An obstructed exhaust system component, specifically the rearmost device designed to reduce engine noise, can impede the expulsion of exhaust gases. This restriction creates backpressure, hindering the efficient clearing of cylinders during the exhaust stroke. Consequently, the engine’s ability to intake fresh air and fuel is compromised, leading to incomplete combustion and reduced overall efficiency. An example is a vehicle experiencing sluggish acceleration and decreased top speed despite the accelerator pedal being fully depressed.

The efficient removal of exhaust gases is critical for optimal engine performance. Historically, exhaust systems primarily focused on noise reduction, but modern designs also prioritize minimizing backpressure to maximize power output and fuel economy. The inability to properly expel exhaust has a direct and significant impact on engine breathing, which is a key determinant of its operational effectiveness. Neglecting this issue can lead to further engine damage over time, including overheating and reduced lifespan.

Therefore, diagnosing potential exhaust restrictions is a necessary step when addressing diminished engine performance. The severity of the obstruction directly correlates with the magnitude of power reduction. Evaluating the exhaust system’s integrity, including a thorough inspection for blockages, forms a vital part of standard vehicle maintenance procedures. Identifying and rectifying these issues promptly ensures the engine operates within its designed parameters, preserving both performance and longevity.

Addressing Exhaust Restriction and Power Reduction

The following points offer guidance on diagnosing and resolving potential issues arising when an obstructed noise reduction device impairs engine performance.

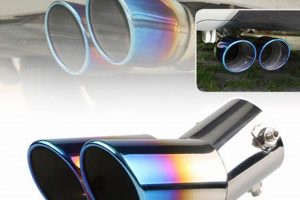

Tip 1: Perform a Visual Inspection: Closely examine the device for external damage such as dents, rust, or punctures. These can indicate internal collapse or corrosion, leading to restricted airflow.

Tip 2: Listen for Unusual Noises: A rattling or hissing sound emanating from the exhaust system may suggest a broken baffle or internal obstruction.

Tip 3: Check for Excessive Backpressure: A professional mechanic can use a backpressure gauge to measure exhaust pressure. Elevated readings signify a potential blockage.

Tip 4: Evaluate Exhaust Gas Flow: Compare the exhaust flow from the tailpipe to that of a similar, properly functioning vehicle. Reduced flow indicates a restriction.

Tip 5: Consider the Vehicle’s Age and Mileage: Older vehicles are more susceptible to exhaust system corrosion and internal component failure, increasing the likelihood of blockages.

Tip 6: Consult a Qualified Technician: If the cause of power reduction remains unclear, seek professional diagnosis. Incorrectly addressing exhaust issues can lead to further engine damage.

Regular maintenance and timely diagnosis of exhaust system problems are essential for maintaining optimal engine efficiency and preventing significant performance degradation. Ignoring the symptoms can lead to costly repairs and reduced vehicle lifespan.

Implementing these measures helps ensure proper engine operation and mitigates performance deficits stemming from exhaust system malfunctions.

1. Restriction

Restriction, specifically within the exhaust system, directly correlates with the reduction of engine power. When the exhaust flow is impeded, particularly by a clogged muffler, the engine experiences increased backpressure. This elevated pressure prevents the efficient expulsion of combustion byproducts from the cylinders. As a result, the engine’s ability to draw in fresh air and fuel is compromised, leading to incomplete combustion and a reduction in power output. The degree of power loss is directly proportional to the level of restriction present within the exhaust system.

For example, consider a scenario where rust accumulates within the muffler, gradually constricting the exhaust passageways. Initially, the power reduction might be subtle, manifesting as slightly reduced acceleration. However, as the restriction worsens, the power loss becomes increasingly noticeable, impacting the vehicle’s ability to climb hills or merge onto highways safely. Similarly, debris lodged within the muffler, such as carbon deposits or foreign objects, can create a significant blockage, leading to immediate and substantial power reduction. Ignoring these symptoms can cause further damage to the engine as it works harder to overcome the exhaust restriction.

Understanding the connection between exhaust restriction and power loss is crucial for effective vehicle maintenance and troubleshooting. Identifying and addressing exhaust blockages promptly ensures optimal engine performance and fuel efficiency. Failure to do so can lead to long-term engine damage and increased operating costs. Therefore, regular exhaust system inspections and maintenance are essential for preserving vehicle performance and longevity.

