A device attached to the exhaust system of a motor vehicle, typically used in Fruitville, is designed to reduce the noise emitted by the engine. An example would be a mechanic replacing this component on a customer’s car to address excessive exhaust sound.

The importance of this item lies in its contribution to noise pollution reduction and adherence to local regulations. Historically, advancements in its design have led to more efficient sound dampening capabilities and improved vehicle performance.

The subsequent sections will delve into the specific types, materials, and installation procedures associated with this vital automotive component and its maintenance considerations for optimal functionality.

Maintenance and Longevity Tips

This section outlines essential practices to ensure optimal performance and extended lifespan of exhaust noise reduction devices in Fruitville vehicles.

Tip 1: Routine Inspection: Schedule regular inspections, at least twice annually, to identify early signs of corrosion, rust, or physical damage. Early detection prevents extensive damage and costly repairs. Example: Check for rust spots during oil changes.

Tip 2: Prompt Repair: Address any identified issues immediately. Delaying repairs can lead to further damage to the exhaust system and decreased vehicle efficiency. Example: A small hole should be patched or the component replaced without delay.

Tip 3: Avoid Short Trips: Minimize frequent short trips, as they can lead to moisture buildup within the exhaust system, accelerating corrosion. Example: Combine errands into longer trips to allow the exhaust system to heat up fully and evaporate moisture.

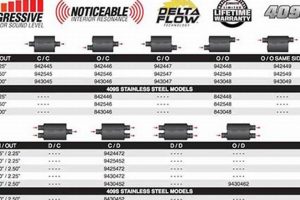

Tip 4: Use Quality Components: When replacing components, opt for high-quality, corrosion-resistant materials that are designed for the specific vehicle model. Example: Choose stainless steel over aluminized steel for better longevity in areas with road salt.

Tip 5: Regular Cleaning: Clean the exhaust system periodically to remove accumulated road debris, salt, and grime, particularly during winter months. Example: Rinse the undercarriage of the vehicle, focusing on the exhaust system, after exposure to road salt.

Tip 6: Monitor Exhaust Sounds: Pay close attention to any changes in exhaust sound, which may indicate a developing issue. Example: A louder-than-usual exhaust note can signal a leak or damage to the noise reduction component.

Tip 7: Professional Maintenance: Seek professional assistance for complex repairs or maintenance procedures to ensure proper installation and prevent further damage. Example: Have a qualified mechanic perform welding repairs or replace damaged components.

Adhering to these maintenance guidelines will contribute to the sustained performance, reduced noise pollution, and prolonged lifespan of the exhaust system’s noise reduction components in Fruitville vehicles.

The subsequent section will explore the environmental impact and regulatory considerations surrounding vehicle noise emissions and control measures.

1. Sound Reduction

Sound reduction is the primary functional characteristic of a vehicle’s exhaust noise dampening device, such as those commonly used in Fruitville. The device’s effectiveness in sound reduction directly affects the level of noise pollution emitted by the vehicle. The core principle relies on internal baffling and sound absorption techniques to minimize the intensity of exhaust noises. A malfunctioning or poorly designed device will fail to adequately reduce noise levels, leading to increased environmental noise and potential regulatory non-compliance. For instance, a vehicle with a compromised exhaust noise reduction device can produce significantly higher decibel levels, exceeding permissible limits in residential areas, causing disturbance and potentially incurring fines.

Effective sound reduction is achieved through a combination of engineering principles and material selection. The internal structure of the noise dampening device directs exhaust gases through a series of chambers and passages, causing sound waves to cancel each other out through destructive interference. Additionally, the use of sound-absorbing materials, such as fiberglass or specialized packing, further dampens the acoustic energy. Properly functioning exhaust noise dampening components contribute to a more pleasant driving experience and minimize the impact of vehicle noise on the surrounding environment. Regular inspection and maintenance are essential to ensure that these devices continue to provide optimal sound reduction throughout their lifespan.

In summary, sound reduction is an intrinsic and critical aspect of automotive exhaust systems in Fruitville. Its effectiveness is dependent on design, materials, and maintenance. Failure to prioritize sound reduction compromises regulatory compliance, increases noise pollution, and diminishes the quality of life within the community. Therefore, maintaining these components is paramount for responsible vehicle operation.

2. Material Durability

The longevity and effectiveness of exhaust noise reduction devices in Fruitville are directly contingent upon the material durability of their construction. The harsh operating environment, characterized by high temperatures, corrosive exhaust gases, and exposure to road debris and moisture, necessitates the use of robust materials. Premature failure due to material degradation leads to increased noise pollution, necessitating frequent replacements and incurring additional costs for vehicle owners. For example, an exhaust device constructed from low-grade steel may succumb to rust and corrosion within a few years, whereas a device fabricated from stainless steel or aluminized steel is likely to provide significantly extended service life. The initial investment in materials with superior durability directly translates to long-term cost savings and reduced environmental impact.

