Removing the vehicle’s rearmost exhaust component, known as a muffler, is a modification some vehicle owners undertake. A frequent question arises about whether this alteration can trigger the malfunction indicator lamp, often called the “check engine light.” This light signals that the car’s onboard diagnostic system has detected an anomaly. The potential relationship between exhaust modifications and the illumination of this warning is what warrants careful examination.

The rearmost exhaust component primarily serves to reduce noise levels generated by the engine’s combustion process. Its removal does not inherently improve engine performance and, depending on local regulations, may violate noise ordinances. Furthermore, while the immediate consequence of removing this component is increased exhaust volume, the long-term effects can be more nuanced, especially when considering its impact on the vehicle’s emissions control systems.

The subsequent discussion will address factors that determine if such a modification influences the diagnostic system and causes the malfunction indicator lamp to activate. The integrity of the vehicle’s oxygen sensors, the presence of other exhaust system modifications, and the specific vehicle model all play a role in determining whether this alteration leads to the activation of the check engine light.

Tips Regarding Exhaust Modifications and Diagnostic Warnings

Implementing alterations to a vehicle’s exhaust system necessitates careful consideration. Avoiding unintended activation of the malfunction indicator lamp requires awareness of potential complications. The following guidelines offer crucial advice.

Tip 1: Before initiating any modifications, thoroughly research the vehicle’s specific make and model. Certain vehicles are more sensitive to exhaust system changes than others. Online forums and repair manuals provide valuable insights.

Tip 2: Understand the function of oxygen sensors. These sensors monitor exhaust gas composition. Alterations to the exhaust system can disrupt their readings, leading to fault codes and the illumination of the check engine light.

Tip 3: If the vehicle has multiple oxygen sensors (upstream and downstream), consider the impact on both. Modifications affecting the catalytic converter, even indirectly, can trigger downstream sensor errors.

Tip 4: When considering exhaust modifications, examine local and state regulations concerning noise emissions. Modifications that increase noise levels may be illegal, resulting in fines or mandatory repairs.

Tip 5: Ensure all connections are secure and leak-free after any exhaust modification. Exhaust leaks can disrupt sensor readings and trigger the malfunction indicator lamp.

Tip 6: If the check engine light illuminates after an exhaust modification, utilize an OBD-II scanner to retrieve the diagnostic trouble code (DTC). This code provides clues as to the source of the problem.

Tip 7: Consult with a qualified mechanic or exhaust specialist before proceeding with modifications, particularly if unfamiliar with automotive systems. Professional guidance can prevent costly errors and ensure compliance with regulations.

Following these recommendations can minimize the likelihood of triggering the malfunction indicator lamp and ensure any exhaust system adjustments are performed safely and legally. A proactive approach prevents unnecessary complications.

These considerations are fundamental to a well-informed approach to exhaust modification. Consult the remaining sections for further details.

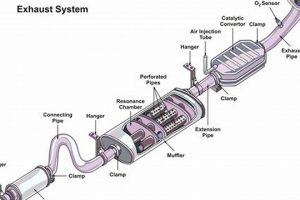

1. Oxygen Sensor Functionality

Oxygen sensors are pivotal components of a vehicle’s emission control system. Located in the exhaust stream, these sensors measure the amount of oxygen present in the exhaust gases. This information is relayed to the engine control unit (ECU), which uses it to adjust the air-fuel mixture to maintain optimal combustion and minimize emissions. Proper oxygen sensor functionality is therefore crucial for efficient engine operation and compliance with emissions regulations. The exhaust modification, such as muffler delete, can directly impact the environment around the oxygen sensor, disrupting the accurate monitoring of gas composition.

