The specified component designates a particular aftermarket exhaust part designed to replace the factory-installed muffler in a vehicle’s exhaust system. It is engineered to alter the sound characteristics and potentially improve the exhaust flow of the engine. This specific part number identifies a product within the FlowFX series, known for its performance enhancements and distinct sound profile.

This type of replacement part is frequently utilized by automotive enthusiasts seeking to modify their vehicle’s sound and performance. Potential benefits include a more aggressive exhaust note, and under certain conditions, improvements in horsepower and torque. The development and adoption of such components reflect a long-standing interest in vehicle customization and performance optimization within the automotive community.

The subsequent discussion will elaborate on the specifications, installation considerations, performance expectations, and overall value proposition associated with performance mufflers. It will also touch upon the potential impact on vehicle emissions and compliance with local regulations.

Installation and Usage Considerations

This section provides crucial guidance for users considering or having installed the specified performance muffler.

Tip 1: Verify Compatibility: Ensure the specified exhaust component is compatible with the target vehicle’s make, model, and year before purchase and installation. Consult manufacturer specifications or a qualified automotive technician.

Tip 2: Professional Installation: While some may attempt self-installation, engaging a qualified exhaust technician is highly recommended. Proper welding, alignment, and leak checks are crucial for optimal performance and longevity.

Tip 3: Exhaust System Integrity: Prior to installing the replacement muffler, thoroughly inspect the existing exhaust system for rust, leaks, or damage. Address any pre-existing issues to maximize the benefits of the new component and prevent future problems.

Tip 4: Consider Local Regulations: Be aware of local noise ordinances and emissions regulations. The installation of an aftermarket muffler may alter the vehicle’s sound profile and potentially affect its compliance with applicable laws. Research relevant regulations beforehand.

Tip 5: Monitor Performance: After installation, monitor the vehicle’s performance and fuel economy. While performance gains are possible, they may not be immediately apparent and can vary depending on driving conditions and vehicle modifications.

Tip 6: Periodic Inspection: Regularly inspect the muffler and exhaust system for leaks, damage, or corrosion. Promptly address any issues to maintain optimal performance and prevent costly repairs.

Tip 7: Proper Maintenance: Clean the exhaust tips periodically to prevent corrosion and maintain aesthetic appeal. Use appropriate cleaning products designed for stainless steel or other materials used in the muffler’s construction.

Adherence to these recommendations will contribute to a successful installation, ensure optimal performance, and maximize the lifespan of the specified aftermarket exhaust component.

The following section will explore the potential long-term impacts of this type of modification and strategies for mitigating potential drawbacks.

1. Sound Characteristics

The sound characteristics of the specified muffler represent a primary factor influencing consumer choice and perceived value. The FlowFX series, to which the part belongs, is generally engineered to produce a more aggressive and noticeable exhaust note compared to factory-installed mufflers. This altered sound results from the internal design of the muffler, which typically incorporates less restrictive baffling or chambering, modifying the way exhaust gases resonate and exit the system. The resulting sound profile often includes increased volume, a deeper tone, and a reduction in high-frequency noise. For example, a vehicle equipped with this muffler will exhibit a more pronounced rumble at idle and a louder, more assertive sound during acceleration.

The specific sound characteristics are also influenced by the vehicle’s engine type, exhaust system configuration, and the presence of other aftermarket components. For instance, on a V8 engine, the muffler will generally produce a deeper and louder tone than on a smaller inline-four engine. Furthermore, the installation of headers or a high-flow catalytic converter, in conjunction with the muffler, can further amplify and modify the exhaust sound. The perceived quality of the sound, including the absence of raspiness or drone, is also a crucial consideration for many consumers.

Ultimately, the sound characteristics of the muffler are a subjective matter, with preferences varying among individuals. However, understanding the design principles that contribute to the sound, such as chamber size, baffle configuration, and material composition, allows for a more informed purchasing decision. It is essential to consider local noise regulations and personal preferences when selecting the muffler, as excessive noise levels can be disruptive and potentially illegal. Selecting the correct product is thus crucial to customer satisfaction.

2. Exhaust Flow

The specified performance muffler directly influences exhaust flow, which is a critical determinant of engine performance. The flowmaster 71416 flowfx muffler is designed to reduce backpressure compared to OEM (Original Equipment Manufacturer) mufflers. Reduced backpressure allows exhaust gases to exit the engine more efficiently, potentially leading to increased horsepower and torque, especially at higher RPMs. For example, dyno testing of a vehicle before and after installation of this type of muffler might demonstrate a measurable increase in peak horsepower and a shift in the torque curve. This enhancement occurs because the engine expends less energy pushing exhaust gases out, thereby freeing up power to drive the wheels.