Selecting appropriate materials for these devices also involves considering the specific operating conditions prevalent in Fruitville. Exposure to road salt during winter months accelerates corrosion, requiring materials with enhanced resistance to chloride attack. Furthermore, the vibrational stresses induced by engine operation necessitate materials with high fatigue strength. Practical applications of this understanding include the use of coatings and surface treatments to further enhance corrosion resistance, as well as the implementation of rigorous testing protocols to assess the long-term durability of different materials under simulated operating conditions. The durability of the materials chosen directly influences the reliability, performance, and overall cost-effectiveness of exhaust noise reduction in the Fruitville context.

In summation, material durability is a critical factor influencing the performance and lifespan of exhaust components in Fruitville vehicles. The selection of corrosion-resistant and structurally sound materials is paramount for minimizing noise pollution, reducing maintenance costs, and ensuring long-term compliance with noise emission regulations. While challenges exist in balancing cost considerations with material performance, prioritizing durability represents a responsible approach to vehicle maintenance and environmental stewardship.

3. Regulation Compliance

Regulation compliance, specifically concerning noise emissions, directly impacts the selection, installation, and maintenance of exhaust sound dampening devices in Fruitville. These devices must meet established noise level standards set by local ordinances and environmental protection agencies. Non-compliance results in penalties, including fines and mandatory corrective actions. The effectiveness of these devices in mitigating exhaust noise is thus not merely a matter of preference but a legal requirement enforced through regular inspections and audits. For instance, vehicles failing noise level tests due to a defective or improperly installed device are subject to repair orders to achieve compliance.

The specific requirements governing exhaust noise emissions vary depending on the vehicle type and the geographical location within Fruitville. Factors such as population density, proximity to residential areas, and sensitivity of local ecosystems influence the stringency of noise regulations. Practical implications of this regulatory landscape include the need for certified mechanics who possess the expertise to properly install and maintain compliant exhaust systems. Furthermore, vehicle owners must exercise due diligence in selecting aftermarket devices, ensuring they meet or exceed the stipulated performance standards. Local auto shops provide regulation-compliant equipment to ensure the vehicle is within the legal requirement.

In summary, adherence to noise emission regulations is an integral aspect of vehicle ownership and operation in Fruitville. Exhaust noise reduction devices are indispensable components for achieving regulatory compliance, and their performance is subject to legal scrutiny. The challenges lie in navigating the complexities of evolving regulations, selecting appropriate devices, and ensuring ongoing maintenance to prevent non-compliance. The understanding and implementation of these principles are essential for fostering a quieter and more environmentally responsible community.

4. Installation Quality

Installation quality significantly impacts the performance and longevity of exhaust noise reduction devices, such as those commonly used in Fruitville. Proper installation ensures the device functions as designed, effectively reducing noise pollution and complying with local regulations. Conversely, substandard installation can compromise the device’s effectiveness, leading to increased noise levels, premature failure, and potential regulatory violations.

- Correct Alignment and Mounting

Ensuring the proper alignment of the device within the exhaust system is crucial for optimal performance. Misalignment can cause leaks, increased backpressure, and reduced sound dampening. Correct mounting prevents vibrations and stress on the device, extending its lifespan. An improperly aligned device may rattle or resonate, negating its intended noise reduction capabilities.

- Proper Sealing of Connections

Leak-free connections are essential for preventing exhaust gas leaks, which not only increase noise levels but also pose safety risks. The use of appropriate gaskets, sealants, and fasteners is vital for creating airtight seals. Leaks at the connections diminish the effectiveness of the device and can lead to the release of harmful exhaust gases into the environment.

- Use of Compatible Hardware

Employing hardware that is compatible with the device and the vehicle’s exhaust system is critical for secure and reliable installation. The use of incorrect or low-quality hardware can result in loose connections, corrosion, and eventual failure. Compatible hardware ensures proper fitment, prevents damage to the device, and maintains the integrity of the exhaust system.

- Adherence to Manufacturer Specifications

Following the manufacturer’s installation guidelines is paramount for ensuring proper functionality and preventing damage to the device. Deviating from these specifications can void warranties and compromise the device’s performance. Adhering to the specified torque values, mounting procedures, and other recommendations ensures the device operates as intended and meets regulatory requirements.

These facets of installation quality are interconnected and collectively determine the effectiveness and durability of exhaust noise reduction devices in Fruitville. While the device itself plays a significant role, proper installation is equally important for realizing its full potential. Neglecting any of these aspects can undermine the benefits of the device and lead to adverse consequences for vehicle owners and the community.

