A component designed to reduce the noise emitted by an internal combustion engine, typically found in vehicles, achieves this through a series of chambers and tubes that attenuate sound waves. An example is the device attached to a car’s exhaust system to lessen the loudness of engine operation.

This device plays a vital role in noise pollution control and enhances the driving experience by decreasing cabin noise. Its development has evolved significantly over time, with advancements in materials and design leading to more efficient and durable units. Functioning units contribute to regulatory compliance regarding noise emissions, maintaining community standards.

This component represents one element within a broader system, influencing vehicle performance and environmental impact. Subsequent discussion will explore the factors affecting its performance, maintenance requirements, and its role in achieving optimal engine efficiency.

Guidance on Maximizing the Performance of Exhaust Noise Reduction Devices

The following recommendations will assist in ensuring the optimal functionality and longevity of systems designed to diminish engine noise.

Tip 1: Regular Inspection: Periodically examine the component for signs of corrosion, physical damage, or leaks. Early detection of these issues can prevent more extensive and costly repairs.

Tip 2: Prompt Replacement of Worn Parts: If any part of the system exhibits significant wear, such as rust or holes, it should be replaced without delay to maintain effectiveness and prevent further deterioration.

Tip 3: Careful Driving Practices: Avoid subjecting the vehicle to extreme conditions such as driving over large obstacles or impacting the underside, as these can cause physical damage.

Tip 4: Professional Installation: When installing a replacement, ensure it is performed by a qualified technician. Incorrect installation can compromise performance and potentially damage other vehicle systems.

Tip 5: Consider Material Upgrades: When replacement is necessary, explore options made from more durable materials, such as stainless steel, to enhance lifespan and resistance to corrosion.

Tip 6: Address Unusual Noises Immediately: Investigate any unusual sounds emanating from the exhaust system promptly. These noises can indicate a developing problem that requires attention.

Adherence to these suggestions will contribute to the consistent and effective operation of the system, thereby maximizing its benefits and extending its service life.

Following these guidelines is a proactive approach to maintaining vehicle performance and minimizing environmental impact.

1. Attenuation

Attenuation, the reduction in sound intensity, is a primary function of exhaust noise reduction devices. Its effectiveness is a key determinant of the device’s overall performance and its contribution to noise pollution control. Variations in design and materials directly influence the level of sound attenuation achieved.

- Internal Chamber Design

The configuration of internal chambers within the device dictates how sound waves are reflected and absorbed. Complex chamber arrangements, incorporating strategically placed baffles and resonators, enhance sound wave cancellation. Straight-through designs, conversely, typically offer less attenuation but may improve exhaust flow.

- Sound Absorption Materials

Materials like fiberglass packing or specialized acoustic fabrics line the interior, absorbing sound energy and converting it into heat. The density, type, and placement of these materials directly impact the frequency range and degree of attenuation achieved. Degradation of these materials over time diminishes their effectiveness.

- Resonance Frequency Tuning

The device’s design incorporates specific resonant frequencies to counteract dominant engine noise frequencies. Precise tuning of these frequencies maximizes the reduction of targeted sound waves. Changes to the exhaust system or engine can alter these frequencies, affecting the device’s overall attenuation performance.

- Perforated Tube Placement

Perforated tubes strategically positioned within the device alter the path of sound waves, causing destructive interference. The diameter and spacing of perforations influence the frequencies that are most effectively attenuated. The arrangement must balance attenuation with backpressure to avoid negatively affecting engine performance.

Effective attenuation is a crucial parameter in the selection and evaluation of exhaust noise reduction devices. Understanding the underlying principles governing attenuation, and how design elements contribute to its realization, facilitates informed decisions regarding vehicle modifications and maintenance. The aforementioned design considerations contribute to ensure reduction of noise effectively for the vehicle.

2. Backpressure

The flow of exhaust gases through an engine exhaust system, including the noise reduction device, is intrinsically linked to a phenomenon known as backpressure. This term refers to the resistance encountered by the exhaust gases as they exit the engine cylinders and traverse the exhaust system. The design and condition of the device directly influence backpressure levels, creating a cause-and-effect relationship. A device with excessive internal restrictions increases backpressure, potentially hindering engine performance. Conversely, a design that minimizes restrictions reduces backpressure, often improving engine efficiency but possibly compromising noise reduction capabilities. The selection of the noise reduction device must carefully balance backpressure and acoustic performance to achieve optimal overall vehicle operation. For example, high-performance vehicles often utilize devices with reduced backpressure to maximize power output, even if it means slightly increased exhaust noise.