The internal construction of the muffler dictates its flow characteristics. Straight-through designs, often found in performance mufflers, provide a less restrictive path for exhaust gases compared to baffled or chambered designs commonly used in factory mufflers to reduce noise. However, achieving optimal exhaust flow involves a delicate balance. Excessively free-flowing exhaust can, in some cases, reduce low-end torque due to decreased scavenging effects within the exhaust manifold. Therefore, matching the muffler to the specific engine characteristics and intended use of the vehicle is essential. A properly selected and installed muffler enhances engine breathing, promoting efficient combustion and improved performance.

In conclusion, the relationship between the specified performance muffler and exhaust flow is one of cause and effect. The design of the muffler directly impacts the flow of exhaust gases, which, in turn, affects engine performance. Understanding this relationship is crucial for automotive enthusiasts seeking to optimize their vehicle’s power output and overall driving experience, while taking into consideration the potential trade-offs and the importance of matching the muffler to the vehicle’s specific needs.

3. Vehicle Compatibility

Vehicle compatibility represents a fundamental consideration when evaluating the suitability of the flowmaster 71416 flowfx muffler for a particular application. Incorrect fitment can lead to installation difficulties, compromised performance, and potential damage to the vehicle’s exhaust system. Proper matching ensures the muffler integrates seamlessly with the existing exhaust components, maximizing its intended benefits.

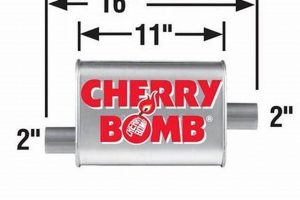

- Exhaust Pipe Diameter

The inlet and outlet diameters of the muffler must precisely match the existing exhaust piping on the target vehicle. Mismatched diameters necessitate the use of adapters, which can introduce turbulence and restrict exhaust flow, negating the performance benefits of the aftermarket muffler. An example includes a vehicle with 2.25-inch diameter exhaust pipes requiring a muffler with corresponding dimensions to ensure a direct, uncompromised connection.

- Muffler Dimensions and Chassis Clearance

Physical dimensions of the flowmaster 71416 flowfx muffler, including length, width, and height, must be compatible with the available space under the vehicle’s chassis. Insufficient clearance can result in the muffler contacting other components, leading to noise, vibration, and potential damage. Furthermore, improper fitment can affect ground clearance, increasing the risk of scraping or damage from road hazards.

- Hanger Locations and Mounting Points

The location and configuration of the muffler hangers must align with the existing mounting points on the vehicle’s frame or exhaust system. Mismatched hanger locations require modifications, such as welding or fabrication, which can compromise the structural integrity of the exhaust system and increase installation costs. Accurate alignment ensures the muffler is securely supported, preventing stress on the exhaust pipes and minimizing vibration.

- Engine Type and Displacement

While physical fitment is critical, the flowmaster 71416 flowfx muffler’s internal design should also be appropriate for the vehicle’s engine type and displacement. A muffler designed for a large displacement V8 engine may not perform optimally on a smaller inline-four engine, potentially leading to reduced torque or undesirable sound characteristics. Matching the muffler’s flow capacity to the engine’s requirements ensures efficient exhaust scavenging and optimal performance gains.

In conclusion, thorough verification of vehicle compatibility is paramount before purchasing and installing the flowmaster 71416 flowfx muffler. Careful consideration of exhaust pipe diameter, muffler dimensions, hanger locations, and engine specifications ensures proper fitment, optimal performance, and long-term reliability. Consulting manufacturer specifications and seeking professional advice can mitigate the risk of incompatibility and maximize the benefits of the aftermarket exhaust component.

4. Material Durability

Material durability is a critical attribute directly impacting the lifespan and performance of the flowmaster 71416 flowfx muffler. The exhaust system is subject to extreme conditions, including high temperatures, corrosive gases, road salts, and physical impacts. The materials used in the muffler’s construction must withstand these challenges to prevent premature failure and maintain optimal functionality. For example, a muffler constructed from low-grade steel will corrode rapidly in regions with harsh winters, leading to exhaust leaks, reduced performance, and the need for replacement. Conversely, a muffler made from high-quality stainless steel will resist corrosion, ensuring a longer service life and consistent performance.

