A vehicle component designed to reduce the noise emitted from the engine’s exhaust system. Functionally, this part uses chambers and tubes strategically designed to reflect sound waves, causing them to cancel each other out and thereby decreasing the overall noise level. A defective or improperly installed component can lead to increased noise pollution and potential vehicle performance issues.

The incorporation of this technology in automotive design provides multiple advantages. Beyond mitigating noise, contributing to a more pleasant environment, it plays a role in meeting regulatory standards concerning noise emissions. Historically, the evolution of these components mirrors advancements in automotive engineering, with modern designs often incorporating catalytic converters to further reduce harmful emissions, showcasing an integrated approach to performance and environmental responsibility.

Understanding the function and maintenance of such components is crucial for both vehicle owners and automotive professionals. Subsequent sections will delve into specific aspects, including common issues, maintenance best practices, and the impact of aftermarket options on vehicle performance and emissions.

Essential Guidance for Muffler Maintenance and Longevity

Proper upkeep of exhaust components is crucial for optimal vehicle performance, regulatory compliance, and noise reduction. Adhering to these guidelines ensures extended lifespan and mitigates potential issues.

Tip 1: Regular Visual Inspection: Conduct routine visual checks for signs of corrosion, damage, or leaks. Early detection prevents further deterioration and costly repairs. For example, rust accumulation on the outer casing warrants immediate attention.

Tip 2: Monitor Exhaust Noise Levels: Any noticeable increase in exhaust volume signals a potential problem. This could indicate a hole, crack, or failing internal baffle. Prompt diagnosis is necessary to prevent further damage.

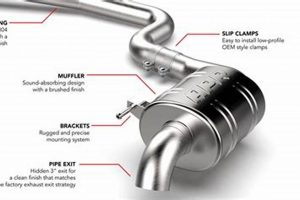

Tip 3: Address Unusual Vibrations: Excessive vibrations emanating from the exhaust system might indicate loose mounting hardware or internal component failure. Tighten or replace worn-out hangers and brackets to restore stability.

Tip 4: Avoid Short Trips When Possible: Frequent short trips fail to allow the exhaust system to reach optimal operating temperature, leading to moisture buildup and accelerated corrosion. Opt for longer routes when feasible to promote evaporation.

Tip 5: Ensure Proper Drainage: Condensation can accumulate within the muffler. Verify that drainage holes are clear to prevent water retention and subsequent rust formation. Use a small wire to clear any blockages.

Tip 6: Consider Rust Inhibitors: Applying rust-inhibiting coatings to the exterior surface can significantly extend the lifespan, particularly in regions with high road salt usage. Follow manufacturer instructions for application.

Tip 7: Promptly Replace Worn Components: Ignoring minor issues inevitably leads to major problems. Replace failing components, such as hangers or clamps, without delay to prevent consequential damage.

Adherence to these guidelines promotes longevity, reduces noise pollution, and helps to maintain efficient vehicle operation.

The subsequent sections will further address specific diagnostic procedures and replacement options for optimal exhaust system performance.

1. Noise Reduction

The primary function of an automotive exhaust component is the attenuation of engine noise. The effectiveness of this process directly correlates to the internal design and construction of the unit. Specifically, a well-designed component employs a series of chambers, resonators, and baffling systems to manipulate and reduce the amplitude of sound waves generated by the combustion process. Without adequate noise reduction, vehicles would produce excessive noise pollution, leading to regulatory violations and diminished quality of life in urban environments. For example, improperly baffled systems can generate noise levels exceeding permissible limits, resulting in fines and vehicle inspection failures.

Achieving optimal noise reduction necessitates a balance between sound attenuation and exhaust flow. Excessive restrictions within the component can diminish engine performance by increasing backpressure. Therefore, the design must carefully balance sound dampening features with minimal flow impedance. Modern designs often incorporate sophisticated computer modeling to optimize this trade-off. Furthermore, material selection plays a critical role. The gauge and composition of the steel used directly impact its ability to dampen vibrations and withstand the corrosive environment of exhaust gases. For instance, stainless steel variants offer superior corrosion resistance and often exhibit enhanced noise reduction capabilities compared to standard aluminized steel.

