A device designed to attenuate engine noise, while also producing a lower frequency tone, alters the auditory characteristics of a vehicle’s exhaust. This specialized component modifies the sound wave propagation, resulting in a less harsh and more resonant acoustic signature. Examples include aftermarket exhaust systems engineered for specific vehicle models and intended to produce a distinctive rumble.

The significance of such a modification lies in its capacity to influence driver and bystander perceptions. Benefits can extend to enhancing the perceived performance of the vehicle, contributing to a more satisfying driving experience. Historically, the pursuit of particular exhaust notes has been a consistent element in automotive customization, reflecting an individual’s or brand’s aesthetic preferences.

Subsequent discussions will delve into the specific design principles affecting the performance characteristics, materials employed in their construction, and the regulatory considerations surrounding alterations to vehicle exhaust systems.

Considerations for Optimized Exhaust Acoustics

The following are guidelines regarding the optimization of exhaust acoustics, specifically focused on achieving a deeper and more resonant sound profile. These considerations are applicable to individuals seeking to modify their vehicle’s exhaust system or engineers designing new systems.

Tip 1: Volume and Internal Chamber Design: The overall volume of the component directly impacts the resonant frequency. Larger internal chambers generally produce lower frequencies. Careful consideration should be given to internal baffle configurations to tailor sound wave reflections and cancellations.

Tip 2: Pipe Diameter Optimization: The diameter of the exhaust piping influences both exhaust flow and sound wave propagation. Increasing the diameter can lower the frequency, but may also negatively impact engine performance if not properly matched to the engine’s characteristics.

Tip 3: Material Selection for Acoustic Properties: The material used in the construction plays a role in sound absorption and reflection. Thicker-gauge metals generally exhibit lower resonance, while specific alloys can influence the overall tonal quality.

Tip 4: Resonator Integration: Resonators are specifically designed to cancel out unwanted frequencies. Incorporating a resonator tuned to a specific high-frequency range can further refine the exhaust note and enhance the perception of a deeper tone.

Tip 5: Tailpipe Design and Exit Angle: The shape and exit angle of the tailpipe also contribute to the final acoustic output. Larger diameter tailpipes and specific exit angles can amplify lower frequencies and project the sound more effectively.

Tip 6: Welding Quality and Sealing: Exhaust leaks can introduce unwanted hissing sounds and disrupt the intended acoustic profile. Ensure high-quality welding and proper sealing of all joints to maintain the integrity of the sound.

Tip 7: Catalytic Converter Impact: Note that removing or modifying the catalytic converter can significantly alter the exhaust sound, often increasing its volume and harshness. Legal and environmental regulations should be strictly adhered to.

By carefully considering these design elements, one can effectively shape the acoustic characteristics of an exhaust system to achieve a desired sound profile. However, a balanced approach considering performance, regulations, and aesthetic goals is essential.

The subsequent sections will explore the legal aspects, maintenance considerations, and performance implications of exhaust modifications.

1. Resonance Frequency Control

Resonance frequency control is a fundamental aspect of the design and function of a vehicle exhaust system, particularly when the objective is to produce a lower frequency acoustic output. The manipulation of resonance within the exhaust system directly determines the tonal qualities and perceived depth of the sound.

- Chamber Volume and Dimensions

The size and shape of internal chambers within the component dictate the wavelengths of sound that are amplified. Larger chambers promote lower resonant frequencies, contributing to a deeper tone. Conversely, smaller chambers favor higher frequencies. The careful calculation and implementation of chamber dimensions are essential for achieving the desired sound profile.

- Baffle Design and Placement

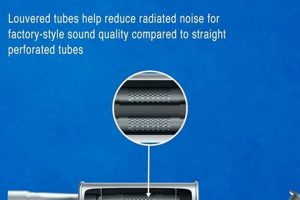

Baffles, internal obstructions within the system, reflect and redirect sound waves. Their arrangement affects both the amplitude and the frequency of the resulting sound. Strategic placement of baffles can selectively cancel out undesirable high-frequency components, further enhancing the perception of a lower and more profound tone.

- Helmholtz Resonance

Specific designs exploit Helmholtz resonance, a phenomenon where a cavity with an opening resonates at a specific frequency. By tuning the cavity to a target low frequency, the overall sound produced can be substantially enriched with the desired characteristics. Improper tuning can result in unwanted booming or droning sounds.

- Acoustic Damping Materials

The utilization of sound-absorbing materials, such as fiberglass or steel wool packing, influences the system’s resonance by selectively attenuating certain frequencies. The type, density, and placement of these materials can be used to fine-tune the acoustic properties, reducing harshness and promoting a cleaner, deeper sound.

Therefore, effective control over resonance frequency is a prerequisite for designing exhaust systems that produce a desired acoustic output. The relationship between chamber volume, baffle design, Helmholtz resonance, and damping materials determines the final sound signature. The careful orchestration of these elements is critical to achieving a targeted low-frequency, resonant sound while minimizing undesirable noise characteristics.