A malfunctioning or clogged device can significantly increase backpressure, resulting in several adverse effects. Increased backpressure can lead to reduced engine horsepower and torque, decreased fuel efficiency, and increased engine operating temperatures. In extreme cases, excessive backpressure can damage engine components. Monitoring and maintaining the condition of the noise reduction device is crucial to ensuring that backpressure remains within acceptable levels. Practical applications of this understanding include routine inspections of the exhaust system, selection of appropriate replacement devices based on engine specifications, and prompt repair of any exhaust system damage that could impede exhaust gas flow. Consider a scenario where an older vehicle experiences a gradual decline in performance and fuel economy; a likely culprit is a partially blocked device, causing elevated backpressure and hindering engine efficiency.

In summary, backpressure constitutes a critical factor in the performance of engine exhaust systems and the selection and maintenance of noise reduction devices. Understanding the correlation between the device’s design and condition, and its impact on backpressure, is essential for optimizing engine efficiency, maintaining vehicle performance, and preventing potential engine damage. Balancing the need for effective noise reduction with the necessity of minimizing backpressure represents a core challenge in exhaust system design and management. This balance is essential for maximizing engine potential and increasing vehicle lifespan.

3. Materials

The selection of materials for exhaust noise reduction devices directly impacts their performance, durability, and overall effectiveness. The harsh environment within an exhaust system necessitates materials capable of withstanding high temperatures, corrosive gases, and physical stress.

- Steel Alloys

Various steel alloys, including aluminized steel and stainless steel, are common materials. Aluminized steel provides corrosion resistance at a lower cost, while stainless steel offers superior durability and resistance to rust, extending the device’s lifespan. The selection depends on the intended application and the vehicle’s operating environment. For example, vehicles operating in regions with heavy road salt usage benefit significantly from stainless steel components.

- Sound Absorption Media

Materials like fiberglass, mineral wool, and specialized synthetic fibers are used to absorb sound waves within the device. The density, composition, and placement of these materials influence the frequencies attenuated and the overall noise reduction achieved. Over time, these materials can degrade due to heat and moisture, reducing their effectiveness. High-performance devices may use advanced materials designed for greater longevity and heat resistance.

- Coatings and Treatments

Protective coatings are applied to the external surfaces to prevent corrosion and extend the component’s lifespan. Ceramic coatings, for example, provide enhanced thermal resistance and protect against extreme temperatures. Internal treatments can also be used to improve resistance to chemical attack from exhaust gases. Such treatments help maintain the integrity of the device over prolonged use.

- Internal Component Materials

The material of internal components such as baffles, resonators and tubes affects not only the acoustics but also the durability of the product. Thicker gauges and sturdier welds contribute to a component’s lifespan and resistance to vibration. Consider the difference between a low-cost, thin-walled device and a premium product with robust construction: the investment in stronger internal components will result in a product that endures longer and withstands the rigors of daily use.

The choice of appropriate materials represents a critical design consideration for exhaust noise reduction devices. Careful selection, based on the intended application and operating conditions, is essential to ensure optimal performance, extended lifespan, and compliance with noise regulations.

4. Construction

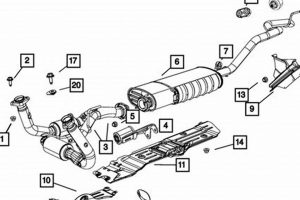

The manner in which an exhaust noise reduction device is constructed dictates its effectiveness, durability, and impact on vehicle performance. The internal architecture, welding techniques, and assembly processes directly influence the device’s ability to attenuate sound, resist corrosion, and withstand mechanical stress. Poor construction leads to premature failure, reduced noise reduction, and potential engine damage. Conversely, robust construction ensures longevity, optimal performance, and compliance with noise emission standards. For example, a device featuring poorly welded seams is susceptible to leaks, compromising its noise reduction capabilities and potentially emitting harmful exhaust gases. Another example, poorly designed internal baffles that suffer fatigue or metal fracturing due to increased noise or heat can also have the same effect and render a device useless. Therefore, evaluating construction quality is paramount when selecting a component.

Detailed examination of the construction includes assessing the quality of welds, the thickness of materials, and the design of internal chambers. High-quality welds ensure structural integrity, preventing leaks and maintaining the device’s intended shape. Thicker materials provide greater resistance to corrosion and physical damage, extending the lifespan of the device. The complexity and precision of internal chamber designs contribute to effective sound attenuation. Automotive manufacturers often employ robotic welding techniques to achieve consistent and reliable welds, ensuring the structural integrity of each unit. Likewise, advanced simulation software is employed to optimize internal chamber designs, balancing noise reduction with minimal backpressure. Consider the contrast between a mass-produced, budget-oriented device and a hand-fabricated, performance-engineered unit: the level of attention to construction detail directly corresponds to the device’s performance and longevity.

