A modification involving the removal of the exhaust component designed to attenuate engine noise, specifically applied to a particular Infiniti model, the Q50, results in a discernible alteration of the vehicle’s acoustic characteristics. This procedure effectively bypasses the sound-dampening functionality typically provided by the factory-installed part.

The appeal of this modification stems from the perceived improvement in auditory feedback from the engine and exhaust system. Proponents often cite enhanced performance as a potential byproduct, although this is typically marginal and subjective. The decision to implement such a change may be driven by a desire for a more aggressive sound profile or alignment with specific aftermarket performance philosophies.

The subsequent sections will explore the ramifications of this alteration, including potential legal and regulatory considerations, effects on vehicle emissions, and alternative options for achieving similar, yet potentially more refined, outcomes. Examining these factors provides a more complete understanding of the trade-offs inherent in modifying an exhaust system.

Considerations for Modifying the Infiniti Q50 Exhaust System

Modifying a vehicle’s exhaust system requires careful evaluation. These points highlight critical aspects to contemplate before undertaking such a change.

Tip 1: Verify Local Regulations: Prior to any modifications, confirm adherence to local noise ordinances and vehicle code. Many jurisdictions have specific decibel limits, and alterations may lead to non-compliance and potential penalties.

Tip 2: Assess Potential Emissions Impact: Removing components can impact the vehicle’s emissions profile. This may result in failure during emissions testing or potential environmental consequences. Research and consider the impact on catalytic converter function.

Tip 3: Evaluate Performance Claims: While some believe a modification will increase horsepower, gains are often minimal and may not justify the effort or expense. Independent dyno testing can provide objective performance data.

Tip 4: Understand Acoustic Changes: Removing the stock muffler significantly alters the vehicle’s sound. It’s essential to anticipate the increased volume and potentially altered tone, which may not be suitable for all driving conditions or personal preferences.

Tip 5: Research Alternative Exhaust Options: Numerous aftermarket exhaust systems offer enhanced sound and potential performance benefits without fully eliminating sound-dampening components. Exploring these options can provide a more balanced approach.

Tip 6: Factor in Installation Costs: Professional installation is recommended to ensure proper fitment and avoid potential damage to the exhaust system or vehicle. Obtain quotes from reputable shops to budget appropriately.

Tip 7: Inspect Welds and Materials: If choosing to fabricate a custom solution, ensure welds are strong and materials are corrosion-resistant for longevity and structural integrity.

Careful research and planning are essential to ensure a successful and legally compliant outcome. Evaluate all factors before making modifications.

The following sections will discuss alternative solutions for enhancing your Q50’s exhaust without sacrificing compliance or potentially harming the environment.

1. Acoustic Alteration

The removal of the factory-installed sound-dampening component from the exhaust system of an Infiniti Q50 fundamentally transforms its acoustic characteristics. This modification significantly increases exhaust volume and alters the tonal quality, creating a more aggressive auditory profile.

- Increased Sound Pressure Level

Eliminating the muffler results in a substantial rise in the decibel level emitted from the exhaust. This heightened sound pressure is particularly noticeable during acceleration and high-RPM operation. The increased sound can be perceived both inside and outside the vehicle, potentially affecting driver fatigue and public perception.

- Change in Exhaust Tone

The factory muffler is engineered to attenuate specific frequencies, producing a refined exhaust note. Without this component, the exhaust tone becomes raw and unfiltered, often characterized by a deeper, more resonant sound. This alteration can introduce unwanted drone or raspiness at certain engine speeds.

- Resonance and Vibration

Deleting the muffler can affect the resonance frequencies within the exhaust system. This may lead to increased vibrations transmitted through the vehicle chassis, contributing to interior noise and potentially impacting the longevity of exhaust components. Careful attention to exhaust hanger placement and material selection becomes critical.

- Subjective Perception and Driver Experience

The perception of acoustic changes is inherently subjective. Some drivers find the enhanced exhaust note exhilarating and indicative of improved performance. Others may find the increased volume and altered tone intrusive and fatiguing, particularly during extended driving. The appropriateness of the modification depends heavily on individual preferences and driving habits.

