A key element in an exhaust system, this component is specifically designed to reduce the noise emitted by an internal combustion engine. Constructed from materials like steel or aluminized steel, it utilizes a series of chambers and baffles to dampen sound waves, effectively lowering the decibel level produced by the vehicle’s operation. For example, a perforated tube surrounded by sound-absorbing material forms a common design, mitigating exhaust pulses and quieting the engine’s roar.

Its significance lies in its contribution to noise pollution reduction and compliance with environmental regulations. By minimizing engine noise, it enhances the driving experience and contributes to a quieter environment in urban and residential areas. Historically, this element has evolved from simple, straight-through designs to more complex, multi-chambered configurations, reflecting advancements in acoustic engineering and increasing demands for quieter vehicles.

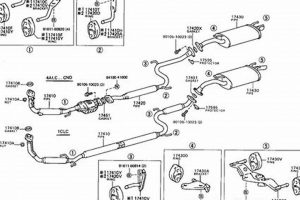

Understanding the construction, function, and maintenance of these elements is critical for ensuring optimal exhaust system performance and longevity. The following sections will delve deeper into specific types, common issues, and best practices for care and repair of related components.

Muffler Part Maintenance and Longevity Tips

Proper care and maintenance of exhaust system components are essential for optimal vehicle performance, reduced noise pollution, and extended component lifespan.

Tip 1: Regular Visual Inspections: Periodically examine the external surface for signs of rust, corrosion, or physical damage. Early detection of these issues can prevent more significant problems.

Tip 2: Address Exhaust Leaks Promptly: Listen for unusual noises emanating from the exhaust system. Leaks not only increase noise levels but can also allow harmful gases to enter the vehicle cabin.

Tip 3: Avoid Short Trips: Frequent short trips do not allow the exhaust system to reach optimal operating temperature, promoting condensation buildup inside, which accelerates corrosion.

Tip 4: Implement Proper Storage Procedures: When storing a vehicle for extended periods, consider applying a rust inhibitor to the external surface to protect against corrosion.

Tip 5: Prompt Replacement of Worn Components: When wear or damage is identified, timely replacement prevents cascading failures within the exhaust system and maintains optimal engine performance.

Tip 6: Catalytic Converter Protection: Ensure proper engine tuning and avoid excessive oil consumption, as these can damage the catalytic converter, leading to backpressure and increased strain on the exhaust components.

Adhering to these maintenance practices will extend the lifespan of the exhaust system and minimize the risk of costly repairs.

The subsequent sections will elaborate on the specific components of the exhaust system and delve into advanced troubleshooting techniques.

1. Noise Reduction

The primary function of an exhaust component is the reduction of engine noise generated during combustion. This is achieved through the strategic design and implementation of internal chambers and baffles. These internal structures manipulate sound waves, causing them to cancel each other out through destructive interference. In essence, the component acts as an acoustic filter, attenuating specific frequencies to minimize the overall noise level emitted by the vehicle. Without effective noise reduction, vehicles would produce excessively loud sounds, contributing significantly to noise pollution and violating noise regulations.

The effectiveness of this process is directly influenced by the material composition, the number and configuration of internal chambers, and the precision of the design. For example, vehicles operating in urban environments require more stringent noise reduction capabilities than those primarily driven in rural areas. Advanced designs incorporate resonators and tuned chambers to target specific frequencies, further enhancing noise attenuation. Furthermore, compliance with stringent regulatory standards, such as those set by the Environmental Protection Agency (EPA), necessitates optimized noise reduction technology in vehicle exhaust systems.

In conclusion, noise reduction is an integral and indispensable characteristic of this element. Its successful implementation hinges on carefully engineered components, strategic design, and compliance with established regulatory frameworks. The effectiveness of noise reduction directly impacts vehicle acceptability, environmental impact, and adherence to legal requirements. The future of exhaust system technology will likely focus on even more sophisticated noise reduction strategies while simultaneously optimizing exhaust flow and minimizing backpressure.

