An optimal exhaust silencing device significantly reduces noise generated by an internal combustion engine. These components are engineered to minimize sound levels while maintaining acceptable backpressure, ensuring efficient engine operation. As an example, a vehicle operating in a noise-sensitive urban environment benefits greatly from a well-designed exhaust silencing device.

The selection of a superior noise reduction component offers numerous advantages, including compliance with noise regulations, enhanced driver and passenger comfort, and reduced noise pollution. Historically, improvements in materials science and acoustic engineering have led to progressively more effective and durable designs. These advancements contribute to a quieter and more environmentally responsible transportation sector.

The following sections will delve into the crucial factors to consider when selecting an appropriate noise reduction component, explore various types available on the market, and discuss maintenance practices to ensure its long-term performance.

Selection and Maintenance Guidance for Superior Exhaust Silencing Devices

This section provides essential guidance for selecting and maintaining high-quality exhaust silencing devices to optimize vehicle performance and minimize noise pollution.

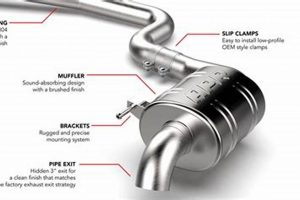

Tip 1: Material Selection: Consider stainless steel or aluminized steel construction for enhanced durability and resistance to corrosion, especially in regions with harsh road conditions. The materials properties directly influence the lifespan and performance of the component.

Tip 2: Internal Design Considerations: Opt for designs incorporating multiple chambers or resonance tuning to effectively attenuate a broad range of frequencies. Complex internal geometries contribute to superior noise reduction capabilities.

Tip 3: Backpressure Optimization: Ensure the selected device maintains acceptable backpressure levels to prevent engine performance degradation. Excessive backpressure can reduce horsepower and fuel efficiency.

Tip 4: Compliance with Regulations: Verify that the chosen component meets all applicable local and national noise regulations. Adherence to legal standards is paramount for legal operation.

Tip 5: Professional Installation: Engage a qualified mechanic for proper installation to ensure a secure and leak-free connection to the exhaust system. Incorrect installation can compromise noise reduction and introduce safety hazards.

Tip 6: Regular Inspection: Conduct periodic visual inspections for signs of damage, corrosion, or leaks. Early detection of issues can prevent costly repairs and maintain optimal performance.

Tip 7: Prompt Repairs: Address any identified problems, such as leaks or damaged components, immediately to prevent further deterioration and maintain noise reduction effectiveness. Neglecting repairs can lead to escalating issues.

Selecting a durable and well-maintained exhaust silencing device offers significant benefits, including reduced noise pollution, enhanced vehicle longevity, and compliance with regulatory requirements.

The subsequent sections will explore specific product recommendations and address frequently asked questions related to exhaust silencing device technology.

1. Noise reduction efficiency

Noise reduction efficiency is a primary determinant of a superior exhaust silencing device. Its fundamental role is to mitigate the acoustic energy generated by the combustion process within an internal combustion engine. Higher efficiency translates directly into a quieter operating environment, contributing to reduced noise pollution. The effectiveness of the device in attenuating sound pressure levels is quantified in decibels (dB); a substantial decrease in dB corresponds to a significant improvement in noise reduction efficiency. The internal construction, including the number and configuration of baffles, resonators, and sound-absorbing materials, dictates this efficiency. For example, a device utilizing Helmholtz resonators can effectively target and neutralize specific frequencies, thereby maximizing noise reduction.

An effective exhaust silencing device with high noise reduction efficiency offers tangible benefits. Vehicles equipped with these components are more likely to meet increasingly stringent noise regulations imposed by governmental agencies. Furthermore, reduced noise levels enhance the comfort of vehicle occupants and minimize disturbance to surrounding communities. Consider a commercial delivery vehicle operating in a densely populated residential area; a component with superior noise reduction capabilities minimizes the impact of its operations on the local residents. The choice of materials, such as fiberglass packing or stainless steel, also plays a role. Materials with higher density and sound-absorbing properties contribute to better overall noise reduction performance. The physical dimensions and geometry of the device are further design parameters influencing noise abatement.

In summary, noise reduction efficiency is an indispensable attribute of a superior exhaust silencing device. It not only dictates the level of noise attenuation but also significantly impacts regulatory compliance, environmental responsibility, and overall user experience. The design considerations, including internal construction and material selection, directly influence the performance characteristics. Understanding the principles governing noise reduction is crucial for selecting a component that balances noise abatement with engine performance and durability. Ongoing research and development in acoustic engineering continue to refine the technology and enhance the noise reduction capabilities of these essential automotive components.

