An assessment of an adhesive product designed for temporary repair of exhaust systems. These evaluations typically analyze the product’s effectiveness in sealing leaks, its ease of application, and its durability under varying temperature conditions. Assessments also consider the value proposition in relation to cost and alternative repair methods.

The significance of such an analysis lies in providing consumers with data to make informed decisions regarding quick and cost-effective exhaust system repairs. A product’s ability to withstand the rigors of a vehicle’s exhaust system, coupled with simple application, contributes to its overall practicality. Understanding its limitations, compared with more permanent solutions, sets realistic expectations for its use.

The subsequent discussion will delve into specific performance characteristics, application guidelines, and potential alternatives available to consumers seeking exhaust system repair solutions. It will further examine critical factors affecting the lifespan of adhesive exhaust repair products and offer insights on maximizing their effectiveness.

Maximizing Adhesive Exhaust Repair Efficacy

The following guidance addresses effective application and usage of adhesive exhaust repair materials, extending their functional lifespan.

Tip 1: Surface Preparation is Crucial. Thoroughly clean the damaged area of the exhaust system, removing rust, dirt, and grease. A wire brush is often necessary to ensure optimal adhesion.

Tip 2: Precise Application is Key. Apply the adhesive tape or patch directly over the damaged area, ensuring complete coverage and minimizing air gaps. Overlapping the edges of the damage area is generally recommended.

Tip 3: Temperature Considerations are Important. Adhere to the manufacturer’s temperature guidelines during application and initial curing. Extreme temperatures, either too hot or too cold, can negatively impact adhesion.

Tip 4: Gradual Heat Exposure is Advisable. After application, allow the vehicle to idle for a brief period before extended driving. This permits the adhesive to cure gradually, minimizing the risk of premature failure due to rapid temperature fluctuations.

Tip 5: Monitor for Early Signs of Failure. Regularly inspect the repaired area for cracks, peeling, or other signs of degradation. Addressing these issues promptly can prevent further damage and extend the repair’s lifespan.

Tip 6: Consider Complementary Products. In conjunction with tape, certain exhaust repair putties or cements can enhance the seal and improve long-term durability. Select products compatible with the tape’s materials.

Tip 7: Understand Limitations. Adhesive repairs are typically temporary. For significant damage or persistent exhaust leaks, professional welding or component replacement remains the most reliable solution.

Implementing these suggestions maximizes the likelihood of a successful temporary exhaust system repair, providing short-term relief until a more permanent solution can be implemented.

The subsequent section will summarize the overall effectiveness and user satisfaction associated with adhesive exhaust repair products and provide a concluding perspective.

1. Adhesion Strength

Adhesion strength represents a primary determinant of a muffler tape’s effectiveness. A tape’s ability to strongly adhere to the exhaust system surface directly impacts its capacity to create and maintain a seal against exhaust gases. Insufficient adhesion results in leaks, negating the tape’s purpose. Reviews consistently emphasize adhesion as a critical performance metric. Products exhibiting poor adhesion ratings, even with proper application, receive unfavorable assessments.

The effectiveness of adhesive tapes for repairing exhaust systems hinges on proper surface preparation. Without thorough cleaning of the damaged area (removal of rust, dirt, and grease), the tape will likely fail to adhere adequately, regardless of its inherent adhesive properties. Practical examples include instances where users applied tape to insufficiently cleaned surfaces, resulting in premature failure and compromised exhaust sealing.

In conclusion, adhesion strength is fundamental to the overall efficacy of muffler repair tape, and serves as a pivotal point of “tiger patch muffler tape review”. Real-world application demonstrates that even high-quality tape becomes ineffective without appropriate surface preparation. Addressing adhesion capabilities is central in evaluating the suitability of muffler repair products, as this directly correlates to successful temporary exhaust system sealing.

2. Temperature Resistance

Temperature resistance is a crucial attribute in evaluating exhaust repair tapes. An exhaust system operates under significant thermal stress, making a tape’s capacity to withstand high temperatures without degradation a key performance indicator.

- Material Degradation at High Temperatures

Muffler tapes are often composed of materials that can degrade or lose adhesive properties at elevated temperatures. This degradation leads to seal failure and reduced product lifespan. A tape exhibiting poor temperature resistance will crack, peel, or lose adhesion, rendering it ineffective in a short period. Reviews often document instances where certain tapes failed due to inability to handle operating temperatures, specifically those encountered closer to the engine.