The specific alloy and gauge of the materials used directly influence the muffler’s ability to withstand these environmental stressors. Thicker gauge materials provide greater resistance to physical damage from road debris and impacts. Furthermore, the quality of the welds and the application of protective coatings contribute significantly to overall durability. For example, a muffler with poorly executed welds is susceptible to cracking and failure under stress, while a protective coating can shield the underlying metal from corrosion. The choice of materials and construction techniques is a direct reflection of the manufacturer’s commitment to longevity and performance.

In conclusion, the material durability of the flowmaster 71416 flowfx muffler is a crucial factor determining its long-term value and performance. Selecting a muffler constructed from high-quality, corrosion-resistant materials ensures extended service life, reliable performance, and protection against the harsh conditions encountered in the exhaust system environment. Ignoring this aspect can lead to frequent replacements and diminished performance, ultimately costing more in the long run. This element must therefore be central to purchase considerations.

5. Installation Complexity

The installation complexity associated with the flowmaster 71416 flowfx muffler significantly influences the overall cost and satisfaction derived from its use. Several factors contribute to this complexity, ranging from basic mechanical skills to specialized tools and knowledge of exhaust system dynamics.

- Direct-Fit Replacement vs. Universal Fit

The ease of installation is largely determined by whether the muffler is designed as a direct-fit replacement for the original equipment manufacturer (OEM) muffler or as a universal-fit component. A direct-fit muffler is engineered to match the dimensions and mounting points of the OEM part, requiring minimal modification for installation. Conversely, a universal-fit muffler often necessitates cutting, welding, and fabrication to adapt to the vehicle’s existing exhaust system. For example, a direct-fit flowmaster 71416 flowfx muffler would bolt directly into the existing hangers, while a universal version may require custom brackets to be welded onto the exhaust pipes. This distinction impacts the time required for installation and the level of expertise necessary.

- Required Tools and Equipment

The installation process may demand a range of specialized tools and equipment, affecting the complexity. Basic tools such as wrenches, sockets, and screwdrivers are typically required. However, more complex installations may necessitate access to a welder, cutting torch, and pipe bender. Furthermore, safety equipment, including eye protection and gloves, is essential to prevent injury. The availability of these tools and the installer’s proficiency in their use directly correlate with the ease and success of the installation process. The absence of necessary tools can significantly prolong the installation or result in a substandard outcome.

- Exhaust System Condition and Accessibility

The condition of the existing exhaust system and its accessibility play a crucial role in installation complexity. A corroded or damaged exhaust system can hinder the removal of the OEM muffler, requiring additional effort to disassemble rusted bolts or cut through seized connections. Limited access to the exhaust system due to the vehicle’s design or the presence of other components can further complicate the process. For instance, on some vehicles, it may be necessary to remove suspension components or heat shields to gain sufficient access to the muffler. These factors can significantly increase the time and effort required for installation.

- Welding Requirements and Skill Level

As noted previously, universal-fit installations often necessitate welding to properly connect the flowmaster 71416 flowfx muffler to the existing exhaust system. Welding requires a high degree of skill and experience to ensure a strong, leak-free joint. Improper welding can result in exhaust leaks, reduced performance, and potential safety hazards. Furthermore, welding can alter the properties of the surrounding metal, making it more susceptible to corrosion. The presence of welding requirements significantly increases the installation complexity and may necessitate professional assistance.

In summary, the installation complexity associated with the flowmaster 71416 flowfx muffler is influenced by a combination of factors, including the fitment type, tool requirements, exhaust system condition, and the need for welding. Understanding these factors allows prospective buyers to assess their own capabilities and determine whether professional installation is necessary, ensuring a successful outcome and avoiding potential complications.

6. Regulatory Compliance

The intersection of regulatory compliance and the flowmaster 71416 flowfx muffler centers on noise emission standards and exhaust modification restrictions mandated by federal, state, and local authorities. Aftermarket exhaust components, including mufflers, are often subject to specific decibel limits, and their installation can affect a vehicle’s adherence to these regulations. The 71416 FlowFX muffler, designed to alter exhaust sound, has the potential to increase noise levels beyond legal thresholds in certain jurisdictions. For instance, many municipalities have noise ordinances that prohibit excessively loud vehicles, and installing an aftermarket muffler that violates these ordinances can result in fines or citations. A vehicle originally certified as compliant may lose that status after modification.