2. Material durability

Material durability is a critical attribute dictating the overall lifespan and performance of an exhaust silencing device. The exhaust system endures substantial thermal stress, exposure to corrosive elements such as road salts and acids, and mechanical vibrations. Therefore, the selection of robust materials is paramount in ensuring the long-term functionality and reliability of the device. A compromise in material durability invariably leads to premature degradation, necessitating frequent replacements and incurring higher operational costs. The “best muffler” is characterized, in part, by its ability to withstand these harsh operating conditions without succumbing to corrosion, cracking, or structural failure.

For instance, stainless steel, particularly grades like 304 or 409, is often preferred for its superior resistance to corrosion. Consider a vehicle operating in regions with severe winter conditions where de-icing salts are liberally applied to roadways. An exhaust silencing device constructed from lower-grade steel or a material lacking adequate corrosion protection would be highly susceptible to rust and eventual structural compromise. In contrast, a stainless-steel component would exhibit significantly enhanced longevity under the same conditions. Aluminized steel presents a more economical alternative, offering a degree of corrosion resistance through an aluminum coating. However, its lifespan is generally shorter compared to stainless steel, especially in highly corrosive environments. The gauge, or thickness, of the material used also plays a pivotal role. Thicker materials exhibit greater resistance to mechanical damage and vibrational fatigue.

In summary, material durability directly influences the lifespan, performance, and overall value proposition of an exhaust silencing device. Choosing materials with inherent resistance to corrosion, thermal stress, and mechanical wear is crucial for minimizing maintenance costs and ensuring continued regulatory compliance. Neglecting material durability considerations ultimately leads to premature component failure and potentially compromises vehicle performance and safety. Therefore, material selection forms a cornerstone in the identification of a superior exhaust silencing device.

3. Backpressure optimization

Backpressure optimization constitutes a critical engineering parameter in the design and selection of an effective exhaust silencing device. Exhaust backpressure refers to the resistance encountered by exhaust gases as they flow through the exhaust system. Excessive backpressure impedes the efficient expulsion of exhaust gases from the engine cylinders, resulting in reduced engine power, decreased fuel efficiency, and elevated operating temperatures. Conversely, insufficient backpressure, while seemingly beneficial, can disrupt the scavenging process, leading to incomplete combustion and increased emissions. The optimal exhaust silencing device, therefore, strikes a delicate balance, minimizing backpressure while simultaneously achieving effective noise attenuation.

An illustrative example is found in performance-oriented vehicles. Aftermarket exhaust systems designed to enhance horsepower often incorporate silencing devices that prioritize flow over sound suppression. While these systems may yield demonstrable power gains, they sometimes fail to adequately control noise levels, potentially violating local regulations. A carefully engineered exhaust silencing device, designed with backpressure optimization as a primary objective, will maintain a balance. This will deliver a meaningful reduction in noise without significant power loss. This can be achieved through strategic design of the internal passages and use of materials that offer minimal resistance to gas flow. Another example lies in turbocharged vehicles, where maintaining optimal backpressure is particularly critical. Excessive backpressure can negatively impact turbocharger performance and lifespan, while insufficient backpressure can reduce boost response. Therefore, in these applications, the exhaust silencing device must be meticulously designed to complement the turbocharger’s characteristics.

In conclusion, backpressure optimization is an indispensable consideration in the pursuit of an optimal exhaust silencing solution. The selected device should not merely suppress noise; it must do so without compromising engine performance or increasing emissions. Understanding the interplay between backpressure, engine characteristics, and regulatory requirements is essential for making informed decisions regarding exhaust system components. The challenge lies in achieving a design that harmonizes noise reduction with efficient exhaust gas flow, ensuring that the device functions effectively as an integral component of the engine’s overall performance envelope.

4. Corrosion resistance

Corrosion resistance is a paramount attribute contributing to the classification of an exhaust silencing device as optimal. The undercarriage of a vehicle, where this component resides, is subjected to a continuous barrage of corrosive agents, including road salts used for de-icing, moisture, and chemical contaminants. Absent adequate corrosion resistance, the exhaust silencing device will degrade prematurely, compromising its structural integrity and acoustic performance. The cause-and-effect relationship is direct: exposure to corrosive elements results in material degradation, which, in turn, leads to increased noise output and potential exhaust leaks. The “best muffler” fundamentally withstands these assaults, maintaining its functionality over an extended lifespan.

