An automotive exhaust component designed to reduce engine noise and enhance vehicle performance through a specific internal baffling system. This particular unit is characterized by its large internal passages and optimized flow design, aiming to provide a balance between sound attenuation and minimal backpressure.

The benefits of this type of exhaust component include a potential increase in horsepower and torque, improved fuel efficiency (depending on the application), and a more controlled exhaust note compared to open exhaust systems. Historically, these units have been favored for their durability and cost-effectiveness, making them a popular choice for both street and light performance vehicles.

The subsequent sections will delve into the specific features, installation considerations, and maintenance requirements associated with selecting and using this type of exhaust component, providing a detailed understanding of its application in optimizing vehicle exhaust systems.

Selection and Application Guidance

This section provides crucial guidance for selecting and appropriately applying this specific exhaust component to ensure optimal performance and longevity.

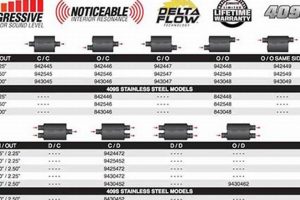

Tip 1: Verify Compatibility: Before purchasing, confirm the unit’s inlet and outlet sizes match the vehicle’s existing exhaust system dimensions. Incompatibility can lead to installation difficulties and compromised performance.

Tip 2: Consider Engine Displacement: Match the unit’s flow capacity to the engine’s displacement. An undersized unit can create excessive backpressure, while an oversized unit may not provide sufficient sound attenuation.

Tip 3: Evaluate Exhaust System Condition: Prior to installation, inspect the entire exhaust system for leaks, rust, or damage. Addressing existing issues ensures the component operates within a healthy system.

Tip 4: Employ Professional Installation: Unless experienced in exhaust system modifications, seek professional installation services. Proper welding and alignment are critical for a secure and leak-free connection.

Tip 5: Monitor Exhaust System Sound: After installation, monitor the exhaust note for unusual noises or vibrations. These could indicate leaks or improper installation that requires immediate attention.

Tip 6: Regularly Inspect for Corrosion: Periodically inspect the unit for signs of rust or corrosion, especially in regions with harsh weather conditions. Promptly address corrosion to prevent premature failure.

Tip 7: Account for Vehicle Modifications: If the vehicle has performance modifications (e.g., aftermarket headers), select the product according to engine’s output to reach optimized performance.

Adhering to these guidelines ensures proper selection, installation, and maintenance, maximizing the benefits of this exhaust component and preventing potential problems.

The subsequent section will address the common misconceptions and troubleshooting techniques associated with this exhaust component.

1. Sound Attenuation

Sound attenuation is a primary function of this specific exhaust component, influencing the vehicle’s noise level and overall driving experience. Its relevance stems from regulations governing vehicle noise emissions and driver/passenger comfort considerations.

- Internal Baffling Design

The internal design incorporates a series of strategically placed baffles. These baffles redirect and dampen exhaust gas pulses, reducing noise amplitude. For instance, the “Tri-Flow” design utilizes three internal passages to split and diffuse the sound waves, significantly decreasing perceived loudness.

- Absorption Materials

Some units incorporate sound-absorbing materials, such as fiberglass packing, within the muffler body. These materials convert sound energy into heat, further reducing noise levels. However, the effectiveness of these materials can degrade over time, requiring periodic replacement.

- Resonance Chamber Tuning

The muffler’s internal chambers are tuned to specific frequencies to counteract and neutralize undesirable exhaust tones. This technique aims to produce a smoother, more controlled exhaust note while minimizing overall noise output.

- Impact on Performance

Excessive sound attenuation can increase backpressure, potentially reducing engine performance. Therefore, the unit design balances noise reduction with minimal flow restriction to achieve optimal sound control without compromising power output.

The interplay between these facets dictates the overall effectiveness of sound attenuation, influencing the component’s suitability for various vehicle applications and driver preferences. Achieving the optimal balance ensures compliance with noise regulations while maintaining acceptable performance levels.

2. Flow Optimization

Flow optimization within an exhaust component directly relates to the efficient expulsion of exhaust gases from the engine. This crucial aspect determines power output, fuel efficiency, and engine longevity, making it a critical performance parameter of the component.

