An exhaust system component designed for vehicles, manufactured by Yonaka Motorsports, facilitates the expulsion of exhaust gases from the engine. It often incorporates a resonator and muffler to reduce noise levels, while also potentially influencing exhaust flow and engine performance. These systems are commonly aftermarket parts, meaning they are intended to replace original equipment manufacturer (OEM) components.

The appeal of these systems often lies in their potential to enhance vehicle sound, aesthetics, and performance characteristics. Historically, modifications to exhaust systems have been pursued to achieve a more aggressive engine note, improve horsepower, and customize the vehicle’s appearance. Furthermore, aftermarket options frequently offer different material choices, such as stainless steel, which can provide increased durability and resistance to corrosion. The design and construction can impact exhaust gas velocity, potentially leading to optimized engine efficiency and power output.

The subsequent discussion will delve into various aspects related to aftermarket exhaust components, including materials, design considerations, performance implications, installation processes, and legal compliance issues. Considerations will also be given to the selection criteria and consumer decision-making process related to these components.

Guidance on Aftermarket Exhaust Component Selection

The following information provides essential guidance for those considering an aftermarket exhaust component. Careful consideration of these points will ensure a suitable choice and proper installation.

Tip 1: Research Compatibility: Verify the exhaust system’s compatibility with the specific vehicle make, model, and year. Incompatible systems can lead to fitment issues, performance degradation, or potential engine damage. Consult manufacturer specifications and cross-reference part numbers before purchase.

Tip 2: Assess Material Quality: Prioritize systems constructed from durable materials like stainless steel. Stainless steel offers resistance to corrosion and heat, contributing to a longer lifespan, particularly in regions with harsh weather conditions.

Tip 3: Evaluate Sound Characteristics: Understand the intended sound profile of the aftermarket exhaust. Consider the decibel level and tonal qualities to ensure compliance with local noise regulations and personal preferences. Research online sound clips or seek reviews to gauge the auditory impact.

Tip 4: Consider Installation Complexity: Assess the level of installation expertise required. Some aftermarket exhaust systems may require professional installation due to modifications or adjustments. Factor in installation costs when budgeting for the upgrade.

Tip 5: Verify Legal Compliance: Ensure the aftermarket exhaust system meets all applicable local, state, and federal regulations. Some modifications may void warranties or violate emissions standards. Verify that the system is either street-legal or intended for off-road use only.

Tip 6: Inspect Welding Quality: Examine the quality of welds on the exhaust system. Poorly executed welds can weaken the structure and lead to premature failure. Look for smooth, consistent welds with no signs of porosity or cracking.

Tip 7: Check for Proper Exhaust Flow: Understand the design’s effect on exhaust flow. Efficient exhaust flow can enhance engine performance, while restrictions can negatively impact horsepower and fuel economy. Consult performance data and dyno tests if available.

Proper selection of aftermarket exhaust systems necessitates thorough research, meticulous attention to detail, and a clear understanding of legal requirements. By adhering to these recommendations, individuals can ensure a satisfactory outcome.

The subsequent sections will explore specific use-case examples and technical specifications to facilitate a more comprehensive understanding.

1. Sound Attenuation

Sound attenuation, the reduction of noise emitted by a vehicle’s exhaust system, is a primary function of the component. The degree and quality of sound attenuation directly impact the suitability of an exhaust component for street use and driver preference. The design and materials employed directly determine its effectiveness in mitigating exhaust noise.

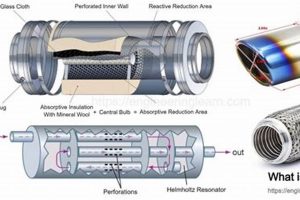

- Internal Baffling Design

The internal structure of an exhaust component, specifically the arrangement of baffles and chambers, plays a critical role in sound wave cancellation. Complex baffle designs force exhaust gases through a tortuous path, disrupting sound waves and reducing their amplitude. The specific design is tailored to achieve a target sound level and tonal quality. For example, a system intended for street use will typically feature more restrictive baffling than one designed for off-road applications.

- Resonator Integration

Resonators are specialized chambers designed to cancel specific frequencies within the exhaust sound spectrum. They operate by creating sound waves that are out of phase with the primary exhaust noise, resulting in destructive interference. The size and placement of resonators are carefully calculated to target the frequencies most objectionable to the human ear, such as drone or rasp. The presence and effectiveness of resonators directly influence the overall sound quality.

- Muffler Packing Material

The packing material surrounding the internal components of the exhaust is crucial for absorbing high-frequency sound waves. Materials like fiberglass, steel wool, or ceramic wool are commonly used. The density and type of packing material influence the sound attenuation characteristics. Over time, packing material can degrade due to heat and vibration, leading to increased exhaust noise. The longevity of the packing material impacts the long-term performance of the noise reduction system.

