The undertaking of creating a noise reduction device for pneumatic machinery, utilizing readily available materials and self-directed construction methods, is a resourceful solution for mitigating operational sound emissions. This process typically involves adapting containers, baffles, and sound-absorbing materials to dampen the percussive release of compressed air. An example includes modifying a plastic bottle with strategically placed foam padding to capture and disperse exhaust noise.

Reducing the decibel level of compressed air systems enhances user comfort, particularly in enclosed workspaces, and can contribute to compliance with occupational health and safety standards regarding noise exposure. Historically, individuals and small businesses have employed such techniques to address noise pollution without incurring the expense of commercially manufactured products. This approach fosters ingenuity and promotes sustainable practices through repurposing discarded items.

The following sections will delve into the principles of sound dampening, explore specific design considerations, and provide step-by-step instructions for constructing effective sound suppression devices for air compressors. This will include a materials overview and a discussion of the safety precautions necessary when working with tools and compressed air systems.

Essential Considerations for Noise Reduction Device Construction

The construction of a custom noise reduction device for air compressors requires careful attention to detail and adherence to safety guidelines. The following tips aim to improve the effectiveness and longevity of the created device.

Tip 1: Acoustic Material Selection: Appropriate materials significantly influence noise reduction. Closed-cell foams, dense fabrics, and sound-dampening wraps offer varying degrees of sound absorption. Experimentation with multiple materials may yield optimal results.

Tip 2: Internal Chamber Design: The internal configuration of the device should aim to disrupt the direct path of sound waves. Baffles, offset chambers, and labyrinthine passages can effectively dissipate acoustic energy.

Tip 3: Secure Fastening Methods: Reliable attachment to the air compressor is critical. Vibration-resistant fasteners, such as lock nuts and rubber washers, prevent loosening and maintain the integrity of the device.

Tip 4: Heat Dissipation Considerations: Air compressors generate heat. Ensure the noise reduction device allows for adequate ventilation to prevent overheating. Conductive materials or strategically placed vents can facilitate heat transfer.

Tip 5: Pressure Relief Mechanisms: Implement a pressure relief valve or a controlled escape path to prevent excessive backpressure within the device. This mitigates the risk of damage to the compressor or the noise reduction device itself.

Tip 6: Regular Inspection and Maintenance: Periodic examination of the device’s components is essential. Check for wear, cracks, or material degradation. Replace or repair components as needed to maintain performance and safety.

Tip 7: Noise Level Measurement: Utilize a decibel meter to objectively assess the effectiveness of the constructed device. Record sound levels before and after installation to quantify the noise reduction achieved.

Implementing these tips improves the functionality, safety, and longevity of the fabricated noise reduction device. Careful planning and execution are essential to achieving the desired results.

The subsequent sections of this article will address safety protocols and comprehensive material selection guidelines, ensuring a well-informed and responsible approach to noise reduction device construction.

1. Material Selection

Material selection is a fundamental determinant in the efficacy of homemade air compressor noise reduction devices. The acoustic properties, durability, and thermal resistance of chosen materials directly influence the device’s performance and operational lifespan.

- Acoustic Absorbency

Materials with high acoustic absorbency are essential for attenuating sound waves. Examples include mineral wool, fiberglass, and specialized acoustic foams. These materials convert sound energy into heat, reducing the overall noise level. The specific choice of material must consider its frequency-dependent absorption characteristics to effectively target the compressor’s dominant noise frequencies.

- Casing Material Integrity

The outer casing material provides structural support and containment for the sound-absorbing elements. Robust materials such as thick-walled PVC pipe, metal sheeting, or durable plastics are suitable choices. The selected material should withstand the vibrations and potential impacts associated with air compressor operation. Furthermore, the casing must effectively seal the internal components to prevent sound leakage.

- Thermal Resistance

Air compressors can generate heat during operation, necessitating the use of materials with adequate thermal resistance. Flammable materials should be avoided. Materials like mineral wool offer good thermal insulation properties, preventing heat buildup within the noise reduction device. The selection should account for the compressor’s maximum operating temperature to ensure the device’s structural integrity and prevent material degradation.

- Density and Mass

Denser materials provide a greater barrier to sound transmission. Incorporating dense layers, such as mass-loaded vinyl or thick rubber sheeting, can effectively block sound waves. The mass of the material increases the device’s overall inertia, reducing its susceptibility to vibration and minimizing the transmission of noise through the structure itself.