2. Backpressure

Backpressure, defined as the resistance to exhaust gas flow within an exhaust system, is a critical factor in engine performance. A clogged muffler directly increases backpressure. The internal obstructions within a restricted muffler create significant resistance to the expulsion of exhaust gases. This increased resistance forces the engine to expend more energy pushing exhaust out, reducing the energy available for generating power at the crankshaft. Consequently, the engine’s volumetric efficiency decreases, leading to incomplete combustion and reduced power output. The effect is analogous to breathing through a constricted airway; the engine struggles to expel waste, impairing its ability to take in fresh air and fuel.

The relationship between a blocked muffler, backpressure, and power reduction is not linear. A minor increase in backpressure may result in a negligible performance impact. However, as the obstruction worsens, the backpressure increases exponentially, leading to a significant and noticeable loss of power. For example, a vehicle with a partially clogged muffler might exhibit reduced acceleration and decreased fuel economy. In contrast, a vehicle with a severely blocked muffler could experience significant power loss, stalling, and potential engine damage due to excessive heat buildup caused by the trapped exhaust gases. The design of the exhaust system, including pipe diameter and catalytic converter efficiency, also influences the overall impact of backpressure on performance.

Understanding the dynamics of backpressure and its relationship to exhaust system restrictions is vital for effective vehicle maintenance and diagnostics. Regular inspections of the exhaust system, including visual checks for rust, damage, or unusual noises, can help identify potential blockages early on. Addressing these issues promptly, whether through muffler replacement or exhaust system cleaning, mitigates the negative effects of excessive backpressure, restoring engine power and efficiency. Failing to do so can lead to further engine damage and reduced vehicle lifespan, underscoring the practical significance of this understanding for both vehicle owners and technicians.

3. Efficiency

Engine efficiency, in the context of exhaust systems, represents the effectiveness with which an engine converts fuel into usable power while minimizing waste. An obstructed exhaust system, particularly one involving a blocked muffler, directly undermines this efficiency, impacting several critical aspects of engine operation.

- Combustion Efficiency

A restricted exhaust flow due to a clogged muffler hinders the complete expulsion of burnt gases from the cylinders. This incomplete clearing reduces the available space for fresh air and fuel mixture during the intake stroke, leading to incomplete combustion. Less efficient combustion results in a lower energy yield per fuel cycle, diminishing overall engine output. For instance, if the muffler is severely blocked, a significant portion of the fuel may remain unburnt, exiting as emissions and resulting in wasted fuel and reduced power.

- Volumetric Efficiency

Volumetric efficiency refers to how effectively an engine fills its cylinders with air-fuel mixture. Increased backpressure from a clogged muffler impedes the scavenging process, reducing the amount of fresh air and fuel that can enter the cylinders. This reduction lowers the volumetric efficiency, causing a disproportionate decrease in power relative to fuel consumption. Imagine a scenario where the cylinders are only partially filled due to exhaust obstruction; the engine must work harder, consuming more fuel to achieve the same level of performance as a system operating with unobstructed flow.

- Thermal Efficiency

A malfunctioning muffler can affect thermal efficiency by altering engine operating temperatures. Restricted exhaust flow can cause exhaust gases to linger in the combustion chamber, leading to increased engine temperatures. Excessive heat can damage engine components and reduce the efficiency of the combustion process. Consider a situation where a clogged muffler causes the engine to overheat; the elevated temperatures can lead to pre-ignition or detonation, further reducing efficiency and potentially causing engine damage.

- Fuel Economy

The cumulative effect of reduced combustion, volumetric, and thermal efficiencies directly translates into decreased fuel economy. An engine struggling to overcome exhaust restriction requires more fuel to produce the same amount of power. This increased fuel consumption is a direct consequence of the compromised efficiency resulting from the exhaust obstruction. For example, a vehicle experiencing a clogged muffler may exhibit a noticeable decrease in miles per gallon (MPG) as the engine compensates for the reduced power output.

These facets demonstrate that maintaining a clear and unrestricted exhaust system is essential for optimal engine efficiency. A clogged muffler compromises combustion, volumetric, and thermal efficiencies, resulting in reduced power output, increased fuel consumption, and potential engine damage. Regular maintenance and prompt attention to exhaust system issues are vital for preserving vehicle performance and minimizing operational costs.

4. Combustion

Combustion, the chemical process of rapid oxidation that generates heat and light, is fundamentally linked to engine power output. An exhaust system obstruction, specifically a clogged muffler, significantly impacts combustion efficiency, directly influencing overall engine performance. Understanding the relationship between combustion and exhaust flow is crucial for diagnosing and addressing power loss issues.

- Incomplete Combustion

A clogged muffler creates backpressure, hindering the complete removal of exhaust gases from the cylinders. This residual gas displaces a portion of the fresh air and fuel mixture during the intake stroke, leading to incomplete combustion. Incomplete combustion results in reduced energy release per combustion cycle, directly decreasing engine power. For example, unburnt fuel may exit the exhaust system, indicating a less efficient combustion process due to restricted exhaust flow. This is evident in elevated hydrocarbon emissions detected during emissions testing.

