A crucial component of the exhaust system for a specific model year of a popular pickup truck, this part is responsible for dampening engine noise. It operates by using internal chambers and baffles to reduce the amplitude of sound waves generated by the engine’s combustion process. This component is typically located along the exhaust pipe, downstream from the catalytic converter and upstream of the tailpipe. An example would be replacing a rusted-out or damaged unit on the vehicle.

This device plays a significant role in maintaining acceptable noise levels, both for the vehicle’s occupants and the surrounding environment. Its functionality impacts vehicle compliance with noise regulations and contributes to driver and passenger comfort. Historically, the design and materials used in these devices have evolved, reflecting advancements in materials science and noise reduction technology. This evolution has led to increased durability, improved performance, and reduced weight.

Understanding the specifications, potential replacement options, common issues, and proper installation procedures associated with this component is essential for vehicle maintenance and repair. The subsequent sections will delve into these aspects in greater detail, providing a comprehensive overview.

Essential Maintenance Tips

The following guidelines offer essential information for ensuring the longevity and optimal performance of the vehicle’s exhaust noise reduction system.

Tip 1: Routine Visual Inspection: Periodically examine the exterior of the unit for signs of rust, corrosion, or physical damage. Early detection of these issues can prevent more significant problems and costly repairs. For example, a small rust spot can be treated before it compromises the structural integrity of the component.

Tip 2: Check for Exhaust Leaks: Listen for unusual hissing or roaring sounds emanating from underneath the vehicle. These noises often indicate an exhaust leak, which can reduce engine performance and fuel efficiency. A leak near the unit itself often requires immediate attention.

Tip 3: Ensure Proper Mounting: Inspect the mounting hardware, including hangers and brackets, for looseness or damage. Secure mounting is critical for preventing excessive vibration and stress on the unit, which can lead to premature failure. Check for worn rubber isolators, as these dampen vibration.

Tip 4: Address Unusual Noises Promptly: Investigate any rattling or clanging sounds coming from the exhaust system. These noises can indicate internal damage to the unit or loose components within the exhaust system. A rattling sound could be a sign of a detached baffle inside the component.

Tip 5: Consider Material Upgrades: When replacing the original equipment part, explore options made from stainless steel or aluminized steel for increased resistance to corrosion and extended service life. This provides greater durability, especially in regions with harsh winter conditions.

Tip 6: Proper Installation Techniques: Ensure all connections are properly sealed during installation to prevent exhaust leaks. Utilize new gaskets and hardware to ensure a tight and secure fit. Verify that the component is correctly aligned and supported to avoid undue stress on the exhaust system.

Tip 7: Catalytic Converter Health: The life expectancy of this component depends on the health of other related components. The condition of the catalytic converter can affect back pressure, and thus the overall exhaust system. Be sure that your vehicles catalytic converter is operating as designed.

Adhering to these tips will contribute to a quieter, more efficient, and longer-lasting exhaust system.

The subsequent section will provide information about selecting the appropriate replacement, should the original part require replacement.

1. OEM specifications

Original Equipment Manufacturer (OEM) specifications for the specified model year and vehicle exhaust component are fundamental to ensuring proper fit, performance, and regulatory compliance. These specifications define the precise dimensions, materials, internal design, and performance parameters established by the vehicle manufacturer during the original design and production of the vehicle. Deviations from these specifications can result in reduced engine performance, increased noise levels, or failure to meet emissions standards.

For instance, the internal baffling configuration, a key element of OEM specifications, directly impacts the frequency and amplitude of sound waves produced by the engine. An incorrect baffle design, resulting from a non-OEM component, can lead to an undesirable exhaust note or excessive noise. Furthermore, the diameter and length of the inlet and outlet pipes are critical for maintaining proper backpressure, which influences engine efficiency and power output. Aftermarket components that do not adhere to OEM dimensions may create backpressure issues, potentially affecting fuel economy and overall engine performance. This may also lead to a failed inspection.

