The exhaust component specific to the Infiniti G35 is designed to reduce engine noise and direct exhaust gases away from the vehicle. It’s a crucial part of the vehicle’s exhaust system, playing a role in both sound suppression and emissions control. A properly functioning component contributes to a quieter and more environmentally sound operation of the vehicle.

This specific part significantly impacts the vehicle’s overall acoustic signature. An original equipment version often prioritizes noise reduction for a refined driving experience. Aftermarket options can provide a range of sound profiles, from a near-stock level of quietness to a more aggressive, performance-oriented sound. Furthermore, some higher-performance replacements may offer slight improvements in exhaust flow, potentially leading to minor gains in engine power and efficiency. Early models and later revisions may have different designs impacting performance and sound.

The following discussion will explore the various aspects of this part, including its construction, common problems, and available replacement options. Performance characteristics and installation considerations will also be addressed.

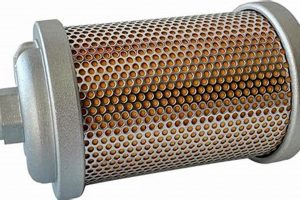

Infiniti G35 Muffler

Proper maintenance and informed selection regarding the exhaust component are crucial for optimal performance and longevity of the Infiniti G35. The following points provide insights to ensure optimal operation and informed decision-making.

Tip 1: Inspect Regularly for Corrosion: Road salt and environmental factors can accelerate corrosion. Periodic visual inspections for rust, especially around welds and inlets/outlets, are crucial. Early detection prevents costly repairs.

Tip 2: Address Exhaust Leaks Promptly: Unusual noises, such as hissing or popping, could indicate an exhaust leak. Delaying repairs can lead to decreased fuel efficiency, reduced performance, and potential damage to other exhaust system components.

Tip 3: Consider Material When Replacing: Aftermarket options include aluminized steel, stainless steel, and titanium. Stainless steel offers superior corrosion resistance compared to aluminized steel, while titanium provides even greater durability and weight reduction but comes at a higher cost.

Tip 4: Understand Sound Expectations: Aftermarket replacements vary significantly in sound output. Research sound clips and reviews before purchasing to ensure the replacement aligns with the desired acoustic profile. A louder exhaust may not always translate to increased performance.

Tip 5: Verify Compatibility Before Purchasing: Ensure the selected replacement is specifically designed for the Infiniti G35 model year. Incorrect fitment can lead to installation difficulties and compromised performance.

Tip 6: Professional Installation Recommended: While some may attempt DIY installation, proper alignment and sealing are critical. A qualified mechanic can ensure correct installation, minimizing the risk of leaks and other issues.

Tip 7: Check Local Regulations: Some jurisdictions have noise level restrictions. Ensure any aftermarket replacement complies with local laws to avoid potential fines.

Adhering to these considerations ensures optimal performance, longevity, and legal compliance concerning the Infiniti G35 exhaust component.

The following sections will provide detailed information about common problems and available solutions for the exhaust component of the Infiniti G35.

1. Sound level management

Sound level management is a primary function dictated by the Infiniti G35 exhaust component. The design and construction of this part directly correlate to the level of noise emitted by the vehicle, influencing the driving experience and regulatory compliance.

- Internal Chamber Design

The internal structure of the component, including the number and configuration of baffles and resonators, dictates the degree of sound attenuation. More complex designs generally result in greater noise reduction. Aftermarket options often alter these internal designs to achieve different sound profiles, potentially increasing or decreasing the overall noise level.

- Material Composition

The materials used in construction impact sound absorption and vibration dampening. Denser materials, such as stainless steel, tend to resonate less than thinner materials, potentially contributing to a deeper and less harsh exhaust note. The thickness of the material also plays a role in minimizing vibrations that can amplify exhaust noise.

