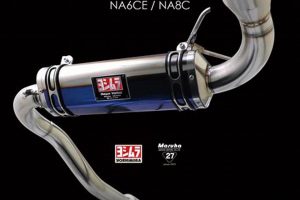

An automotive component engineered for exhaust systems, it is designed to attenuate engine noise while optimizing exhaust flow. This device commonly features a stainless steel construction for enhanced durability and resistance to corrosion, and is often selected by vehicle enthusiasts seeking a balance between performance and a refined sound profile.

The selection of this component often results in a noticeable alteration of the vehicle’s auditory characteristics, delivering a deeper, more aggressive tone compared to factory-installed alternatives. Furthermore, its design aims to minimize backpressure within the exhaust system, potentially contributing to improved engine efficiency and power output. Its adoption reflects a driver’s focus on both acoustic enhancement and possible performance gains.

The subsequent sections will delve into specific aspects, including its construction characteristics, the resulting acoustic properties, performance implications, and considerations for installation and compatibility with various vehicle models.

Enhancing Performance and Sound with an Aftermarket Muffler

Selecting and installing an aftermarket muffler requires careful consideration to ensure optimal performance and desired sound characteristics. The following tips provide guidance for maximizing the benefits of such an upgrade.

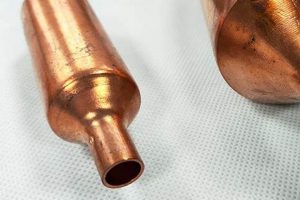

Tip 1: Material Selection: Prioritize stainless steel construction. This material offers superior resistance to corrosion, extending the lifespan of the component, especially in regions with harsh weather conditions or road salts.

Tip 2: Diameter Matching: Ensure the inlet and outlet diameters of the new muffler match the existing exhaust system. A mismatch can create bottlenecks, negating potential performance gains and potentially causing exhaust leaks.

Tip 3: Professional Installation: Consider professional installation. Experienced technicians possess the necessary tools and expertise to ensure proper fitment, preventing exhaust leaks and potential damage to the exhaust system.

Tip 4: Evaluate Sound Levels: Research and listen to sound clips before purchasing. Aftermarket mufflers significantly alter the exhaust note; ensure the desired sound level aligns with personal preferences and local noise regulations.

Tip 5: Check Local Regulations: Investigate local noise ordinances before installation. Some jurisdictions have restrictions on vehicle noise levels, and exceeding these limits can result in fines or required modifications.

Tip 6: Assess Compatibility: Confirm compatibility with the vehicle’s make and model. While universal options exist, direct-fit applications generally ensure seamless integration and minimize the need for fabrication.

Tip 7: Consider Resonator Pairing: Evaluate the potential need for a resonator. Adding a resonator can further refine the exhaust note, minimizing unwanted drone at specific engine speeds.

By adhering to these guidelines, individuals can effectively enhance both the acoustic and performance characteristics of their vehicle through the strategic selection and installation of an aftermarket muffler.

The following sections will provide further detailed analyses into the component’s impact on exhaust flow dynamics and engine efficiency.

1. Stainless Steel Construction

Stainless steel construction represents a critical element in the design and longevity of an exhaust component. The selection of stainless steel directly correlates with the component’s resistance to corrosion, a significant factor in exhaust system lifespan. Exhaust systems are exposed to high temperatures, condensation, and corrosive byproducts of combustion, rendering less durable materials prone to rapid degradation. For instance, mild steel systems, while less expensive, exhibit a substantially shorter lifespan compared to stainless steel counterparts, particularly in regions with high road salt usage during winter months. The inherent properties of stainless steel, specifically its chromium content, form a protective layer that inhibits rust formation, ensuring sustained structural integrity.

The implications of stainless steel construction extend beyond mere durability. The material’s inherent strength allows for thinner gauge materials to be used without compromising structural integrity. This reduced weight contributes to minor improvements in vehicle handling and fuel efficiency. Furthermore, stainless steel’s resistance to thermal fatigue, the weakening of material due to repeated heating and cooling cycles, ensures consistent performance characteristics over an extended operational period. Consider the case of high-performance vehicles where exhaust temperatures fluctuate rapidly; a stainless steel exhaust component maintains its structural integrity and performance characteristics more reliably than other materials.