These facets of acoustic alteration represent key considerations when evaluating the removal of the muffler from a Q50. The amplified volume, altered tone, and potential for increased resonance must be carefully weighed against the desired auditory experience and potential impacts on comfort and drivability. Furthermore, local regulations regarding noise emissions should be thoroughly investigated to ensure compliance.

2. Regulatory Compliance

The practice of removing a specific exhaust component from an Infiniti Q50 introduces a significant concern regarding regulatory compliance. Exhaust systems are subject to federal, state, and local regulations designed to control noise pollution and emissions. Altering the factory configuration, particularly by eliminating a muffler, frequently leads to violations of these regulations. Many jurisdictions enforce noise ordinances with specific decibel limits. A muffler delete typically elevates exhaust noise beyond acceptable levels, resulting in fines or mandatory vehicle modifications to restore compliance. The EPA also sets standards for vehicle emissions, and while a simple muffler replacement may not directly impact regulated emissions, depending on the model year and how it impacts the whole exhaust system that may connect to Catalytic Converter, altering exhaust components can indirectly affect performance and trigger diagnostic trouble codes, potentially leading to inspection failure.

Consider, for example, California’s stringent vehicle code. Law enforcement officials can issue citations for modified exhaust systems that exceed established noise limits. In practice, officers may use calibrated sound level meters to measure exhaust noise at a specified distance from the vehicle. A documented muffler delete would almost certainly fail such a test. Furthermore, some states mandate periodic vehicle inspections, which include verification of the exhaust system’s integrity and compliance with emissions standards. A visibly modified exhaust could prompt a more thorough inspection, leading to rejection and required remediation. These enforcement actions serve to deter illegal modifications and maintain community noise levels.

In conclusion, the removal of a muffler from a Q50 without careful consideration of regulatory requirements creates a substantial risk of non-compliance. The ramifications extend beyond mere inconvenience and can include financial penalties, mandatory repairs, and restrictions on vehicle operation. Individuals contemplating such a modification should thoroughly investigate applicable laws and regulations and weigh the potential consequences against the perceived benefits. Prioritizing legal compliance safeguards individual rights and promotes responsible vehicle modification practices.

3. Emissions Impact

The removal of a sound-dampening component from a Q50 exhaust system, while primarily intended to alter auditory characteristics, carries potential implications for vehicle emissions. Though a muffler itself is not a primary component in emissions control, its removal can indirectly affect the performance and longevity of related systems.

- Catalytic Converter Function

While the muffler itself does not directly control emissions, altering the exhaust flow dynamics can impact the operating temperature of the catalytic converters. Changes in exhaust backpressure and flow velocity may affect the efficiency of the catalytic converters in oxidizing pollutants such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx). If the catalytic converters are not operating within their optimal temperature range, emissions may increase.

- Oxygen Sensor Readings

The oxygen sensors, located upstream and downstream of the catalytic converters, provide feedback to the engine control unit (ECU) about the exhaust gas composition. These sensors are critical for maintaining the proper air-fuel ratio and ensuring efficient combustion. Modifications to the exhaust system can alter the readings from these sensors, potentially leading to incorrect fuel trim adjustments and elevated emissions. For example, a significant change in exhaust flow could cause the downstream oxygen sensor to register values outside of its normal operating range, prompting the ECU to enter a fault mode.

- Fuel Efficiency and Combustion Efficiency

Changes to the exhaust system can affect the scavenging of exhaust gases from the cylinders. Optimized exhaust scavenging can improve cylinder filling with fresh air and fuel, leading to more complete combustion and improved fuel efficiency. Conversely, alterations that disrupt this process can result in incomplete combustion and increased fuel consumption. Although the effect of a muffler delete on fuel efficiency may be subtle, the cumulative impact over time can be measurable.