- Material Thickness and Construction

The gauge and type of metal used in the component’s construction affect sound transmission. Thicker materials generally provide better sound insulation, reducing the amount of noise that radiates from the system’s exterior. Furthermore, the welding techniques employed can impact noise levels. Poorly executed welds can create vibrations and rattles, contributing to unwanted noise. The overall construction quality directly affects the noise reduction capacity.

Therefore, its capability in sound attenuation is a key factor determining its compliance with noise regulations and the comfort of the vehicle’s occupants. Optimizing these design elements is essential for balancing performance gains with acceptable noise levels in street-driven vehicles. Careful consideration must be given to baffle design, resonator integration, packing material, and construction methods to ensure effective sound attenuation without compromising exhaust flow.

2. Exhaust Flow

Exhaust flow, the movement of spent gases from the engine’s combustion chamber through the exhaust system and out into the atmosphere, is intrinsically linked to the design and performance characteristics of an aftermarket component. The component’s design directly influences the velocity and volume of exhaust gases expelled, with alterations potentially impacting engine efficiency, horsepower output, and overall vehicle performance. The relationship between the internal configuration and the resulting exhaust flow is a crucial aspect of system evaluation.

The internal structure, including the diameter of the piping, the presence and design of baffles, and the integration of resonators, governs the resistance to exhaust gas movement. A component with a larger diameter and fewer obstructions generally facilitates higher exhaust flow rates, potentially reducing backpressure and increasing horsepower, particularly at higher engine speeds. Conversely, a design with excessive baffling may restrict exhaust flow, leading to increased backpressure, reduced engine efficiency, and potential performance limitations. For example, a system designed for a high-performance vehicle will often prioritize maximizing exhaust flow, even at the expense of some noise attenuation, while a system intended for a daily driver may strike a balance between performance and noise reduction. A restrictive component can negate the performance gains from other engine modifications. Furthermore, the welding quality and the smoothness of internal bends impact exhaust gas velocity, with imperfections creating turbulence and impeding flow.

In summary, exhaust flow is a critical determinant of system performance. Its design significantly impacts the movement of exhaust gases and subsequently influences engine efficiency and power output. Balancing exhaust flow with other factors, such as noise attenuation and regulatory compliance, is essential for selecting a suitable aftermarket exhaust component that meets the needs of the vehicle and the driver. Understanding the specific design features that affect exhaust flow is paramount for making informed decisions and achieving desired performance characteristics.

3. Material Durability

The longevity and performance of an exhaust system are intrinsically linked to the durability of its constituent materials. In the context of aftermarket exhaust components, including systems manufactured by Yonaka Motorsports, material choice is a primary determinant of resistance to corrosion, thermal stress, and mechanical wear. The selection of materials directly impacts the lifespan of the component and its ability to maintain optimal performance over time. Inferior materials are susceptible to premature failure, necessitating costly replacements and potentially compromising vehicle performance.

Stainless steel, commonly employed in the construction of aftermarket exhaust systems, offers superior resistance to corrosion compared to mild steel. This resistance is particularly crucial in regions with harsh climates or environments where exposure to road salts and moisture is prevalent. For instance, a stainless steel exhaust system on a vehicle operating in a northern state during winter will exhibit significantly longer service life than an equivalent system constructed from mild steel. The cost differential between stainless steel and mild steel is often justified by the increased durability and reduced maintenance requirements. The gauge of the metal also plays a role; thicker materials are generally more resistant to mechanical damage and thermal fatigue. A thin-walled system may be more susceptible to cracking or deformation under extreme operating conditions. The type of welding employed also influences durability; high-quality welds ensure structural integrity and prevent leaks.

In summary, material durability is a critical attribute of an aftermarket exhaust component. The choice of materials, such as stainless steel, directly impacts resistance to corrosion, thermal stress, and mechanical wear. Selecting a system constructed from durable materials is essential for ensuring long-term performance, minimizing maintenance costs, and maximizing the lifespan of the exhaust system. Neglecting material durability can result in premature failure and diminished vehicle performance.

4. Vehicle Compatibility

Vehicle compatibility is a paramount consideration when selecting an aftermarket exhaust component. The component must be engineered to integrate seamlessly with the specific vehicle’s chassis, engine configuration, and existing exhaust system architecture. Mismatched components can result in installation difficulties, performance degradation, and potential damage to the vehicle. Therefore, verifying compatibility is a critical step in the selection process.

