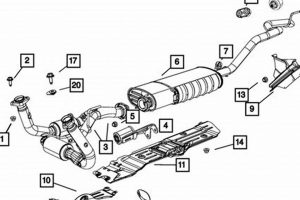

This component is a crucial element in vehicle exhaust systems, serving as the joint between the muffler and other exhaust pipes. It provides a secure and leak-proof connection, ensuring efficient channeling of exhaust gases away from the engine. An example would be a clamp or flange that joins the tailpipe to the silencer.

A properly functioning joint of this type is essential for maintaining optimal engine performance and reducing emissions. A damaged or corroded one can lead to exhaust leaks, reduced fuel efficiency, increased noise, and potentially harmful gases entering the vehicle cabin. Historically, these junctions were simple welds, but modern designs incorporate more sophisticated materials and clamping mechanisms for improved durability and ease of maintenance.

The selection and maintenance of this junction are key factors in the overall health and performance of an exhaust system. The following sections will delve into specific materials, installation techniques, and common issues related to this critical part.

Muffler Connector

Proper maintenance and selection are crucial to ensure optimal exhaust system performance and longevity. The following tips offer guidance on maximizing the effectiveness of these components.

Tip 1: Material Selection: Choose materials appropriate for the vehicle and operating environment. Stainless steel offers superior corrosion resistance compared to aluminized steel, particularly in regions with harsh winters or coastal environments. This choice directly impacts the lifespan of the junction.

Tip 2: Secure Clamping: Ensure adequate clamping force during installation. Over-tightening can damage pipes, while insufficient force can lead to leaks. Torque specifications provided by the manufacturer should be strictly adhered to.

Tip 3: Regular Inspection: Conduct routine visual inspections for signs of corrosion, rust, or damage. Early detection of issues can prevent more significant problems down the line, such as complete exhaust system failure.

Tip 4: Proper Alignment: During installation, ensure proper alignment of pipes. Misalignment can create stress on the junction and accelerate wear. Using appropriate exhaust hangers is critical to maintaining proper alignment.

Tip 5: Anti-Seize Application: Apply anti-seize compound to bolts and threads during assembly. This facilitates easier disassembly for future maintenance or repairs, preventing seizing due to corrosion.

Tip 6: Professional Installation: For complex exhaust systems or when lacking experience, consider professional installation. Certified technicians possess the necessary tools and expertise to ensure proper installation and prevent future issues.

Tip 7: Replacement Timing: Replace corroded or damaged components promptly. Ignoring these problems can lead to exhaust leaks, reduced fuel efficiency, and potential safety hazards.

Implementing these practices enhances the efficiency and lifespan of these vital components, contributing to overall vehicle performance and safety.

The subsequent section will cover common troubleshooting techniques and diagnostic procedures.

1. Secure attachment

Secure attachment is a primary function. Failure to achieve this state results in immediate and consequential operational deficiencies. The joint must withstand constant vibration, temperature fluctuations, and exposure to corrosive elements. The integrity of the seal is compromised if the attachment weakens, resulting in exhaust leaks, noise pollution, and potential safety hazards. For example, a vehicle subjected to frequent off-road use or heavy loads requires a more robust connection than one used for standard commuting. The practical significance lies in preventing catastrophic failure, which can lead to costly repairs and vehicle downtime. A fractured union can allow extremely hot exhaust gases to contact combustible materials under the vehicle, potentially igniting a fire.

The means of achieving secure attachment vary depending on the exhaust system design and materials. Common methods include welding, clamping, and flanging. Each method has distinct advantages and disadvantages concerning cost, ease of installation, and long-term reliability. Welding offers a permanent, leak-proof seal but is difficult to perform in situ. Clamps provide a balance of ease of installation and adjustability but may require periodic retightening. Flanges offer a rigid, leak-proof connection but are more complex and expensive to install. The selection of the attachment method should consider the specific application and environmental conditions.

In conclusion, the capacity to create a robust and enduring union between the silencer and adjacent exhaust piping is non-negotiable for optimal performance and safety. The challenges involve selecting appropriate materials and attachment methods, ensuring proper installation techniques, and implementing a regular inspection and maintenance schedule. The principles governing its secure attachment extend to the entire exhaust system, highlighting the importance of a holistic approach to vehicle maintenance.

2. Leak-proof seal

The achievement of a leak-proof seal is paramount in the performance and longevity of an exhaust system component. The primary function of this system section is to efficiently channel exhaust gases away from the engine, minimizing emissions and noise pollution. Any compromise in the integrity of this union directly undermines these objectives. Exhaust leaks introduce harmful gases into the vehicle cabin, degrade engine performance, increase noise levels, and contribute to environmental pollution. A compromised seal also reduces the effectiveness of the catalytic converter, further increasing harmful emissions. For instance, a pinhole leak near the passenger compartment can introduce carbon monoxide, a colorless, odorless, and potentially lethal gas. A compromised seal may result in the vehicle failing emissions inspections, rendering it illegal to operate on public roads.

