A primary function of a vehicle’s exhaust system component is to reduce the noise produced by the engine. This component, often cylindrical in shape, utilizes internal chambers and passages to dampen sound waves. For example, as exhaust gases pass through it, they are forced through a series of baffles and resonating chambers, which effectively cancels out much of the engine’s roar.

The significance of this part lies in its contribution to noise pollution reduction, making vehicles more environmentally and socially acceptable. Historically, its development coincided with increased urbanization and a growing awareness of the impact of vehicle noise on public health and quality of life. Its effectiveness is also directly linked to improved driver and passenger comfort during vehicle operation.

Understanding its role in the overall exhaust system is crucial for diagnosing performance issues and ensuring regulatory compliance. Therefore, further discussion will delve into its construction, common problems, and maintenance best practices.

Guidance on Muffler Function and Maintenance

The following guidance addresses crucial aspects regarding the operation and upkeep of the exhaust noise reduction device, promoting optimal performance and longevity.

Tip 1: Regular Visual Inspection: Conduct periodic visual examinations of this component for signs of rust, corrosion, or physical damage. Early detection can prevent minor issues from escalating into significant problems requiring costly replacements.

Tip 2: Listen for Unusual Noises: Be attentive to any changes in the vehicle’s exhaust sound. A louder than usual or rattling exhaust may indicate internal damage or a breach in the component’s structure.

Tip 3: Check for Exhaust Leaks: Inspect the seams and connections around this component for exhaust leaks. Leaks not only diminish its sound-dampening capabilities but can also introduce harmful gases into the vehicle cabin.

Tip 4: Promptly Address Corrosion: If surface rust is observed, address it promptly with rust inhibitors or protective coatings. This will slow down the corrosion process and extend the component’s lifespan.

Tip 5: Ensure Proper Mounting: Verify that the component is securely mounted and that all hangers and brackets are in good condition. Loose mountings can cause excessive vibration and premature wear.

Tip 6: Consider Driving Conditions: Vehicles frequently driven in harsh conditions (e.g., salty roads) are more susceptible to corrosion. More frequent inspections and maintenance are recommended in such environments.

Adhering to these recommendations will help ensure efficient operation, minimize the risk of failure, and maintain compliance with noise regulations.

By prioritizing the noise reduction device’s health, vehicle owners can contribute to a quieter environment and avoid potentially expensive repairs. The concluding section will summarize the key considerations outlined in this article.

1. Sound wave attenuation

Sound wave attenuation is a fundamental principle upon which the operation of the exhaust noise reduction device depends. It is the process by which the energy, and therefore the amplitude, of sound waves is reduced as they propagate through a medium. In this context, the device serves as the medium, actively diminishing the intensity of engine exhaust noise before it is released into the environment.

- Internal Baffling and Chambers

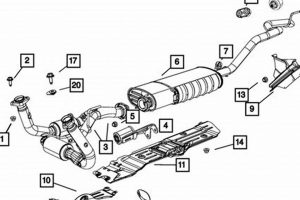

The internal design of this vehicular component typically incorporates a series of baffles and resonating chambers. These structures are strategically placed to reflect, absorb, and cancel out sound waves. As exhaust gases pass through these complex pathways, the sound waves encounter numerous obstacles, leading to a reduction in their overall energy. This multifaceted approach is crucial for achieving effective sound wave attenuation.

- Destructive Interference

A key mechanism in sound wave attenuation is destructive interference. The internal chambers are designed to create reflected sound waves that are out of phase with the original sound waves generated by the engine. When these out-of-phase waves collide, they cancel each other out, resulting in a significant reduction in noise levels. This phenomenon is deliberately engineered within this part to minimize the overall noise output.

- Absorption Materials

In some designs, sound-absorbing materials, such as fiberglass or specialized packing, are incorporated into its construction. These materials convert the sound energy into heat through friction, further reducing the amplitude of the sound waves. The type and amount of absorptive material used can significantly impact the component’s overall effectiveness.

- Frequency-Specific Attenuation

Different frequencies of sound are attenuated to varying degrees. The specific design of its internal structure is often tuned to target the most prominent and objectionable frequencies generated by the engine. This frequency-specific attenuation ensures that the component is most effective at reducing the overall perceived loudness of the exhaust noise.

The various methods employed for sound wave attenuation are integrated to achieve a significant reduction in engine exhaust noise. Without effective attenuation, vehicles would generate excessive noise, contributing to noise pollution and potentially violating noise regulations. The performance of this component is therefore essential for both environmental compliance and maintaining a comfortable driving experience.