- Engine Configuration Matching

The engine configuration, including the number of cylinders, engine displacement, and valvetrain design, dictates the required exhaust flow characteristics. Systems designed for inline engines will not be suitable for V-shaped engines, and vice versa. Similarly, a system designed for a naturally aspirated engine may not be optimal for a turbocharged engine, as turbocharged engines require different exhaust flow dynamics. Failure to match the system to the engine configuration can lead to performance losses and potential engine damage.

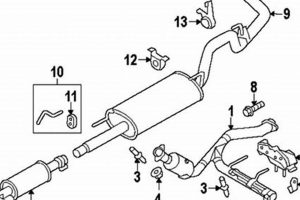

- Chassis Integration Points

The aftermarket exhaust component must align with the vehicle’s existing mounting points and exhaust hangers. Discrepancies in these integration points can necessitate modifications to the chassis or the exhaust system, increasing installation complexity and potentially compromising structural integrity. Furthermore, proper alignment is crucial for preventing vibrations and ensuring that the exhaust system does not interfere with other vehicle components.

- Exhaust System Diameter and Routing

The diameter of the aftermarket component must be compatible with the existing exhaust system. Significant differences in diameter can create bottlenecks or turbulence, negatively impacting exhaust flow and engine performance. Additionally, the routing of the exhaust piping must be consistent with the vehicle’s undercarriage to avoid obstructions and ensure adequate ground clearance. Improper routing can lead to damage from road hazards or interference with suspension components.

- Emissions Compliance Considerations

In certain jurisdictions, aftermarket exhaust components must meet specific emissions standards. Modifying or removing catalytic converters, for example, may be illegal and can result in failed emissions tests. Ensuring that the component is compliant with local regulations is essential for avoiding fines and maintaining the vehicle’s legal status. The component must be designed to function effectively with the vehicle’s existing emissions control systems.

Therefore, vehicle compatibility is an indispensable consideration when selecting an aftermarket exhaust component. Proper integration with the engine configuration, chassis, and existing exhaust system is critical for ensuring optimal performance, preventing damage, and maintaining regulatory compliance. Neglecting this factor can lead to significant problems and compromise the overall functionality of the vehicle.

5. Installation Process

The installation process represents a critical juncture in realizing the potential benefits of an aftermarket exhaust component. Incorrect installation of such a system can negate performance gains, create safety hazards, and potentially damage the vehicle. The integration process directly influences the component’s functionality, durability, and overall effectiveness. This is particularly relevant in the context of components manufactured by Yonaka Motorsports, where precise fitment and alignment are essential for optimal performance. Therefore, a thorough understanding of the installation process is indispensable for both professional installers and vehicle owners.

The installation process is not merely a matter of bolting the component into place. It often necessitates precise measurements, careful alignment, and specialized tools. For example, when replacing a factory exhaust system with an aftermarket component, the installer must ensure that all connections are properly sealed to prevent exhaust leaks. An exhaust leak can reduce engine performance, increase noise levels, and pose a health hazard due to the escape of harmful gases into the passenger compartment. Furthermore, the installer must verify that the new system does not interfere with other vehicle components, such as the suspension, fuel lines, or brake lines. Interference can lead to mechanical damage and compromise vehicle safety. The tightening torque of bolts and fasteners must adhere to manufacturer specifications to ensure secure connections without damaging the components. The lack of proper torque can cause vibration, loosening, and eventual failure of the exhaust system. In cases where welding is required, skilled welding techniques are essential for creating strong, leak-proof joints.

In summary, the installation process is integral to the successful integration of an aftermarket exhaust system. Proper installation ensures optimal performance, prevents safety hazards, and maximizes the lifespan of the component. Neglecting the intricacies of the installation process can have significant consequences, underscoring the importance of meticulous attention to detail and adherence to manufacturer guidelines. The benefits of a high-quality exhaust system can only be realized with a competent and careful installation.

6. Aesthetic Design

Aesthetic design, in the context of aftermarket exhaust components, contributes significantly to the overall visual appeal of a vehicle. While functional performance remains paramount, the aesthetic characteristics of components, including those from Yonaka Motorsports, influence consumer preferences and brand perception. The visual design elements integrate with the vehicle’s styling, thereby playing a crucial role in personalization and customization.

- Tip Finish and Style

The exhaust tip represents the most visible element of the exhaust system. Different tip finishes, such as polished stainless steel, black chrome, or burnt titanium, offer varied aesthetic effects. Angled, rolled, or slash-cut tip styles further diversify the visual presentation. These design choices impact the perceived sportiness, aggressiveness, or elegance of the vehicle. The visibility and placement of the tip contribute to the overall aesthetic impression.