- Exhaust System Resonance

The length and diameter of the entire exhaust system, including the component, influence the resonant frequencies produced by the engine. Modifying the component can shift these frequencies, altering the overall sound characteristics. Certain modifications can lead to undesirable drone at specific engine speeds.

- Compliance with Noise Regulations

The original equipment component is designed to meet specific noise emission standards. Aftermarket options must also adhere to these regulations in applicable jurisdictions. Exceeding legal noise limits can result in fines and vehicle inspection failures.

The interplay between internal design, material selection, exhaust system resonance, and regulatory compliance dictates the effectiveness of sound level management within the Infiniti G35 exhaust system. Understanding these aspects is crucial for informed decision-making when considering replacement or modification of the exhaust component.

2. Exhaust flow optimization

Exhaust flow optimization is a critical consideration when addressing the Infiniti G35 component. Efficient expulsion of exhaust gases directly impacts engine performance, fuel economy, and overall vehicle responsiveness. Modifications or replacements of this part can significantly alter the flow characteristics, yielding noticeable changes in these areas.

- Internal Diameter and Smoothness

The internal diameter of the component directly affects the volume of gas that can pass through, while the smoothness of the internal surfaces minimizes turbulence. Reduced turbulence translates to less energy loss as exhaust gases exit the engine. Aftermarket components often boast larger diameters and polished interiors to facilitate greater exhaust flow, potentially increasing horsepower and torque.

- Baffle Design and Placement

Baffles are internal structures used to attenuate sound. Their design and placement impact the resistance to exhaust flow. A poorly designed baffle system can create significant backpressure, hindering engine performance. Performance-oriented components often utilize fewer or strategically placed baffles to balance sound reduction with minimal flow restriction. Modifications to baffle design must consider the trade-off between noise levels and exhaust efficiency.

- Mandrel Bending Technique

The method used to bend the tubing during manufacturing influences the cross-sectional area and smoothness of the exhaust path. Mandrel bending maintains a consistent diameter throughout the bend, preventing flow restrictions. Crush bending, a less expensive alternative, can constrict the tubing at the bend, impeding exhaust flow. High-performance exhaust systems typically employ mandrel-bent tubing for optimal gas flow.

- Catalytic Converter Integration

The integration of the catalytic converter, an emissions control device, directly impacts the exhaust stream. High-flow catalytic converters are designed to minimize flow restriction while effectively reducing harmful emissions. Replacing the factory catalytic converter with a high-flow unit can improve exhaust flow but must comply with applicable emissions regulations.

The aforementioned factors directly influence the degree to which the Infiniti G35 component facilitates efficient exhaust flow. Understanding these elements allows for informed decision-making when selecting replacement components or modifying the existing exhaust system to optimize engine performance while maintaining regulatory compliance.

3. Material durability

The durability of materials used in the Infiniti G35 exhaust component is paramount due to the harsh operating environment. Exposure to high temperatures, corrosive road salts, and constant vibration necessitates careful material selection to ensure longevity and reliable performance. Material failure leads to compromised sound suppression, exhaust leaks, and potential damage to other vehicle components.

- Corrosion Resistance and Material Choice

Aluminized steel, stainless steel, and titanium are commonly used materials. Aluminized steel provides a basic level of protection but is susceptible to rust in regions with heavy road salt usage. Stainless steel offers superior corrosion resistance, extending the lifespan of the exhaust. Titanium provides the highest level of corrosion resistance and significant weight reduction, though at a higher cost. The environmental conditions where the vehicle is operated heavily influence the optimal material choice.

- Weld Quality and Joint Integrity

Welds are inherently vulnerable points in any exhaust system. Poorly executed welds compromise structural integrity and accelerate corrosion. High-quality welding techniques, such as TIG welding, create stronger, more corrosion-resistant joints. Regular inspection of welds for cracks or rust is essential to prevent premature failure. Factory welds often undergo rigorous quality control, while aftermarket options vary in weld quality.

