A specific type of automotive exhaust component, designed to enhance exhaust flow and, in some instances, alter the sound profile of a vehicle. Characterized by its internal baffling and construction, it aims to provide a less restrictive pathway for exhaust gases compared to some other designs. As an example, certain performance enthusiasts install these components seeking increased engine output and a more aggressive exhaust note.

These components are valued for their potential to improve engine efficiency by reducing backpressure. This reduction can lead to increased horsepower and torque, particularly in applications where the factory exhaust system is deemed restrictive. Historically, modifications of this nature have been a common practice in the automotive aftermarket, driven by a desire for improved performance and customization.

The following sections will delve into the construction, performance characteristics, installation considerations, and overall impact on vehicle performance associated with this type of exhaust modification.

Installation and Optimization Tips

The successful integration of a performance exhaust component requires careful consideration of several factors to ensure optimal performance and longevity.

Tip 1: Select the Appropriate Model: Ensure compatibility with the vehicle’s make, model, and engine configuration. Incorrect fitment can lead to performance issues and potential damage.

Tip 2: Professional Installation is Recommended: While DIY installation is possible, engaging a qualified technician is advised to guarantee proper installation, welding, and alignment, minimizing the risk of leaks or structural failures.

Tip 3: Check Local Regulations: Before installation, verify compliance with local noise ordinances and emissions regulations. Some modifications may be illegal in certain jurisdictions.

Tip 4: Use Quality Mounting Hardware: Replace worn or damaged exhaust hangers and clamps with high-quality replacements to prevent premature component failure and ensure a secure fit.

Tip 5: Inspect Welds and Connections: After installation, meticulously inspect all welds and connections for leaks. Even minor leaks can negatively impact performance and fuel efficiency.

Tip 6: Consider Engine Tuning: In some cases, installing this exhaust component may require adjustments to the engine’s computer to optimize performance and prevent potential issues like lean running conditions.

These guidelines aim to promote responsible and effective implementation, maximizing benefits while minimizing potential drawbacks. Proper research, installation, and maintenance are critical.

The following concluding section summarizes key considerations and long-term implications related to this modification.

1. Reduced Backpressure

Reduced backpressure is a key performance objective often sought through the installation of specific exhaust components. In the context of performance modification, backpressure, or the resistance to exhaust flow, significantly influences engine efficiency and overall power output. This section examines the relationship between reduced backpressure and particular muffler designs.

- Engine Performance Enhancement

Reduced backpressure promotes more efficient expulsion of exhaust gases from the engine cylinders. This allows for a more complete combustion cycle, leading to increased horsepower and torque, particularly at higher RPM ranges. This enhancement is most noticeable in forced induction applications.

- Exhaust Gas Velocity

The design promotes increased exhaust gas velocity, which helps to scavenge the cylinders more effectively during the exhaust stroke. Higher exhaust gas velocity can improve throttle response and overall engine responsiveness. The design is intended to maintain velocity while minimizing restriction.

- Fuel Efficiency Considerations

While primarily intended for performance enhancement, reduced backpressure can also contribute to improved fuel efficiency in some scenarios. More efficient exhaust flow reduces the engine’s workload, potentially resulting in better mileage, especially under consistent driving conditions. This benefit is often secondary to the performance gains.

- Compatibility and Tuning

Achieving optimal performance gains through reduced backpressure requires careful consideration of engine tuning. Modifications to the engine control unit (ECU) may be necessary to ensure the engine is running optimally with the new exhaust configuration. Failure to tune the engine appropriately can result in decreased performance or potential engine damage.

The design is often selected specifically to achieve the benefits outlined above. However, it is crucial to recognize that achieving the desired results requires careful planning, professional installation, and, potentially, engine tuning to ensure compatibility and optimal performance.

2. Enhanced Exhaust Flow

Enhanced exhaust flow is a primary characteristic associated with specific exhaust system components. The design of these components, particularly internal baffling and pathway configuration, directly influences the rate at which exhaust gases are expelled from the engine. This section details specific facets of enhanced exhaust flow in relation to this design.

- Reduced Restriction

The design aims to minimize obstructions within the exhaust system, thereby decreasing backpressure. Reduced restriction allows exhaust gases to exit the engine more efficiently. This is achieved through smoother bends and larger internal diameters compared to conventional muffler designs. Examples include straighter flow paths within the component that avoid sharp angles, directly contributing to a reduction in exhaust gas velocity reduction.

- Optimized Gas Scavenging

Improved exhaust flow promotes more effective scavenging of combustion byproducts from the engine cylinders. Efficient scavenging leads to a more complete combustion cycle in subsequent iterations, resulting in increased power output. The internal structure can be designed to create a slight vacuum effect, drawing out exhaust gases more rapidly, thereby optimizing engine efficiency. This effect is most pronounced at higher engine speeds.