- System Material and Finish

The material itself, whether stainless steel or titanium, contributes to the system’s aesthetic. Stainless steel provides a clean, metallic appearance, while titanium offers a distinctive blue-grey hue. The finish, such as polished, brushed, or ceramic-coated, further influences the visual impact. A well-polished system can enhance the vehicle’s premium aesthetic, while a ceramic-coated system may offer a more understated, performance-oriented look. The overall material selection and finish contribute significantly to visual appeal.

- Welding and Construction Details

The quality and style of the welds contribute to the overall aesthetic impression. Clean, TIG-welded seams convey a sense of craftsmanship and attention to detail. Visible welds, particularly those with consistent and uniform bead patterns, are often considered aesthetically pleasing. The overall construction details, including the precision of bends and the symmetry of the system, influence the visual appeal. Superior construction reflects positively on the component’s quality and design.

- Brand Integration and Logo Placement

The strategic placement of the brand logo on the exhaust system contributes to brand recognition and aesthetic appeal. The logo can be subtly integrated into the design or prominently displayed to emphasize brand identity. The size, style, and placement of the logo influence the overall visual impact. A well-executed logo integration enhances the component’s aesthetic and reinforces brand loyalty. This serves as a visual cue of the product’s quality and origin.

In summary, the aesthetic design elements of aftermarket exhaust systems, including tip finishes, material choices, welding details, and brand integration, collectively shape the visual appeal of the vehicle. The integration of these elements must harmonize with the vehicle’s styling and reflect the owner’s preferences. These aesthetic considerations, while secondary to functional performance, play a significant role in consumer purchasing decisions and brand perception within the aftermarket automotive industry.

Frequently Asked Questions Regarding Aftermarket Exhaust Components

The following section addresses common inquiries and misconceptions surrounding aftermarket exhaust components. The information is intended to provide clarity and facilitate informed decision-making.

Question 1: Does installing this component automatically increase horsepower?

Horsepower gains are not guaranteed with the installation of this component. Performance improvements depend on various factors, including engine characteristics, existing modifications, and proper installation. While some applications may yield noticeable horsepower increases, others may exhibit minimal or negligible gains. The component primarily influences exhaust flow, which can indirectly affect engine output.

Question 2: Will this void the vehicle’s warranty?

The impact on a vehicle’s warranty depends on the specific terms of the warranty and applicable consumer protection laws. In some jurisdictions, manufacturers cannot void a warranty solely due to the installation of an aftermarket component unless they can demonstrate that the component directly caused the failure. It is advisable to consult the vehicle’s warranty documentation and seek legal advice if concerns arise.

Question 3: Are these components legal for street use in all locations?

Legal compliance varies significantly by jurisdiction. Many areas have noise regulations and emissions standards that aftermarket exhaust components must meet. It is incumbent upon the vehicle owner to verify compliance with all applicable local, state, and federal regulations. Some components are explicitly designated for off-road use only.

Question 4: Can this component negatively impact fuel economy?

Alterations to exhaust flow can influence fuel economy, although the extent of the impact varies. In some cases, improved exhaust flow can enhance fuel efficiency. Conversely, improper installation or an incompatible component can lead to reduced fuel economy. Driving habits and engine tuning also play a significant role.

Question 5: How frequently should this component be inspected for maintenance?

Regular inspections are recommended to ensure the component’s structural integrity and optimal performance. The frequency of inspections depends on factors such as driving conditions, climate, and material quality. A visual inspection for signs of corrosion, leaks, or damage should be conducted at least annually.

Question 6: Can installation be performed by a non-professional?

While some installations may be straightforward, others require specialized tools and expertise. Incorrect installation can compromise performance, create safety hazards, and potentially damage the vehicle. It is advisable to seek professional installation unless the individual possesses the necessary skills and equipment.

In summary, aftermarket exhaust component selection and installation involve numerous considerations. Understanding these factors is essential for achieving desired performance improvements while ensuring legal compliance and maintaining vehicle integrity.

The subsequent sections will explore specific models and applications in greater detail.

Conclusion

This exploration has illuminated key facets concerning aftermarket exhaust components, with specific attention given to “yonaka muffler.” Critical aspects such as sound attenuation, exhaust flow dynamics, material durability, vehicle compatibility, installation procedures, and aesthetic design have been examined. These factors collectively determine the performance, longevity, and suitability of such components for diverse vehicular applications.

The informed selection and proper installation of exhaust systems represent a significant investment in vehicle performance and aesthetic refinement. Continued diligence in research, adherence to regulatory standards, and commitment to quality craftsmanship will ensure the enduring relevance of aftermarket exhaust technologies within the automotive landscape. Further investigation should focus on long-term performance data and comparative analyses of various system designs to optimize future advancements in exhaust system engineering.