- Diagnostic Trouble Codes (DTCs)

Many modern vehicles, including the Q50, are equipped with sophisticated onboard diagnostic systems that monitor the performance of various engine and emissions-related components. Significant alterations to the exhaust system, such as removing a muffler, can trigger diagnostic trouble codes if the resulting changes in exhaust flow or sensor readings fall outside of acceptable parameters. These DTCs can illuminate the check engine light and may require professional diagnosis and repair. For example, a code related to catalytic converter efficiency or oxygen sensor performance may be triggered after a muffler delete.

These aspects collectively illustrate the potential for a seemingly simple exhaust modification to influence vehicle emissions. While a muffler delete may not directly cause catastrophic emissions failures, the cumulative effects on catalytic converter function, oxygen sensor readings, fuel efficiency, and diagnostic trouble codes warrant careful consideration. Assessing these factors is crucial for understanding the environmental and operational implications of altering an exhaust system.

4. Performance Perceptions

The correlation between perceived performance gains and the action of removing a specific exhaust component from a Q50 often relies on subjective interpretation rather than quantifiable data. The amplified exhaust note and altered sound profile resulting from the modification create an aural illusion of increased power and responsiveness. Drivers may interpret the more aggressive sound as an indication of enhanced engine performance, even when objective measurements reveal minimal or negligible gains. This perceptual bias underscores the importance of distinguishing between the psychological impact of sound and actual improvements in horsepower, torque, or acceleration.

For instance, an individual may report improved acceleration after a muffler delete, attributing this to the “freer flowing” exhaust. However, dyno testing conducted before and after the modification might reveal a difference within the margin of error or, in some cases, even a slight decrease in power at certain RPM ranges. The perceived improvement is often driven by the more visceral driving experience, where the increased noise and sensation of engine revving contribute to a sense of enhanced performance. This is not to say all changes are imaginary, some intake and exhaust modifications can alter the engine’s VE (Volumetric Efficiency). Without a proper tune however these gains may not be realized.

Therefore, understanding the role of “Performance Perceptions” in the context of a “muffler delete q50” is crucial for informed decision-making. Individuals considering such a modification should prioritize objective performance data and resist the allure of purely subjective impressions. Real-world performance gains should be validated through quantifiable measurements, while the auditory experience should be evaluated based on personal preferences and potential impacts on driving comfort and noise regulations. Failing to do so may result in disappointment or lead to the mistaken belief that measurable performance improvements have been realized. As a final note the ECM will need to be reflashed or tuned to properly adjust for the altered exhaust flow. Without a proper tune there may not be any gains.

5. Installation Requirements

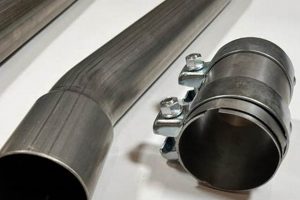

The implementation of a specific exhaust modification on an Infiniti Q50 necessitates adherence to precise installation protocols. This process, involving the removal of a factory-installed sound-dampening component, demands technical expertise and specialized equipment to ensure structural integrity and prevent potential damage to the vehicle’s exhaust system or related components. Improper installation can lead to exhaust leaks, premature component failure, and compromised vehicle performance. Successful implementation requires a thorough understanding of exhaust system design, welding techniques, and vehicle-specific torque specifications. An example includes incorrect welding, which can introduce stress points and cause cracks to propagate through the exhaust tubing, leading to leaks and reduced efficiency.

The practical application of these requirements involves several key steps. Initially, the vehicle must be safely lifted and supported to provide adequate access to the exhaust system. Next, precise measurements and cutting techniques are required to remove the existing component while preserving the integrity of the surrounding exhaust piping. If a replacement pipe is being installed to take the muffler’s place, it must be of compatible diameter and material. Skilled welding techniques are then essential to create a secure and leak-free connection between the existing exhaust system and the replacement component. Proper alignment of the exhaust system is crucial to avoid contact with the vehicle chassis or other components, which can cause vibrations and noise. The use of appropriate mounting hardware and torque specifications further ensures long-term stability and prevents loosening due to vibration or thermal expansion. A real-world scenario involves misaligned components which can impact ground clearance which can lead to physical damage of exhaust system.