Effective noise reduction is not merely a matter of regulatory compliance; it directly influences the overall driving experience and environmental impact of vehicles. While design and material selection are critical, proper installation and maintenance are equally important. Leaks or damage to the system can compromise its noise-reducing capabilities. Therefore, regular inspections and timely repairs are essential to ensure continued effectiveness. The combination of advanced design, durable materials, and diligent maintenance ensures that exhaust components effectively mitigate noise pollution, contributing to a quieter and more environmentally responsible transportation ecosystem.

2. Exhaust Flow

Exhaust flow, defined as the rate at which combustion byproducts are expelled from an engine, is intrinsically linked to the operation of this component. This component is designed to manage the velocity and volume of exhaust gases, impacting both engine performance and emissions. Restrictions to flow within this part increase backpressure, potentially diminishing engine power and fuel efficiency. A well-designed unit optimizes flow by employing internal structures that minimize turbulence and resistance. For example, a component with excessively restrictive baffling can significantly reduce horsepower, whereas a free-flowing design enhances performance, albeit potentially at the expense of noise reduction.

The internal architecture of the component directly dictates the characteristics of exhaust flow. Straight-through designs offer minimal restriction, favored in performance applications. Chambered designs, while providing superior noise reduction, inherently introduce more resistance. Consider aftermarket options; these often advertise improved flow rates, but their effectiveness depends on the specific engine and exhaust system configuration. Furthermore, the diameter of the inlet and outlet pipes impacts flow capacity, necessitating careful matching to the engine’s displacement and power output. Modifications such as increasing pipe diameter without corresponding engine tuning can sometimes yield negligible or even negative performance results.

Understanding the relationship between exhaust flow and this component is crucial for both performance optimization and ensuring regulatory compliance. Selecting a component that appropriately balances flow characteristics with noise reduction requirements is essential. The consequence of ignoring this interaction is reduced engine lifespan and excessive noise pollution, while proactive management leads to optimal performance and environmental responsibility.

3. Material Durability

The longevity and operational effectiveness of a vehicle’s exhaust component are directly correlated with the durability of the materials used in its construction. Exhaust systems are subjected to extreme conditions, including high temperatures, corrosive exhaust gases, road salts, and physical impacts. Therefore, material selection dictates the lifespan and performance of the component. Insufficient durability results in premature failure, leading to increased noise pollution, potential emissions violations, and the necessity for frequent replacements. For example, a component constructed from low-grade steel will corrode rapidly in regions with high road salt usage, whereas a stainless steel variant may withstand similar conditions for significantly longer periods.

The relationship between material durability and exhaust component function manifests through several mechanisms. Corrosion weakens the structural integrity, leading to leaks and diminished noise reduction capabilities. Thermal stress causes fatigue and cracking, further compromising the component’s effectiveness. The choice of material directly influences its resistance to these factors. Stainless steel alloys, such as 304 or 409 stainless, offer superior corrosion resistance and high-temperature strength compared to aluminized steel or mild steel. This translates to a longer service life, reduced maintenance costs, and consistent performance over time. The practical significance of this understanding lies in the ability to make informed decisions when selecting replacement parts, prioritizing durable materials to minimize future issues. For instance, an individual residing in a coastal area with high humidity would greatly benefit from a stainless steel component over a less durable alternative.

In summary, material durability is a critical factor affecting the performance, lifespan, and overall value of exhaust components. Selecting materials appropriate for the operating environment and application extends the component’s service life, reduces the risk of failure, and ensures continued compliance with noise and emissions regulations. The challenges associated with material selection include balancing cost considerations with long-term durability needs. However, prioritizing durable materials ultimately proves more cost-effective due to reduced replacement frequency and improved vehicle performance.