The importance of corrosion resistance extends beyond mere longevity. A corroded exhaust silencing device can develop leaks, releasing harmful exhaust gases into the environment and potentially posing a health hazard to vehicle occupants. Moreover, corrosion weakens the structural components, increasing the risk of catastrophic failure while driving. For example, a vehicle operating in coastal regions, exposed to saltwater spray and high humidity, requires an exhaust silencing device with exceptional corrosion resistance. Materials like stainless steel, specifically grades 304 and 316, offer superior protection compared to aluminized steel or standard carbon steel. The selection of appropriate joining methods, such as welding with corrosion-resistant alloys, further enhances the overall durability of the assembly.

In summation, corrosion resistance is not merely a desirable feature but a fundamental necessity for a high-quality exhaust silencing device. The capacity to withstand the rigors of the undercarriage environment dictates the device’s lifespan, performance, and safety. Understanding the mechanisms of corrosion and selecting materials and manufacturing processes that mitigate its effects are crucial for ensuring the long-term reliability and environmental responsibility of the exhaust system. Consequently, corrosion resistance stands as a key determinant in identifying an optimal exhaust silencing device.

5. Installation compatibility

Installation compatibility is a fundamental characteristic influencing the assessment of an exhaust silencing device. An optimal device inherently possesses ease of integration with the target vehicle’s exhaust system, minimizing the need for extensive modifications or custom fabrication. A direct-fit replacement minimizes labor costs and potential complications associated with improper installation, safeguarding the vehicle’s performance and compliance. Compatibility challenges can arise when dimensions, hanger locations, or inlet/outlet configurations deviate from the vehicle’s original specifications.

For example, consider a scenario where a replacement exhaust silencing device, despite exhibiting excellent noise reduction characteristics, necessitates significant cutting, welding, or bracket relocation for proper fitment. This increases installation time and introduces potential points of failure. An improper weld or misaligned hanger can compromise the exhaust system’s integrity, leading to leaks, vibrations, and premature component wear. In contrast, a device designed as a direct replacement, conforming precisely to the vehicle’s factory specifications, ensures a seamless installation process. Installation compatibility, therefore, directly influences the overall cost-effectiveness and long-term reliability of the exhaust system.

In summation, installation compatibility transcends mere convenience; it embodies a crucial aspect of system integrity and maintainability. An optimal exhaust silencing device, in addition to superior noise reduction and durability, demonstrably minimizes installation complexities. This ensures both proper functionality and cost-effectiveness over the vehicle’s lifespan. Consequently, installation compatibility forms an essential criterion in evaluating the merits of a proposed exhaust silencing solution, linking directly to its real-world practicality and suitability.

6. Longevity

Longevity is an indispensable characteristic of a superior exhaust silencing device, directly influencing its lifecycle cost and overall value proposition. The primary function of such a device is noise reduction; however, its ability to perform this function consistently over an extended period dictates its true effectiveness. A component exhibiting exceptional noise attenuation upon initial installation, but failing prematurely due to material degradation or structural compromise, is demonstrably not optimal. Longevity ensures that the initial investment yields a sustained return, minimizing the frequency and expense of replacements. The factors contributing to longevity are multifaceted, encompassing material selection, design robustness, and resistance to environmental stressors.

Consider a fleet of commercial vehicles operating under demanding conditions. The replacement of exhaust silencing devices represents a significant maintenance expense. A device characterized by enhanced longevity demonstrably reduces downtime, labor costs, and the cumulative expense of parts. Conversely, a less durable device necessitates more frequent replacements, disrupting operational schedules and increasing the total cost of ownership. Real-world examples abound: stainless steel exhaust silencing devices routinely outlast those constructed from lower-grade materials, justifying their higher initial cost through extended service life. Furthermore, design features that mitigate stress concentrations and vibrational fatigue contribute significantly to longevity. Proper installation and adherence to recommended maintenance practices further augment the lifespan of the component.

In conclusion, longevity is not merely a desirable feature; it is a fundamental attribute that defines a high-quality exhaust silencing device. It directly impacts operational costs, reduces environmental impact by minimizing replacement frequency, and ensures sustained compliance with noise regulations. Ignoring longevity in the selection process ultimately leads to increased expenses and potential compromises in performance and reliability. Therefore, longevity should be a primary consideration in the identification of an optimal exhaust silencing solution.

7. Regulatory compliance

Regulatory compliance is inextricably linked to the determination of an optimal exhaust silencing device. Noise regulations, enacted at local, state, and federal levels, establish permissible noise limits for vehicles operating within specified jurisdictions. A device failing to meet these mandated standards, irrespective of its other attributes, cannot be classified as optimal. The connection is causal: an exhaust silencing device’s ability to effectively attenuate engine noise directly influences its capacity to comply with prevailing regulations. Failure to comply can result in fines, operational restrictions, or the vehicle’s removal from service. The “best muffler,” therefore, inherently integrates regulatory compliance as a core performance criterion.

