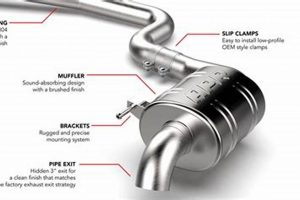

This automotive component plays a critical role in the exhaust system, mitigating noise generated by the engine’s combustion process. Typically constructed from materials like steel or aluminized steel, it’s designed with internal chambers and baffles to dampen sound waves. As an example, a damaged or corroded unit can lead to increased vehicle noise and potential emissions issues.

Its significance lies in contributing to a quieter driving experience and complying with noise pollution regulations. Historically, advancements in design have focused on achieving optimal sound reduction without compromising engine performance. This part’s operational effectiveness directly affects the overall comfort and environmental impact of a vehicle.

Understanding the function and importance of this component provides a necessary foundation for exploring topics such as its maintenance, repair, and selection of appropriate replacements. Subsequent discussions will address common issues, troubleshooting techniques, and considerations for choosing the right unit for specific vehicle applications.

Maintenance and Longevity Tips

The following guidelines are provided to ensure optimal performance and extend the lifespan of this vital exhaust system component.

Tip 1: Regular Inspection: Conduct periodic visual examinations for signs of corrosion, rust, or physical damage. Early detection of these issues can prevent more significant problems.

Tip 2: Address Exhaust Leaks Promptly: Exhaust leaks, often indicated by unusual noises or smells, can accelerate deterioration. Timely repair or replacement is crucial.

Tip 3: Avoid Short Trips: Frequent short journeys may lead to condensation build-up within the system, promoting corrosion. Longer trips allow for complete evaporation of moisture.

Tip 4: Proper Installation: When replacing the unit, ensure proper installation and secure mounting to prevent stress and vibration-related damage.

Tip 5: Maintain Engine Performance: Suboptimal engine performance can lead to increased exhaust emissions and higher temperatures, potentially affecting its durability.

Tip 6: Consider Environmental Factors: Exposure to road salt and harsh weather conditions can accelerate corrosion. Regular washing and application of protective coatings may be beneficial in such environments.

Adherence to these recommendations contributes to a quieter vehicle operation, reduced emissions, and extended component life, ultimately resulting in cost savings and improved vehicle performance.

Implementing these preventative measures will maximize the benefits of this exhaust system element, setting the stage for a comprehensive understanding of troubleshooting and replacement options.

1. Sound Attenuation

Sound attenuation is a primary function and a defining characteristic of this component. The internal design, incorporating chambers, baffles, and sometimes sound-absorbing materials, serves to reduce the amplitude and intensity of exhaust noise generated by the engine’s combustion process. The effectiveness of this sound reduction directly impacts vehicle noise levels, influencing both driver comfort and compliance with noise pollution regulations.

For example, a poorly designed or damaged unit will exhibit reduced sound attenuation, resulting in increased noise emissions. This increased noise can lead to driver fatigue on long journeys and potentially result in legal penalties in areas with strict noise ordinances. Conversely, a properly functioning and well-designed unit effectively dampens sound waves, contributing to a quieter and more comfortable driving experience. This also supports environmental well-being by reducing noise pollution in urban and residential areas.

In summary, sound attenuation represents a critical performance metric. Its efficiency directly correlates with vehicle compliance, driver comfort, and overall environmental impact. Understanding the relationship between design, condition, and sound attenuation characteristics is essential for selecting, maintaining, and troubleshooting this exhaust system component. Failures in sound attenuation underscore the importance of regular inspections and timely replacements to maintain optimal vehicle performance and environmental responsibility.

2. Exhaust Flow Optimization

Exhaust flow optimization within this component is paramount to engine performance and overall system efficiency. The internal design directly influences the backpressure exerted on the engine. Excessive backpressure hinders the expulsion of exhaust gases, reducing volumetric efficiency and potentially diminishing power output. Conversely, insufficient backpressure, although seemingly beneficial, can disrupt scavenging effects, leading to incomplete combustion and increased emissions. The design, therefore, strives to achieve a balance that facilitates efficient exhaust gas removal without compromising engine performance.