2. Exhaust Flow

Exhaust flow is critically influenced by elements designed for noise reduction. The internal structure of these components, while essential for sound attenuation, also presents a potential obstruction to the free passage of exhaust gases. An optimal system design seeks to minimize this obstruction to maintain engine efficiency.

- Backpressure Generation

The design of the internal chambers and baffles directly impacts the backpressure exerted on the engine. A poorly designed system creates excessive backpressure, hindering the engine’s ability to expel exhaust gases efficiently. This increased backpressure can lead to reduced horsepower, decreased fuel economy, and increased engine wear. Therefore, the internal configuration must balance noise reduction with minimal airflow restriction.

- Diameter of Internal Passages

The diameter of the internal passages within the component significantly affects the volume and velocity of exhaust gases. Narrow passages create bottlenecks, reducing exhaust flow and increasing backpressure. Conversely, overly wide passages may compromise noise reduction effectiveness. The selection of appropriate passage diameters is crucial for optimizing exhaust flow and minimizing performance losses.

- Smoothness of Internal Surfaces

Rough or uneven internal surfaces can disrupt laminar flow, creating turbulence and increasing resistance to exhaust gas movement. Polished or smooth internal surfaces minimize friction and promote smoother, more efficient exhaust flow. This attention to detail in manufacturing contributes to overall engine performance and fuel efficiency.

- Material Selection

The material used in construction influences the thermal properties and resistance to corrosion, both of which can impact exhaust flow. Materials with poor thermal conductivity can lead to heat buildup, altering gas density and flow characteristics. Corrosion can roughen internal surfaces, increasing flow resistance. Selecting materials resistant to heat and corrosion is essential for maintaining consistent exhaust flow over the lifespan of the vehicle.

The complex relationship between the core component and exhaust flow underscores the importance of a holistic design approach. Effective noise reduction must be achieved without compromising engine performance, requiring careful optimization of internal geometries, material selection, and manufacturing processes. This interplay ensures that the exhaust system functions efficiently, reducing noise pollution while maintaining or enhancing vehicle performance.

3. Material Durability

Material durability is a paramount consideration in the design and manufacturing of exhaust system components. The operational environment subjects these components to extreme conditions, including high temperatures, corrosive gases, and physical stresses. Consequently, the selection of appropriate materials is crucial for ensuring longevity and reliable performance.

- Corrosion Resistance

Exhaust gases contain corrosive byproducts of combustion, such as sulfuric acid and water vapor. Materials must exhibit high resistance to these corrosive agents to prevent premature degradation. For example, aluminized steel is commonly used due to its protective aluminum coating, which forms a barrier against corrosion. Stainless steel offers even greater resistance but is typically more expensive. The implications of inadequate corrosion resistance include exhaust leaks, reduced noise reduction effectiveness, and potential damage to other vehicle components.

- Thermal Stability

Exhaust systems operate at elevated temperatures, often exceeding several hundred degrees Celsius. Materials must maintain their structural integrity and mechanical properties at these temperatures. Excessive thermal expansion or contraction can lead to stress fractures and eventual failure. High-quality steel alloys are often selected for their ability to withstand these thermal stresses. Failure to consider thermal stability can result in component deformation, exhaust leaks, and reduced performance.

- Mechanical Strength

Exhaust components are subjected to vibration and physical impacts from road debris. Materials must possess sufficient mechanical strength to resist these forces and prevent damage. Thicker gauge materials and reinforced designs are often employed to enhance mechanical strength. Inadequate mechanical strength can result in component cracking, breakage, and premature failure, especially in vehicles operating in harsh environments.

- Weldability

Fabrication of exhaust systems often involves welding various components together. Materials must exhibit good weldability to ensure strong and reliable joints. Poor weldability can lead to weak or porous welds, which are susceptible to failure under stress. Specialized welding techniques and filler materials are often employed to optimize weld quality. Failure to achieve sound welds can result in exhaust leaks, structural weakness, and compromised performance.

In summary, the material durability is a critical factor influencing the lifespan, reliability, and performance of exhaust components. Careful material selection, considering corrosion resistance, thermal stability, mechanical strength, and weldability, is essential for ensuring optimal performance and minimizing the risk of premature failure. The trade-offs between material cost, weight, and performance must be carefully considered to achieve the desired balance for a given application.