A muffler delete alters the exhaust flow and potentially the backpressure within the exhaust system. This change can affect the oxygen sensor’s readings. For example, if the altered exhaust flow causes the sensor to cool down more rapidly or become exposed to ambient air due to leaks, it may generate inaccurate data. An oxygen sensor reporting lean conditions when the engine is running rich or vice versa can lead the ECU to make incorrect adjustments. Furthermore, if the readings deviate significantly from expected values, the ECU may interpret this as a sensor malfunction, triggering the check engine light. In cases where the oxygen sensor is located very close to the muffler, the impact from the delete can be exacerbated.

In summary, the direct correlation between the oxygen sensor’s operation and the muffler delete resides in the exhaust environment. Alterations to exhaust flow, backpressure, and temperature introduced by removing the muffler can compromise the sensor’s ability to provide accurate data. This, in turn, can lead to diagnostic errors and the activation of the check engine light. Ensuring the correct placement and protection of these sensors after modifications are implemented can help mitigate these effects.

2. Backpressure Alterations

The removal of the muffler directly influences exhaust backpressure, a critical factor affecting engine performance and potentially triggering the malfunction indicator lamp. Backpressure is the resistance to exhaust gas flow within the exhaust system. Engine management systems are designed with a specific level of backpressure in mind. When the muffler is removed, this resistance is lessened, resulting in reduced backpressure. This alteration can affect scavenging efficiency, which is the process of removing exhaust gases from the cylinder during the exhaust stroke. In certain engine designs, decreased backpressure can diminish scavenging, leading to incomplete combustion and altered exhaust gas composition.

The engine control unit (ECU) relies on data from various sensors, including oxygen sensors, to regulate the air-fuel mixture and ignition timing. If the backpressure changes significantly due to the muffler delete, the oxygen sensors might detect an imbalance in the air-fuel ratio. For example, reduced backpressure can lead to a leaner exhaust gas mixture, prompting the ECU to compensate by injecting more fuel. However, if the ECU’s compensation range is insufficient to address the change, it can trigger fault codes related to fuel trim or oxygen sensor performance, illuminating the check engine light. Certain vehicle models are more susceptible to backpressure alterations than others, often depending on the complexity and sensitivity of their engine management systems. In some cases, installing aftermarket components designed to manage exhaust flow after a muffler delete can mitigate the risk of triggering a warning light.

In summary, a muffler delete’s impact on backpressure can disrupt the engine’s carefully calibrated operating parameters. The consequences, including altered air-fuel ratios and inaccurate sensor readings, can lead to the activation of the malfunction indicator lamp. Understanding the potential impact of backpressure alterations is crucial when contemplating such modifications, and proactive measures, such as ECU tuning or installing backpressure-regulating components, may be necessary to prevent diagnostic errors. The sensitivity to backpressure alterations varies by vehicle make and model, underscoring the importance of vehicle-specific research before proceeding.

3. Diagnostic System Sensitivity

The diagnostic system’s inherent sensitivity plays a critical role in determining whether a modification, such as a muffler delete, triggers the malfunction indicator lamp. The stringency with which a vehicle’s onboard diagnostics monitor exhaust system parameters dictates the likelihood of detecting even minor deviations from expected values.

- OBD-II Thresholds

On-Board Diagnostics II (OBD-II) systems employ pre-defined thresholds for various engine and emissions parameters. If a parameter, such as oxygen sensor voltage or fuel trim level, falls outside the acceptable range specified by these thresholds, a diagnostic trouble code (DTC) is generated, and the check engine light illuminates. Some vehicles have tighter thresholds than others. A muffler delete, by altering exhaust flow and potentially affecting oxygen sensor readings, might push certain parameters beyond these thresholds, resulting in a DTC. The sensitivity of the OBD-II system determines how minor these alterations must be to trigger a warning. For example, a vehicle with very strict emissions monitoring may flag even a slight change in exhaust composition, while a less sensitive system might tolerate larger deviations.