In summary, the utilization of stainless steel in the construction of such exhaust components signifies a commitment to durability, performance, and longevity. The material’s inherent resistance to corrosion, thermal fatigue, and its ability to facilitate lighter designs collectively contribute to a superior product. While initial costs may be higher, the long-term benefits associated with reduced maintenance, extended lifespan, and consistent performance justify the material selection. The understanding of this connection is vital for informed purchasing decisions, enabling consumers to prioritize lasting value over short-term cost savings.

2. Aggressive Exhaust Note

The term “aggressive exhaust note” denotes a specific sound characteristic produced by an engine’s exhaust system, typically characterized by a louder, deeper, and more pronounced tone compared to a factory-equipped system. Within the context of a specific performance muffler, this attribute arises from the internal design, which manipulates exhaust gas flow. This manipulation is intended to minimize backpressure while simultaneously amplifying and shaping the sound waves generated by the engine. The resulting auditory output signifies a deliberate departure from the subdued sound profile of a stock vehicle, often desired by automotive enthusiasts seeking to enhance the perceived performance and character of their vehicles. As a component, the “Aggressive Exhaust Note” is a key selling point of the specific muffler, reflecting a design philosophy that prioritizes both auditory impact and performance gains. The success of the implementation depends on striking a balance, ensuring the sound profile is desirable without causing excessive noise pollution or violating local noise regulations.

The creation of an “aggressive exhaust note” is achieved through several design features. Internal baffling configurations, chamber sizes, and the type of sound-absorbing materials employed all contribute to the final auditory signature. For example, a straight-through muffler design, often found in performance applications, tends to produce a louder and more raw sound due to the minimal obstruction of exhaust gases. In contrast, chambered mufflers utilize a series of internal chambers to cancel out specific frequencies, resulting in a more controlled and refined “aggressive” tone. The specific model utilizes a combination of these principles, employing carefully engineered baffles and resonance chambers to achieve its signature sound. The practical application of this understanding lies in enabling consumers to make informed decisions based on their desired auditory experience. Those seeking a subtle increase in sound level may opt for a chambered design, while those prioritizing maximum volume may prefer a straight-through or similar configuration.

In summary, the “Aggressive Exhaust Note” represents a deliberate engineering outcome, achieved through specific design choices within the exhaust component. The sound profile is intrinsically linked to the muffler’s internal structure, material composition, and overall design philosophy. While the appeal of an “aggressive exhaust note” is subjective, understanding the underlying engineering principles allows consumers to align their preferences with the available product options. However, it is imperative to consider legal restrictions and societal impact when selecting an exhaust system with an “aggressive exhaust note,” ensuring that the chosen system enhances the driving experience without compromising environmental and community standards.

3. Reduced Backpressure

Within the context of exhaust system design, the term “reduced backpressure” denotes a decrease in the resistance encountered by exhaust gases as they flow from the engine to the atmosphere. This characteristic is a primary objective in the design and selection of performance exhaust components, including specific mufflers. The subsequent discussion outlines the critical facets of “reduced backpressure” as it pertains to these mufflers.

- Engine Efficiency Enhancement

Lowering backpressure facilitates more efficient expulsion of exhaust gases from the combustion chamber. This, in turn, reduces the energy the engine expends overcoming exhaust resistance, translating to increased horsepower and torque output. The design of the muffler is instrumental in achieving this, utilizing smooth bends and optimized internal flow paths to minimize turbulence and restriction.

- Turbocharger Spool-Up Improvement

In turbocharged engines, reduced backpressure downstream of the turbocharger can significantly improve its spool-up time. Lower exhaust resistance allows the turbine to spin more freely and rapidly, resulting in quicker boost response and reduced turbo lag. The specific muffler’s design is intended to minimize any additional backpressure introduced by the exhaust system, thereby optimizing turbocharger performance.

- Fuel Economy Considerations

While primarily focused on performance gains, reduced backpressure can also contribute to improved fuel economy under certain operating conditions. By allowing the engine to breathe more freely, the engine management system may be able to optimize fuel delivery and ignition timing, resulting in slight improvements in fuel efficiency. The extent of this improvement is contingent on driving style and other vehicle modifications.