4. Regulatory Compliance

Adherence to established vehicular noise and emissions standards is a critical function directly impacted by the performance of exhaust system components. These regulations, enforced at the local, state, and federal levels, dictate permissible noise levels and limit the release of harmful pollutants into the atmosphere. A malfunctioning or non-compliant exhaust component directly contravenes these established legal requirements. For example, a component lacking adequate sound dampening capabilities may produce excessive noise levels, resulting in fines or vehicle inspection failure. Similarly, a component that bypasses or impairs the function of catalytic converters can lead to elevated emissions of pollutants such as hydrocarbons, nitrogen oxides, and carbon monoxide, resulting in similar penalties and contributing to environmental degradation. Regulatory compliance, therefore, functions as a fundamental requirement of exhaust system design and maintenance.

The practical significance of regulatory compliance extends beyond the avoidance of fines and penalties. Functioning exhaust systems mitigate environmental impact and contribute to public health and well-being. Specific standards, such as those outlined by the Environmental Protection Agency (EPA) in the United States or similar regulatory bodies in other countries, establish concrete thresholds for pollutant emissions. Exhaust system components must demonstrably meet these standards to ensure legal vehicle operation. Modification of these components or the installation of aftermarket parts must be scrutinized to confirm continued compliance. For instance, aftermarket components advertised as performance enhancements require verification of their impact on emissions. Ignoring regulatory compliance exposes vehicle operators to legal repercussions and undermines broader societal efforts to reduce air pollution.

In summary, regulatory compliance stands as a non-negotiable aspect of exhaust system design, maintenance, and modification. A component’s ability to meet established noise and emissions standards directly influences its legality and environmental impact. Challenges associated with achieving compliance include balancing performance enhancements with regulatory requirements and ensuring the proper functioning of emission control devices. However, adhering to these regulations promotes responsible vehicle operation, safeguards public health, and contributes to a sustainable environment. Continued focus on compliance is crucial for both individual vehicle owners and the automotive industry as a whole.

5. Installation Quality

The effectiveness of any vehicle exhaust component is inextricably linked to the quality of its installation. Even the most meticulously engineered and durable component will fail to deliver optimal performance if improperly installed. Poor installation practices create numerous problems, ranging from exhaust leaks and reduced engine performance to potential safety hazards. Consider a scenario where the component’s mounting brackets are not securely fastened; the resultant vibrations can cause premature failure, leading to exhaust leaks and increased noise pollution. Furthermore, improper alignment of connecting pipes can create excessive stress on joints, accelerating corrosion and necessitating costly repairs. The importance of skilled installation as an integral element is underscored by the direct correlation between proper execution and long-term performance.

Practical examples illustrate the critical significance of quality installation. A component improperly sealed at its connection points will emit exhaust gases into the passenger cabin, posing a health risk to occupants. Insufficient clearance between the component and other vehicle components can lead to overheating and potential fire hazards. Furthermore, over-tightening of fasteners can damage the component or the vehicle’s exhaust manifold, requiring additional repairs. Automotive professionals, therefore, adhere to strict installation procedures, utilizing torque specifications and appropriate sealing compounds to ensure a secure and leak-free connection. This meticulous approach is essential for maximizing the component’s lifespan and ensuring compliance with emissions regulations. Aftermarket components, while sometimes offering performance gains, require particular attention during installation to ensure compatibility and prevent damage to the vehicle’s exhaust system.

In summary, installation quality is not merely a supplementary consideration; it forms an essential component of this system’s effectiveness. Improper installation practices negate the benefits of even the highest-quality components, leading to performance degradation, safety hazards, and potential regulatory violations. The challenges associated with ensuring quality installation lie in the need for skilled technicians, adherence to proper procedures, and the use of appropriate tools and materials. However, prioritizing quality installation yields significant returns in terms of component lifespan, vehicle performance, and overall safety. Therefore, meticulous installation procedures are crucial for maximizing the benefits of any automotive exhaust component.

6. Maintenance Schedule

The operational lifespan and efficiency of this critical vehicle component is fundamentally linked to adherence to a structured maintenance schedule. Neglecting recommended maintenance intervals precipitates premature degradation, resulting in increased noise emissions, reduced fuel efficiency, and potential regulatory non-compliance. A proactive maintenance schedule serves as a preventative measure, mitigating the impact of corrosion, thermal stress, and physical damage. For example, a vehicle operated in a region with heavy road salt application necessitates more frequent inspections and protective treatments than one driven in a drier climate. Consistent maintenance, therefore, minimizes the long-term cost of operation and extends the effective lifespan of this part.