- Internal Passage Design

The internal configuration employs large diameter, mandrel-bent passages to minimize restrictions and turbulence within the exhaust flow. The design reduces backpressure and facilitates a smoother exit for exhaust gases. An example would be the use of a straight-through design for maximum flow, in contrast to traditional baffled systems which inherently cause more resistance.

- Minimized Backpressure

Backpressure, the resistance to exhaust flow, directly impacts engine performance. By optimizing internal passage design and reducing obstructions, backpressure is minimized. Lower backpressure allows the engine to expel exhaust gases more easily, which results in increased horsepower and torque, especially at higher RPMs. Excessive backpressure can lead to reduced power and increased engine temperatures.

- Turbulence Reduction

Turbulence within the exhaust system creates resistance and impedes flow efficiency. Careful design of internal components aims to minimize turbulence by creating smooth transitions and avoiding sharp angles. Reduction in turbulence facilitates laminar flow which improves exhaust gas velocity and overall engine efficiency.

- Scavenging Effect

Optimized flow can create a scavenging effect, where the exiting exhaust gases help to draw out subsequent exhaust pulses from the cylinder. This helps improve cylinder filling and enhances combustion efficiency. The design is made to promote the development of negative pressure waves during exhaust cycles, aiding in drawing more exhaust volume away from the engine.

These design elements collectively contribute to improved exhaust flow efficiency. Reduced backpressure, minimized turbulence, and enhanced scavenging work synergistically to optimize engine performance. The component’s design focuses to improve the flow rate and gas velocity which are all core elements in improving engine output.

3. Durability

Durability is a critical attribute, influencing its lifespan and overall value proposition. The materials and construction techniques employed directly determine the component’s resistance to environmental factors and operational stresses, impacting its longevity and reliability.

For example, models constructed from aluminized steel offer enhanced corrosion resistance compared to standard steel, extending their service life in regions with harsh road conditions or high salt exposure. Welds are important; reinforced welds withstand vibrations and impacts from road debris, mitigating the risk of structural failure over time. Internal baffling construction is crucial, ensuring the unit’s ability to maintain its structural integrity under prolonged exposure to high-temperature exhaust gases. The practical consequence of poor durability includes premature failure, requiring costly replacement and potentially impacting vehicle performance.

Understanding the durability characteristics, therefore, is crucial for making informed purchase decisions. Selecting a unit constructed from robust materials and utilizing reinforced construction techniques ensures a longer service life and reduces the likelihood of unexpected maintenance costs. While initial cost might be higher, a durable unit provides a greater return on investment in the long term by minimizing the need for frequent replacements.

4. Backpressure

Backpressure, the resistance to exhaust gas flow, is a critical factor influencing engine performance when selecting an exhaust component. Understanding the relationship between backpressure and the design characteristics of components such as this component is essential for optimizing engine efficiency and power output.

- Internal Design and Backpressure

The internal configuration of the exhaust component directly dictates the level of backpressure generated. Straight-through designs with minimal obstructions offer lower backpressure compared to baffled systems. The component’s “Tri-Flow” design attempts to strike a balance, reducing noise while minimizing restrictions to exhaust flow. An inappropriate design can cause power loss.

- Engine Performance Implications

Excessive backpressure hinders the engine’s ability to expel exhaust gases efficiently. This can lead to reduced horsepower, decreased fuel economy, and increased engine operating temperatures. Conversely, insufficient backpressure can also negatively impact performance, particularly in low-end torque. The selection of an exhaust component should align with the engine’s specific characteristics and performance goals.

- Diameter and Backpressure Relationship

The diameter of the exhaust piping, including the component’s inlet and outlet, influences backpressure. A smaller diameter pipe creates more resistance, increasing backpressure. Conversely, a larger diameter pipe reduces backpressure, but may not be suitable for all engine applications. Matching the pipe diameter to the engine’s displacement and power output is critical.

- Impact on Scavenging

Backpressure affects the scavenging effect, where exhaust pulses help to draw out subsequent exhaust gases from the cylinder. Optimizing backpressure can improve cylinder filling and enhance combustion efficiency. An efficient backpressure design is supposed to ensure a powerful pulse to clear the engine cylinder.

The efficient operation of such exhaust components, hinges on a careful balance between sound attenuation and backpressure management. The component must mitigate noise effectively while ensuring minimal restriction to exhaust flow, thereby optimizing engine performance across the operating range. A poorly-selected or improperly installed component will degrade the engine’s efficiency.