- Heat Dissipation Enhancement

Efficient exhaust gas flow contributes to improved heat dissipation from the engine and exhaust system. Reduced backpressure allows for quicker removal of hot exhaust gases, preventing heat buildup in the engine compartment and exhaust components. This can lead to improved component longevity and reduced risk of heat-related damage. The muffler’s design aims to facilitate efficient heat removal, promoting overall system reliability.

The pursuit of reduced backpressure through the incorporation of a specifically designed muffler is often motivated by a desire to optimize engine performance and responsiveness. While tangible gains are contingent on various factors, the design considerations inherent in the component reflect a focus on minimizing exhaust flow restriction to achieve performance improvements. However, considerations regarding noise levels and compliance with local regulations remain paramount.

4. Enhanced Sound Profile

The auditory characteristics of an exhaust system significantly influence the perceived quality and driving experience of a vehicle. The term “enhanced sound profile,” when associated with a specific muffler, refers to a deliberate modification of the exhaust note intended to improve its tonal quality, volume, and overall character. The selection of an “enhanced sound profile” through the installation of such a muffler represents a conscious decision to alter the vehicle’s acoustic signature.

- Frequency Modulation

The muffler’s internal design directly influences the frequencies that are amplified or attenuated within the exhaust stream. This manipulation of frequencies contributes to the overall tonal quality of the exhaust note. For instance, some mufflers are engineered to emphasize lower frequencies, resulting in a deeper, more resonant sound. The specific model’s design incorporates chambers and baffling intended to achieve a particular balance of frequencies, resulting in its signature tone.

- Volume Control

The volume of the exhaust note is another critical aspect of the sound profile. Mufflers are designed to reduce exhaust noise to varying degrees, often balancing the need for noise reduction with the desire for a more prominent sound. A performance-oriented muffler typically aims for a moderate increase in volume compared to the factory system, providing a noticeable change in sound without being excessively loud or intrusive. The specific design seeks to achieve this balance, offering a distinct auditory improvement while remaining within acceptable noise levels.

- Resonance Dampening

Exhaust systems can generate unwanted resonances, often perceived as drone or harshness, at specific engine speeds. Mufflers designed for an “enhanced sound profile” incorporate features to dampen these resonances, resulting in a smoother and more refined sound. Resonance chambers and strategically placed sound-absorbing materials contribute to the mitigation of undesirable frequencies. The intent is to deliver a more pleasant and less fatiguing auditory experience, particularly during extended driving.

- Material Influence

The materials used in the muffler’s construction can also influence the sound profile. Stainless steel, commonly employed in performance mufflers, offers specific acoustic properties compared to aluminized steel or other materials. The density and rigidity of the material affect the propagation of sound waves within the muffler, contributing to the overall tonal characteristics. This model’s stainless steel construction plays a role in its distinct sound signature.

The facets outlined above contribute to the comprehensive “enhanced sound profile” associated with these mufflers. The careful manipulation of frequency, volume, resonance, and the influence of material choices combine to create a specific auditory experience. The objective is not merely to increase the volume of the exhaust note but to refine its quality, resulting in a more pleasing and engaging sound that complements the vehicle’s performance characteristics.

5. Performance Optimization

Performance optimization, in the context of automotive exhaust systems and components such as the aftermarket muffler, refers to the strategies and design features implemented to maximize engine output, efficiency, and responsiveness. The potential of these components to contribute to performance enhancement is a central consideration for vehicle owners and automotive enthusiasts. The following outlines key facets of performance optimization linked to the implementation of this component.

- Exhaust Flow Dynamics

The component is engineered to reduce restrictions in the exhaust flow path. By minimizing backpressure, the engine expends less energy expelling exhaust gases, which translates to more power available at the crankshaft. For example, a stock exhaust system on a high-performance vehicle may exhibit significant backpressure, limiting the engine’s potential. Replacing the restrictive muffler with this aftermarket alternative can measurably improve exhaust gas velocity, leading to enhanced engine breathing and increased horsepower.