Understanding and adhering to OEM specifications is critical for ensuring that a replacement component functions as intended and maintains the vehicle’s original performance characteristics. Using components that do not conform to these specifications may lead to unforeseen issues and compromise the vehicle’s overall reliability and compliance. Therefore, proper research and selection based on reliable sources of OEM specification data are paramount when replacing this specific vehicle component.

2. Material composition

Material composition is a determining factor in the lifespan, performance, and cost of the 2004 Ford F150 exhaust noise reduction device. The materials employed directly affect its ability to withstand extreme temperatures, corrosive elements, and physical stresses encountered during operation. The selection of appropriate materials balances durability requirements with cost considerations.

- Mild Steel Construction

Many original equipment and aftermarket options utilize mild steel due to its relatively low cost and ease of fabrication. However, mild steel is susceptible to corrosion, especially in environments with road salt. This corrosion can lead to premature failure, necessitating replacement. The use of protective coatings can extend the lifespan, but ultimately, mild steel units have a shorter service life compared to those constructed from more durable materials.

- Aluminized Steel Construction

Aluminized steel offers enhanced corrosion resistance compared to mild steel. A thin layer of aluminum alloy is applied to the steel surface, providing a barrier against oxidation. This material is commonly used in aftermarket components as a compromise between cost and durability. While offering improved resistance, it’s still susceptible to corrosion in harsh environments, albeit at a slower rate than mild steel.

- Stainless Steel Construction

Stainless steel provides the highest level of corrosion resistance. Its chromium content forms a passive layer that protects the underlying steel from oxidation, even when scratched. Stainless steel units represent a more significant upfront investment but offer a substantially longer lifespan, making them a cost-effective choice in the long term, particularly in regions with aggressive road salt usage.

- Internal Component Materials

The materials used in the internal baffling system are also vital. While the outer casing may be resistant to corrosion, the internal baffles are subjected to rapid heating and cooling cycles, leading to thermal fatigue. Often, internal components are made from a different grade of steel than the outer casing due to design considerations. The properties of the internal components will also have an effect on the acoustic properties of the exhaust noise reduction device.

The selection of an appropriate material for this particular F150 model year unit hinges on budgetary constraints, environmental conditions, and the desired lifespan of the component. While cost-effective options exist, investing in more durable materials like stainless steel provides long-term benefits by reducing the frequency of replacements and ensuring reliable performance over an extended period. Ultimately, it’s a balance between immediate savings and total cost of ownership.

3. Noise Reduction

The capacity to attenuate exhaust noise is a primary function of the 2004 Ford F150’s exhaust noise reduction device. The effectiveness of this component in mitigating engine noise is a critical factor influencing both driver comfort and compliance with noise regulations. Internal design and material properties determine the level of sound attenuation achieved.

- Internal Baffling Design

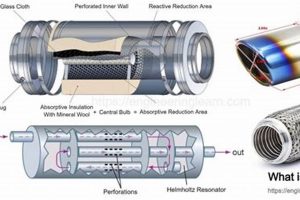

The internal structure, typically consisting of chambers and baffles, is engineered to disrupt and redirect sound waves. These baffles create destructive interference, reducing the amplitude of specific frequencies produced by the engine. The number, shape, and arrangement of baffles directly correlate with the degree of noise reduction. A more complex baffling system generally yields greater noise attenuation but may also increase backpressure.

- Acoustic Absorption Materials

Some designs incorporate sound-absorbing materials, such as fiberglass or specialized packing, to further dampen noise. These materials convert sound energy into heat through friction, reducing the intensity of the sound waves as they pass through the component. The effectiveness of these materials diminishes over time as they degrade due to exposure to high temperatures and exhaust gases.

- Resonator Integration

Resonators are sometimes integrated into the exhaust system, often upstream of the exhaust noise reduction device, to target and eliminate specific frequencies that contribute to unwanted noise or drone. These resonators are designed to create a Helmholtz resonance effect, canceling out targeted frequencies through destructive interference. The effectiveness of a resonator is highly dependent on its precise tuning to the engine’s acoustic profile.