In summary, the construction of an exhaust noise reduction device is a critical determinant of its overall quality and performance. A thorough understanding of construction techniques, material properties, and design principles allows for informed decisions regarding selection, installation, and maintenance. Challenges related to construction often involve balancing cost considerations with the need for durability and performance. Adherence to stringent manufacturing standards and rigorous quality control processes is essential to ensure that the components function reliably and meet regulatory requirements.

5. Resonance

Resonance plays a crucial role in the functionality of a component used to diminish exhaust noise. This phenomenon is integral to how these devices attenuate sound waves produced by an internal combustion engine. Understanding resonance is therefore essential to understanding the complete mechanism that controls noise in vehicles.

- Helmholtz Resonance

Helmholtz resonance describes the phenomenon where a volume of air within a cavity (e.g., a chamber inside the device) resonates at a specific frequency. A familiar example is blowing across the top of a bottle to produce a tone. Exhaust systems use Helmholtz resonators to cancel out specific engine noise frequencies. By tuning the resonator to the dominant noise frequency, sound waves are effectively trapped and dissipated, contributing to noise reduction.

- Quarter-Wave Resonance

Quarter-wave resonators are tubes of a specific length, open at one end and closed at the other (or effectively closed due to impedance mismatch), that resonate when their length is one-quarter of the wavelength of the sound they are intended to cancel. In an exhaust system, these resonators are designed to target particular frequencies, creating destructive interference that reduces noise output. Precise length calculation is essential for targeting the correct frequency.

- Chamber Geometry and Tuning

The shape and size of internal chambers within an exhaust noise reduction device directly influence resonant frequencies. Varying the chamber dimensions alters the frequencies at which the air inside resonates, allowing engineers to tailor the device’s performance to specific engine noise profiles. Careful chamber design can create multiple resonant frequencies for broader noise reduction.

- Material Properties and Vibration

The materials from which an exhaust noise reduction device is constructed can also exhibit resonant behavior. The device’s outer shell, for example, may vibrate at certain frequencies, contributing to or detracting from the overall noise reduction effect. Damping materials are sometimes applied to the exterior to minimize unwanted vibrations and optimize acoustic performance.

The application of resonance principles represents a key aspect of exhaust noise reduction technology. By carefully manipulating resonant frequencies and chamber geometries, engineers can design effective systems for reducing unwanted engine noise while optimizing engine performance. Effective deployment of these principles leads to a quieter operation, complying with regulatory and practical driving purposes.

6. Durability

Durability, the ability to withstand wear, pressure, or damage, is a critical attribute of exhaust noise reduction devices. The operational environment of these devices exposes them to high temperatures, corrosive chemicals, and mechanical stresses, demanding robust construction and resistant materials.

- Material Selection and Longevity

The choice of materials directly influences the lifespan of the device. Stainless steel alloys offer superior corrosion resistance compared to aluminized steel, extending the device’s service life, particularly in regions with harsh weather conditions or prevalent road salt usage. Low-grade materials degrade rapidly, leading to premature failure and increased replacement costs. High-quality materials result in extended functionality and reliability.

- Weld Integrity and Structural Stability

The quality of welds significantly impacts the structural integrity of the device. Robust, consistent welds prevent leaks and ensure the device maintains its shape and function under pressure and vibration. Weak or poorly executed welds are prone to cracking and failure, compromising noise reduction and potentially causing exhaust leaks. Strong welds contribute to the overall durability and performance of the component.

- Resistance to Thermal Stress

Exhaust systems experience extreme temperature fluctuations during vehicle operation. The device must withstand these thermal cycles without cracking or warping. Materials with high thermal resistance, coupled with designs that accommodate expansion and contraction, contribute to long-term durability. Devices susceptible to thermal stress exhibit premature failure and reduced effectiveness.

- Protection Against Corrosion

Exposure to corrosive exhaust gases and environmental elements necessitates effective corrosion protection. Coatings, such as ceramic or aluminized layers, shield the underlying metal from chemical attack, preventing rust and extending the component’s lifespan. Inadequate corrosion protection leads to rapid degradation and eventual failure of the device.

The durability of exhaust noise reduction devices is a key factor in their long-term cost-effectiveness and environmental impact. Investing in durable, well-constructed components minimizes the frequency of replacements, reducing waste and ensuring consistent noise reduction performance throughout the vehicle’s lifespan. Moreover, durable components enhance vehicle reliability and safety by preventing exhaust leaks and maintaining optimal engine performance.

7. Installation

Proper installation of an exhaust noise reduction device is crucial to achieving its intended performance and ensuring vehicle safety. A poorly installed device can lead to reduced noise attenuation, exhaust leaks, compromised engine performance, and potential damage to other vehicle systems. Therefore, meticulous attention to installation procedures is paramount.