2. Exhaust gas pathway

The exhaust gas pathway is an integral element of an exhaust noise reduction device, dictating its functionality and efficiency. This pathway defines the route exhaust gases take through the device, directly impacting sound attenuation. Its design dictates the degree to which sound waves are dampened. A complex pathway, characterized by baffles and chambers, increases surface area and reflection points, amplifying noise reduction. Conversely, a straight or unobstructed pathway offers minimal noise reduction capabilities.

For instance, in high-performance vehicles, the gas pathway might be optimized for minimal restriction, allowing for improved engine output, but often at the expense of increased exhaust noise. Conversely, passenger vehicles typically prioritize a more intricate pathway, sacrificing some performance for a quieter ride. This compromise demonstrates the fundamental link between gas flow and noise suppression within the system. Damage to this pathway, such as corrosion-induced holes or collapsed baffles, compromises its designed function, resulting in increased noise levels and potential safety concerns due to exhaust leaks.

In summary, the exhaust gas pathway is not merely a conduit for exhaust gases; it is a critical component influencing the device’s ability to reduce noise. Understanding its configuration and potential points of failure is paramount for effective maintenance and ensuring compliance with noise regulations. The integrity of this pathway directly affects both vehicle performance and environmental impact, underscoring its significance.

3. Corrosion resistance materials

The selection of corrosion-resistant materials is paramount to the longevity and effective operation of a vehicle exhaust noise reduction device. These devices are exposed to extremely harsh conditions, including high temperatures, condensation, road salt, and corrosive chemicals present in exhaust gases. The operational environment directly contributes to degradation, making material selection a critical design consideration. The consequences of using unsuitable materials include premature failure, increased noise levels due to breaches in the device’s structure, and potential exhaust leaks, presenting safety hazards. The employment of appropriate corrosion-resistant alloys directly mitigates these risks. For example, aluminized steel, stainless steel, and specialized coatings are frequently utilized to withstand these demanding conditions, significantly extending the lifespan of the component and ensuring sustained performance.

Consider the practical implications: A component constructed from mild steel in a region with heavy winter salting on roads might only last a year or two before significant corrosion necessitates replacement. Conversely, a device made from stainless steel in the same environment could easily last five to ten years or more. This difference translates directly into reduced maintenance costs for vehicle owners and a decrease in the environmental impact associated with frequent replacements. Furthermore, the sustained structural integrity provided by corrosion-resistant materials ensures consistent noise reduction performance throughout the device’s operational life, maintaining compliance with noise regulations and contributing to a quieter environment.

In conclusion, the link between corrosion resistance and the functionality of an exhaust noise reduction device is undeniable. The judicious selection of materials designed to withstand corrosive elements is not merely a matter of extending service life; it is crucial for ensuring sustained performance, environmental responsibility, and vehicle safety. Addressing corrosion proactively through material choice is, therefore, a fundamental aspect of design and maintenance within the automotive industry.

4. Engine noise reduction

Effective engine noise reduction is intrinsically linked to the function of a vehicle’s exhaust noise reduction device. This component is specifically engineered to attenuate the sound waves generated by the engine’s combustion process. The intensity of these sounds, if unabated, would result in significant noise pollution. The correlation between the device’s performance and the resultant noise level is direct: a fully functional component effectively minimizes noise, while a degraded or damaged component allows increased noise to escape. As an example, a vehicle experiencing a rusted-through exhaust system exhibits a distinctly louder engine sound, demonstrating the component’s diminished noise reduction capability. This directly affects environmental noise levels and potentially violates local noise ordinances.

The practical application of this understanding lies in maintenance and diagnostics. Identifying unusual engine noise can serve as an indicator of potential problems with the component. Regular inspections for corrosion, leaks, or damage allow for proactive repairs, maintaining optimal noise reduction. Furthermore, understanding how various designs affect noise attenuation enables informed decisions when selecting replacement parts. A larger or more complex component generally offers superior noise reduction, but might also impact exhaust flow, requiring a balance between performance and environmental considerations.

In conclusion, engine noise reduction is not merely a consequence of an exhaust system component’s function but is its primary purpose. Monitoring vehicle sound levels and understanding the link between component condition and noise output are essential for responsible vehicle ownership. Addressing issues promptly ensures regulatory compliance, minimizes environmental impact, and contributes to a quieter community environment. The challenge lies in balancing performance and noise reduction, requiring informed decisions based on vehicle usage and environmental considerations.

5. System pressure regulation

System pressure regulation is an often-overlooked but crucial aspect of exhaust system design, directly influencing the performance and longevity of components, including the device responsible for sound attenuation. Maintaining optimal pressure within the system is vital for ensuring efficient engine operation and preventing undue stress on individual parts. Fluctuations outside the acceptable range can indicate underlying issues and potentially lead to component failure. The effectiveness of exhaust noise reduction relies, in part, on proper pressure management.