Consider, for example, the scenario where a unit designed for a high-performance engine is installed on a standard vehicle. The reduced backpressure might initially appear advantageous, but it could disrupt the engine’s carefully calibrated air-fuel ratio, resulting in decreased fuel economy and increased emissions. Conversely, installing a restrictive unit designed for a small engine on a larger, more powerful engine can lead to significant power loss and potential engine damage due to excessive backpressure. Thus, proper selection and maintenance are essential for ensuring optimized exhaust flow.

In summary, exhaust flow optimization is a critical aspect of this exhaust component’s functionality. Its impact extends to engine performance, fuel efficiency, and emissions control. Understanding the relationship between internal design, backpressure, and engine characteristics is crucial for selecting and maintaining the correct component for a specific application, ultimately contributing to optimal vehicle performance and environmental responsibility. A mismatch in design can lead to detrimental effects, highlighting the practical significance of this consideration.

3. Material Durability

Material durability constitutes a critical attribute of this exhaust system component, directly influencing its lifespan and performance under operating conditions. The exhaust system experiences high temperatures, corrosive gases, and mechanical stresses, necessitating the use of robust materials capable of withstanding these conditions. Premature failure due to corrosion, thermal fatigue, or physical damage compromises the component’s primary functions of noise attenuation and exhaust flow optimization. For instance, using low-grade steel can result in rapid corrosion, leading to exhaust leaks and increased noise levels, thereby negating the intended benefits.

The choice of materials such as stainless steel, aluminized steel, or titanium alloys directly affects the component’s resistance to degradation. Stainless steel offers superior corrosion resistance, extending its lifespan in harsh environments. Aluminized steel provides a more cost-effective alternative with reasonable corrosion protection. Titanium alloys, while offering exceptional strength-to-weight ratio and corrosion resistance, are typically reserved for high-performance applications due to their higher cost. In practical applications, a vehicle frequently driven in regions with heavy road salt usage would benefit significantly from a unit constructed of stainless steel, mitigating the corrosive effects and prolonging its service life. Conversely, a vehicle operating in a relatively dry climate might suffice with an aluminized steel variant.

In conclusion, material durability is intrinsically linked to the long-term functionality and cost-effectiveness. Selecting the appropriate material based on environmental conditions and operational demands is paramount for ensuring reliable performance and minimizing the need for frequent replacements. Ignoring this aspect can result in diminished performance, increased maintenance costs, and potential environmental consequences, highlighting the practical significance of material considerations in the context of this exhaust system component.

4. Vehicle Compatibility

Vehicle compatibility is a paramount consideration when selecting and installing this exhaust component. A mismatch between the component and the vehicle’s specifications can lead to performance degradation, installation difficulties, and potential engine damage. The exhaust system is intricately designed to work in harmony with the engine’s characteristics, and any deviation from the specified parameters can disrupt this delicate balance. For example, installing a unit designed for a V8 engine on a four-cylinder engine can create insufficient backpressure, resulting in decreased low-end torque and increased fuel consumption. The proper fit, dimensions, and flow characteristics must align with the vehicle’s make, model, and year to ensure optimal function.

Beyond performance considerations, physical compatibility is equally important. Mounting points, pipe diameters, and overall dimensions must match the vehicle’s exhaust system configuration to facilitate a secure and leak-free installation. Attempting to force-fit an incompatible unit can damage the exhaust system, create exhaust leaks, and potentially compromise vehicle safety. A real-world example involves attempting to install a unit designed for a sedan on an SUV; the difference in chassis design and exhaust routing typically renders such installations impractical or impossible without significant modifications, which may void warranties or compromise structural integrity. Manufacturers often provide detailed compatibility charts to ensure accurate selection.