- Adaptive Learning Capabilities

Modern engine control units (ECUs) often incorporate adaptive learning capabilities, allowing them to adjust engine parameters over time to compensate for wear, environmental conditions, and minor modifications. However, the adaptive learning range is limited. If a muffler delete causes significant changes to exhaust flow or backpressure, the ECU may be unable to compensate fully. The system might attempt to adjust fuel trims or ignition timing, but if the required adjustments exceed its adaptive range, the check engine light will activate. Diagnostic systems on some vehicles can ‘learn’ around minor modifications; however, a muffler delete may create changes that are too significant for the adaptive learning process.

- Sensor Calibration and Accuracy

The accuracy and calibration of sensors, particularly oxygen sensors and mass airflow sensors, directly influence the diagnostic system’s ability to detect anomalies. If these sensors are not properly calibrated or are nearing the end of their lifespan, they might provide inaccurate data to the ECU. A muffler delete could exacerbate these inaccuracies, leading to misinterpretations and the triggering of false alarms. For instance, an aging oxygen sensor that is already slow to respond might provide even more erratic readings after a muffler delete, increasing the probability of a diagnostic error. Similarly, a slightly miscalibrated mass airflow sensor, combined with altered exhaust flow, could result in incorrect air-fuel mixture calculations, leading to diagnostic trouble codes.

- Complexity of Diagnostic Routines

The sophistication of the diagnostic routines within the ECU significantly impacts its sensitivity to modifications. Some vehicles employ complex algorithms to analyze sensor data, taking into account various operating conditions and historical trends. These routines are designed to differentiate between genuine malfunctions and transient deviations caused by external factors. A more complex diagnostic routine might be better equipped to distinguish between a legitimate emissions problem and the effects of a muffler delete. However, even sophisticated routines can be overwhelmed by drastic changes in exhaust characteristics. The depth and breadth of diagnostic analysis implemented by the vehicle manufacturer thus affects the likelihood that the check engine light will illuminate following an exhaust system modification.

In conclusion, the sensitivity of a vehicle’s diagnostic system is a critical determinant in whether a muffler delete results in the activation of the malfunction indicator lamp. Factors such as OBD-II thresholds, adaptive learning capabilities, sensor calibration, and the complexity of diagnostic routines all contribute to this sensitivity. A comprehensive understanding of these factors is crucial for vehicle owners contemplating exhaust modifications, as it allows them to assess the potential risks and take appropriate preventative measures. Vehicles with highly sensitive diagnostic systems are more likely to trigger the check engine light, even with relatively minor alterations to the exhaust system.

4. Catalytic Converter Impact

The functionality of the catalytic converter is intrinsically linked to the activation of the malfunction indicator lamp following a muffler delete. The catalytic converter’s primary role involves reducing harmful emissions from the engine by catalyzing chemical reactions that convert pollutants such as hydrocarbons, carbon monoxide, and nitrogen oxides into less harmful substances like carbon dioxide, water, and nitrogen. The catalytic converter’s efficiency is monitored by oxygen sensors positioned upstream and downstream of the converter itself. These sensors measure the oxygen content of the exhaust gases entering and exiting the converter, providing data used by the engine control unit (ECU) to assess converter performance. A muffler delete, while located downstream of the catalytic converter, can indirectly influence its operation and the readings of these oxygen sensors.

A significant alteration in exhaust flow dynamics resulting from the removal of the muffler can impact the temperature and pressure within the exhaust system, potentially affecting the catalytic converter’s operational efficiency. For instance, decreased backpressure resulting from the muffler delete can alter the exhaust gas residence time within the converter, potentially reducing its ability to effectively catalyze the pollutant conversion process. The downstream oxygen sensor might then detect an increase in pollutants exiting the converter, signaling a problem to the ECU. Furthermore, the altered exhaust flow could also affect the temperature distribution within the catalytic converter. Catalytic converters operate within a specific temperature range for optimal performance; excessively high or low temperatures can reduce their efficiency and even damage the catalyst material. The ECU interprets deviations from expected oxygen sensor readings as a sign of catalytic converter malfunction, triggering a diagnostic trouble code and illuminating the check engine light. Some vehicles employ sophisticated algorithms that compare the signal patterns of upstream and downstream oxygen sensors to assess catalytic converter efficiency. Even subtle alterations in exhaust flow caused by a muffler delete might disrupt these patterns, leading to a false indication of converter failure.