5. Horsepower Increase

Enhancing horsepower is a primary objective for many automotive enthusiasts, and the selection of an exhaust component plays a crucial role in achieving this goal. The component’s design and performance characteristics directly impact engine efficiency and, consequently, power output.

- Reduced Backpressure and Power Output

An exhaust system component designed to minimize backpressure allows the engine to expel exhaust gases more efficiently. The reduction in backpressure translates directly into increased horsepower, particularly at higher engine speeds (RPMs). For example, replacing a restrictive stock muffler with a less restrictive unit like the Dynomax Super Turbo often results in a noticeable gain in horsepower, especially in modified engines.

- Optimized Exhaust Flow and Scavenging

The specific internal design of the component optimizes exhaust flow. Efficient exhaust flow promotes a scavenging effect, where the exiting exhaust gases help to draw out subsequent exhaust pulses from the cylinders. This improved cylinder filling enhances combustion and contributes to increased horsepower and torque. A well-designed system enhances this natural effect.

- Engine Tuning and Exhaust Modifications

Modifying the exhaust system with a higher-flowing component often necessitates adjustments to the engine’s fuel and ignition maps. Retuning the engine to account for the improved exhaust flow allows the engine to take full advantage of the reduced backpressure and optimized scavenging. This synergy between exhaust modifications and engine tuning maximizes horsepower gains. For example, remapping the ECU for an engine with performance-oriented exhaust and intake components can yield the full range of benefits.

- Impact on Torque

While primarily focused on horsepower, the selection and design of an exhaust component also influence torque. Torque, the rotational force of the engine, is crucial for acceleration and drivability. By optimizing exhaust flow and reducing backpressure, this component can improve torque, enhancing the overall driving experience. Torque improvement is particularly noticeable at lower and mid-range engine speeds, which are key in day-to-day driving.

The interplay between reduced backpressure, optimized exhaust flow, engine tuning, and torque enhancement underscores the potential for increasing horsepower through the use of this component. Selecting a unit that matches the engine’s characteristics and performance goals is crucial for realizing these gains. Therefore, careful consideration is warranted when selecting an exhaust component to achieve the desired horsepower increase while maintaining optimal engine performance and drivability.

6. Installation Complexity

The installation complexity associated with this exhaust component influences both the cost and the potential for successful integration into a vehicle’s exhaust system. Understanding these challenges is crucial for both professional installers and vehicle owners considering this upgrade.

- Welding Requirements

Most installations necessitate welding to ensure a secure and leak-free connection to the existing exhaust system. This requires specialized equipment and expertise. Amateur welding can result in exhaust leaks, reduced performance, and potential safety hazards. The type of welding, such as MIG or TIG, should be appropriate for the materials involved.

- Customization and Fitment

While designed for universal fitment, some vehicles may require modifications to the exhaust system for proper installation. This can include cutting, bending, or adapting existing pipes to accommodate the unit’s dimensions. Customization increases installation time and cost and may require specialized tools and skills.

- Vehicle-Specific Considerations

The complexity of installation varies significantly depending on the vehicle’s make, model, and existing exhaust system configuration. Some vehicles offer easy access and straightforward replacement, while others require extensive disassembly and modification. Factors such as the presence of catalytic converters, oxygen sensors, and frame obstructions can complicate the installation process.

- Potential for Exhaust Leaks

Improper installation, particularly inadequate welding or sealing, can result in exhaust leaks. These leaks reduce performance, increase noise levels, and can pose a safety risk due to the potential for carbon monoxide exposure. Thorough inspection and testing following installation are crucial to identify and address any leaks.

The combination of welding requirements, customization needs, vehicle-specific factors, and the risk of exhaust leaks highlights the potential complexity of this component’s installation. While some installations may be relatively straightforward, others require professional expertise to ensure optimal performance and safety. Evaluating the vehicle’s specific needs and the installer’s capabilities is essential before undertaking the installation process.

7. Corrosion Resistance

Corrosion resistance is a critical performance characteristic influencing the lifespan and long-term value of this automotive exhaust component. Exhaust systems are inherently exposed to harsh conditions, including high temperatures, moisture, road salts, and corrosive chemicals. The material composition and manufacturing processes employed in the unit’s construction directly determine its ability to withstand these elements and resist degradation over time. Premature corrosion can lead to exhaust leaks, reduced performance, increased noise levels, and ultimately, component failure. For instance, in regions with heavy winter salting, exhaust systems made from standard steel can corrode rapidly, necessitating frequent replacements.