- Impact on Seal Integrity

High temperatures can affect the tape’s ability to maintain a tight seal. Thermal expansion and contraction of the exhaust system components, coupled with the tape’s own expansion and contraction, can create gaps or stress points in the seal. Tapes with inadequate temperature resistance are more susceptible to these effects, compromising seal integrity and leading to exhaust leaks. For instance, users may report an initial successful repair that quickly deteriorates once the exhaust system reaches its normal operating temperature.

- Long-Term Performance Implications

The long-term performance of an exhaust repair tape is directly linked to its temperature resistance. A tape that degrades quickly under high temperatures will require frequent replacement, negating its cost-effectiveness. Reviews evaluating long-term performance often emphasize the importance of temperature resistance in predicting the product’s lifespan. Comparisons between different tapes frequently highlight the superior durability of products designed to withstand extreme heat.

- The role of Heat Shielding

Some premium muffler tapes incorporate heat-shielding materials to mitigate direct exposure to high exhaust temperatures. This heat shield reflects radiant heat away from the adhesive layer, preserving its integrity and extending the tape’s functional life. User feedback and product evaluations frequently underscore the benefits of these protective measures, noting enhanced durability and resistance to heat-induced degradation.

Evaluating temperature resistance is therefore essential. A high-quality muffler tape must withstand elevated temperatures without compromising its adhesive properties or seal integrity. Products failing to meet this criterion receive negative assessments, underlining the critical connection between temperature resistance and overall product efficacy.

3. Application Ease

Application ease significantly influences consumer perception and subsequent evaluations of muffler repair tape products. The connection between the product’s design, instructions, and practical use affects the overall user experience, directly impacting satisfaction. Complicated application processes can lead to improper use, undermining the product’s intended function and yielding negative feedback. A product perceived as easy to apply reduces the risk of user error and increases the likelihood of a successful temporary exhaust system repair.

User reviews frequently highlight application ease as a major factor influencing their assessment. For instance, clear and concise instructions, pre-cut tape sizes, and pliable materials can facilitate easier wrapping around complex exhaust system contours. Conversely, ambiguous instructions, difficult-to-handle materials, or the need for specialized tools detract from application ease, resulting in frustration. Real-world examples demonstrate that products with streamlined application processes receive more positive evaluations, irrespective of their inherent material qualities. A straightforward application can mitigate the impact of minor material shortcomings, while a cumbersome application can overshadow superior material properties.

Therefore, application ease is a non-trivial component of a comprehensive product review. It addresses not only the product’s inherent characteristics, but also its user-friendliness and accessibility. By prioritizing simplicity and clarity in design and instruction, manufacturers can increase user satisfaction and enhance the overall product perception, thereby influencing the tenor and positivity of product assessments. Failing to account for application ease can lead to a misrepresentation of the product’s practical value and potential benefits for consumers.

4. Durability Assessment

Durability assessment plays a crucial role in the comprehensive evaluation of adhesive exhaust repair products. The longevity of a temporary repair dictates its practical value and overall cost-effectiveness. A thorough durability assessment examines a product’s resistance to environmental factors, physical stress, and prolonged exposure to high temperatures. This informs a consumer’s decision regarding the suitability of such a product for their needs.

- Resistance to Thermal Cycling

Exhaust systems experience frequent temperature fluctuations. A product’s ability to withstand repeated thermal expansion and contraction without cracking, peeling, or losing adhesion is paramount. Reviews often report instances where tapes failed prematurely due to inadequate thermal cycling resistance, highlighting this as a critical point in durability assessment.

- Resistance to Road Debris and Moisture

Exhaust systems are constantly exposed to road debris and moisture. A durable product must resist abrasion from rocks and other road hazards, as well as the corrosive effects of water and salt. Tests simulating exposure to these conditions provide insights into a tape’s long-term viability. Products that deteriorate rapidly under these conditions receive unfavorable durability ratings.

- Adhesive Bond Integrity Over Time

Even with optimal initial adhesion, the strength of the adhesive bond can degrade over time due to prolonged exposure to heat and environmental factors. A comprehensive durability assessment involves monitoring the adhesive bond strength throughout the product’s expected lifespan. Reductions in bond strength correlate directly with decreased repair effectiveness and diminished consumer satisfaction.

- Material Degradation Analysis

The inherent resistance of the tape’s constituent materials to degradation under normal operating conditions is a key component of durability assessment. This involves analyzing material composition and conducting accelerated aging tests to predict long-term performance. Material degradation, such as embrittlement or loss of elasticity, can compromise the tape’s structural integrity and lead to premature failure.