- Temperature Management

Efficient exhaust flow aids in temperature management within the exhaust system. Rapid removal of hot exhaust gases prevents heat buildup, potentially extending the lifespan of exhaust components and reducing the risk of thermal damage to surrounding engine components. Lower temperatures within the exhaust system can also improve the efficiency of catalytic converters, contributing to reduced emissions. This is especially critical in turbocharger-equipped vehicles, where exhaust gas temperatures are significantly higher.

- Performance Enhancement in Forced Induction Engines

In turbocharged or supercharged engines, enhanced exhaust flow is particularly critical. Forced induction systems rely on the efficient expulsion of exhaust gases to maintain optimal boost pressure and prevent compressor surge. A well-designed system can significantly improve the responsiveness and overall power output of these engines. The reduced backpressure allows the turbocharger to spool up more quickly, resulting in improved acceleration and reduced turbo lag.

The aforementioned facets highlight the significance of enhanced exhaust flow. Performance gains, improved temperature management, and optimized engine efficiency are all interconnected aspects that contribute to the overall effectiveness of a performance exhaust modification. Real-world performance data demonstrates significant improvements, provided that the complete system is properly designed and optimized for the specific vehicle application.

3. Sound Alteration

Sound alteration represents a significant characteristic influenced by specific muffler designs. The design directly impacts the amplitude, frequency, and overall timbre of the exhaust note. This section elucidates the various ways in which this design contributes to modifications in sound characteristics.

- Frequency Modification

Internal baffling and chamber designs attenuate specific frequencies within the exhaust stream, resulting in a change in the perceived tone. These mufflers often reduce lower frequencies while amplifying mid-range or higher frequencies, creating a more aggressive or pronounced sound. Examples include chambered designs which cancel out specific wavelengths through destructive interference, altering the overall frequency profile. The implications extend to vehicle sound profiles, affecting both perceived performance and potential noise regulation compliance.

- Amplitude Modulation

The design also influences the overall volume, or amplitude, of the exhaust sound. Less restrictive designs tend to increase the overall sound level, while more complex baffling systems can reduce it. Examples involve straight-through designs offering minimal restriction, resulting in elevated decibel levels. The implications can include a more visceral auditory experience for the driver, potentially exceeding legal noise limits in certain localities.

- Resonance Tuning

Specific design features induce resonance within the exhaust system, which can alter the character of the sound. Careful tuning of resonance frequencies can create a more pleasing or desirable sound. Examples encompass specific chamber dimensions which induce constructive interference at predetermined frequencies, resulting in a deeper or more throaty sound. The implication is the ability to fine-tune the exhaust note for aesthetic or performance enhancement.

- Material Influence

The material used in the construction influences sound propagation. Materials such as stainless steel or titanium produce distinct tonal qualities compared to aluminized steel. Stainless steel often provides a brighter, more metallic sound, while aluminized steel results in a softer tone. Examples demonstrate that stainless steel resonates differently under excitation from exhaust pulses, creating a sharper sound compared to aluminized steel. The implications relate to the overall exhaust sound characteristics and durability, as different materials react uniquely under high temperatures and pressures.

These facets demonstrate that the design contributes directly to sound alterations in vehicles. Different design elements and material choices allow for customization of the exhaust sound, enhancing vehicle performance and aesthetics.

4. Performance Gains

Performance gains, specifically horsepower and torque increases, are a primary driver behind the adoption of components of this nature. The reduced backpressure and enhanced exhaust flow facilitate more efficient expulsion of exhaust gases from the engine cylinders. This efficient gas expulsion reduces the workload on the engine during the exhaust stroke, allowing for a more complete combustion cycle. Real-world examples include dyno testing results showing gains of 5-15 horsepower in naturally aspirated engines and more significant gains, often exceeding 20 horsepower, in turbocharged applications. The practical significance lies in improved acceleration, enhanced throttle response, and increased overall engine output. This improved efficiency translates to a more responsive and potentially more fuel-efficient vehicle, given similar driving conditions.

Further performance enhancements can be realized when combined with other engine modifications, such as cold air intakes, performance headers, and optimized engine tuning. In turbocharged engines, the reduction in backpressure can allow the turbocharger to spool up more quickly, leading to increased boost pressure and improved low-end torque. However, it is crucial to ensure that the engine is properly tuned to account for the changes in exhaust flow. Without proper tuning, the engine may run lean, leading to decreased performance and potentially engine damage. For example, vehicles running aftermarket systems often require an engine control unit (ECU) remap to optimize fuel delivery and ignition timing, ensuring peak performance and engine longevity. The implications of not tuning are significant, impacting both immediate performance and long-term reliability.