- Backpressure Management

The primary goal of pressure regulation is to minimize backpressure the resistance to exhaust gas flow. Excessive backpressure can reduce engine power, decrease fuel efficiency, and increase engine operating temperatures. The exhaust noise reduction component must be designed to attenuate sound without significantly impeding gas flow. Its internal design, including baffle configuration and chamber size, directly affects the level of backpressure generated. Optimizing this design is essential to strike a balance between noise reduction and engine performance. A restrictive design can exacerbate backpressure issues, leading to performance degradation and potential engine damage.

- Pressure Wave Dynamics

The exhaust system experiences dynamic pressure waves generated by the cyclical firing of the engine’s cylinders. These pressure waves can contribute to noise and vibration. The exhaust noise reduction device is designed to dampen these pressure fluctuations, smoothing out the flow and reducing overall system noise. Internal chambers and resonators are strategically placed to cancel out specific frequencies and minimize pressure spikes. Effective pressure wave management contributes to both noise reduction and improved engine performance.

- Impact of System Leaks

Leaks within the exhaust system disrupt pressure regulation and compromise the effectiveness of the noise reduction component. Even small leaks can alter the system’s pressure profile, leading to increased noise levels and reduced engine efficiency. A leak upstream of the noise reduction device diminishes its ability to attenuate sound, while leaks downstream can introduce unwanted noise and potentially exhaust fumes into the vehicle cabin. Regular inspections for exhaust leaks are crucial for maintaining proper system pressure and ensuring optimal performance.

- Catalytic Converter Influence

The catalytic converter, another key component in the exhaust system, also influences pressure regulation. A clogged or damaged catalytic converter can significantly increase backpressure, negatively impacting engine performance and potentially shortening the lifespan of other exhaust components, including the sound attenuation device. Maintaining the catalytic converter in good working order is essential for ensuring proper system pressure and optimizing the performance of the entire exhaust system. Regular emissions testing and prompt attention to any warning signs of catalytic converter failure are crucial.

In conclusion, proper system pressure regulation is inextricably linked to the overall effectiveness of an exhaust system, including its noise reduction capabilities. Addressing pressure-related issues, such as excessive backpressure or exhaust leaks, is essential for maintaining engine performance, ensuring component longevity, and minimizing environmental noise pollution. Ignoring these aspects can lead to costly repairs and compromise the intended function of the exhaust noise reduction device. Therefore, comprehensive maintenance should incorporate pressure monitoring and correction alongside visual inspections and noise assessments.

Frequently Asked Questions About Exhaust Noise Reduction

The following addresses prevalent inquiries regarding exhaust system noise reduction devices, offering clarity on their function and maintenance.

Question 1: What is the primary function of a vehicular exhaust noise reduction device?

The primary function is to diminish the audible noise produced by the internal combustion engine as exhaust gases are expelled.

Question 2: How does a typical exhaust noise reduction device achieve sound attenuation?

Sound attenuation is achieved through a combination of internal baffling, resonating chambers, and, in some designs, sound-absorbing materials, which collectively reduce the amplitude of sound waves.

Question 3: What materials are commonly used in the construction of exhaust noise reduction devices?

Common materials include aluminized steel, stainless steel, and various alloys selected for their resistance to corrosion and high temperatures.

Question 4: How does a malfunctioning exhaust noise reduction device affect vehicle performance?

A malfunctioning component can lead to increased exhaust noise, reduced fuel efficiency, and potential engine damage due to increased backpressure. Exhaust leaks can also introduce harmful gases into the vehicle cabin.

Question 5: What are the common indicators of a failing exhaust noise reduction device?

Common indicators include a noticeably louder exhaust sound, rattling noises emanating from underneath the vehicle, and visible signs of rust or physical damage.

Question 6: What maintenance practices are recommended for exhaust noise reduction devices?

Recommended practices include regular visual inspections for rust and damage, prompt repair of exhaust leaks, and replacement of worn or corroded components to ensure optimal performance and regulatory compliance.

Understanding these key aspects is crucial for ensuring the proper functioning and longevity of the exhaust system. Neglecting maintenance can lead to increased noise pollution and potential safety hazards.

The following section will present a concluding summary of the information discussed within this article.

Conclusion

This exploration has clarified the meaning of a critical vehicular component. The device’s function extends beyond mere noise reduction; it is integral to environmental responsibility and regulatory compliance. Its design incorporates principles of sound wave attenuation, optimized gas flow, and material science to minimize engine noise while maintaining engine performance. The integrity of this component is directly correlated with reduced noise pollution and safe vehicle operation.

Continued advancements in material technology and acoustic design are expected to further enhance the effectiveness and longevity of these devices. Prioritizing its proper maintenance and understanding its function remains a critical aspect of responsible vehicle ownership, contributing to a quieter and healthier environment for all.