These facets of durability assessment collectively inform the user of “tiger patch muffler tape review,” allowing consumers to make informed purchasing decisions based on real-world longevity expectations. A tape’s capacity to withstand the rigors of the exhaust system environment, as evidenced by rigorous testing and user feedback, directly correlates with its overall value and effectiveness as a temporary repair solution.

5. Cost Effectiveness

Cost-effectiveness is a critical component influencing evaluations of adhesive exhaust repair products. Its significance stems from balancing the initial purchase price against the product’s performance and longevity. A low initial cost does not guarantee cost-effectiveness if the product fails prematurely or requires frequent replacement. Conversely, a higher-priced product exhibiting superior durability and prolonged effectiveness can provide a better long-term value proposition. The relationship between initial expenditure and sustained performance drives consumer perceptions of overall value and informs reviews.

Reviews frequently assess cost-effectiveness by comparing the product’s price to its lifespan and performance relative to alternative repair methods, such as professional welding or component replacement. For instance, a tape priced significantly lower than a welding repair might appear appealing initially. However, if the tape fails within a short timeframe, necessitating repeated purchases and applications, the overall cost can exceed that of a single, more permanent welding repair. The assessment of cost-effectiveness also considers the time and effort involved in applying the repair tape, further influencing the overall value equation. Products that demand extensive preparation or require specialized tools may be deemed less cost-effective due to the additional associated costs and time investments.

Evaluating cost-effectiveness entails a comprehensive understanding of the product’s capabilities, lifespan, and alternatives. Manufacturers providing transparent performance data and realistic longevity expectations enable consumers to make informed purchasing decisions based on a balanced assessment of initial cost versus long-term value. In summary, a favorable review is often linked to a demonstrable balance between product price, performance, and durability, aligning consumer expectations with realistic, cost-conscious solutions.

6. Material Composition

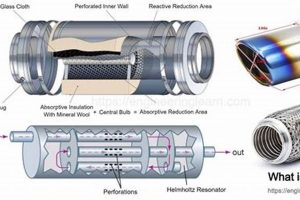

The materials constituting an exhaust repair tape directly dictate its performance characteristics, rendering material composition a central element in any “tiger patch muffler tape review.” The tape’s ability to withstand high temperatures, resist corrosion, maintain adhesion, and endure physical stress is fundamentally determined by the types and proportions of materials used in its construction. For example, a tape incorporating fiberglass reinforcement often exhibits superior tensile strength and heat resistance compared to one composed solely of a polymeric adhesive. Therefore, the selection and quality of materials serve as primary indicators of a product’s overall effectiveness and durability.

The practical implications of material composition are evident in real-world applications. Tapes utilizing high-temperature adhesives, such as silicone-based compounds, demonstrate enhanced adhesion and longevity when subjected to extreme exhaust system temperatures. Conversely, tapes employing less robust adhesives may fail prematurely, leading to seal breaches and requiring frequent reapplication. Similarly, the presence or absence of a reflective aluminum layer can significantly impact a tape’s ability to dissipate heat, preventing degradation of the adhesive and prolonging its lifespan. The interaction between different materials within the tape also plays a crucial role. A well-engineered tape will incorporate materials that are chemically compatible and designed to work synergistically, maximizing overall performance.

In conclusion, the material composition of an exhaust repair tape directly influences its ability to withstand the demanding conditions of an exhaust system environment. A thorough “tiger patch muffler tape review” must prioritize a detailed analysis of the materials used, considering their individual properties, interactions, and overall contribution to the product’s performance, durability, and long-term cost-effectiveness. Overlooking the material composition can result in inaccurate assessments and misinformed purchasing decisions, potentially leading to dissatisfaction and increased repair costs.

7. Longevity Expectation

Longevity expectation represents a significant variable influencing consumer satisfaction and shaping the overall evaluation of an adhesive exhaust repair product. It describes the anticipated duration of effective performance before product failure. High longevity expectations, if unmet, lead to negative assessments, while realistic expectations, aligned with the product’s capabilities, contribute to a more favorable “tiger patch muffler tape review.” The discrepancy between perceived product lifespan and actual performance fundamentally determines customer satisfaction.