- Shell Construction and Thickness

The thickness and rigidity of the outer shell also contribute to noise reduction. A thicker shell helps to contain sound vibrations and prevent them from radiating outwards. The material used in the shell construction also influences its ability to dampen sound. For example, some aftermarket units utilize double-walled construction for enhanced noise attenuation.

The level of noise reduction achieved by the 2004 Ford F150’s exhaust component is a multifaceted outcome of its internal design, materials, and integration within the broader exhaust system. Optimizing noise reduction requires careful consideration of these factors to strike a balance between minimizing exhaust noise and maintaining engine performance.

4. Exhaust Flow

Exhaust flow, the movement of combusted gases from the engine through the exhaust system, is intrinsically linked to the function and performance of the 2004 Ford F150 exhaust noise reduction device. Restriction within the unit, whether due to design or internal obstruction, directly impacts engine efficiency and power output. Excessive backpressure caused by a poorly designed or clogged unit impedes the evacuation of exhaust gases, leading to reduced volumetric efficiency, increased pumping losses, and diminished horsepower. Conversely, optimizing exhaust flow contributes to improved engine breathing, enhanced combustion, and increased overall performance.

The internal configuration of the exhaust noise reduction device profoundly influences exhaust flow dynamics. Baffles and internal chambers, while crucial for sound attenuation, also introduce resistance to the flow of exhaust gases. The challenge lies in designing a system that effectively reduces noise without significantly hindering exhaust flow. Real-world examples illustrate this trade-off: performance-oriented aftermarket units often prioritize exhaust flow over noise reduction, resulting in louder but more powerful vehicles. Conversely, OEM replacements typically emphasize noise reduction, potentially sacrificing some performance to maintain acceptable sound levels. Clogging, often due to corrosion or debris accumulation, represents a common cause of restricted flow, negatively affecting fuel economy and engine responsiveness.

Understanding the relationship between exhaust flow and the 2004 Ford F150 exhaust noise reduction device is of practical significance for maintenance and performance enhancement. Diagnosing exhaust restrictions through backpressure testing allows technicians to identify potential problems within the unit. Selecting replacement components that balance noise reduction and flow optimization is essential for maintaining vehicle performance and efficiency. Regular inspection and maintenance help prevent obstructions, ensuring optimal engine operation and prolonging the lifespan of the exhaust system. The connection between this device and Exhaust flow is a relationship that must be considered during any exhaust repair.

5. Corrosion resistance

Corrosion resistance is a critical attribute of the 2004 Ford F150 exhaust noise reduction device, directly influencing its longevity and operational effectiveness. The device is constantly exposed to harsh environmental conditions, including road salt, moisture, and extreme temperature fluctuations. These factors accelerate the corrosion process, potentially leading to structural failure and reduced performance. A direct consequence of compromised corrosion resistance is the development of rust, which weakens the metal and can ultimately result in exhaust leaks, increased noise levels, and the need for premature replacement. Without adequate protection, the device’s service life is significantly diminished, increasing maintenance costs and vehicle downtime. For example, a unit constructed from non-corrosion-resistant materials in a region with heavy winter salting may only last a few years before requiring replacement.

The choice of materials and manufacturing processes directly impacts the corrosion resistance of the exhaust component. As previously mentioned, mild steel, while cost-effective, offers limited protection against corrosion. Aluminized steel provides improved resistance but remains susceptible to rust over time. Stainless steel offers superior corrosion resistance due to its inherent chromium content, making it a more durable and long-lasting option, particularly in environments with high salt exposure. Protective coatings, such as ceramic-based paints, can also enhance corrosion resistance, providing an additional barrier against the elements. These coatings are often applied to aftermarket units to extend their lifespan. Proper installation techniques, such as avoiding damage to protective coatings and ensuring secure connections, further contribute to minimizing corrosion risks.