In summary, the connection between performance gains and exhaust modifications is clear. Reduced backpressure and enhanced flow directly contribute to improved engine efficiency and increased power output. While these gains are often modest in isolation, they can be amplified through complementary modifications and proper engine tuning. The understanding of these relationships is crucial for achieving the desired performance improvements while maintaining engine reliability and complying with local regulations.

5. Aftermarket Availability

The scope and diversity of aftermarket options for exhaust components directly influence a consumer’s ability to personalize or enhance vehicle performance. The subsequent details outline key facets of aftermarket availability in relation to these components.

- Wide Range of Manufacturers and Brands

The aftermarket presents a multitude of manufacturers and brands specializing in exhaust systems. This competition fosters innovation and offers consumers a diverse selection of components at various price points. For instance, numerous companies produce versions tailored to specific vehicle makes and models, each offering unique sound profiles and performance characteristics. The implications encompass enhanced consumer choice, potential for competitive pricing, and varied levels of product quality.

- Diverse Construction Materials and Designs

Aftermarket availability extends to various construction materials, including stainless steel, aluminized steel, and titanium, each offering distinct performance and durability characteristics. Furthermore, a broad spectrum of internal designs caters to different performance objectives and sound preferences. One example is the option for “straight-through” designs promoting maximum exhaust flow versus chambered designs that modulate sound. Implications include tailored customization for performance or aesthetics and varying degrees of resistance to corrosion and wear.

- Application-Specific Solutions

The aftermarket provides solutions tailored to specific vehicle applications, including direct-fit replacements and universal fit components. Direct-fit replacements simplify installation, while universal components offer greater flexibility for custom installations. One example is components designed specifically for turbocharged vehicles, featuring larger diameters and optimized flow paths to handle increased exhaust gas volume. This impacts installation complexity, potential performance gains, and adaptability to modified or custom vehicles.

- Online and Retail Distribution Channels

Accessibility is facilitated through extensive online and retail distribution networks. Consumers can easily research, compare, and purchase components from various sources, including online marketplaces, specialty retailers, and local automotive shops. Examples include the prevalence of online vendor information, as well as local performance shops specializing in exhaust system upgrades. The implications include ease of product access and information gathering, and expanded consumer knowledge.

The wide-ranging aftermarket availability significantly impacts the accessibility, affordability, and customization options. The diversity of manufacturers, materials, designs, and distribution channels empowers consumers to tailor their exhaust systems to meet specific performance, aesthetic, and budgetary requirements.

6. Installation Considerations

Proper installation is paramount for optimal performance and longevity. Incorrect installation can negate performance gains, create unsafe operating conditions, or damage related components. This is particularly relevant with performance exhaust modifications given the increased flow and temperature dynamics.

- Vehicle Compatibility

Prior to installation, verifying compatibility with the vehicle’s make, model, and engine configuration is crucial. Incorrect fitment can lead to leaks, structural stress, and reduced performance. An example includes different flange designs for varied engine types. The implications of ignoring vehicle compatibility are potentially severe, ranging from exhaust leaks to irreversible damage.

- Mounting and Alignment

Correct mounting and alignment of exhaust components are essential to prevent stress fractures and ensure proper exhaust flow. Misalignment can create points of excessive pressure, leading to premature failure. Using proper hardware and ensuring adequate clearance from surrounding components are essential. The implications of inadequate mounting include vibration-induced failures and heat transfer issues.

- Welding and Sealing

If welding is required, employing proper welding techniques and materials is critical for a robust and leak-free seal. Inadequate welding can lead to exhaust leaks, which degrade performance and increase noise levels. Professional welding is recommended. The implications of poor welding practices include compromised performance, potential sensor malfunctions, and increased emissions.

- Local Regulations Compliance

Confirming compliance with local noise and emissions regulations before installation is essential. Modifications that violate these regulations can result in fines or vehicle impoundment. Some municipalities have strict noise ordinances, and altering exhaust systems may exceed legal limits. The implications of non-compliance include legal penalties and potential difficulties with vehicle inspections.

The interplay of these factors determines the ultimate success of the installation. Addressing vehicle compatibility, ensuring proper mounting and alignment, employing sound welding practices, and verifying regulatory compliance contribute to the desired performance enhancement while minimizing potential complications. These factors also increase longevity and prevent unsafe operating conditions. Careful planning and execution are crucial for optimizing the performance of exhaust modifications.

