This aftermarket exhaust component is engineered to enhance the auditory experience and performance characteristics of a vehicle’s engine. Specifically designed as a replacement for the factory-installed unit, it alters the exhaust flow and sound profile. For example, a vehicle fitted with this component often exhibits a more aggressive and pronounced exhaust note compared to its stock configuration.

The appeal of this modification lies in its potential to increase horsepower and torque output, alongside its contribution to a more visceral driving experience through an amplified sound. Historically, enthusiasts have sought such components to personalize their vehicles and extract additional performance. This type of modification provides a readily accessible avenue for enhancing both the aesthetic and functional aspects of a vehicle.

Understanding the specific applications, performance gains, and installation considerations associated with this product is vital. Examining factors such as vehicle compatibility, material composition, and compliance with local regulations is critical for informed decision-making. Further detailed analysis will explore these aspects in subsequent sections.

Guidance on Utilizing Aftermarket Exhaust Components

The following guidelines address crucial aspects related to the selection, installation, and maintenance of performance-enhancing exhaust systems. Adherence to these points promotes optimal performance, longevity, and compliance with regulatory standards.

Tip 1: Verify Vehicle Compatibility: Confirm the specific part number matches the vehicle’s make, model, and year. Incompatible components may lead to performance degradation or installation difficulties. For instance, installing a system designed for a V8 engine on a V6 platform is fundamentally incompatible.

Tip 2: Prioritize Material Quality: Select exhaust systems constructed from durable materials, such as stainless steel or aluminized steel. These materials exhibit superior resistance to corrosion and heat-related degradation, extending the component’s lifespan.

Tip 3: Consult Professional Installation Services: While DIY installation is possible, employing a qualified mechanic ensures proper fitment and alignment. Improper installation can result in exhaust leaks, reduced performance, and potential damage to other vehicle components.

Tip 4: Monitor Exhaust System for Leaks: Periodically inspect the exhaust system for any signs of leaks, such as unusual noises or visible exhaust fumes. Addressing leaks promptly maintains optimal performance and prevents potential safety hazards.

Tip 5: Comply with Local Noise Regulations: Be aware of and adhere to local noise ordinances regarding vehicle exhaust levels. Excessive noise can result in fines and legal repercussions.

Tip 6: Evaluate Performance Objectives: Determine the desired performance gains before selecting an exhaust system. Different designs offer varying levels of performance enhancement; therefore, aligning the choice with specific goals is crucial.

Tip 7: Account for Potential Drone: Be cognizant of the potential for “drone,” an unpleasant resonant frequency generated by some aftermarket exhaust systems at specific RPM ranges. Research and select systems known for minimizing drone to ensure a comfortable driving experience.

Proper selection and maintenance provide enhanced performance and long-term durability. Careful planning enables informed decision-making, avoiding potential pitfalls associated with aftermarket modifications.

The subsequent section will address factors concerning legal constraints and environmental impact when utilizing this component.

1. Aggressive exhaust tone

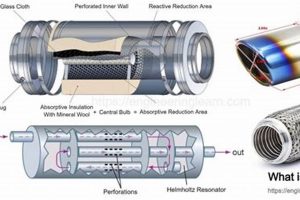

The exhaust component in question, known for its aggressive tone, fundamentally alters the sound signature of a vehicle. This characteristic is not merely an aesthetic modification; it represents a deliberate engineering choice influencing both auditory perception and, potentially, the perceived performance of the vehicle. The “aggressive tone” is a direct consequence of the internal design of the component, impacting the way exhaust gases are processed and released. For instance, the internal baffling and chamber configurations are specifically tuned to generate a louder, more resonant sound compared to stock mufflers. This tonal shift is commonly sought by enthusiasts aiming to project a more powerful and assertive presence.