In conclusion, the successful execution of this particular modification on a Q50 hinges on meticulous attention to installation details. Challenges include the potential for exhaust leaks, structural failure, and compromised vehicle performance if proper techniques and specifications are not followed. Recognizing the importance of these aspects is essential for achieving the desired auditory enhancement while maintaining vehicle reliability and compliance with relevant safety standards. The long-term success of the modification is directly linked to the quality of the installation process, emphasizing the need for qualified technicians and adherence to established best practices.

Frequently Asked Questions

This section addresses common inquiries regarding the removal of the muffler from an Infiniti Q50, providing objective information to facilitate informed decision-making.

Question 1: What specific changes can be expected in the exhaust sound after removing the muffler on a Q50?

The absence of the muffler will lead to a significant increase in overall exhaust volume. The tone will become more aggressive, typically deeper and more resonant, and may exhibit increased raspiness or drone at certain engine speeds. Expect a noticeable alteration in the auditory experience both inside and outside the vehicle.

Question 2: Does a muffler delete on a Q50 violate any laws or regulations?

This modification frequently violates local noise ordinances and potentially federal or state emissions regulations. Many jurisdictions have decibel limits for vehicle exhaust, and a muffler delete is likely to exceed these limits. Verify applicable laws and regulations before proceeding to avoid fines or other penalties. Federal emissions tampering laws may apply as well.

Question 3: Will removing the muffler from a Q50 increase engine horsepower or torque?

Quantifiable performance gains are typically minimal and may not justify the modification. While some individuals report subjective improvements, objective dyno testing often reveals negligible differences or, in some cases, even slight decreases in power, particularly at lower RPMs. The perceived increase is often attributable to the change in exhaust sound.

Question 4: Is the removal of the muffler a reversible modification on a Q50?

Reversing this modification requires reinstallation of the original muffler or a suitable aftermarket replacement. This may involve welding or the use of exhaust clamps to ensure a secure and leak-free connection. The reversibility depends on the method used for the initial removal and the availability of replacement components.

Question 5: What are the potential drawbacks of removing the muffler on a Q50?

Potential drawbacks include increased exhaust noise, potential legal ramifications, the possibility of increased drone or raspiness, and the risk of impacting emissions performance. Furthermore, the absence of a muffler may lead to increased resonance and vibration transmitted through the vehicle chassis.

Question 6: Can alternative exhaust modifications achieve a similar sound profile without removing the muffler?

Numerous aftermarket exhaust systems offer enhanced sound and potential performance benefits without completely eliminating sound-dampening components. These systems often incorporate resonators and tuned mufflers to achieve a desired exhaust note while mitigating excessive noise and potential legal issues. Exploring these alternatives represents a more balanced approach.

In summary, removing the muffler from a Q50 entails significant trade-offs regarding sound, legality, and potential performance. A comprehensive understanding of these factors is essential for making an informed decision.

The following section will explore alternative modifications and strategies for optimizing the exhaust system of an Infiniti Q50 without resorting to component removal.

Muffler Delete Q50

The preceding discussion has explored various facets of the “muffler delete q50” modification, encompassing acoustic alteration, regulatory compliance, emissions impact, performance perceptions, and installation requirements. Analysis reveals that this practice involves inherent trade-offs and potential complications. The amplified exhaust note, while appealing to some, frequently violates noise regulations. The perceived performance benefits are often subjective, and the potential for adverse effects on emissions and vehicle reliability cannot be disregarded.

Considering these factors, individuals contemplating a “muffler delete q50” should prioritize a comprehensive evaluation of applicable laws, regulations, and potential consequences. Responsible vehicle modification necessitates a commitment to compliance and a balanced assessment of potential benefits versus demonstrable risks. Thorough research and professional consultation are strongly advised to ensure informed decision-making and mitigate potential adverse outcomes. The ultimate decision should be based on a clear understanding of both the desired outcome and the potential ramifications for vehicle operation and legal compliance.