In summary, while a muffler delete does not directly remove or damage the catalytic converter, it can indirectly influence its operation and the readings of the oxygen sensors that monitor its performance. Alterations in exhaust flow, temperature, and pressure can all contribute to reduced catalytic converter efficiency or inaccurate sensor readings. The ECU, relying on this sensor data, might then misinterpret these changes as a catalytic converter malfunction, resulting in the activation of the check engine light. Therefore, a comprehensive understanding of the potential impact on the catalytic converter is essential when considering a muffler delete, particularly on vehicles equipped with sensitive emissions control systems. Vigilant monitoring of the oxygen sensor readings and overall engine performance is advisable following such a modification to ensure continued emissions compliance and prevent unnecessary diagnostic warnings.

5. Exhaust Leak Potential

The potential for exhaust leaks is a significant consideration when evaluating whether removing the muffler will trigger the malfunction indicator lamp. The integrity of the exhaust system is crucial for maintaining proper engine function and emissions control. Disruptions to this integrity, particularly those introducing leaks, can directly impact sensor readings and overall system performance, increasing the likelihood of a diagnostic warning.

- Compromised Connections

During a muffler delete, the existing exhaust system is typically cut, and a new section of pipe is welded or clamped in place to replace the muffler. These connections are potential points of failure if not executed with precision. Poor welding, misaligned flanges, or improperly tightened clamps can create small gaps that allow exhaust gases to escape. Even minute leaks can disrupt the carefully calibrated flow of exhaust gases, affecting oxygen sensor readings and potentially triggering fault codes related to fuel trim or emissions system inefficiency.

- Sensor Placement Disruption

Exhaust leaks near oxygen sensors can have a particularly pronounced effect on the diagnostic system. Oxygen sensors measure the oxygen content of the exhaust gases, providing crucial data for the engine control unit (ECU) to adjust the air-fuel mixture. If a leak occurs upstream of an oxygen sensor, ambient air can be drawn into the exhaust stream, diluting the exhaust gases and causing the sensor to report a leaner condition than actually exists. The ECU might then compensate by adding more fuel, leading to a rich fuel mixture and potentially triggering fault codes related to oxygen sensor performance or fuel trim imbalances. Leaks downstream of the sensor may not directly impact readings, but introduce enough ambient air that engine running performance may become impacted.

- Backpressure Alteration Effects

Exhaust leaks, similar to a muffler delete itself, can alter the backpressure within the exhaust system. A leak effectively creates an additional exit point for exhaust gases, reducing the overall resistance to flow. As previously discussed, changes in backpressure can affect scavenging efficiency and alter the engine’s volumetric efficiency. The ECU, relying on sensor data calibrated for a specific backpressure range, might struggle to compensate for these changes, leading to deviations in air-fuel ratios and potentially triggering the check engine light. Leaks in the exhaust system, therefore, compound the effects of the muffler delete on backpressure and increase the risk of diagnostic warnings.

- Material Degradation Acceleration

Exhaust leaks can accelerate the degradation of surrounding exhaust system components. Hot exhaust gases escaping from a leak can cause localized overheating, leading to corrosion, cracking, or weakening of nearby pipes, flanges, or welds. This, in turn, can exacerbate the existing leak or create new leak points, further disrupting the exhaust system’s integrity. The cumulative effect of these leaks can overload the diagnostic system’s ability to compensate, ultimately resulting in the activation of the malfunction indicator lamp. Moreover, the escaping hot exhaust gases can damage nearby wiring harnesses or sensors, leading to additional diagnostic problems unrelated to the muffler delete itself.