- Air-Fuel Ratio Imbalance

Optimal combustion requires a precise air-fuel mixture. A clogged muffler disrupts this balance by preventing the efficient scavenging of exhaust gases, indirectly affecting the intake of air. The engine control unit (ECU) may attempt to compensate for the altered exhaust flow, but its adjustments may not fully correct the imbalance, leading to suboptimal combustion. Consider a scenario where the ECU enriches the mixture to compensate for perceived lean conditions; this corrective action can further degrade fuel economy and increase emissions without fully restoring power.

- Increased Cylinder Temperatures

Restricted exhaust flow can cause exhaust gases to linger within the cylinders, raising cylinder temperatures. Elevated temperatures can lead to pre-ignition or detonation, both of which disrupt the controlled combustion process and reduce engine efficiency. Such uncontrolled combustion events can also cause engine damage over time. For instance, sustained operation with a clogged muffler might cause overheating and premature wear of piston rings and cylinder walls, further compromising combustion and power output.

- Carbon Deposits

Incomplete combustion, caused by a restricted exhaust system, leads to increased carbon deposit formation within the engine. These deposits accumulate on valves, pistons, and cylinder heads, insulating these components and further hindering heat transfer. The reduced heat transfer compromises combustion efficiency, creating a feedback loop that exacerbates the problem. A real-world example is the buildup of carbon on intake valves, restricting airflow and further degrading combustion performance.

These interconnected aspects highlight the critical role of a properly functioning exhaust system in maintaining efficient combustion. A clogged muffler disrupts the combustion process, leading to power loss, increased emissions, and potential engine damage. Regular maintenance, including exhaust system inspections and muffler replacement when necessary, is essential for preserving optimal engine performance and preventing the detrimental effects of impaired combustion.

5. Performance

Engine performance, encompassing metrics such as power output, acceleration, and fuel efficiency, is directly affected by the condition of the exhaust system. A clogged muffler, by impeding the free flow of exhaust gases, significantly reduces overall vehicle performance. The resulting backpressure within the exhaust system hampers the engine’s ability to effectively expel spent gases, leading to reduced volumetric efficiency and incomplete combustion. This, in turn, manifests as a noticeable decrease in acceleration, diminished horsepower, and a decline in fuel economy. For instance, a vehicle struggling to maintain speed on inclines, or exhibiting sluggish throttle response, may be experiencing performance degradation due to a restricted exhaust caused by a blockage in the muffler. The severity of the performance decline is directly proportional to the degree of obstruction within the muffler.

The impact on performance extends beyond merely reduced acceleration and power. An inefficient exhaust system can also lead to increased engine operating temperatures, placing additional stress on internal components and potentially shortening the engine’s lifespan. Furthermore, incomplete combustion results in higher levels of harmful emissions, contributing to environmental pollution. Regular inspections of the exhaust system, including visual assessments for rust, damage, or unusual noises, can help identify potential obstructions early on. Pressure testing the exhaust system is a reliable method for gauging the backpressure and identifying if muffler replacement is required to restore vehicle performance to optimal levels.

In summary, a clogged muffler has a demonstrably negative impact on engine performance. By restricting exhaust flow, it diminishes power output, reduces fuel efficiency, and increases emissions. Maintaining a properly functioning exhaust system, with a clean and unobstructed muffler, is essential for preserving optimal vehicle performance and extending engine longevity. Addressing exhaust system issues promptly ensures that the engine operates within its intended parameters, providing a reliable and efficient driving experience. Recognizing the symptoms of a clogged muffler and addressing them proactively is a practical step toward preserving the overall health and performance of the vehicle.

6. Maintenance

Preventative maintenance plays a pivotal role in mitigating the performance degradation associated with exhaust system obstructions. Regular inspections and timely interventions prevent the accumulation of deposits and corrosion that contribute to muffler blockages, thereby preserving optimal engine power output.

- Routine Visual Inspections

Periodic visual examinations of the exhaust system, including the muffler, can identify early signs of rust, physical damage, or corrosion. These indicators suggest potential internal deterioration that could lead to restricted airflow. Early detection allows for proactive replacement or repair, preventing significant power loss. For instance, noticing surface rust on the muffler during a standard vehicle check-up allows for timely treatment or replacement, avoiding future exhaust restrictions.