- Material Thickness and Gauge

The thickness of the metal used significantly affects the component’s resistance to physical damage and vibration fatigue. Thicker gauge materials withstand impacts from road debris and resist cracking due to constant vibration. Aftermarket components may use thinner gauge materials to reduce costs, sacrificing durability. Factory components typically adhere to specific thickness standards to ensure adequate durability under normal operating conditions.

- Thermal Stress and Fatigue Resistance

The component undergoes repeated heating and cooling cycles, generating thermal stress. Materials with high thermal fatigue resistance withstand these cycles without cracking or warping. Stainless steel exhibits superior thermal fatigue resistance compared to aluminized steel. The operating temperature range of the engine and the driving style influence the rate of thermal fatigue. Frequent short trips, where the exhaust system does not fully heat up, can exacerbate corrosion due to condensation within the component.

The selection of durable materials and the implementation of robust manufacturing processes are fundamental to the longevity and performance of the Infiniti G35 exhaust component. Careful consideration of material properties and weld quality is crucial when selecting replacement parts or modifying the exhaust system. Selecting for durability directly minimizes the frequency and expense of repairs, while sustaining performance over the vehicle’s lifespan.

4. Corrosion resistance

Corrosion resistance is a critical factor in the longevity and reliable operation of the exhaust component on the Infiniti G35. The component is exposed to high temperatures, moisture, road salts, and other corrosive elements, making the selection of corrosion-resistant materials paramount. Premature failure due to corrosion can lead to exhaust leaks, increased noise, and reduced performance.

- Material Composition and Corrosion Rates

Different materials exhibit varying degrees of corrosion resistance. Aluminized steel, while cost-effective, offers limited protection against corrosion and is susceptible to rust in environments with frequent exposure to road salt. Stainless steel provides significantly improved corrosion resistance due to its chromium content, which forms a protective oxide layer. Titanium offers the highest level of corrosion resistance but is often reserved for high-performance applications due to its higher cost. The specific alloy of stainless steel also influences corrosion resistance, with 304 stainless steel being a common choice.

- Protective Coatings and Galvanic Corrosion

Protective coatings, such as ceramic coatings, can provide an additional layer of protection against corrosion. These coatings act as a barrier, preventing corrosive elements from directly contacting the metal surface. However, damage to the coating compromises its effectiveness. Galvanic corrosion, which occurs when dissimilar metals are in contact in the presence of an electrolyte, can also be a concern. Proper material selection and the use of dielectric insulators can mitigate this risk.

- Environmental Factors and Accelerated Corrosion

Environmental factors significantly influence the rate of corrosion. Regions with cold climates and heavy road salt usage experience accelerated corrosion. Frequent short trips, where the exhaust system does not fully heat up, can also promote corrosion due to condensation within the component. Coastal environments, with high levels of airborne salt, present an especially corrosive environment. Regular cleaning and inspection can help mitigate the effects of these environmental factors.

- Weld Integrity and Corrosion Vulnerability

Welds are often the most vulnerable points for corrosion to initiate. The welding process can alter the microstructure of the metal, making it more susceptible to corrosion. Proper welding techniques, such as TIG welding, and the use of corrosion-resistant filler metals are essential. Regular inspection of welds for signs of rust or cracking is crucial for identifying and addressing potential corrosion issues before they escalate.

Therefore, selecting the appropriate material, applying protective coatings, mitigating galvanic corrosion, and ensuring weld integrity are all critical aspects of maximizing corrosion resistance and extending the service life of the exhaust component on the Infiniti G35. These considerations directly impact the long-term reliability and performance of the vehicle’s exhaust system, particularly in harsh operating environments.