The careful selection and integration of these materials are crucial for constructing effective and reliable air compressor noise reduction solutions. The appropriate choice maximizes the device’s sound dampening capabilities while ensuring its longevity and operational safety. Experimentation with different material combinations may lead to optimized noise reduction performance.

2. Design Optimization

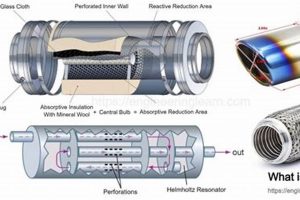

The effectiveness of any “air compressor muffler diy” endeavor hinges directly on design optimization. The internal architecture, dimensions, and materials arrangement function as the primary determinants of noise reduction performance. Poor design inherently limits the muffler’s capability to attenuate sound waves, irrespective of the quality of materials employed. Consider, for example, a straight-through pipe acting as a muffler; it provides minimal noise reduction due to the unimpeded passage of sound. Conversely, a design incorporating multiple expansion chambers, baffling, and sound-absorbing materials forces sound waves to reflect and dissipate energy, leading to a significant reduction in noise levels.

Practical application of design optimization principles involves a systematic approach to muffler construction. This encompasses calculating chamber volumes based on target frequencies, strategically positioning baffles to redirect sound waves, and selecting sound-absorbing materials appropriate for the compressor’s noise profile. The implementation of Helmholtz resonators, tuned to specific frequencies, can further enhance noise cancellation. A well-optimized design also considers backpressure, ensuring it remains within acceptable limits to prevent compressor overheating or performance degradation. Failure to account for these variables results in a suboptimal muffler, potentially offering only marginal improvements over an unmodified exhaust port.

In summary, design optimization represents a crucial component of successful “air compressor muffler diy” projects. It dictates the degree to which noise reduction is achieved and directly influences the compressor’s operational efficiency and longevity. A thorough understanding of acoustic principles and careful consideration of design parameters are essential for maximizing the effectiveness of a self-constructed muffler. The challenges in this area stem from the complexity of acoustic phenomena and the need for precise calculations, highlighting the importance of informed decision-making throughout the design and construction process.

3. Noise Reduction

Noise reduction is the central impetus behind constructing a custom muffler for air compressors. The operational sounds emitted by these devices, often characterized by high decibel levels and sharp frequencies, can contribute to auditory fatigue and disrupt working environments. A focused effort to minimize these emissions directly relates to user comfort and regulatory compliance.

- Acoustic Damping Principles

The core of noise reduction lies in the application of acoustic damping principles. These involve converting sound energy into other forms of energy, typically heat, through absorption, reflection, and diffusion. Materials like closed-cell foam and mineral wool are utilized to absorb sound waves, while baffles strategically placed within the muffler redirect and scatter sound, effectively reducing the sound level. The effectiveness of the muffler is directly proportional to the efficiency with which it implements these principles.

- Frequency Specific Attenuation

Air compressors generate a complex range of frequencies. Effective noise reduction requires targeting the dominant frequencies specific to the compressor model. This necessitates analyzing the compressor’s sound profile and tailoring the muffler design to attenuate those particular frequencies. For instance, Helmholtz resonators, precisely tuned chambers, can be incorporated to cancel out specific frequencies through destructive interference.

- Material Selection and Placement

The selection and placement of materials significantly impact noise reduction. Denser materials, such as mass-loaded vinyl, act as barriers to sound transmission, while porous materials absorb sound energy. Strategic layering of different materials optimizes performance. For example, a dense outer layer coupled with an inner layer of sound-absorbing foam can effectively dampen both low and high-frequency noise.

- Environmental Considerations

Beyond direct noise reduction, environmental factors play a role. Confined spaces amplify noise. An air compressor muffler diy project must consider the operating environment. Enhancements to the space with acoustic panels or room dividers can amplify the noise reduction efforts of the muffler.

These considerations, when properly addressed, transform a standard air compressor into a device that meets not only its intended function, but does so without becoming a source of discomfort or regulatory concern. The success of “air compressor muffler diy” relies on understanding and applying these principles of noise reduction effectively. The integration of sophisticated designs with appropriate material choices offers a tangible and measurable improvement in the acoustic environment.

4. Safety Protocols

Safety protocols are paramount in the construction and implementation of homemade air compressor mufflers. Deviations from established safety guidelines can lead to equipment damage, personal injury, or compromise the device’s functionality. The inherently pressurized nature of air compressor systems demands a rigorous approach to safety throughout the entire process.