4. Chamber design

The configuration of internal chambers within an exhaust component dictates its effectiveness in attenuating noise and optimizing exhaust flow. These chambers serve as acoustic resonators and expansion zones, influencing sound wave propagation and gas velocity. The design parameters are critical to achieving the desired balance between noise reduction and engine performance.

- Resonance Frequency Tuning

Chamber dimensions and geometries are engineered to resonate at specific frequencies, targeting dominant noise components produced by the engine. By creating destructive interference at these frequencies, the overall noise level is reduced. The positioning and shape of internal baffles influence resonance characteristics. Incorrect tuning can result in ineffective noise reduction or even amplification of certain frequencies.

- Expansion and Contraction Zones

Chambers act as expansion zones, allowing exhaust gases to expand and cool, which reduces their velocity and pressure. Subsequent contraction zones further manipulate gas flow, promoting turbulence and mixing. This process contributes to noise reduction and helps to maintain consistent exhaust flow. The size and shape of these zones must be carefully calculated to optimize gas dynamics.

- Baffle Configuration

Baffles are strategically positioned within the chambers to deflect and redirect sound waves, increasing the path length and promoting destructive interference. The shape, angle, and spacing of baffles significantly impact noise reduction effectiveness. Baffle designs can range from simple perforated plates to complex, curved structures. Improper baffle placement can create excessive backpressure or compromise noise attenuation.

- Acoustic Absorption Materials

Chambers often incorporate acoustic absorption materials, such as fiberglass or mineral wool, to further dampen sound waves. These materials absorb sound energy, converting it into heat. The type, density, and placement of absorption materials influence their effectiveness. Over time, these materials can degrade due to heat and moisture, reducing their acoustic performance.

The interplay of resonance frequency tuning, expansion/contraction zones, baffle configuration, and acoustic absorption materials dictates the overall performance of an exhaust system component. Optimizing these chamber design parameters is crucial for achieving the desired noise reduction while minimizing the impact on engine performance and ensuring compliance with regulatory standards.

5. Sound Absorption

Sound absorption is a critical mechanism within a muffler, serving to reduce the amplitude of sound waves generated by the internal combustion engine. Without effective sound absorption, the acoustic energy would propagate freely, resulting in unacceptable noise levels and regulatory non-compliance.

- Acoustic Material Composition

Acoustic absorption is often achieved through the use of porous materials such as fiberglass, mineral wool, or specialized synthetic composites packed within the chambers of a muffler. These materials possess intricate internal structures that convert sound energy into heat via friction as sound waves propagate through them. The selection of a specific material depends on its sound absorption coefficient, temperature resistance, and durability under the harsh operating conditions of an exhaust system. For example, high-temperature-rated fiberglass is commonly employed due to its balance of performance and cost-effectiveness.

- Layer Thickness and Density

The thickness and density of the sound-absorbing layer directly influence its effectiveness. Thicker layers provide a longer path for sound waves to travel through the material, increasing the opportunity for energy dissipation. Higher density materials generally offer improved sound absorption at higher frequencies but can also increase backpressure within the muffler. Therefore, optimization of layer thickness and density is crucial for balancing noise reduction and engine performance. A common design approach involves layering materials with different densities to achieve broad-spectrum sound absorption.

- Perforated Core Interactions

A perforated core, typically a metal tube with precisely sized and spaced perforations, is often used to support and protect the sound-absorbing material. The perforations allow sound waves to enter the material while also providing structural support. The size, density, and pattern of these perforations significantly affect the sound absorption characteristics. Smaller perforations offer better sound absorption at high frequencies but can restrict exhaust flow. Larger perforations provide better flow but may compromise high-frequency noise reduction. An example design features a staggered perforation pattern to optimize both sound absorption and exhaust flow characteristics.

