aspects of the muffler nissan altima, encompassing its function, maintenance, material composition, compatibility, and regulatory implications. Understanding these elements is crucial for ensuring optimal vehicle performance, regulatory compliance, and environmental responsibility.

The long-term integrity of the vehicle and the well-being of the environment necessitate diligent attention to the exhaust system’s health. Responsible maintenance and the informed selection of replacement components are paramount, ensuring both a compliant and quiet operation. Prioritizing these factors represents a commitment to sustainable vehicle ownership and environmental stewardship.