- Scheduled Exhaust System Checks

Integrating exhaust system examinations into routine maintenance schedules ensures that potential blockages are identified and addressed before they severely impact engine performance. Mechanics can assess exhaust flow using pressure tests, indicating whether the muffler is contributing to excessive backpressure. A scheduled pressure test reveals a gradual increase in backpressure, signalling the need to address a partially clogged muffler before it drastically reduces engine power.

- Timely Replacement of Worn Components

Mufflers, like all vehicle components, have a limited lifespan. Replacing a muffler nearing the end of its service life prevents the likelihood of internal collapse or excessive rust accumulation, both of which can severely restrict exhaust flow. Replacing an aging muffler at a manufacturer-recommended interval prevents the development of significant exhaust restrictions, maintaining optimal engine performance.

- Addressing Corrosion and Rust

Corrosion and rust are major contributors to muffler blockages. Treating surface rust and addressing underlying corrosion issues promptly minimizes the risk of internal deterioration and subsequent exhaust restrictions. Applying rust inhibitors to the muffler during routine maintenance helps extend its lifespan and prevent the development of performance-impairing blockages. Regular application of rust preventative measures limits the risk of exhaust restrictions.

These maintenance practices collectively contribute to preventing muffler blockages, thereby preserving optimal engine performance and fuel efficiency. Neglecting these preventative measures increases the likelihood of experiencing power loss and reduced engine lifespan, emphasizing the economic and operational benefits of regular exhaust system maintenance. Consistent attention to the condition of the muffler helps mitigate the performance consequences associated with exhaust restrictions.

Frequently Asked Questions

The following questions address common concerns regarding the relationship between exhaust system blockages and engine performance.

Question 1: How does a compromised exhaust system affect engine power?

A compromised exhaust system, specifically one with an obstructed noise reduction device, increases backpressure within the engine. This elevated backpressure impedes the efficient expulsion of exhaust gases from the cylinders, reducing the engine’s ability to intake fresh air and fuel. This results in incomplete combustion, diminished power output, and decreased fuel efficiency.

Question 2: What are the primary indicators of an obstructed exhaust system?

Indicators include reduced acceleration, diminished top speed, decreased fuel economy, unusual noises emanating from the exhaust system (rattling, hissing), and potentially elevated engine operating temperatures. A professional backpressure test provides definitive confirmation.

Question 3: Can a partially clogged muffler still significantly impact engine performance?

Yes, even a partially clogged muffler can noticeably reduce engine performance. The degree of power reduction is directly proportional to the severity of the obstruction. A gradual accumulation of rust or debris can progressively restrict exhaust flow, leading to a gradual decline in engine power and fuel economy.

Question 4: Is muffler replacement always necessary when diagnosing an exhaust restriction?

Muffler replacement is often necessary, particularly if the obstruction is caused by internal collapse, significant corrosion, or irreparable damage. However, in some cases, the obstruction may be due to external debris, which can be removed. A thorough inspection is required to determine the appropriate course of action.

Question 5: Can a compromised catalytic converter also contribute to power loss?

Yes, a malfunctioning or clogged catalytic converter, situated upstream of the muffler, can also create significant backpressure and reduce engine power. Diagnosing the source of the exhaust restriction is crucial for effective repair.

Question 6: How frequently should exhaust system inspections be performed?

Exhaust system inspections should be integrated into routine vehicle maintenance schedules, typically every 12 months or 12,000 miles. More frequent inspections are recommended for vehicles operating in harsh environments or those with a history of exhaust system problems.

Maintaining a properly functioning exhaust system is essential for preserving optimal engine performance, fuel efficiency, and minimizing harmful emissions. Regular inspections and prompt attention to exhaust system issues are crucial for ensuring reliable vehicle operation.

Proceed to understand how exhaust system design impacts overall engine output.

Conclusion

The preceding discussion elucidates that a compromised exhaust system component, specifically a clogged muffler, can cause loss of power. The restriction imposed by the blocked muffler impedes the efficient expulsion of exhaust gases, leading to increased backpressure and reduced combustion efficiency. This, in turn, diminishes engine performance, as evidenced by reduced acceleration, decreased fuel economy, and potentially elevated operating temperatures. Timely identification and remediation of exhaust system obstructions are therefore crucial for preserving optimal vehicle operation.

The significance of maintaining a properly functioning exhaust system extends beyond immediate performance considerations. Addressing exhaust restrictions proactively contributes to extending engine lifespan, minimizing harmful emissions, and maximizing fuel efficiency. Vehicle owners and technicians must recognize the detrimental effects of neglecting exhaust system maintenance and prioritize routine inspections to ensure sustained engine health and reliable vehicle operation. Continued diligence in this area will contribute to both improved vehicle performance and reduced environmental impact.