5. Proper fitment

Proper fitment is a non-negotiable requirement when dealing with an exhaust component for an Infiniti G35. Its importance stems directly from the vehicle’s design, where precise dimensions and mounting points are engineered to ensure a sealed and structurally sound exhaust system. A component that does not conform to these specifications will inevitably lead to problems, beginning with exhaust leaks. These leaks diminish engine performance, contribute to elevated noise levels, and pose a safety risk due to the potential for carbon monoxide intrusion into the vehicle cabin. For example, an aftermarket part designed for a different model year G35, despite appearing similar, might have slightly misaligned flange bolt patterns. This misalignment prevents a complete seal, causing an audible hissing and a noticeable drop in engine responsiveness.

Beyond exhaust leaks, improper fitment introduces mechanical stress to the exhaust system. An exhaust component that is forced into position creates tension on surrounding parts, including exhaust manifolds, catalytic converters, and the vehicle’s undercarriage. This stress accelerates wear and tear and can ultimately lead to cracks, breaks, or even damage to related components. Consider an instance where an oversized component contacts the undercarriage: The persistent vibration of the engine, coupled with road impacts, can chafe against the undercarriage, leading to corrosion and structural weakening over time. The absence of a secure fit also increases the risk of component detachment, posing a hazard to both the vehicle and other road users.

In conclusion, proper fitment of the exhaust component on an Infiniti G35 is not merely a matter of convenience, but an essential prerequisite for safe, efficient, and reliable vehicle operation. Ignoring this aspect leads to a cascade of problems, ranging from performance degradation and increased noise to potential safety hazards and accelerated wear of related components. Precise adherence to manufacturer specifications and careful verification of compatibility are therefore critical to ensure the long-term health and integrity of the vehicle’s exhaust system.

6. Regulatory compliance

Regulatory compliance concerning the Infiniti G35 exhaust component encompasses a series of legal requirements and standards designed to govern vehicle emissions and noise levels. These regulations aim to protect public health and the environment by limiting the release of pollutants and mitigating noise pollution. Adherence to these standards is mandated by federal, state, and local authorities, and non-compliance can result in fines, penalties, and vehicle inspection failures. Replacement or modification of the original exhaust component must therefore consider its impact on the vehicle’s ability to meet these regulatory benchmarks.

- Federal Emissions Standards

The United States Environmental Protection Agency (EPA) sets federal emission standards for all vehicles, including the Infiniti G35. These standards limit the amount of pollutants, such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx), that a vehicle can emit. The exhaust component, including the catalytic converter, plays a crucial role in reducing these pollutants. Aftermarket exhaust components must be designed to ensure that the vehicle continues to meet these federal standards. Failure to do so is a violation of federal law and can result in substantial penalties. For example, removing or altering the catalytic converter is strictly prohibited under federal regulations.

- State and Local Noise Ordinances

Many states and municipalities have noise ordinances that regulate the permissible sound levels emitted by vehicles. These ordinances are designed to minimize noise pollution and maintain a certain quality of life for residents. The exhaust component is a primary contributor to vehicle noise. Aftermarket components that significantly increase the exhaust volume may violate these noise ordinances. Some jurisdictions use decibel meters to measure vehicle noise levels and issue citations to drivers whose vehicles exceed the established limits. For instance, a modified Infiniti G35 with a straight-pipe exhaust system may produce noise levels exceeding local ordinances, resulting in a fine.

- California Air Resources Board (CARB) Regulations

California has its own set of stringent air quality regulations, overseen by the California Air Resources Board (CARB). Aftermarket exhaust components sold or used in California must be CARB-compliant, meaning they have been tested and certified to meet specific emission standards. CARB-compliant components are typically labeled with an Executive Order (EO) number, indicating their approval for use in California. Installing a non-CARB-compliant exhaust component on an Infiniti G35 registered in California is illegal and can result in the vehicle failing a smog check. For example, a performance exhaust component marketed for the G35 may be legal in other states but require a CARB EO number for legal installation and use in California.