- Pressure Relief Mechanisms

Integrating a pressure relief valve is critical to prevent over-pressurization within the DIY muffler. Air compressors generate substantial pressure, and a failure within the muffler, such as blockage, could lead to dangerous pressure buildup. The pressure relief valve acts as a fail-safe, automatically releasing excess pressure and preventing potential explosions or ruptures. Without this safety measure, the risk of catastrophic failure increases substantially.

- Material Compatibility and Temperature Resistance

Selecting materials incompatible with the compressed air environment or prone to degradation at elevated temperatures introduces significant safety risks. Certain plastics, for example, may weaken or become brittle when exposed to pressurized air or the heat generated by the compressor. Employing materials rated for the expected pressure and temperature range is essential to prevent structural failure and the release of hazardous debris.

- Secure Fastening and Connections

Ensuring secure and reliable connections between the muffler and the air compressor is vital. Vibration and pressure fluctuations can loosen poorly secured fittings, leading to air leaks or complete detachment of the muffler. This presents a hazard, as the sudden release of pressurized air can cause injury. Properly sized fittings, thread sealants, and robust fastening methods mitigate the risk of accidental disconnections.

- Hearing Protection and Workspace Safety

Despite the muffling efforts, the air compressor may still emit significant noise levels. Wearing appropriate hearing protection during operation is crucial to prevent long-term auditory damage. Additionally, maintaining a clear and organized workspace reduces the risk of accidents. Securing the air compressor and muffler to prevent tipping or movement further enhances safety.

Adherence to these safety protocols is not merely a recommendation, but a fundamental requirement for engaging in “air compressor muffler diy.” Neglecting these precautions introduces unacceptable risks. A thorough understanding of air compressor systems, material properties, and safety best practices is imperative for safe and successful muffler construction.

5. Performance Evaluation

Rigorous performance evaluation is an indispensable step in the “air compressor muffler diy” process. It provides quantifiable data regarding the efficacy of the constructed device, ensuring that it meets the intended noise reduction goals without compromising the air compressor’s operational parameters. Without such evaluation, the project remains speculative, lacking evidence of genuine improvement.

- Decibel Level Measurement

Quantifying the sound reduction achieved by the DIY muffler is paramount. Decibel meters are employed to measure sound pressure levels at a consistent distance from the compressor, both before and after muffler installation. The difference in decibel readings provides a clear indication of the muffler’s noise attenuation capability. A statistically significant reduction is crucial to validate the muffler’s effectiveness. For instance, a reduction from 90 dB to 75 dB is a measurable improvement, signifying a substantial decrease in perceived loudness.

- Backpressure Assessment

While noise reduction is the primary objective, it must not come at the expense of the air compressor’s performance. Excessive backpressure within the muffler can impede airflow, leading to decreased efficiency, overheating, and potential damage to the compressor. Manometers are used to measure backpressure, ensuring it remains within the manufacturer’s specified limits. Elevated backpressure necessitates design modifications to optimize airflow while maintaining noise reduction.

- Frequency Spectrum Analysis

Air compressors generate a wide range of frequencies, and mufflers may be more effective at attenuating certain frequencies than others. Spectrum analyzers provide a detailed breakdown of the sound frequencies produced by the compressor, allowing for targeted muffler design. For example, if the compressor exhibits a prominent peak at 1 kHz, the muffler can be specifically tuned to attenuate that frequency. This targeted approach maximizes noise reduction effectiveness.

- Operational Temperature Monitoring

The muffler’s presence can potentially affect the air compressor’s operating temperature. Inadequate ventilation or insulation within the muffler can lead to heat buildup, potentially causing the compressor to overheat. Temperature sensors are used to monitor the compressor’s temperature during operation with the muffler installed. Significant temperature increases necessitate design adjustments to improve ventilation or reduce insulation, ensuring the compressor operates within safe temperature limits.

These performance evaluation techniques provide concrete data, guiding design refinements and ensuring that the “air compressor muffler diy” project achieves the desired noise reduction while maintaining the air compressor’s operational integrity. These measurements transform the effort from a speculative project into an evidence-based enhancement.