- Resonator Integration

In some muffler designs, resonators are integrated to target specific frequencies of noise. These resonators, typically side branches or Helmholtz resonators, are tuned to cancel out specific frequencies through destructive interference. The sound-absorbing material then works to attenuate the remaining broadband noise. This combination of resonant cancellation and absorption offers a highly effective approach to noise reduction across a wide frequency range. An example application involves the use of a Helmholtz resonator to target low-frequency rumble, while the sound-absorbing material addresses higher-frequency hisses.

The effectiveness of sound absorption within a muffler is a complex interplay of material properties, design parameters, and operating conditions. A well-designed system utilizes a combination of these factors to achieve optimal noise reduction without compromising engine performance or long-term durability. Continued advancements in materials science and acoustic engineering promise to further enhance the sound absorption capabilities of muffler technology.

6. Backpressure

Backpressure, defined as the resistance to exhaust gas flow, is an inherent characteristic influenced by muffler design. The internal structure of a muffler, while essential for sound attenuation, inevitably creates a degree of backpressure. Understanding and managing this pressure is crucial for optimizing engine performance and minimizing potential negative impacts.

- Internal Chamber Design and Flow Restriction

The number, size, and configuration of internal chambers and baffles directly affect backpressure. Complex chamber designs with numerous baffles typically provide greater sound reduction but also increase resistance to exhaust flow. Straight-through designs, conversely, offer minimal backpressure but may compromise sound attenuation. An example would be a high-performance muffler designed with fewer internal obstructions to minimize backpressure and maximize horsepower, at the expense of some noise reduction. The implication is a trade-off between acoustic performance and engine efficiency.

- Pipe Diameter and Flow Capacity

The diameter of the inlet and outlet pipes of the muffler impacts exhaust gas velocity and backpressure. Undersized pipes restrict flow, increasing backpressure and potentially hindering engine performance. Oversized pipes may reduce backpressure but can also lead to turbulent flow and diminished scavenging effects. For instance, installing a muffler with an inlet pipe that is significantly smaller than the exhaust manifold outlet will create a bottleneck, increasing backpressure and reducing engine power. Proper sizing is critical for optimal performance.

- Acoustic Packing Material and Flow Impedance

The type and density of acoustic packing material, such as fiberglass or steel wool, can affect backpressure. Denser packing materials generally provide better sound absorption but also create greater resistance to exhaust gas flow. Over time, packing material can become compressed or degraded, further increasing backpressure. For example, a muffler packed with densely packed steel wool will offer superior sound attenuation but will also exhibit higher backpressure compared to a muffler with loosely packed fiberglass. Regular inspection and replacement of packing material can mitigate this issue.

- Catalytic Converter Integration and Combined Backpressure

When a muffler is installed downstream of a catalytic converter, the combined backpressure of both components must be considered. A clogged or restricted catalytic converter can significantly increase overall backpressure, exacerbating any flow limitations imposed by the muffler. For example, if a vehicle has a partially blocked catalytic converter and a performance muffler with minimal internal restrictions, the catalytic converter may become the dominant source of backpressure, negating the benefits of the low-restriction muffler. Diagnosis of the entire exhaust system is essential for accurate backpressure assessment.

The interplay between muffler design and backpressure necessitates careful consideration of engine characteristics and performance goals. Selecting a muffler with appropriate internal characteristics and pipe dimensions is critical for optimizing engine power, fuel efficiency, and sound attenuation. Furthermore, routine inspection of the entire exhaust system, including the catalytic converter and muffler, is essential for maintaining optimal performance and preventing excessive backpressure.

7. Vehicle Compatibility

Vehicle compatibility is a fundamental aspect of muffler selection, directly influencing performance, emissions compliance, and overall system integration. Mufflers are not universally interchangeable; variations in engine type, vehicle model, and exhaust system design necessitate specific muffler characteristics. Incorrect fitment can lead to reduced engine efficiency, increased noise levels, and potential damage to other exhaust system components. For instance, installing a muffler designed for a four-cylinder engine on a V8 engine will likely result in excessive backpressure, hindering performance, or insufficient noise attenuation, violating noise regulations. The physical dimensions, inlet/outlet configurations, and flow characteristics must precisely match the vehicle’s specifications to ensure proper operation.