The importance of the aggressive tone extends beyond subjective preference. In certain motorsports applications, the distinct sound can assist drivers in audibly gauging engine RPMs and load, providing supplementary feedback alongside instrumentation. Furthermore, the audibility can serve as an alert to other drivers and pedestrians, potentially enhancing safety in specific scenarios. However, it is essential to acknowledge the potential drawbacks. An overly aggressive exhaust tone may contravene local noise ordinances, resulting in fines or restrictions. Additionally, prolonged exposure to high-decibel levels can contribute to noise pollution and hearing fatigue. Therefore, a balanced assessment of the benefits and detriments is critical.

In summary, the aggressive exhaust tone is an intrinsic and defining characteristic of the component, driven by intentional design and manufacturing choices. While the amplified sound offers perceived advantages, the real-world impact necessitates careful consideration of legal compliance, environmental impact, and personal tolerance. The pursuit of performance enhancements should always be tempered by an understanding of the wider ramifications of such modifications.

2. Performance enhancement potential

The concept of “performance enhancement potential” is intrinsically linked to this particular aftermarket exhaust system component. The degree to which this component enhances a vehicle’s performance is a primary motivator for its adoption. The following facets explore aspects of this connection.

- Exhaust Flow Optimization

This component is designed to reduce backpressure within the exhaust system. By facilitating a smoother and more efficient flow of exhaust gases, the engine expends less energy on expulsion, theoretically freeing up horsepower and torque. The extent of this effect varies based on engine characteristics and other modifications. For instance, a high-performance engine with supporting modifications such as an upgraded air intake system will likely experience a more significant gain compared to a stock engine.

- Engine Tuning Synergies

While the installation of this component may provide a nominal increase in performance independently, its true potential is often realized when coupled with engine tuning. A qualified technician can recalibrate the engine’s computer to optimize fuel and ignition timing based on the modified exhaust flow. This synergistic effect can yield substantial improvements in both horsepower and torque curves across the RPM range. Examples include adjusting the air/fuel ratio for optimal combustion and advancing ignition timing to capitalize on the reduced backpressure.

- Weight Reduction Contribution

Aftermarket exhaust components often offer a weight advantage compared to their factory counterparts. While not always a primary focus, any reduction in vehicle weight contributes to improved acceleration and handling. The extent of the weight reduction depends on the materials used in the construction. Stainless steel, for example, offers a good balance of durability and weight savings. The cumulative effect of weight reduction, even if marginal, is a tangible improvement in overall vehicle performance.

- Auditory Feedback and Perceived Performance

The enhanced sound produced can contribute to the perceived performance gains. The more aggressive exhaust note may create the impression of greater power and responsiveness, even if the objective gains are modest. The human element of driver experience is important, as increased engagement can lead to a more spirited driving style. In this context, the psychological impact of the altered sound profile plays a role in the perceived “performance enhancement potential” of the component.

In summary, the “performance enhancement potential” represents a combination of factors, ranging from exhaust flow optimization to engine tuning synergies and weight reduction. While subjective perception also contributes to the perceived experience, the aggregate effect represents the true value proposition for individuals seeking to upgrade their vehicle’s exhaust system.

3. Stainless steel construction

The implementation of stainless steel construction in the aforementioned exhaust component represents a deliberate engineering decision aimed at enhancing durability and longevity. Stainless steel, owing to its inherent resistance to corrosion and high-temperature degradation, is a material of choice for exhaust systems operating in harsh environments. The presence of water, salts, and corrosive chemicals, common in road environments, rapidly degrade exhaust systems constructed from lesser materials. Stainless steel mitigates these effects, extending the operational lifespan of the component and ensuring consistent performance over time. For example, a vehicle operating in a region with heavy winter salting would experience a significantly reduced lifespan of a standard steel exhaust compared to one fabricated from stainless steel.

The practical significance of this construction material extends to maintaining the structural integrity of the exhaust system. Fractures and failures in exhaust components lead to performance losses, increased noise pollution, and potential safety hazards. Stainless steel exhibits superior resistance to fatigue and stress cracking compared to conventional steel alloys, reducing the risk of such failures. The initial investment in a stainless steel exhaust system, though potentially higher, yields long-term cost savings by minimizing the need for frequent replacements and repairs.