- Component Compatibility

Ensuring compatibility between the device and the vehicle’s exhaust system is the first critical step. The device must match the exhaust pipe diameter, mounting points, and vehicle specifications to guarantee a secure and leak-free connection. Incompatible components can create exhaust leaks, increase noise levels, and potentially damage the engine. For example, attempting to install a device designed for a four-cylinder engine on a six-cylinder engine’s exhaust system can result in significant performance issues.

- Secure Mounting and Sealing

Proper mounting hardware and sealing techniques are essential to prevent exhaust leaks. Using the correct clamps, hangers, and gaskets ensures a secure and leak-proof connection between the device and the exhaust pipes. Insufficiently tightened clamps or damaged gaskets can lead to exhaust leaks, increasing noise levels and potentially introducing harmful exhaust gases into the vehicle cabin. Applying exhaust sealant appropriately can further ensure a leak-free connection.

- Alignment and Clearance

Correct alignment of the device within the exhaust system is vital to prevent stress and potential damage. The device should be positioned to avoid contact with other vehicle components, such as the chassis or suspension, which can cause vibrations and premature wear. Insufficient clearance can lead to rattling noises and, in severe cases, structural damage to the device or other vehicle parts. Taking the time to ensure proper alignment and clearance is a safeguard against future problems.

- Professional Expertise

While some installations may appear straightforward, the expertise of a qualified technician is often necessary to ensure optimal results. Technicians possess the knowledge and tools to properly install the device, troubleshoot potential issues, and verify its performance. Attempting a complex installation without the necessary skills and equipment can result in improper installation, voiding warranties and potentially causing significant damage. Professional installation provides assurance of proper functioning and compliance with safety standards.

In conclusion, the installation process is inextricably linked to the performance and longevity of exhaust noise reduction devices. Paying careful attention to component compatibility, secure mounting, proper alignment, and leveraging professional expertise ensures that the device functions as intended, contributing to a quieter and safer vehicle operation. These facets are integral in maximizing the utility of the noise reduction system.

Frequently Asked Questions Regarding Exhaust Noise Reduction

The following questions and answers address common concerns and misunderstandings related to the system employed in reducing exhaust noise and optimizing vehicle performance. These insights are provided for informational purposes and should not substitute professional consultation.

Question 1: What is the typical lifespan of the component?

Lifespan varies based on material, usage conditions, and maintenance. Stainless steel units generally outlast aluminized steel versions. Regular inspection and prompt repair extend service life.

Question 2: Does an aftermarket unit improve vehicle performance?

Some aftermarket units are designed to reduce backpressure, potentially enhancing engine power. However, careful selection is necessary to avoid compromising noise reduction or violating emission standards.

Question 3: Can the system be repaired, or does it require complete replacement?

Minor damage, such as small leaks, can sometimes be repaired. Extensive corrosion or structural damage typically necessitates replacement for optimal performance and safety.

Question 4: How does the component affect fuel efficiency?

A properly functioning unit minimally impacts fuel efficiency. A damaged or clogged unit can increase backpressure, reducing fuel economy.

Question 5: Are there legal restrictions regarding aftermarket systems?

Noise emission regulations vary by jurisdiction. It is imperative to ensure any aftermarket system complies with applicable local, state, and federal laws.

Question 6: What are the signs of a failing system?

Increased exhaust noise, reduced engine performance, visible corrosion, and exhaust leaks are indicators of potential system failure. Prompt inspection is recommended upon noticing these symptoms.

These FAQs provide a foundational understanding of the function, maintenance, and implications of exhaust noise reduction systems. Consulting with a qualified mechanic is advisable for specific vehicle-related concerns.

The subsequent section will delve into the environmental impact of different exhaust systems and the role of noise reduction technologies in minimizing pollution.

Conclusion

This exploration has detailed the critical role of an exhaust noise reduction device, addressing its functionality, material composition, construction methods, and influence on vehicle performance. Understanding these elements provides a comprehensive perspective on optimizing vehicle operation while adhering to environmental regulations. Careful consideration of materials and construction impacts longevity and sound dampening capabilities, contributing to a decrease in acoustic pollution and a vehicle’s overall performance.

Continued awareness and proper maintenance of such systems remain essential for mitigating noise pollution, improving fuel efficiency, and sustaining optimal engine operation. Vigilance in identifying and rectifying issues will yield long-term benefits, contributing to a safer and more environmentally conscious transportation ecosystem. This commitment to system maintenance reinforces a dedication to both vehicle longevity and responsible environmental stewardship.