To enhance corrosion resistance, manufacturers often utilize aluminized steel in the construction of this and similar exhaust components. Aluminizing involves coating the steel with a layer of aluminum, which forms a protective barrier against rust and corrosion. Stainless steel is another option, offering superior corrosion resistance but typically at a higher cost. The quality of the aluminizing or stainless steel, as well as the integrity of welds and seams, significantly affects the component’s ability to withstand corrosive environments. For example, a poorly welded seam can create a point of vulnerability where corrosion initiates and spreads. The practical significance of this lies in the extended lifespan of the exhaust component, reducing the frequency of replacements and minimizing maintenance costs.

The selection of corrosion-resistant materials and robust construction techniques is paramount for ensuring the longevity and reliability of automotive exhaust components. While initial cost considerations are important, investing in a component with enhanced corrosion resistance often proves more economical in the long run by mitigating the risk of premature failure and the associated expenses of replacement. This understanding underscores the importance of carefully evaluating material specifications and construction details when choosing an exhaust component for any vehicle. The challenge lies in balancing cost with the need for long-term durability, particularly in regions with aggressive environmental conditions.

Frequently Asked Questions

The following questions address common inquiries regarding the selection, application, and performance characteristics of this exhaust component. The information provided aims to offer clarity and guidance for prospective users.

Question 1: What is the typical lifespan of this exhaust component?

Lifespan varies depending on environmental conditions, usage, and material construction. Units constructed from aluminized steel generally last longer than standard steel components. Regular inspection and maintenance, such as addressing surface rust, can extend its service life.

Question 2: Does this component require professional installation?

While some experienced individuals may undertake installation, professional installation is generally recommended. Welding, precise alignment, and proper sealing are critical for optimal performance and preventing exhaust leaks. Improper installation can void warranties and create safety hazards.

Question 3: Will this component significantly alter the vehicle’s exhaust sound?

This exhaust component provides a balance between sound attenuation and performance. It typically produces a deeper, more controlled exhaust note compared to stock units, without being excessively loud. The exact sound level is influenced by the engine, exhaust system configuration, and the presence of other aftermarket components.

Question 4: Is this exhaust component compatible with all vehicle makes and models?

While designed for universal fitment, compatibility is not guaranteed for all vehicles. Verifying the component’s dimensions, inlet/outlet sizes, and exhaust system configuration is essential before purchase. Some vehicles may require modifications for proper installation.

Question 5: Can this component improve fuel economy?

Improved fuel economy is a potential benefit, particularly when combined with other performance upgrades and proper engine tuning. Reducing backpressure can improve engine efficiency, potentially leading to slight gains in fuel mileage. However, results vary depending on driving habits and vehicle condition.

Question 6: Does the use of this exhaust component void the vehicle’s warranty?

The impact on a vehicle’s warranty depends on the manufacturer and the nature of the modification. Generally, aftermarket components do not automatically void the entire warranty, but may affect coverage for related parts. Consulting the vehicle’s warranty documentation and a qualified service advisor is recommended.

The information presented here clarifies common concerns and provides a foundation for informed decision-making regarding the component. However, consulting with qualified automotive professionals is always advisable for specific applications.

The subsequent section will delve into user testimonials and case studies, providing real-world examples of this component’s performance and suitability for various automotive applications.

Dynomax Super Turbo Muffler

This exploration has elucidated the multifaceted characteristics of the dynomax super turbo muffler, encompassing its sound attenuation capabilities, flow optimization attributes, durability considerations, backpressure implications, potential horsepower augmentation, installation complexities, and corrosion resistance properties. These interwoven elements directly influence the unit’s performance, longevity, and suitability within diverse automotive applications. A comprehensive understanding of these attributes is paramount for informed selection and integration.

The presented analysis serves as a foundation for discerning whether the dynomax super turbo muffler aligns with specific performance objectives and vehicle requirements. Further research and professional consultation are encouraged to ensure optimal application and realize the full potential of this exhaust component. The selection and integration of exhaust components represent a critical aspect of vehicle performance and maintenance, necessitating careful consideration and informed decision-making.