In summary, the selection of stainless steel as the primary construction material for this exhaust component is driven by the need for durability, corrosion resistance, and structural integrity. This choice translates into extended operational life, reduced maintenance requirements, and enhanced overall value for the end-user. The selection of materials directly dictates the real-world reliability and performance of the system, making it a critical factor in overall evaluation.

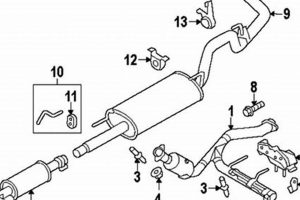

4. Direct bolt-on fitment

The characteristic of “direct bolt-on fitment” is a critical factor in the adoption and implementation of the exhaust system. This term denotes the design compatibility allowing for straightforward installation using existing factory mounting points, without requiring extensive modifications or custom fabrication. The concept is directly related to ease of installation and decreased labor costs.

- Facilitated Installation Process

The direct bolt-on design simplifies the installation process, enabling both professional technicians and mechanically inclined individuals to perform the upgrade with relative ease. The component is engineered to align precisely with the vehicle’s existing exhaust system mounting points, hangers, and flanges. This eliminates the need for cutting, welding, or drilling, reducing installation time and minimizing the potential for errors. For instance, a system designed as a direct bolt-on typically includes all necessary hardware, such as bolts, nuts, and gaskets, to facilitate a seamless installation.

- Reduced Labor Costs

The streamlined installation process translates into reduced labor costs for individuals opting for professional installation services. The reduced installation time means fewer billable hours from a mechanic or exhaust shop, decreasing the overall expense of the upgrade. This is particularly advantageous for individuals seeking to improve their vehicle’s performance on a budget, as the savings on labor can offset the cost of the component itself.

- Reversibility and Compatibility

The direct bolt-on nature of the design allows for easy reversibility. If, at any point, the vehicle owner wishes to revert to the original factory exhaust system, the aftermarket component can be readily removed and the original system reinstalled using the same mounting points. This is particularly relevant for leased vehicles or situations where modifications are discouraged or prohibited. Furthermore, ensuring compatibility with factory oxygen sensors and catalytic converters is crucial. A properly designed direct bolt-on system will integrate seamlessly with these existing components, avoiding potential error codes or performance issues.

- Quality Control and Standardization

Direct bolt-on fitment necessitates adherence to stringent quality control standards during the manufacturing process. Precise measurements and consistent fabrication are essential to guarantee that the component aligns correctly with the target vehicle. This standardization minimizes variations and ensures that the product meets the expectations of the end-user. The adherence to standardized fitment also simplifies inventory management for retailers and distributors, reducing the complexity of product selection and ensuring accurate compatibility information.

In conclusion, the direct bolt-on nature of the component enhances its appeal by simplifying installation, reducing labor expenses, and facilitating reversibility. This characteristic aligns with the needs of both seasoned automotive enthusiasts and those seeking straightforward, easily implemented performance upgrades.

5. Minimal weight reduction

The phrase “minimal weight reduction,” when considered in relation to the aforementioned exhaust component, signifies that while there may be a decrease in the overall mass of the vehicle following installation, this reduction is not a primary design objective nor a significant performance factor. The focus of the design centers primarily on altering the sound profile and, to a lesser extent, optimizing exhaust flow, rather than achieving substantial weight savings. For example, if a stock muffler weighs 15 pounds and the aftermarket component weighs 13, the 2-pound reduction, while measurable, is unlikely to translate into a discernible improvement in acceleration or handling for most vehicles. Therefore, potential purchasers should not prioritize weight reduction as a leading reason for choosing this specific component.

The importance of understanding this “minimal” aspect lies in setting realistic expectations for performance gains. Overemphasizing weight reduction can lead to misinterpretations regarding the component’s overall effectiveness. It is crucial to evaluate the component holistically, considering its sound characteristics, material quality, and ease of installation, rather than solely focusing on a marginal weight difference. A practical application involves comparing the specifications of various aftermarket exhaust systems, noting that products advertised with a focus on significant weight reduction often command a higher price point, utilize more exotic materials (such as titanium or carbon fiber), and target specialized applications like motorsports, where even small weight savings are crucial.