The design and material selection play crucial roles in achieving and maintaining a leak-proof seal. Precise machining of mating surfaces, coupled with the use of appropriate sealing materials (e.g., gaskets, sealants), is essential. Clamping mechanisms must provide uniform pressure distribution to ensure a consistent seal around the entire circumference of the connection. Welding, when employed, requires skilled execution to prevent porosity or incomplete fusion, both of which can lead to leaks. Consider the application of thread sealants on fasteners used in flanged connections, prevents leaks caused by imperfections in the threads or gradual loosening due to vibration. In high-performance applications, specialized gaskets made from high-temperature materials are often necessary to withstand extreme heat and pressure.

In conclusion, a leak-proof seal is not merely a desirable attribute, but a fundamental requirement for proper exhaust system operation and environmental compliance. The practical significance of this understanding lies in the ability to diagnose and address seal failures promptly, preventing costly repairs, ensuring occupant safety, and minimizing environmental impact. The continual vigilance in monitoring and maintaining the sealing integrity of these components is a critical aspect of responsible vehicle ownership and maintenance practices.

3. Material compatibility

The selection of materials for a silencer joining component is critically dependent on material compatibility to ensure long-term structural integrity and functional performance. A mismatch in material properties can lead to accelerated corrosion, mechanical failure, and compromised exhaust system operation. This component is typically situated in a harsh environment, exposed to high temperatures, corrosive gases, and mechanical stress. Material compatibility considerations are essential for preventing galvanic corrosion, a process that occurs when dissimilar metals are in electrical contact in the presence of an electrolyte. For example, directly joining steel to aluminum without an insulating barrier results in rapid corrosion of the aluminum due to its lower galvanic potential. Such corrosion weakens the attachment, leading to exhaust leaks and potential component failure.

Beyond galvanic corrosion, thermal expansion coefficients must also be considered. Materials with significantly different expansion rates can induce stress at the connection point as temperatures fluctuate. Over time, this stress can cause cracking, loosening of fasteners, and eventual failure of the union. An example would be using a stainless steel connector with a carbon steel exhaust pipe; the different expansion rates, especially in a hot climate, can lead to stress fractures in the carbon steel near the weld or clamp point. Furthermore, the chemical compatibility of materials with exhaust gases is crucial. Certain metals may be susceptible to corrosion from specific components within the exhaust stream, such as sulfur compounds or chlorides. A connector made of low-grade steel could corrode rapidly in an environment with high sulfur content, significantly shortening its lifespan.

Therefore, careful attention to material compatibility is essential when selecting or replacing silencer joining components. It is recommended to use materials that are galvanically compatible and have similar thermal expansion coefficients. Where dissimilar metals are unavoidable, the use of insulating barriers and protective coatings can mitigate the risk of corrosion. Selecting materials that are resistant to the specific chemical environment of the exhaust stream ensures long-term durability and reliability. Neglecting these considerations can lead to premature failure of the joint, necessitating costly repairs and potentially compromising vehicle safety and emissions compliance.

4. Corrosion resistance

Corrosion resistance is a paramount design and material selection factor for any silencer joint component. Located within the undercarriage of a vehicle, this junction is constantly subjected to a harsh environment characterized by moisture, road salts, and high exhaust gas temperatures, making it exceptionally vulnerable to degradation.

- Material Composition and Grade

The grade and composition of the metal significantly affect its susceptibility to corrosion. Stainless steel alloys, particularly those containing molybdenum, offer superior resistance to pitting and crevice corrosion compared to standard carbon steel. Aluminized steel provides a degree of protection but is more prone to degradation when the aluminum coating is compromised. A high-quality alloy with chromium content can greatly increase the lifespan of the component in corrosive environments.

- Protective Coatings and Treatments

The application of protective coatings such as ceramic-based paints, powder coatings, or sacrificial zinc layers can substantially enhance corrosion resistance. These coatings act as a barrier, preventing corrosive agents from directly contacting the underlying metal. Regular application of rust-inhibiting sprays can also prolong the component’s lifespan, especially in regions with heavy road salt usage. Protective coatings also can prevent galvanic corrosion between dissimilar metals.

- Weld Quality and Integrity

The integrity of welds is crucial, as weld defects such as porosity or incomplete fusion provide initiation sites for corrosion. High-quality welding techniques, such as TIG or MIG welding with appropriate filler materials, minimize the risk of corrosion-related failures. Proper post-weld cleaning and passivation further enhance corrosion resistance by removing surface contaminants and promoting the formation of a protective oxide layer.