5. Vehicle Performance

Vehicle performance, encompassing factors like fuel efficiency, horsepower, and engine responsiveness, is intrinsically linked to the exhaust system’s functionality, including the exhaust sound dampening device. Its design and condition can either enhance or hinder these performance aspects, directly impacting the vehicle’s overall operational capabilities.

- Exhaust Flow Restriction

An exhaust sound dampening device with excessive internal restriction impedes the free flow of exhaust gases. This restriction increases backpressure on the engine, reducing horsepower and fuel efficiency. For example, a severely clogged or poorly designed exhaust system, especially in older vehicles, can significantly diminish acceleration and fuel economy. Modern designs minimize backpressure while still achieving effective sound reduction.

- Engine Tuning and Calibration

The design of the exhaust sound dampening device can influence the engine’s tuning and calibration. Engine control units (ECUs) rely on feedback from exhaust gas sensors to optimize fuel injection and ignition timing. Alterations to the exhaust system, including the device, can affect these sensor readings, potentially requiring recalibration to maintain optimal performance. Replacing a factory-designed device with an aftermarket component can alter exhaust gas flow, necessitating ECU adjustments.

- Catalytic Converter Integration

The exhaust sound dampening device is often integrated with the catalytic converter, a critical component for emissions control. The catalytic converter’s performance relies on maintaining optimal exhaust gas temperatures and flow rates. A malfunctioning or improperly designed exhaust noise reduction component can negatively impact the catalytic converter’s efficiency, leading to increased emissions and reduced fuel economy. For instance, a leak upstream of the catalytic converter can alter exhaust gas composition, reducing its ability to convert pollutants.

- Weight and Aerodynamics

The weight and aerodynamic properties of the exhaust system, including the exhaust noise reduction device, can subtly influence vehicle performance. Excess weight can reduce acceleration and handling, while poor aerodynamic design can increase drag. Manufacturers strive to minimize weight and optimize the shape of these components to minimize their impact on overall vehicle performance. Aftermarket modifications, particularly those involving larger or heavier components, may compromise these design considerations.

These elements highlight how the exhaust sound dampening device is not merely a noise reduction component but an integral part of the vehicle’s overall performance ecosystem. Maintaining the device in good condition and selecting appropriate replacements or modifications are essential for preserving the vehicle’s intended performance characteristics.

6. Corrosion Resistance

Corrosion resistance is a critical attribute of exhaust sound dampening devices operating in Fruitville. The region’s climate, characterized by seasonal variations in temperature and humidity, coupled with the application of road salt during winter months, creates a highly corrosive environment for automotive components. The exhaust system, including the noise reduction device, is particularly vulnerable due to its exposure to both external environmental factors and internal corrosive exhaust gases. Lack of adequate corrosion resistance leads to premature failure of the device, resulting in increased noise pollution, higher maintenance costs, and potential regulatory non-compliance. For example, an exhaust device constructed of standard steel, when subjected to Fruitville’s winter conditions, will exhibit significant rust within a single season, potentially requiring replacement within two years.

The selection of materials with inherent corrosion resistance, such as stainless steel or aluminized steel, is therefore paramount. These materials form a protective oxide layer that inhibits further corrosion. Furthermore, protective coatings can enhance corrosion resistance, providing an additional barrier against environmental elements. Routine maintenance practices, such as washing the undercarriage of the vehicle to remove road salt, also contribute to extending the lifespan of the exhaust system. Ignoring these considerations can lead to consequential expenses and environmental repercussions.

In summary, corrosion resistance is indispensable for the effective and durable operation of exhaust sound dampening devices in Fruitville. Material selection, protective coatings, and diligent maintenance are key strategies for mitigating the effects of corrosion and ensuring long-term compliance with noise regulations. The economic and environmental implications of neglecting corrosion resistance warrant careful attention from vehicle owners and maintenance professionals alike.

7. Noise Pollution

Noise pollution, a pervasive environmental concern in urban and suburban areas like Fruitville, is directly influenced by the efficacy of vehicle exhaust systems. Inadequate or malfunctioning exhaust components significantly contribute to elevated noise levels, impacting community well-being and violating established noise ordinances.

- Increased Sound Levels

A compromised exhaust system lacking effective sound dampening mechanisms emits higher decibel levels, disrupting residential areas, schools, and other noise-sensitive locations. For example, a vehicle with a removed or damaged exhaust component generates excessive noise, exceeding permissible limits and causing disturbances. The magnitude of sound level increase is directly proportional to the degree of exhaust system degradation.