Furthermore, some regions have regulations concerning modifications to a vehicle’s emission control system. Although the 71416 FlowFX muffler is primarily a sound-altering device and not directly involved in catalytic conversion or other emission control processes, its installation can indirectly affect emissions compliance. For example, alterations to the exhaust system that increase exhaust flow can, in some cases, impact the performance of the catalytic converter, potentially leading to increased emissions. In states with stringent emission testing programs, vehicles with modified exhaust systems may fail inspection if emissions levels exceed permissible limits. California, for instance, has specific regulations regarding aftermarket exhaust systems and requires them to be CARB (California Air Resources Board) compliant to be legally used on vehicles registered in the state. This places the onus on the vehicle owner to ensure the selected muffler meets these standards.

In conclusion, navigating the complexities of regulatory compliance when installing the flowmaster 71416 flowfx muffler requires careful consideration of both noise emission standards and potential impacts on exhaust emissions. Vehicle owners should research local regulations, ensure the selected muffler is compliant with these regulations, and be prepared to demonstrate compliance during vehicle inspections. Failure to adhere to these requirements can result in legal penalties and negate the intended benefits of the aftermarket exhaust component. This underlines the importance of responsible modification and adherence to legal frameworks.

Frequently Asked Questions Regarding the flowmaster 71416 flowfx muffler

This section addresses common inquiries and clarifies misconceptions surrounding the installation and performance characteristics of the specified aftermarket muffler.

Question 1: Does the flowmaster 71416 flowfx muffler guarantee a specific horsepower increase?

The installation of the flowmaster 71416 flowfx muffler does not guarantee a fixed horsepower increase. Performance gains are contingent upon various factors, including engine type, existing modifications, and the overall condition of the vehicle’s exhaust system. While the muffler is designed to improve exhaust flow, the actual increase in horsepower may vary.

Question 2: Is professional installation required for the flowmaster 71416 flowfx muffler?

Professional installation is strongly recommended, although not always strictly required. Proper welding, alignment, and leak checks are crucial for optimal performance and longevity. Individuals lacking the necessary skills and equipment should seek professional assistance to avoid potential complications and ensure proper fitment.

Question 3: Will the flowmaster 71416 flowfx muffler cause my vehicle to fail an emissions test?

The flowmaster 71416 flowfx muffler is not designed to interfere with the vehicle’s emission control system. However, alterations to the exhaust system can, in some cases, impact emissions levels. It is incumbent upon the vehicle owner to ensure compliance with local emissions regulations following installation.

Question 4: Does the flowmaster 71416 flowfx muffler come with a warranty?

Warranty coverage for the flowmaster 71416 flowfx muffler varies depending on the retailer and manufacturer policies. Potential purchasers should consult the warranty documentation provided at the time of purchase to understand the terms and conditions of coverage.

Question 5: Is the flowmaster 71416 flowfx muffler street legal in all states?

The legality of the flowmaster 71416 flowfx muffler varies depending on local noise ordinances and exhaust modification regulations. It is incumbent upon the vehicle owner to research and comply with all applicable laws in their jurisdiction.

Question 6: How does the flowmaster 71416 flowfx muffler compare to other mufflers in terms of sound?

The flowmaster 71416 flowfx muffler typically produces a more aggressive and noticeable exhaust note compared to factory-installed mufflers. However, the specific sound characteristics may vary depending on the vehicle’s engine type and exhaust system configuration. Objective comparisons are best achieved through sound clips or in-person demonstrations.

The flowmaster 71416 flowfx muffler represents a component with potential benefits and considerations. Understanding these nuances facilitates informed decision-making and responsible vehicle modification.

The succeeding section will focus on maintenance strategies related to the flowmaster 71416 flowfx muffler to prolong its functional lifespan.

Conclusion

This exposition has detailed several facets of the flowmaster 71416 flowfx muffler, including its design objectives, performance implications, installation considerations, and regulatory compliance. The component’s impact extends from altering a vehicle’s sound profile and exhaust flow to requiring a comprehensive understanding of vehicle compatibility and legal limitations. It is crucial to acknowledge that integrating this aftermarket component is not a simple endeavor but a decision with potential ramifications for both vehicle performance and regulatory adherence.

Therefore, prospective users must carefully evaluate their requirements, technical capabilities, and applicable legal frameworks before proceeding with the installation of the flowmaster 71416 flowfx muffler. A well-informed approach ensures that the benefits are realized responsibly, aligning with both performance goals and adherence to established standards. Prudent implementation will safeguard the vehicle’s operational integrity while satisfying the owner’s desire for enhanced functionality.

![Intermountain Radiator & Muffler: [City/Region] Exhaust Experts Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Intermountain Radiator & Muffler: [City/Region] Exhaust Experts | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-25-300x200.jpg)