Considerations extend beyond basic fitment. Modern vehicles often incorporate sophisticated engine management systems that rely on specific exhaust backpressure parameters. A mismatch between the muffler’s flow characteristics and the engine’s requirements can trigger diagnostic trouble codes (DTCs) and negatively impact fuel economy or emissions performance. Furthermore, physical clearances within the vehicle’s undercarriage dictate the muffler’s size and shape. An incompatible muffler may interfere with other components, such as suspension parts or the fuel tank, posing safety hazards. An example is a situation where a muffler that is too large may make contact with the vehicle’s frame.

Properly aligning muffler selection with vehicle compatibility demands careful attention to manufacturer specifications, part numbers, and detailed technical data. Failure to do so can result in compromised performance, safety risks, and regulatory non-compliance. The complexities involved underscore the importance of consulting qualified technicians or utilizing reliable parts lookup systems to ensure appropriate muffler selection. The overall objective is to maintain the vehicle’s intended performance characteristics, reduce noise emissions, and ensure long-term reliability of the exhaust system.

Frequently Asked Questions Regarding Muffler Components

The following section addresses common inquiries concerning components utilized for exhaust noise reduction in motor vehicles. These questions aim to clarify operational characteristics, maintenance protocols, and performance considerations.

Question 1: What constitutes a typical lifespan for an exhaust noise reduction element?

The service duration is contingent upon factors including material composition, environmental conditions, and driving habits. Elements constructed from aluminized steel may exhibit a lifespan of three to five years under normal operating conditions, while stainless steel variants can extend to ten years or more. Exposure to corrosive environments, such as road salt, and frequent short trips can accelerate degradation.

Question 2: How does the malfunction of a noise reduction element manifest?

Common indicators of failure include increased exhaust noise, the presence of rust or corrosion on the exterior surface, and potential exhaust leaks. In severe cases, the physical disintegration of internal components may occur, resulting in a rattling sound emanating from the exhaust system.

Question 3: Can a high-performance replacement impact fuel economy?

The effect on fuel efficiency depends on the design of the aftermarket component. Certain high-performance options, engineered to minimize backpressure, may yield a marginal improvement in fuel economy. However, improperly sized or designed replacements can increase fuel consumption due to altered exhaust gas dynamics.

Question 4: What are the implications of neglecting a damaged noise reduction element?

Prolonged neglect can lead to increased noise pollution, potential violations of noise regulations, and the propagation of corrosion to other exhaust system components. In extreme scenarios, exhaust leaks can introduce harmful gases into the vehicle cabin, posing a health hazard.

Question 5: Is it feasible to replace a noise reduction element independently?

Independent replacement is possible, provided the individual possesses adequate mechanical aptitude and access to appropriate tools. However, professional installation is recommended to ensure proper fitment, sealing, and alignment, mitigating the risk of future complications.

Question 6: Do aftermarket replacements influence vehicle emissions?

Aftermarket replacements that alter the flow characteristics of the exhaust system can potentially impact emissions performance. Compliance with emissions regulations mandates that any replacement component meet or exceed the performance of the original equipment manufacturer (OEM) part.

These answers offer insights into the operational characteristics and maintenance requirements of exhaust noise reduction components. Diligent adherence to these principles ensures optimal vehicle performance and regulatory compliance.

The subsequent sections will explore advanced troubleshooting techniques and address specialized concerns related to exhaust system management.

Muffler Part Conclusion

This exploration has illuminated the critical role that an exhaust noise reduction element performs in vehicle operation and environmental stewardship. From its internal architecture designed for sound wave attenuation to its impact on engine performance and emissions compliance, the component’s significance is multifaceted. Effective design, material selection, and maintenance are paramount to ensuring its longevity and optimal functionality.

Continued adherence to established maintenance practices and informed decision-making during replacement scenarios remain crucial for vehicle owners and technicians. As automotive technology evolves, so too will the demands placed upon these components, necessitating ongoing vigilance and adaptation to emerging standards and engineering advancements. The muffler part thus remains a vital element in the pursuit of quieter, more efficient, and environmentally responsible transportation.