2. Exhaust Gas Flow

Exhaust gas flow is intrinsically linked to the performance and acoustic properties of a vehicle’s exhaust system. Modifications intended to achieve a lower-frequency tone inevitably impact the movement of exhaust gases. Therefore, a comprehensive understanding of gas dynamics is crucial in designing components that deliver the desired sound without compromising engine efficiency.

- Backpressure Effects

Restrictions in exhaust flow, such as those caused by poorly designed or overly restrictive elements, create backpressure. Excessive backpressure reduces engine power and fuel economy. Designing a component to produce a deep sound while minimizing backpressure requires a careful balance between acoustic tuning and flow efficiency.

- Pipe Diameter and Configuration

The diameter and configuration of the exhaust piping directly influence gas velocity and turbulence. Larger diameter pipes generally reduce backpressure, but can also decrease exhaust gas velocity, potentially affecting scavenging efficiency. The pipe routing, including bends and transitions, should minimize flow restrictions while also facilitating the desired acoustic resonance.

- Internal Obstructions and Baffles

Internal components such as baffles, chambers, and resonators alter the flow path to manipulate sound waves. The placement and design of these obstructions must be carefully considered to avoid creating excessive turbulence or flow restrictions. Computational fluid dynamics (CFD) simulations are often employed to optimize the internal geometry for both acoustic performance and flow efficiency.

- Scavenging Efficiency

Properly tuned exhaust systems can enhance scavenging efficiency, the process of removing exhaust gases from the cylinders and drawing in fresh intake air. Improved scavenging contributes to increased engine power and responsiveness. The design of a device should consider the engine’s firing order and exhaust pulse characteristics to optimize scavenging within the operating RPM range.

In summary, the pursuit of a deep, resonant exhaust note necessitates a holistic approach that considers the complex interaction between exhaust gas flow, acoustic principles, and engine performance. Effective design requires minimizing backpressure, optimizing pipe diameter and configuration, strategically implementing internal obstructions, and enhancing scavenging efficiency. Success depends on a balance of scientific understanding and engineering expertise.

3. Material Acoustic Properties

The acoustic signature of an exhaust component is directly influenced by the materials employed in its construction. The ability of a material to dampen, reflect, or transmit sound waves dictates the frequencies that are amplified or attenuated. This becomes critically important when the objective is to produce a specific, low-frequency auditory output.

For example, thicker-gauge metals tend to exhibit lower resonant frequencies compared to thinner materials. This is because thicker materials possess greater mass and stiffness, reducing their susceptibility to high-frequency vibrations. Stainless steel, commonly used in exhaust systems, offers a balance of durability and acoustic properties, contributing to a cleaner and more controlled sound. However, the specific grade of stainless steel, such as 304 versus 409, will affect the resonance and durability, influencing the overall sound profile. In contrast, materials like titanium, although lightweight and strong, often produce a higher-pitched sound due to their inherent resonant characteristics. Aftermarket components designed to enhance the auditory experience frequently incorporate specific alloys or treatments to modulate the emitted sound. The application of damping materials within the component further shapes the acoustic output by selectively absorbing certain frequencies.

Ultimately, the selection of materials is not solely determined by acoustic considerations but also by factors such as thermal resistance, corrosion resistance, and cost. Balancing these competing requirements is essential to creating durable and effective exhaust systems that deliver the desired auditory experience. Understanding the acoustic properties of various materials enables engineers and designers to precisely tailor the sound characteristics of an exhaust, achieving a deep and resonant tone while maintaining optimal performance and longevity.

4. System Legal Compliance

Adherence to legal standards is a critical factor when modifying a vehicle’s exhaust system, including the installation of components intended to produce a lower-frequency acoustic output. Non-compliance can result in fines, vehicle impoundment, or failure to pass emissions inspections.

- Noise Regulations

Most jurisdictions have established noise limits for vehicles, often measured in decibels (dB). These regulations aim to minimize noise pollution in residential and urban areas. Components must be designed and installed to meet these limits under specified testing conditions. Enforcement can vary, ranging from roadside inspections to formal testing procedures.

- Emissions Standards

Federal and state regulations mandate specific emissions standards for vehicles. Altering the exhaust system, particularly by removing or modifying catalytic converters, can violate these standards. Such modifications may render the vehicle illegal for road use and subject the owner to penalties. Even subtle modifications that alter exhaust flow can potentially impact emissions performance.

- Type Approval and Certification

Some regions require exhaust components to undergo type approval or certification processes, verifying that they meet relevant safety and environmental standards. Components lacking such approval may be deemed illegal for installation on road-going vehicles. Manufacturers often provide documentation demonstrating compliance with applicable regulations.