Understanding the relationship between corrosion resistance and the 2004 Ford F150 exhaust component is essential for informed decision-making regarding maintenance and replacement. Selecting units constructed from corrosion-resistant materials, implementing preventative measures such as regular washing to remove road salt, and addressing minor rust issues promptly can significantly extend the lifespan of the component, reducing long-term maintenance costs and ensuring continued compliance with noise regulations.

6. Installation compatibility

Installation compatibility is a critical factor when replacing the exhaust noise reduction device on the 2004 Ford F150. Direct-fit replacement units are designed to match the original equipment manufacturer (OEM) specifications, ensuring seamless integration with the existing exhaust system. Conversely, universal or non-compatible units may require modifications, potentially compromising structural integrity, exhaust flow, and noise reduction effectiveness. Careful attention to installation compatibility minimizes complications during the replacement process and ensures optimal performance.

- Dimensional Accuracy

Dimensional accuracy refers to the precise measurements of the replacement unit, including its overall length, diameter, and the positioning of inlet and outlet pipes. Deviations from OEM specifications can lead to misalignment with existing exhaust components, requiring cutting, welding, or adapter modifications. Incorrect dimensions may also cause the unit to contact other vehicle components, resulting in vibration, noise, and potential damage. A direct-fit replacement ensures proper alignment and minimizes the need for adjustments.

- Mounting Point Conformity

Mounting point conformity involves the precise location and design of the hangers and brackets used to secure the unit to the vehicle’s chassis. Mismatched mounting points necessitate fabrication of custom brackets or modification of existing ones, increasing installation time and complexity. Incorrect mounting can also place undue stress on the unit and the exhaust system, leading to premature failure. A compatible replacement utilizes the factory mounting points, ensuring secure and stable installation.

- Connection Type and Size

Connection type and size refer to the method and dimensions used to join the unit to the exhaust pipes. Flanged connections, slip-fit connections, and welded connections are common. Mismatched connection types or sizes require adapters or welding, potentially creating exhaust leaks and reducing performance. A compatible replacement utilizes the same connection type and size as the original unit, ensuring a tight and leak-free seal.

- Emissions System Integration

In some cases, the exhaust noise reduction device may be integrated with other emissions control components, such as oxygen sensors or catalytic converters. A compatible replacement must accommodate these components without interfering with their function. Incorrect integration can lead to emissions system malfunctions and failure to meet regulatory requirements. Proper consideration of emissions system integration ensures continued compliance with environmental standards.

The described facets of installation compatibility collectively emphasize its significance in ensuring a straightforward and effective replacement of the exhaust noise reduction device on the 2004 Ford F150. Prioritizing direct-fit replacements that adhere to OEM specifications minimizes installation challenges, promotes optimal performance, and maintains the vehicle’s structural integrity and emissions compliance.

7. Aftermarket options

The aftermarket for the 2004 Ford F150 exhaust component presents a diverse range of options, driven by variations in performance goals, sound preferences, and budgetary considerations. These alternatives extend beyond direct OEM replacements, offering choices that can alter exhaust flow, noise levels, and even the vehicle’s aesthetic. The prevalence of aftermarket choices stems from a desire to customize the vehicle’s performance or address common issues with the original equipment, such as corrosion or restrictive exhaust flow. For instance, individuals seeking improved horsepower may opt for a performance unit designed to reduce backpressure, while others prioritize a louder or deeper exhaust note. These choices have a direct effect on the vehicles overall driving experience and potentially its long-term reliability.

The impact of selecting an aftermarket option can range from subtle alterations to significant modifications. Certain aftermarket units are designed as “cat-back” systems, replacing the entire exhaust system from the catalytic converter rearward, leading to notable gains in horsepower and torque, accompanied by a more aggressive exhaust sound. Conversely, less extensive changes might involve simply swapping out the original equipment noise reduction device with an aftermarket version constructed from stainless steel for enhanced durability, while maintaining a similar sound profile. Real-world examples include individuals installing performance units to enhance off-road capabilities or others choosing quieter, more fuel-efficient units for daily commuting. Choosing an inappropriate aftermarket component can result in decreased performance, increased fuel consumption, or failure to comply with local noise regulations, highlighting the importance of careful selection and research.