- Tampering Prohibitions

Federal and state laws prohibit tampering with vehicle emission control systems. This includes modifying, removing, or rendering inoperative any component designed to control emissions. The exhaust component, including the catalytic converter, is a critical part of the emission control system. Altering or removing these components to improve performance, without ensuring compliance with emission standards, is a violation of tampering prohibitions. For example, replacing the factory catalytic converter with a test pipe (a straight pipe without a catalytic converter) is illegal under federal law and can result in significant fines.

The interplay between federal emissions standards, state and local noise ordinances, CARB regulations, and tampering prohibitions underscores the importance of selecting exhaust components that are both performance-enhancing and legally compliant. Modifying or replacing the original exhaust component on an Infiniti G35 requires careful consideration of these regulatory factors to avoid legal penalties and ensure the vehicle continues to meet environmental standards. Prioritizing regulatory compliance protects both the environment and the vehicle owner from potential legal repercussions.

Frequently Asked Questions

This section addresses common inquiries regarding the Infiniti G35 exhaust component, providing detailed explanations to enhance understanding and informed decision-making.

Question 1: What constitutes a typical lifespan for the factory-installed exhaust component on an Infiniti G35?

The original equipment component typically lasts between 5 and 7 years, contingent upon environmental conditions, driving habits, and maintenance practices. Exposure to road salt, frequent short trips, and aggressive driving patterns can shorten its lifespan.

Question 2: What are the audible indicators of a failing or degraded exhaust component?

Common symptoms include a noticeable increase in exhaust noise, hissing or popping sounds emanating from underneath the vehicle, and a rattling sound, especially upon cold starts. These sounds suggest exhaust leaks or internal component damage.

Question 3: Does upgrading the exhaust component invariably increase vehicle horsepower?

While some aftermarket options are designed to improve exhaust flow and potentially increase horsepower, this is not guaranteed. Any power gains are typically modest and may not be noticeable without other performance modifications. Improved sound and aesthetics are often the primary benefits.

Question 4: Are there specific tools required for replacing the exhaust component on an Infiniti G35?

Replacement generally requires basic hand tools, including wrenches, sockets, and a ratchet. Penetrating oil is often necessary to loosen corroded bolts. A vehicle lift or jack stands are highly recommended for safe and convenient access. Welding equipment may be necessary for certain modifications or repairs.

Question 5: Does replacing the exhaust component affect the vehicle’s emissions testing results?

If the replacement includes the catalytic converter, it is essential to ensure that the new catalytic converter meets or exceeds the original equipment specifications. Using a non-compliant catalytic converter can result in failing an emissions test and violating environmental regulations.

Question 6: Can damage to the exhaust component affect fuel efficiency?

Yes, exhaust leaks caused by a damaged component can disrupt the engine’s air-fuel ratio and reduce fuel efficiency. A properly functioning exhaust system is crucial for optimal engine performance and fuel economy.

In summary, maintaining the Infiniti G35 exhaust component involves proactive inspection, timely repairs, and informed replacement decisions. Understanding the component’s function and potential issues helps ensure continued vehicle performance and regulatory compliance.

The next section will delve into troubleshooting common problems and offering solutions.

Infiniti G35 Muffler

This exploration has detailed the critical aspects of the Infiniti G35 exhaust component, encompassing its function, material considerations, regulatory compliance, and potential issues. From sound level management to exhaust flow optimization and corrosion resistance, each element plays a vital role in the overall performance and longevity of the vehicle. The selection of appropriate replacement parts and adherence to proper maintenance practices are paramount for ensuring optimal operation.

The information presented serves to empower owners and technicians with a comprehensive understanding of this component, facilitating informed decisions regarding maintenance, repair, and modification. Prioritizing regulatory compliance, material durability, and proper fitment will contribute to the continued performance and environmental responsibility of the Infiniti G35. It is imperative to consult qualified professionals for complex repairs or modifications to ensure safety and adherence to applicable regulations.

![Find an Eco Muffler Center Near You: [State/City] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Find an Eco Muffler Center Near You: [State/City] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/01/th-626-300x200.jpg)