- Inspection and Enforcement

Vehicles are often subject to periodic inspections to ensure compliance with safety and emissions standards. During these inspections, exhaust systems are scrutinized for illegal modifications or components that exceed noise limits. Enforcement measures vary, but can include fines, repair orders, or vehicle impoundment.

Therefore, modifying a vehicle’s exhaust system requires careful consideration of applicable laws and regulations. Selecting certified components and ensuring proper installation are essential steps in maintaining legal compliance. Ignorance of the law is not a defense, and vehicle owners bear the responsibility for ensuring their vehicles meet all applicable standards. Failure to comply with these regulations can result in significant penalties and restrictions on vehicle use.

5. Performance Impact Assessment

The integration of a component intended to modify exhaust acoustics necessitates a thorough performance impact assessment. The alteration of exhaust flow characteristics, inherent in such modifications, can influence engine power, torque, and fuel efficiency. An uninformed modification risks compromising vehicle performance in the pursuit of a desired sound profile. For instance, an aftermarket system with excessive backpressure may generate a lower-frequency tone but simultaneously reduce horsepower output, particularly at higher engine speeds. Similarly, a system that excessively reduces backpressure could diminish low-end torque, impacting acceleration. A performance impact assessment provides crucial data to balance acoustic goals with the vehicle’s operational requirements. This process typically involves dyno testing, data logging, and analysis of key engine parameters before and after modification. The results inform decisions on optimal pipe diameter, chamber design, and baffle configuration to minimize adverse effects on vehicle performance.

The assessment extends beyond static measurements to encompass real-world driving scenarios. Considerations include evaluating the impact on fuel consumption during highway cruising, monitoring engine temperature under heavy load, and assessing the overall drivability of the vehicle in everyday traffic. A performance-oriented assessment might incorporate specialized testing such as quarter-mile acceleration runs or lap times on a closed course. These evaluations provide a practical understanding of how the acoustic modification affects the vehicle’s overall performance envelope. Furthermore, a comprehensive assessment includes evaluating potential long-term effects on engine components. Altered exhaust flow can influence cylinder scavenging, leading to increased engine wear or reduced component lifespan. Careful monitoring and analysis mitigate the risk of unforeseen mechanical issues arising from the modification.

In conclusion, a performance impact assessment is an indispensable component of any modification intended to alter exhaust acoustics. This assessment provides quantifiable data to ensure the desired sound profile does not compromise engine performance, drivability, or long-term reliability. The inherent trade-offs between acoustic characteristics and performance metrics necessitate a balanced and informed approach. Ignoring the performance impact of these modifications can result in a vehicle that sounds appealing but delivers diminished performance, increased fuel consumption, or accelerated engine wear.

Frequently Asked Questions

This section addresses common inquiries regarding the characteristics, applications, and implications of acoustic modification devices used in vehicle exhaust systems.

Question 1: What constitutes a “deep sound” in the context of exhaust systems?

A “deep sound” generally refers to an exhaust note characterized by low-frequency components. This often manifests as a resonant, rumbling tone rather than a high-pitched or raspy sound.

Question 2: How do these devices achieve a lower frequency acoustic output?

Such devices typically employ internal chambers, baffles, and tuned resonators to manipulate sound waves, selectively attenuating high frequencies and amplifying lower frequencies.

Question 3: Are there performance trade-offs associated with these modifications?

Yes, altering exhaust flow to achieve a specific sound profile can impact engine performance. Excessive backpressure can reduce power output, while insufficient backpressure can diminish low-end torque.

Question 4: Are these modifications legal in all jurisdictions?

No. Many jurisdictions have noise regulations and emissions standards that limit the permissible sound levels and exhaust modifications. Compliance with these regulations is the owner’s responsibility.

Question 5: What materials are commonly used in the construction of these components?

Stainless steel is frequently used due to its durability and corrosion resistance. However, different alloys and material thicknesses can affect the acoustic properties of the device.

Question 6: Can the installation of these components void a vehicle’s warranty?

Potentially. Modifications that demonstrably cause damage to the vehicle may void the manufacturer’s warranty coverage for affected components.

This information is intended for general guidance only and does not constitute professional advice. Consult with qualified professionals for specific applications and legal requirements.

Subsequent sections will delve into real-world case studies and application examples.

Conclusion

The exploration of the “deep sound muffler” underscores its multifaceted nature, extending beyond mere auditory enhancement. The device represents a complex interplay of acoustic engineering, exhaust gas dynamics, material science, regulatory compliance, and performance considerations. Effective implementation necessitates a comprehensive understanding of these interconnected elements to achieve the desired acoustic signature without compromising vehicle operation or legal standing.

Future advancements in materials and design methodologies hold the potential to further refine the performance characteristics and acoustic properties of these components. However, adherence to ethical and legal guidelines remains paramount. Ongoing research and responsible implementation will ensure that modifications contribute to a more satisfying driving experience while minimizing negative impacts on the environment and public health.