The potential for exhaust leaks introduced during or resulting from a muffler delete represents a significant risk factor for triggering the check engine light. The compromised connections, sensor placement disruptions, backpressure alterations, and accelerated material degradation associated with leaks can all contribute to diagnostic errors. Careful attention to detail during installation, proper welding or clamping techniques, and regular inspections for leaks are essential to minimize the risk of these complications. A well-sealed exhaust system is crucial for maintaining proper engine function, emissions control, and avoiding unnecessary diagnostic warnings.

6. ECU Calibration

Engine Control Unit (ECU) calibration plays a crucial role in determining whether the removal of a muffler triggers the malfunction indicator lamp. The ECU is responsible for managing various engine parameters, including air-fuel mixture, ignition timing, and idle speed, based on data received from numerous sensors. Its calibration is meticulously engineered to optimize engine performance and emissions within the constraints of the factory-specified exhaust system. When a muffler is removed, the resultant changes in exhaust flow and backpressure can disrupt this carefully balanced calibration, potentially leading to diagnostic errors. The factory ECU calibration may no longer be appropriate for the altered exhaust system characteristics.

If the ECU’s programming cannot adapt to the new exhaust dynamics, the engine may run less efficiently, potentially leading to increased emissions or decreased performance. For instance, the ECU might struggle to maintain the correct air-fuel ratio, resulting in a lean or rich condition that triggers oxygen sensor-related diagnostic trouble codes (DTCs) and the activation of the check engine light. In some instances, a custom ECU tune may be necessary to recalibrate the engine management system to account for the changes introduced by the muffler delete. This involves adjusting the ECU’s programming to optimize engine performance and emissions with the modified exhaust system, effectively accommodating the altered exhaust flow characteristics. Performance shops or specialized tuning services often offer such recalibration services, ensuring the vehicle operates within safe and efficient parameters.

In summary, the suitability of the existing ECU calibration is a critical factor in assessing the potential consequences of a muffler delete. While some vehicles might tolerate the modification without significant issues, others are more sensitive to changes in exhaust flow and backpressure. In these cases, a custom ECU tune becomes essential to ensure proper engine operation and prevent the activation of the check engine light. Ignoring the need for recalibration can result in decreased performance, increased emissions, and potential engine damage. Addressing the ECU’s calibration needs following a muffler delete contributes to the longevity and efficiency of the vehicle.

7. Fault Code Interpretation

Following a muffler deletion, if the malfunction indicator lamp illuminates, the subsequent fault code interpretation is paramount in discerning the underlying cause and determining the appropriate course of action. The fault codes generated by the vehicle’s onboard diagnostic system provide specific indications of detected anomalies. These codes are standardized across the automotive industry, allowing mechanics and vehicle owners to identify potential issues by consulting a database or diagnostic tool. In the context of an exhaust modification, accurately interpreting these codes is crucial to determine whether the muffler removal directly induced the problem or if another pre-existing condition is responsible. For example, a code indicating an oxygen sensor malfunction (e.g., P0131, P0134) might suggest that the altered exhaust flow is affecting the sensor’s readings. However, the same code could also indicate a failing sensor unrelated to the modification.

Effective interpretation necessitates a systematic approach. Firstly, it’s important to record all present fault codes and their associated descriptions accurately. Secondly, it is crucial to consider the context of the modification. If the codes appear immediately after the muffler delete, a causal relationship is more probable. However, the timing alone is not conclusive. Analyzing freeze frame data, which captures engine operating conditions when the fault code was triggered, can provide additional clues. For instance, if the fault code is consistently triggered at idle, it might suggest an issue related to backpressure alterations affecting low-speed engine operation. Furthermore, verifying the accuracy of the sensor readings and system components related to the fault code is a critical step. This could involve checking the oxygen sensor’s voltage output or inspecting the exhaust system for leaks. A nuanced understanding of how the vehicle’s emissions control system interacts is therefore critical.