- Weight Reduction

This model is constructed from lightweight materials such as stainless steel, contributing to an overall reduction in vehicle weight. A lighter vehicle requires less energy to accelerate and decelerate, resulting in improved handling and fuel efficiency. For instance, replacing a heavy, factory-installed muffler with a lighter aftermarket option can reduce the vehicle’s curb weight by a noticeable margin, positively impacting its dynamic performance.

- Engine Responsiveness

The reduced backpressure and optimized exhaust flow facilitated by this model can improve engine responsiveness, particularly in turbocharged vehicles. A more efficient exhaust system allows the turbocharger to spool up more quickly, resulting in reduced turbo lag and a more immediate throttle response. In practical terms, this translates to quicker acceleration and improved drivability, particularly in situations requiring rapid changes in speed.

- Thermal Efficiency

Efficient exhaust systems contribute to improved thermal management within the engine compartment. By facilitating the rapid removal of hot exhaust gases, this model helps to reduce heat buildup, which can negatively impact engine performance and component longevity. This is particularly relevant in high-performance applications where engines generate significant amounts of heat. Enhanced thermal efficiency can contribute to more consistent performance and reduced risk of heat-related component failure.

The performance benefits of this specific muffler are directly linked to its ability to improve exhaust flow dynamics, reduce weight, enhance engine responsiveness, and contribute to better thermal efficiency. These factors collectively contribute to an optimized driving experience. However, realizing the full potential of this component often requires complementary modifications to the intake system and engine management software to maximize overall engine performance.

6. Vehicle Compatibility

The concept of vehicle compatibility is paramount when considering the installation of an aftermarket exhaust component. For a “borla type s muffler,” ensuring compatibility dictates not only successful installation but also optimal performance and avoidance of potential damage to the vehicle. Incompatible components can cause issues ranging from simple installation difficulties to severe engine damage. The design parameters of the muffler, including inlet/outlet diameters, hanger positions, and overall length, must align precisely with the target vehicle’s exhaust system architecture.

A concrete example illustrates the importance of vehicle compatibility: installing a “borla type s muffler” intended for a V8 engine onto a vehicle with a four-cylinder engine would result in substantial performance degradation due to altered backpressure characteristics. The engine’s designed operating parameters are predicated on a specific exhaust system configuration; deviations from this can disrupt the air-fuel ratio, potentially leading to engine misfires, reduced power output, and even catalytic converter failure. Furthermore, physical incompatibility could necessitate extensive and costly modifications to the vehicle’s exhaust system, including cutting, welding, and rerouting of pipes, which compromises the integrity of the original design and potentially voids warranties. Another instance involves the installation on a car that has an overall difference in length, which might affect in structural instability. Also the connection location might required to be readjust and that make it incompatible. The correct selection mandates a meticulous review of the manufacturer’s specifications, ensuring the muffler is specifically designed and validated for the intended vehicle’s make, model, and year.

In summation, the link between “vehicle compatibility” and the successful implementation of such mufflers cannot be overstated. Addressing compatibility considerations is paramount for achieving desired performance gains, preserving the vehicle’s structural integrity, and avoiding potentially costly complications. The selection process should prioritize verifying compatibility through manufacturer data and, when necessary, consulting with qualified automotive technicians to ensure seamless integration and optimal results.

7. Installation Complexity

The ease or difficulty associated with installing an automotive component is a significant factor in the decision-making process for vehicle owners and technicians alike. The following outlines key facets of installation complexity as it pertains to the specific muffler.

- Direct-Fit vs. Universal Application

The “borla type s muffler” is often available in both direct-fit and universal configurations. Direct-fit models are engineered to seamlessly integrate with the target vehicle’s existing exhaust system, minimizing or eliminating the need for modifications. Conversely, universal mufflers require adaptation to the vehicle’s exhaust system, potentially involving cutting, welding, and custom fabrication. Installation complexity is significantly higher for universal applications, demanding specialized skills and equipment.

- Required Skill Level and Tools

Even direct-fit installations may necessitate a degree of mechanical aptitude and access to specific tools. A successful installation typically involves disconnecting the existing muffler, aligning the new component, securing it with appropriate fasteners, and ensuring a leak-free seal. The tools required may include wrenches, sockets, a reciprocating saw (for cutting), and welding equipment (for modifications). Universal installations demand a higher level of skill, including proficiency in welding and metal fabrication.