Consider the example of commercial trucking companies operating in urban environments. These vehicles are subject to stringent noise ordinances designed to minimize disturbance to residential areas. A fleet employing exhaust silencing devices that exceed established noise limits faces the prospect of substantial financial penalties and potential limitations on their operating hours. Conversely, a company that invests in exhaust silencing devices certified to meet or exceed applicable standards gains a competitive advantage, ensuring regulatory adherence and operational flexibility. Moreover, manufacturers of exhaust silencing devices must adhere to specific design and performance standards to obtain certification for sale and use in regulated markets. These certifications, such as those issued by environmental protection agencies, provide assurance that the device meets predetermined noise reduction criteria.

In conclusion, regulatory compliance constitutes a non-negotiable attribute of an optimal exhaust silencing device. It is not merely an ancillary consideration but an integral component of its overall performance profile. Manufacturers and operators must prioritize compliance with applicable noise regulations to avoid legal repercussions, maintain operational efficiency, and contribute to a quieter, more environmentally responsible transportation sector. Ignoring regulatory requirements can expose operators to financial risk, damage their reputation, and undermine their commitment to sustainable practices. Therefore, regulatory compliance must be a central tenet in the selection and deployment of exhaust silencing technology.

Frequently Asked Questions Regarding Exhaust Silencing Devices

This section addresses common inquiries and misconceptions surrounding exhaust silencing devices, providing clarity on their functionality, selection, and maintenance.

Question 1: What are the primary factors influencing the performance of an exhaust silencing device?

The performance of an exhaust silencing device is primarily influenced by its internal design, the materials used in its construction, and its proper installation. Internal designs incorporating multiple chambers or tuned resonators generally offer superior noise reduction. Durable materials, such as stainless steel, ensure longevity. Accurate installation prevents leaks and maintains optimal performance.

Question 2: How does the selection of an exhaust silencing device impact fuel efficiency?

An improperly selected exhaust silencing device can negatively impact fuel efficiency by creating excessive backpressure. A device designed to minimize backpressure while effectively attenuating noise is essential for maintaining optimal fuel economy.

Question 3: What are the consequences of operating a vehicle with a damaged or corroded exhaust silencing device?

Operating a vehicle with a damaged or corroded exhaust silencing device can lead to increased noise pollution, reduced engine performance, and potential exposure to harmful exhaust gases. Additionally, it may result in non-compliance with noise regulations and associated penalties.

Question 4: How frequently should an exhaust silencing device be inspected and potentially replaced?

Exhaust silencing devices should be inspected at regular intervals, typically during routine vehicle maintenance. Replacement frequency varies depending on operating conditions and material quality. However, signs of corrosion, damage, or excessive noise output indicate the need for immediate replacement.

Question 5: Does the brand of an exhaust silencing device significantly impact its performance and durability?

The brand of an exhaust silencing device can be indicative of its quality and engineering standards. Reputable manufacturers often invest in research and development to optimize performance and durability. However, evaluating specific product specifications and customer reviews remains crucial, irrespective of brand recognition.

Question 6: Are there specific types of exhaust silencing devices best suited for particular vehicle types or driving conditions?

Certain exhaust silencing devices are engineered to complement specific vehicle types or driving conditions. For instance, performance vehicles may benefit from devices designed to maximize exhaust flow, while vehicles operating in noise-sensitive environments require devices with superior noise reduction capabilities. Selecting a device tailored to the vehicle’s intended use is paramount.

The selection and maintenance of an exhaust silencing device require careful consideration of various factors to ensure optimal performance, longevity, and regulatory compliance.

The subsequent section will provide a comparative analysis of different exhaust silencing device technologies.

Conclusion

The preceding analysis delineates the critical attributes that define the “best muffler.” These encompass noise reduction efficiency, material durability, backpressure optimization, corrosion resistance, installation compatibility, longevity, and regulatory compliance. The selection of a component exhibiting excellence across these parameters ensures optimal vehicle performance, environmental responsibility, and adherence to legal mandates.

The informed application of these principles will guide consumers and professionals toward responsible decision-making in the selection and maintenance of exhaust silencing devices. Prioritizing these factors contributes to a transportation ecosystem characterized by reduced noise pollution and sustained operational efficiency. Continuous evaluation and refinement of exhaust silencing technologies remain essential for addressing evolving regulatory standards and societal expectations.