In summary, the connection between “minimal weight reduction” and the exhaust component implies that while a slight decrease in weight may occur, it is not a defining feature or primary benefit. This understanding facilitates informed decision-making, allowing purchasers to prioritize performance characteristics that more accurately align with their objectives. Addressing the challenge of misinterpreting performance enhancements requires a balanced assessment of all component attributes, rather than focusing solely on unsubstantiated claims or secondary benefits. This realistic appraisal underscores the importance of comprehensive evaluation in the selection of aftermarket automotive components.

6. Amplified sound levels

Amplified sound levels are an inherent and defining characteristic of the component. The core design philosophy of this component centers around a substantial increase in the decibel output of the vehicle’s exhaust system. This amplification is not a coincidental byproduct but a deliberate engineering objective. For example, the component achieves this by minimizing internal baffling and utilizing a straight-through design, which allows exhaust gases to flow with minimal restriction, thereby increasing the volume and intensity of the emitted sound. The sonic alteration serves both aesthetic and perceived performance purposes, appealing to enthusiasts seeking a more pronounced auditory presence.

The importance of amplified sound levels must be considered within the context of legal and environmental constraints. While some individuals appreciate a louder exhaust note, many jurisdictions have noise ordinances that restrict the permissible decibel levels of vehicles. Exceeding these limits can result in fines or even restrictions on vehicle usage. Real-world examples include communities near race tracks or areas with active noise enforcement programs. Furthermore, the amplified sound can contribute to noise pollution, impacting the quality of life for residents in surrounding areas. Therefore, an understanding of local regulations and the potential impact on the environment is crucial for responsible usage.

In summary, the connection between amplified sound levels and the component underscores the deliberate sonic engineering involved. The amplified sound is a central attribute, but its real-world implications necessitate a careful consideration of legal compliance, environmental impact, and social responsibility. The value proposition involves a balance between the desired aesthetic and the adherence to ethical and legal norms. Failure to acknowledge this balance may result in unintended consequences, undermining the overall objective of performance enhancement.

7. Durable, lasting component

The characteristic of being a durable and lasting component holds substantial importance in the context of the aftermarket exhaust component. The investment in an aftermarket exhaust system represents a commitment, and the longevity of that investment significantly influences its overall value. Therefore, the durability and lifespan are critical determinants of its long-term appeal and cost-effectiveness.

- Material Resilience

The materials employed in the construction of the exhaust component directly influence its ability to withstand the rigors of the automotive environment. Factors such as exposure to extreme temperatures, road salts, moisture, and physical impacts necessitate the use of robust materials. Stainless steel, for example, is frequently utilized for its inherent resistance to corrosion and high-temperature degradation. A component crafted from high-quality materials is inherently more likely to exhibit a prolonged service life compared to those fabricated from lesser materials.

- Structural Integrity

Beyond material selection, the structural integrity of the design is paramount. The exhaust system is subjected to constant vibrations and mechanical stresses during vehicle operation. Welds, joints, and mounting points represent potential weak points that, if inadequately designed or executed, can lead to premature failure. A durable component features robust welds, reinforced mounting points, and a design that effectively distributes stress, minimizing the risk of cracking or breakage.

- Resistance to Environmental Factors

An exhaust component’s ability to resist environmental factors such as rust, corrosion, and UV degradation is crucial for maintaining its aesthetic appeal and functional performance. Road salts, particularly prevalent in regions with winter climates, accelerate the corrosion of metal components. Similarly, prolonged exposure to sunlight can degrade certain materials, leading to discoloration or cracking. A durable component incorporates protective coatings or materials that resist these environmental effects, preserving its appearance and functionality over time.

- Long-Term Performance Retention

A durable component not only withstands physical and environmental stresses but also maintains its performance characteristics over an extended period. An exhaust system’s primary function is to efficiently expel exhaust gases from the engine. Over time, internal components can degrade, leading to increased backpressure and reduced engine performance. A durable component incorporates design features that minimize this degradation, such as smooth internal surfaces and corrosion-resistant materials, ensuring consistent performance throughout its lifespan.