- Health and Psychological Effects

Prolonged exposure to elevated noise levels is associated with a range of adverse health effects, including stress, sleep disturbances, hearing impairment, and cardiovascular problems. In Fruitville, persistent noise pollution from vehicle traffic, exacerbated by defective exhaust systems, can contribute to these health issues among residents. The cumulative impact of constant noise exposure compromises quality of life and overall community health.

- Regulatory Non-Compliance

Many municipalities, including Fruitville, have enacted noise ordinances that establish maximum permissible noise levels for vehicles. Vehicles with substandard or modified exhaust systems often fail to meet these regulations, resulting in fines and mandatory repairs. Enforcement of these ordinances is essential for maintaining acceptable noise levels and protecting the community from excessive noise pollution. The failure to comply with noise regulations underscores the necessity of properly maintained exhaust systems.

- Economic Impacts

Noise pollution can indirectly impact property values and economic activity in affected areas. Prolonged exposure to high noise levels can make residential areas less desirable, potentially lowering property values. Additionally, excessive noise can disrupt commercial activities, hindering productivity and impacting business revenue. Addressing noise pollution through effective exhaust system maintenance contributes to preserving property values and fostering a more conducive business environment.

The interconnection between noise pollution and the proper functioning of vehicular exhaust components in Fruitville is evident. Effective exhaust sound dampening contributes significantly to mitigating noise pollution, protecting public health, and upholding regulatory standards. The ongoing maintenance and inspection of exhaust systems are therefore paramount for fostering a quieter and healthier community environment.

Frequently Asked Questions

The following section addresses common inquiries regarding exhaust sound dampening devices in the Fruitville area.

Question 1: What is the expected lifespan of an exhaust device in Fruitville?

The lifespan of an exhaust noise reduction device in Fruitville varies depending on factors such as material quality, driving conditions, and maintenance practices. Typically, a device constructed from aluminized steel may last between three to five years, while a stainless steel device can last seven years or more. Exposure to road salt and frequent short trips can shorten the lifespan.

Question 2: How does a defective exhaust component affect vehicle performance?

A defective device can impede exhaust flow, increasing backpressure on the engine. This increased backpressure can reduce horsepower, fuel efficiency, and overall engine responsiveness. Furthermore, leaks in the exhaust system can disrupt the engine’s oxygen sensor readings, leading to improper fuel-air mixture and further performance degradation.

Question 3: What are the legal requirements for exhaust noise levels in Fruitville?

Fruitville, like many municipalities, has noise ordinances that specify maximum permissible noise levels for vehicles. These ordinances are typically enforced through roadside inspections and noise level testing. Vehicles exceeding the specified noise limits are subject to fines and may be required to undergo repairs to achieve compliance.

Question 4: Can any type of device be installed on a vehicle?

No, not all devices are suitable for every vehicle. It is essential to select a device that is designed for the specific make and model of the vehicle to ensure proper fitment, performance, and regulatory compliance. Aftermarket devices must meet or exceed the performance standards of the original equipment manufacturer (OEM) components. Installation of incompatible devices can result in performance issues, increased noise levels, and potential damage to the exhaust system.

Question 5: What are the signs of a failing exhaust noise reduction component?

Common signs of a failing device include increased exhaust noise, rattling sounds emanating from the exhaust system, visible rust or corrosion, and reduced fuel efficiency. In some cases, a failing device can also trigger the check engine light on the vehicle’s dashboard.

Question 6: Is it possible to repair a damaged device, or does it need to be replaced?

The feasibility of repairing a damaged device depends on the extent and nature of the damage. Minor corrosion or small holes can sometimes be repaired through welding. However, extensive damage or internal component failure typically necessitates replacement. It is advisable to consult with a qualified mechanic to assess the damage and determine the most appropriate course of action.

The information presented here provides a concise overview of key considerations related to exhaust sound dampening devices in Fruitville. It is essential to consult with qualified professionals for specific vehicle maintenance and repair needs.

The following section will provide a conclusion, summarizing the key points covered in this article.

Fruitville Muffler

This exploration of “fruitville muffler” has underscored its crucial role in mitigating noise pollution, ensuring regulatory compliance, and influencing vehicle performance within Fruitville. The analysis encompassed material durability, installation quality, and the interconnectedness of exhaust system components. Considerations regarding lifespan, maintenance, and potential impacts on the community were also addressed.

Given the confluence of environmental regulations, vehicle performance demands, and community well-being, the responsible selection, installation, and maintenance of exhaust noise reduction systems remain paramount. The future necessitates continued advancements in material science and engineering to optimize performance and longevity, minimizing environmental impact and ensuring a quieter, healthier Fruitville. Prioritizing these aspects is not merely a matter of vehicle maintenance but a civic responsibility.