6. Durability Enhancement

Durability enhancement represents a critical facet of any successful “air compressor muffler diy” project. The operational environment of air compressors, characterized by vibrations, pressure fluctuations, and potential exposure to environmental elements, necessitates the construction of a muffler capable of withstanding these stresses over an extended period. A poorly constructed muffler, susceptible to premature failure, not only negates the initial noise reduction benefits but also poses potential safety hazards and requires repetitive replacement efforts. Consider, for instance, a muffler constructed from thin-walled PVC pipe exposed to high temperatures; the pipe may deform or crack, rendering the muffler ineffective and potentially releasing hazardous fragments. Therefore, a deliberate focus on durability is paramount for long-term success.

The selection of robust materials and the implementation of sound construction techniques are central to durability enhancement. High-density plastics, reinforced metal casings, and vibration-resistant fasteners contribute significantly to the muffler’s structural integrity. Furthermore, internal components, such as baffles and sound-absorbing materials, must be securely affixed to prevent displacement or degradation due to constant vibration. The implementation of protective coatings, such as rust-resistant paints or weather-resistant sealants, can further enhance the muffler’s resilience against environmental factors. A practical example is a muffler designed with a steel outer casing and internally reinforced baffles, coupled with high-temperature-rated sound-absorbing materials; this construction inherently possesses a significantly longer lifespan compared to a muffler constructed from lower-quality materials without reinforcement.

In conclusion, durability enhancement is not merely an ancillary consideration but an integral component of “air compressor muffler diy”. It directly impacts the muffler’s long-term performance, safety, and economic viability. By prioritizing robust material selection, sound construction practices, and protective measures, individuals can ensure that their homemade mufflers provide sustained noise reduction benefits and withstand the rigors of the air compressor’s operating environment. The challenges involved highlight the need for a thorough understanding of material properties and construction techniques, underscoring the importance of informed decision-making throughout the project’s lifecycle.

Frequently Asked Questions

This section addresses prevalent inquiries regarding the construction and application of homemade air compressor mufflers. It aims to provide clarity on critical aspects of the process.

Question 1: What are the primary risks associated with constructing a homemade air compressor muffler?

The most significant risks include potential over-pressurization leading to explosions, use of incompatible materials resulting in structural failure, and the creation of excessive backpressure that damages the air compressor. Proper pressure relief mechanisms and careful material selection are crucial.

Question 2: What materials are suitable for sound absorption in a DIY air compressor muffler?

Effective materials include mineral wool, fiberglass batting, and closed-cell acoustic foam. The selection should consider the material’s sound absorption coefficient, thermal resistance, and compatibility with the compressor’s operating environment.

Question 3: How can backpressure be minimized in a DIY air compressor muffler design?

Backpressure reduction is achieved through strategic chamber sizing, optimized baffle placement, and ensuring adequate airflow pathways within the muffler. Pressure gauges should be employed to monitor backpressure levels during operation.

Question 4: Is it possible to achieve significant noise reduction with a homemade air compressor muffler?

Substantial noise reduction is attainable with a well-designed and constructed muffler. The extent of reduction depends on factors such as material selection, internal design, and the specific noise profile of the air compressor. Measurement with a decibel meter is necessary to quantify the results.

Question 5: What safety precautions should be observed during the construction and use of a DIY air compressor muffler?

Essential precautions include wearing hearing protection, utilizing pressure relief valves, ensuring secure connections to prevent air leaks, and avoiding the use of flammable materials. A clear and well-ventilated workspace is also crucial.

Question 6: How can the durability of a homemade air compressor muffler be maximized?

Durability is enhanced through the use of robust casing materials, vibration-resistant fasteners, and protective coatings to shield against environmental elements. Regular inspection and maintenance are essential for identifying and addressing potential issues.

The information provided aims to address common concerns and promote a safe and informed approach to DIY air compressor muffler construction.

The next section will provide a summary, encapsulating the key aspects discussed within this article.

Conclusion

The preceding exploration of air compressor muffler diy has illuminated critical aspects of design, material selection, safety, and performance evaluation. The construction of effective noise reduction devices necessitates a comprehensive understanding of acoustic principles, coupled with meticulous attention to detail and adherence to established safety protocols. The judicious application of these principles yields measurable reductions in operational noise, contributing to enhanced user comfort and compliance with regulatory standards.

The information contained herein serves as a foundation for informed decision-making in the pursuit of self-directed noise mitigation solutions. It encourages a responsible and innovative approach to addressing the challenges associated with air compressor noise pollution. The successful implementation of air compressor muffler diy projects demands a commitment to both technical proficiency and unwavering safety consciousness, ensuring a beneficial outcome for all stakeholders.