The maintenance schedule encompasses various inspection and service procedures tailored to specific vehicle models and operating conditions. Regular visual inspections detect early signs of corrosion, physical damage, or loose mounting hardware. Periodic cleaning removes accumulated debris and prevents the obstruction of drainage holes, mitigating the risk of internal corrosion. The replacement of worn or damaged mounting brackets and hangers ensures proper alignment and prevents excessive vibrations. A well-documented maintenance history facilitates accurate diagnosis and timely repairs, optimizing system performance and minimizing potential downtime. Consider the scenario of a delivery vehicle operating under demanding conditions; a consistent maintenance schedule is paramount for ensuring reliability and minimizing operational disruptions.

In conclusion, the implementation of a comprehensive maintenance schedule is not merely a supplementary task but a fundamental requirement for preserving the functional integrity and extending the service life of this component. The challenges associated with adherence to a maintenance schedule, such as time constraints and financial considerations, are outweighed by the long-term benefits of reduced repair costs, enhanced vehicle performance, and environmental responsibility. Prioritizing maintenance ensures continued compliance with noise and emissions regulations, promotes responsible vehicle operation, and contributes to a sustainable transportation ecosystem.

Frequently Asked Questions Regarding Exhaust Components

The following addresses common inquiries concerning exhaust system components, emphasizing performance, maintenance, and regulatory adherence.

Question 1: What are the primary indicators of exhaust component failure?

A noticeable increase in exhaust noise, visible rust or corrosion, and diminished engine performance are key indicators. The presence of unusual vibrations or rattling sounds from underneath the vehicle also suggests a potential problem.

Question 2: How does the material composition of an exhaust component influence its lifespan?

Material composition significantly impacts longevity. Stainless steel variants offer superior corrosion resistance compared to aluminized or mild steel, extending the component’s service life, particularly in regions with harsh weather conditions.

Question 3: What role does proper installation play in the effectiveness of a muffler?

Proper installation is critical. A poorly installed component can leak, causing noise pollution, reduced fuel efficiency, and potential health hazards. Secured connections and proper alignment are crucial for optimal performance.

Question 4: How frequently should a vehicle’s exhaust system be inspected?

Exhaust system inspections should occur at least annually or whenever unusual noises or performance issues arise. More frequent inspections are recommended for vehicles operating in corrosive environments.

Question 5: What are the potential consequences of operating a vehicle with a non-compliant exhaust system?

Operating a vehicle with a non-compliant exhaust system can result in fines, vehicle inspection failure, and increased air pollution. It may also contribute to diminished engine performance and reduced fuel efficiency.

Question 6: Can aftermarket exhaust components improve vehicle performance?

Aftermarket components can potentially enhance vehicle performance by optimizing exhaust flow. However, compatibility with the vehicle’s engine and emissions control system must be ensured. Verification of continued regulatory compliance is essential.

Understanding these common inquiries facilitates informed decision-making regarding maintenance and upgrades, ensuring optimal vehicle operation and environmental responsibility.

The next article section will delve into specific diagnostic procedures for identifying exhaust system problems.

Conclusion

The preceding analysis has explored various facets of automotive exhaust components, encompassing their functionality, maintenance, regulatory considerations, and impact on vehicle performance. Key points underscored include the importance of material durability, the criticality of proper installation, and the necessity of adhering to a consistent maintenance schedule. Furthermore, understanding the relationship between exhaust flow, noise reduction, and regulatory compliance is essential for informed decision-making.

Therefore, a comprehensive understanding of these components empowers vehicle owners and automotive professionals to make informed choices, optimize vehicle performance, and ensure environmental responsibility. Continued vigilance in monitoring system performance, combined with proactive maintenance practices, contributes to a more sustainable and efficient transportation ecosystem. The commitment to these principles promotes both individual vehicle longevity and broader societal well-being.

![Intermountain Radiator & Muffler: [City/Region] Exhaust Experts Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Intermountain Radiator & Muffler: [City/Region] Exhaust Experts | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-25-300x200.jpg)