In summary, vehicle compatibility is an indispensable criterion for this exhaust system component. It directly influences performance, installation ease, and vehicle safety. Ignoring compatibility can result in reduced efficiency, increased emissions, and potential mechanical failures. Adherence to manufacturer specifications and compatibility guidelines is crucial for ensuring optimal performance and avoiding costly complications. This emphasis underscores the importance of thorough research and informed decision-making when selecting and replacing this vital automotive part.

5. Regulatory compliance

Adherence to noise and emission standards is intrinsically linked to the design and functionality of this exhaust system component. Governmental bodies establish regulations that limit vehicle noise pollution and exhaust emissions. This component serves as a critical element in meeting these standards. Non-compliance can result in fines, vehicle inspection failures, and restrictions on vehicle operation. A deficient or improperly designed unit may fail to adequately attenuate noise or control emissions, thereby violating applicable regulations. For instance, many jurisdictions mandate specific decibel limits for vehicle exhaust noise; a compromised component can cause a vehicle to exceed these limits, resulting in penalties.

The design and material composition must align with prevailing environmental regulations. Some regions impose stringent limits on particulate matter and nitrogen oxides emitted from vehicles. This component’s design, in conjunction with catalytic converters and other emission control devices, plays a crucial role in reducing these pollutants. Manufacturers often engineer these components to meet or exceed regulatory requirements, incorporating advanced technologies to optimize sound reduction and minimize emissions. As a real-world example, European Union emission standards, known as Euro standards, impose progressively stricter limits on vehicle pollutants, requiring manufacturers to innovate continuously in exhaust system design to comply with these regulations.

Regulatory compliance directly impacts the marketability and legality of vehicles. Automakers must demonstrate that their vehicles meet all applicable standards before they can be sold in specific regions. The effectiveness of this component is therefore essential for vehicle certification and compliance. Changes in regulations often necessitate redesigns and improvements to ensure continued compliance, driving innovation in exhaust system technology. The practical significance lies in the potential for substantial financial penalties and reputational damage for manufacturers that fail to meet regulatory requirements, highlighting the component’s critical role in the automotive industry.

Frequently Asked Questions

The following addresses common inquiries regarding this exhaust system component, providing concise and informative answers.

Question 1: What are the primary functions of a Carmona muffler?

The principal roles involve attenuating exhaust noise, optimizing exhaust flow, and ensuring compliance with noise and emission regulations.

Question 2: How does component failure impact vehicle performance?

A damaged unit can lead to increased noise levels, reduced fuel efficiency, diminished engine power, and potential regulatory violations.

Question 3: What materials are commonly used in construction?

Typical materials include steel, aluminized steel, and stainless steel. The choice of material influences durability and resistance to corrosion.

Question 4: How does vehicle compatibility affect component selection?

Selecting a unit specifically designed for the vehicle’s make, model, and engine type is crucial for ensuring proper fit, optimal performance, and avoiding potential damage.

Question 5: What maintenance practices can extend the lifespan?

Regular inspections for corrosion and leaks, prompt repairs, and avoiding frequent short trips can prolong its service life.

Question 6: How do noise and emission regulations influence the design?

Designs must incorporate features that effectively reduce noise and minimize exhaust emissions to comply with applicable environmental standards.

Understanding these frequently asked questions is essential for informed decision-making regarding maintenance, repair, and replacement.

The insights from these FAQs provide a solid foundation for further discussions on troubleshooting common problems and selecting appropriate replacement options.

Conclusion

This exploration of the carmona muffler underscores its complex role within the vehicle exhaust system. From noise attenuation and exhaust flow optimization to material durability, vehicle compatibility, and regulatory compliance, each facet contributes significantly to overall vehicle performance and environmental impact. Understanding these interconnected aspects is vital for informed decision-making regarding maintenance, repair, and replacement.

As automotive technology advances and environmental regulations become more stringent, the carmona muffler will continue to evolve. Ongoing research and development efforts are crucial to ensuring future iterations meet the demands of quieter, more efficient, and environmentally responsible vehicles. Careful consideration of the principles outlined herein will promote responsible vehicle ownership and support a sustainable automotive future.