The considerations of material resilience, structural integrity, resistance to environmental factors, and the maintenance of long-term performance define the durability and lasting nature of the exhaust component. The investment in a system that adequately addresses these factors translates to reduced maintenance costs, consistent performance, and enhanced overall value, aligning with the needs of consumers seeking both enhanced performance and long-term reliability.

Frequently Asked Questions Regarding Aftermarket Exhaust System Components

The following questions address common concerns and misconceptions associated with this specific aftermarket exhaust upgrade, providing clear and concise answers based on technical understanding and industry expertise.

Question 1: Will installation of this component void the vehicle’s factory warranty?

The installation of an aftermarket component may affect certain aspects of the factory warranty, particularly those directly related to the exhaust system. However, the Magnuson-Moss Warranty Act generally protects consumers, preventing manufacturers from voiding the entire warranty simply due to the installation of an aftermarket part. A thorough understanding of the warranty terms and potential impact is advisable.

Question 2: Does this component require modifications to the vehicle’s engine control unit (ECU)?

While the component can be installed without immediate ECU modifications, optimal performance is often achieved with a corresponding ECU tune. An ECU tune can recalibrate fuel and ignition settings to maximize the benefits of the altered exhaust flow. Consultation with a qualified tuner is recommended to determine the necessity and potential benefits of ECU modifications.

Question 3: What is the expected lifespan of this component?

The lifespan of the component is dependent on several factors, including the quality of materials, environmental conditions, and driving habits. Stainless steel components typically exhibit a longer lifespan compared to those constructed from aluminized steel. Regular inspection and maintenance, such as cleaning and tightening of connections, can further extend the component’s lifespan.

Question 4: Is professional installation required, or can this be a do-it-yourself (DIY) project?

While installation is possible as a DIY project for individuals with mechanical aptitude and appropriate tools, professional installation is highly recommended. Proper alignment, tightening of connections, and leak testing are crucial for ensuring optimal performance and preventing potential issues. Improper installation can lead to exhaust leaks, reduced performance, and potential damage to other vehicle components.

Question 5: Does this component comply with local noise regulations?

Compliance with local noise regulations is the responsibility of the vehicle owner. The component is designed to amplify the exhaust sound, and therefore may not be compliant in all jurisdictions. Prior to installation, a thorough understanding of local noise ordinances is crucial to avoid potential fines or legal repercussions. Sound level testing may be necessary to ensure compliance.

Question 6: Will this component improve fuel economy?

The primary objective of this component is to enhance performance and alter the exhaust sound. While improved exhaust flow can potentially contribute to a marginal improvement in fuel economy, this is not a guaranteed outcome. Driving habits and other vehicle modifications have a more significant impact on fuel economy than the installation of this component alone.

In essence, the performance enhancement and auditory experience derived from this exhaust upgrade require careful consideration of legal, technical, and environmental factors. Informed decision-making is paramount.

The subsequent section will discuss best practices for installation.

Concluding Remarks Regarding the SLP Loudmouth 1 Muffler

This analysis has presented an examination of the SLP Loudmouth 1 Muffler, encompassing its potential performance enhancements, construction materials, sound characteristics, ease of installation, and associated considerations. Key points emphasized include the aggressive exhaust tone, the use of stainless steel for durability, the direct bolt-on fitment for simplified installation, and the amplified sound levels necessitating awareness of local regulations. Additionally, the discussion explored the “minimal weight reduction” factor and the importance of durable, lasting component construction.

The acquisition and utilization of the SLP Loudmouth 1 Muffler requires a comprehensive evaluation of its features in relation to individual needs and legal requirements. While the component offers a means to alter a vehicle’s performance and sound profile, responsible application is paramount. Subsequent investigations into specific vehicle compatibility and adherence to sound ordinances should be undertaken before implementing this modification to ensure both optimal performance and compliance.