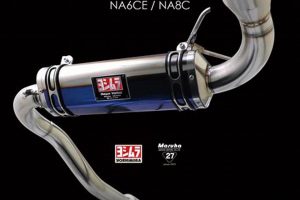

7. Construction Material

The selection of materials significantly influences performance characteristics, durability, and overall cost-effectiveness. This section details specific aspects of construction materials used in the components, highlighting their roles, examples, and implications.

- Stainless Steel

Stainless steel alloys are a prevalent choice due to their corrosion resistance and high-temperature strength. These materials withstand the corrosive effects of exhaust gases and road salts, extending component lifespan. An example includes 304 stainless steel, commonly used in performance applications. Implications encompass increased durability, reduced maintenance, and a premium price point.

- Aluminized Steel

Aluminized steel offers a cost-effective alternative, providing a degree of corrosion protection through an aluminum coating. While less resistant than stainless steel, it extends the lifespan compared to bare steel. An instance of utilization is on components designed for stock or moderate performance upgrades. Its implications are reduced cost with a corresponding decrease in corrosion resistance, leading to a shorter lifespan in harsh environments.

- Titanium

Titanium alloys offer the highest strength-to-weight ratio and exceptional corrosion resistance. Their use results in lightweight components that withstand extreme temperatures and pressures. Examples are seen in high-performance and racing applications, prioritizing weight reduction. The implication of using titanium involves significant weight savings, increased cost, and enhanced durability.

- Inconel

Inconel is a family of high-performance nickel-chromium-based superalloys. Inconel alloys are oxidation and corrosion resistant materials well suited for service in extreme environments subjected to pressure and heat. When exposed to heat, Inconel forms a thick, stable, passivating oxide layer that protects the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high temperature applications where aluminium and steel would succumb to creep as a result of thermally induced crystal vacancies. High temperature strength allows for thinning of the material for added weight savings. Applications include extreme motorsports and aerospace. The implication is significant weight savings and greatly improved durability when compared to even titanium, but at a very high price point.

The choice of construction material dictates the durability, weight, and cost. While stainless steel offers a balance of properties, specialized materials like titanium and Inconel cater to performance applications where weight savings are paramount. The selection process requires careful consideration of budgetary constraints, performance goals, and environmental conditions.

Frequently Asked Questions About Turbo Style Mufflers

This section addresses common inquiries regarding turbo style mufflers, providing objective information to aid in understanding their characteristics and applications.

Question 1: What defines a “turbo style muffler”?

This design typically features a less restrictive internal pathway compared to chambered mufflers, aiming to reduce backpressure and enhance exhaust flow. It does not inherently require a turbocharged engine for its operation.

Question 2: Will installing a turbo style muffler automatically increase horsepower?

While it can contribute to horsepower gains, the extent of the increase depends on the specific vehicle, engine configuration, and the existing exhaust system’s restrictions. Gains are typically more pronounced in turbocharged applications.

Question 3: Are these components universally compatible with all vehicles?

No, compatibility depends on specific vehicle make, model, and engine type. Selecting a component designed for the target vehicle is crucial to ensure proper fitment and optimal performance.

Question 4: Do turbo style mufflers invariably produce louder exhaust notes?

They often result in a louder or more aggressive exhaust sound, but the exact sound profile varies depending on the muffler’s internal design and materials. Some designs prioritize flow over sound attenuation.

Question 5: Are there any potential drawbacks to installing this type of muffler?

Potential drawbacks can include increased exhaust noise (which may violate local regulations), potential drone at certain RPMs, and the possibility of requiring engine tuning to optimize performance.

Question 6: What construction materials are commonly used in turbo style mufflers?

Common materials include stainless steel, aluminized steel, and titanium. Stainless steel offers a balance of durability and cost, while titanium provides the highest strength-to-weight ratio.

Key takeaways include that these components are intended to enhance exhaust flow, potentially increasing horsepower, but the results are variable and depend on multiple factors.

The following section will present a buyer’s guide outlining factors to consider when selecting a suitable component.

Conclusion

The preceding analysis has explored various aspects of the turbo style muffler, including its design characteristics, performance implications, aftermarket availability, and material considerations. This particular component presents a trade-off between exhaust flow enhancement and potential increases in noise levels. Performance gains are contingent upon appropriate selection, proper installation, and potentially, engine recalibration. Furthermore, compliance with local noise regulations should be verified prior to installation.

The implementation of a turbo style muffler requires a thorough understanding of the vehicle’s existing exhaust system and the intended application. Careful consideration of these factors will ultimately determine the success of this modification. Therefore, informed decision-making is paramount when selecting a component suitable for the individuals specific needs and objectives.

![Quietest Carlson Muffler: Performance & Reviews [Year] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Quietest Carlson Muffler: Performance & Reviews [Year] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/01/th-268-300x200.jpg)