- Potential for Exhaust Leaks

Improper installation can lead to exhaust leaks, which can compromise engine performance, reduce fuel efficiency, and pose a safety hazard. Ensuring a tight, leak-free seal at all connection points is critical. This may involve using new gaskets, exhaust sealant, and carefully tightening fasteners to the specified torque. Welding must be performed with precision to prevent leaks and ensure structural integrity. Even small leaks can produce noticeable noise and reduce the effectiveness of the exhaust system.

- Time Investment

Installation complexity directly influences the time required to complete the task. A straightforward direct-fit installation may be accomplished in a few hours, while a universal installation involving extensive modifications can consume significantly more time. The time investment must be considered when weighing the costs of professional installation versus a do-it-yourself approach.

The overall complexity associated with installing this muffler hinges on factors such as the configuration type (direct-fit or universal), the required skill level, the potential for exhaust leaks, and the time investment involved. Careful planning, the use of appropriate tools, and adherence to manufacturer’s instructions are essential for a successful installation and to realize the intended performance and sound enhancements.

Frequently Asked Questions

The following questions address common inquiries and concerns regarding the characteristics, performance, and installation of the component.

Question 1: Will the installation of the component void the vehicle’s warranty?

The installation alone will not automatically void the vehicle’s warranty. However, if the installation or the component itself directly causes a failure of a covered part, the warranty claim may be denied for that specific repair. Consult the vehicle manufacturer or warranty provider for clarification on specific warranty policies.

Question 2: Does the component require modifications to the vehicle’s exhaust system for installation?

This depends on whether the component is a direct-fit or universal model. Direct-fit components are designed for seamless integration with the existing exhaust system and generally do not necessitate modifications. Universal models typically require cutting, welding, and custom fabrication for proper installation. Verify compatibility and installation requirements prior to purchase.

Question 3: Will this component significantly increase the exhaust volume of the vehicle?

The component typically increases exhaust volume compared to the stock muffler, however, the degree of increase is not the only factor. It is designed to deliver a more aggressive sound without being excessively loud or intrusive. Actual sound levels may vary depending on the vehicle and the presence of other exhaust modifications.

Question 4: What is the expected lifespan of the component?

The lifespan of the component depends on factors such as driving conditions, climate, and maintenance practices. A component constructed from stainless steel can offer a significantly longer lifespan compared to those constructed from aluminized steel, especially in environments where road salt is prevalent.

Question 5: Will this component improve the vehicle’s fuel economy?

While not the primary objective, the component can potentially contribute to improved fuel economy by reducing backpressure and enhancing engine efficiency. However, any improvements are typically modest and depend on driving style and other vehicle modifications. Substantial gains in power will consume more fuel. It is essential to remember that aggressive driving could negate fuel-saving benefits, as the extra power being asked from the engine can require more gas.

Question 6: Is professional installation of this component recommended?

Professional installation is recommended, particularly for universal models that require welding and custom fabrication. Even direct-fit installations benefit from the expertise of a qualified technician to ensure proper fitment, prevent exhaust leaks, and avoid potential damage to the exhaust system. The importance is to make sure there is no exhaust leaking, which can be a hazard to health.

This FAQ section aims to address prevalent concerns related to the properties and implementation. The knowledge here helps users make informed decisions.

The following section presents a comparative analysis with other available aftermarket mufflers.

Concluding Remarks

Throughout this exploration, the characteristics, benefits, and considerations surrounding “borla type s muffler” have been delineated. This component serves as a specific example of how aftermarket exhaust technology can be strategically applied to modify a vehicle’s auditory profile and potentially influence engine performance. The significance of material selection, design parameters, and compatibility factors has been emphasized, underscoring the importance of informed decision-making.

The adoption of the aforementioned component, or any similar aftermarket alternative, necessitates a comprehensive understanding of its potential impact on the vehicle’s overall operation and compliance with relevant regulations. The pursuit of enhanced performance or a more distinctive sound profile must be tempered with a responsible approach to vehicle modification. The continued evolution of exhaust system technology suggests future advancements in both performance and acoustic refinement, prompting ongoing evaluation and adaptation within the automotive community.