In conclusion, the availability of aftermarket options for the 2004 Ford F150 exhaust component provides opportunities for customization and performance enhancement, but demands careful consideration. Balancing performance aspirations with noise regulations, budgetary constraints, and potential impacts on vehicle reliability is crucial. While aftermarket alternatives offer a path to optimize or personalize the vehicle, understanding their technical specifications and potential consequences is essential for making informed decisions and avoiding unintended drawbacks. Ultimately, these options create a complex landscape where knowledge and careful planning are paramount to a successful upgrade.

Frequently Asked Questions

This section addresses common inquiries and concerns regarding the exhaust noise reduction device specific to the 2004 Ford F150. The following questions and answers aim to provide clarity and guidance on its function, maintenance, and replacement.

Question 1: What is the expected lifespan of the OEM unit on a 2004 Ford F150?

The lifespan varies significantly depending on environmental conditions and driving habits. In regions with heavy road salt usage, a unit constructed from mild steel may only last 3-5 years. Stainless steel units can last 10 years or more under similar conditions.

Question 2: How does a damaged unit affect engine performance?

A damaged or corroded unit can create exhaust leaks, reducing backpressure and potentially decreasing engine efficiency and power output. Restrictions within a failing unit can also impede exhaust flow, leading to further performance degradation.

Question 3: What are the symptoms of a failing exhaust noise reduction device?

Common symptoms include increased exhaust noise, rattling sounds emanating from underneath the vehicle, reduced fuel economy, and a noticeable decline in engine performance. Visual inspection may reveal rust, corrosion, or physical damage.

Question 4: Is it possible to replace only the exhaust noise reduction device, or is it necessary to replace the entire exhaust system?

In most cases, only the exhaust noise reduction device needs to be replaced if other components of the exhaust system are in good condition. Direct-fit replacement units are designed to integrate seamlessly with the existing exhaust system.

Question 5: Does replacing the unit with an aftermarket component void the vehicle’s warranty?

The impact on the warranty depends on the specific aftermarket component and the terms of the warranty. Generally, replacing the unit with an aftermarket component will not void the entire vehicle’s warranty, but it may void the warranty on related exhaust system components if the aftermarket component is determined to be the cause of a failure.

Question 6: Are there any specific tools required for replacing the exhaust noise reduction device on a 2004 Ford F150?

Basic hand tools, such as wrenches and sockets, are typically required. A penetrating lubricant may be necessary to loosen corroded bolts and hangers. A saw or cutting tool may be needed to remove the old unit if it is heavily corroded or welded in place. Safety glasses and gloves are recommended.

These answers provide a foundation for understanding the function, maintenance, and potential issues associated with the specified vehicle component. Proper diagnosis and informed decision-making are critical for ensuring optimal vehicle performance and longevity.

The next section provides a glossary of terms related to the exhaust system and noise reduction technology.

Conclusion

The preceding analysis has dissected the function, maintenance, and aftermarket considerations surrounding the 2004 Ford F150 exhaust noise reduction device. The analysis encompassed material composition, noise reduction principles, exhaust flow dynamics, corrosion resistance, installation compatibility, and the implications of aftermarket alternatives. Understanding each facet contributes to informed decision-making regarding the vehicle’s exhaust system.

Proper maintenance and component selection are crucial for maintaining vehicle performance, regulatory compliance, and driver satisfaction. Continued adherence to recommended practices and awareness of technological advancements in exhaust system design will ensure the continued reliability and effectiveness of this critical component within the vehicle’s operational lifespan. Diligence in this area extends the service life of the vehicle and safeguards its operational parameters.