The effect of a short product lifespan despite strong initial performance negatively impacts consumer perception. Reviews frequently cite instances where adhesive tapes demonstrated excellent sealing properties upon initial application but deteriorated rapidly within weeks, leading to user dissatisfaction. Conversely, a product with moderate initial performance but demonstrably longer lifespan, even with gradual degradation, tends to receive more positive reviews, as the consistent functionality aligns with a reasonable longevity expectation. Furthermore, a product’s price influences the reasonable expectation of longevity. A low-cost tape is typically associated with a shorter expected lifespan compared to a higher-priced alternative, underscoring the connection between product positioning and consumer expectations.

Therefore, managing and meeting longevity expectations constitutes a crucial aspect of product design and marketing. Manufacturers must communicate clearly regarding the intended lifespan of their products, providing realistic performance expectations based on testing data and application scenarios. By aligning product capabilities with consumer expectations, manufacturers can foster positive perceptions, influencing purchase decisions and ensuring favorable product reviews that reflect a balanced assessment of price, performance, and durability. Misalignment creates negative reviews.

Frequently Asked Questions

The following questions and answers address prevalent inquiries and misconceptions concerning adhesive exhaust repair tapes, providing informative insights for practical application and consumer understanding.

Question 1: How long does adhesive exhaust repair tape typically last?

The lifespan varies considerably depending on product quality, application technique, and operating conditions. Under optimal circumstances, a repair may last several weeks or even months, providing a temporary solution until a permanent repair can be performed. However, extreme heat, road debris, and improper application can significantly shorten the lifespan.

Question 2: Can adhesive exhaust repair tape be used as a permanent solution?

Adhesive exhaust repair tape is not intended as a permanent solution. It serves as a temporary fix to address minor leaks and damage until a professional repair or component replacement can be implemented. Relying solely on adhesive tape for extended periods may compromise vehicle safety and lead to further exhaust system damage.

Question 3: What surface preparation is required before applying adhesive exhaust repair tape?

Thorough surface preparation is essential for optimal adhesion and repair effectiveness. The damaged area should be cleaned meticulously, removing rust, dirt, grease, and any loose particles. A wire brush and degreasing agent are often necessary to ensure proper adhesion. Failure to adequately prepare the surface can result in premature tape failure.

Question 4: Are there any limitations to the types of damage that adhesive exhaust repair tape can address?

Adhesive exhaust repair tape is best suited for addressing small holes, cracks, and minor leaks in exhaust systems. It is not designed for structural repairs, extensive rust damage, or large breaches in the exhaust piping. Attempting to repair significant damage with adhesive tape is unlikely to provide a lasting solution and may pose safety risks.

Question 5: How does temperature affect the performance of adhesive exhaust repair tape?

Temperature plays a crucial role in the performance of adhesive exhaust repair tape. Excessive heat can degrade the adhesive and compromise the seal, while extreme cold can reduce the tape’s pliability and adhesion strength. Selecting a tape specifically designed to withstand high exhaust temperatures is essential for achieving a durable and effective repair.

Question 6: What are the potential risks associated with using adhesive exhaust repair tape?

Improper application or reliance on adhesive exhaust repair tape as a permanent solution can pose several risks. Exhaust leaks can lead to carbon monoxide poisoning, reduced engine performance, and potential fire hazards. Furthermore, a poorly executed repair may detach while driving, creating a safety hazard for other motorists. Regular inspection is paramount.

These frequently asked questions provide fundamental knowledge regarding the practical application, limitations, and potential risks associated with adhesive exhaust repair. Understanding these facets empowers consumers to make informed decisions regarding the appropriateness of this repair method for their specific needs.

The concluding section of this evaluation summarizes the key findings and offers a final perspective on the efficacy and limitations of adhesive exhaust repair solutions, culminating a comprehensive “tiger patch muffler tape review.”

Conclusion

This exploration of “tiger patch muffler tape review” underscores the multifaceted considerations essential for evaluating adhesive exhaust repair products. The analysis encompassed adhesion strength, temperature resistance, application ease, durability, cost-effectiveness, material composition, and longevity expectations. A comprehensive assessment requires consideration of each element. The inherent limitations of relying on adhesive solutions for long-term exhaust system repairs must be acknowledged.

Informed consumers should diligently weigh the benefits of temporary repairs against the potential risks and costs associated with premature product failure. Future innovation in material science may yield enhanced adhesive solutions, yet the fundamental principles of sound exhaust system maintenance and professional repair remain paramount for ensuring vehicle safety and optimal performance.