In summary, fault code interpretation provides a crucial diagnostic bridge linking the symptom (check engine light) to its potential cause following a muffler deletion. A misdiagnosis or misunderstanding of the underlying fault code can result in misdirected repairs or unnecessary expenses. The ability to interpret these codes in relation to the modification serves as a tool to facilitate appropriate corrective actions. A meticulous, systematic, and informed approach to code interpretation can help to distinguish between direct consequences of the muffler delete and unrelated or coincidental issues.

Frequently Asked Questions Regarding Muffler Deletion and Diagnostic Warnings

The following questions address common inquiries and concerns related to muffler removal and the potential activation of the malfunction indicator lamp.

Question 1: Is it definitively guaranteed that a muffler delete will trigger the check engine light?

The activation of the malfunction indicator lamp following a muffler removal is not guaranteed. The outcome depends on various factors including the vehicle’s make, model, diagnostic system sensitivity, and overall condition. While some vehicles tolerate this modification without issue, others are more prone to generating diagnostic trouble codes.

Question 2: What specific diagnostic trouble codes are most commonly associated with muffler removal?

Commonly observed codes include those related to oxygen sensor performance (e.g., P0131, P0134), fuel trim imbalances (e.g., P0171, P0174), and catalytic converter efficiency (e.g., P0420). These codes typically indicate a disruption in the exhaust system’s flow or composition as detected by the vehicle’s sensors.

Question 3: Can resetting the check engine light resolve the issue permanently after a muffler delete?

Resetting the check engine light merely clears the stored diagnostic trouble code. If the underlying cause, such as altered exhaust flow or sensor readings, persists, the light will likely illuminate again. A proper solution requires addressing the root cause, potentially through ECU recalibration or exhaust system modifications.

Question 4: Does the year of the vehicle influence the likelihood of encountering issues after a muffler delete?

Yes, the vehicle’s model year can play a role. Newer vehicles often have more sophisticated diagnostic systems with tighter emissions control parameters. Consequently, these vehicles might be more sensitive to exhaust modifications compared to older models with less stringent monitoring.

Question 5: Are there any preventative measures that can be taken to minimize the risk of a check engine light after a muffler delete?

Several preventative measures can mitigate the risk. These include thorough research of the vehicle’s exhaust system characteristics, careful installation to prevent leaks, and consideration of ECU recalibration. Additionally, using aftermarket components designed to manage exhaust flow can help maintain appropriate backpressure levels.

Question 6: Will installing an aftermarket oxygen sensor spacer resolve check engine light issues related to a muffler delete?

Oxygen sensor spacers, often referred to as “defoulers,” can sometimes trick the ECU into accepting readings from the downstream oxygen sensor. However, the success of this approach varies and it may not address the underlying issue. It is not a universally effective solution and can potentially mask other problems within the emissions system.

In conclusion, muffler deletion introduces variables impacting the vehicle’s emission control system. While not every vehicle will respond with an illuminated malfunction indicator lamp, a thorough understanding of the potential consequences can promote informed decision-making.

The succeeding section addresses the legal ramifications associated with exhaust modifications.

Conclusion

The presented exploration demonstrates that removing a muffler does not unequivocally trigger the malfunction indicator lamp. Rather, the activation of this warning depends upon an intricate interplay of factors including vehicle-specific design characteristics, the sensitivity of the onboard diagnostic system, and the precision of the modification itself. Alterations in exhaust flow and backpressure, coupled with the potential for leaks, can compromise the accuracy of oxygen sensor readings, thereby disrupting the engine control unit’s carefully calibrated operating parameters.

Therefore, prudent vehicle owners considering such an alteration should prioritize thorough research and careful execution. When contemplating modifications, an informed approach incorporating awareness of potential diagnostic consequences, adherence to applicable regulations, and consultation with qualified professionals is essential. Such diligence mitigates the risk of unintended system malfunctions and promotes responsible vehicle maintenance.

![Muffler Delete Cost: What to Expect? [Price Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Muffler Delete Cost: What to Expect? [Price Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-428-300x200.jpg)