- Environmental Factors

The operational environment significantly impacts the rate of corrosion. Vehicles operating in coastal regions, where exposure to salt spray is prevalent, or in areas with harsh winter conditions requiring heavy road salt application, experience accelerated corrosion rates. Furthermore, exposure to high exhaust gas temperatures exacerbates corrosion processes, particularly in the presence of moisture and corrosive compounds.

The ability of a silencer joint component to withstand corrosive forces directly influences its service life and the overall performance of the exhaust system. Prioritizing corrosion resistance through material selection, protective treatments, and quality manufacturing processes is essential for ensuring long-term reliability and preventing costly repairs.

5. Diameter matching

Proper diameter matching is a critical consideration during the selection and installation of any muffler joint. Incompatible dimensions between exhaust components introduce inefficiencies, potentially compromising engine performance, increasing noise levels, and accelerating wear on the exhaust system.

- Exhaust Gas Flow Dynamics

Diameter mismatching disrupts the smooth flow of exhaust gases, creating turbulence and backpressure. This increased backpressure reduces engine efficiency, potentially leading to a decrease in horsepower and fuel economy. For instance, if the pipe is excessively smaller than the muffler inlet, the constricted flow may cause the engine to work harder, resulting in overheating and reduced performance. Proper sizing maintains optimal gas velocity for scavenging and efficient exhaust removal.

- Joint Integrity and Seal

A significant diameter difference complicates the establishment of a secure, leak-proof seal. Attempting to join pipes with mismatched diameters often requires makeshift adapters or excessive clamping force, neither of which provides a reliable long-term solution. This can lead to exhaust leaks, which not only increase noise but also introduce harmful gases into the vehicle cabin. Ensuring components are the same size minimizes the need for excessive clamping and improper sealing methods.

- Component Compatibility and Installation

Diameter incompatibility can render certain joining methods impractical or impossible. Welding, for example, becomes significantly more challenging when dealing with substantial dimensional differences. Similarly, standard clamps designed for a specific pipe size may not provide adequate grip on pipes with significantly smaller or larger diameters. Selecting correctly sized components streamlines installation and reduces the risk of improper or unsafe connections.

- System Resonance and Noise Cancellation

Exhaust systems are often designed to leverage specific pipe diameters to control resonance and cancel out certain frequencies, thus reducing overall noise levels. Introducing diameter mismatches can disrupt these carefully calibrated designs, leading to increased noise or undesirable tonal characteristics. Maintaining consistent dimensions within the exhaust system helps preserve the intended noise-cancellation properties.

The relationship between diameter matching and silencer joint performance is inextricably linked. Deviations from specified dimensions should be addressed promptly to avoid potential problems that could compromise overall vehicle performance, reliability, and safety. Furthermore, proper diameter matching will ensure the exhaust fulfills any legal requirements.

6. Proper alignment

The alignment of exhaust components, particularly the muffler and its interfacing elements, is paramount to the longevity and efficient operation of the exhaust system. A properly aligned silencer union minimizes stress, prevents premature wear, and ensures optimal exhaust gas flow.

- Stress Reduction on Components

Misalignment introduces undue stress on the union and adjacent exhaust piping. This stress concentration accelerates fatigue failure, potentially leading to cracks or breaks in the metal. Ensuring proper alignment distributes forces evenly, mitigating stress and extending the service life of these elements. An example includes the strain on a weld if a silencer is hanging askew, versus a well-aligned exhaust where weight and vibrations are evenly distributed.

- Leak Prevention at Joints

Poor alignment compromises the integrity of the seal, leading to exhaust leaks. Leaks reduce engine efficiency, increase noise pollution, and pose potential health hazards due to the ingress of harmful gases into the vehicle cabin. Accurate alignment facilitates a tight, uniform seal, preventing leaks and ensuring optimal exhaust system performance. Securing with gaskets and correct torque settings are very crucial.

- Minimizing Vibrational Stress

An exhaust system experiences significant vibration during vehicle operation. Misalignment amplifies these vibrations, further stressing the union and its associated hardware. Proper alignment, in conjunction with appropriate exhaust hangers, dampens vibrations, reducing the risk of component failure. A misaligned exhaust will amplify the vibrations through contact with the chassis.

- Facilitating Ease of Maintenance

Accurate alignment simplifies future maintenance and repairs. When components are properly aligned, disassembly and reassembly are less challenging, reducing the risk of damage during servicing. Conversely, misaligned parts often require excessive force to remove, potentially causing damage to threads or adjacent components.

The interplay between proper alignment and the silencer union is thus a critical factor in overall exhaust system reliability and performance. By minimizing stress, preventing leaks, and facilitating maintenance, accurate alignment ensures the long-term health and efficiency of the vehicle’s exhaust system.

Frequently Asked Questions About Muffler Connectors

The following questions address common concerns and provide essential information regarding these crucial exhaust system components.

Question 1: What are the primary functions of a muffler connector?

Its primary function is to provide a secure, leak-proof joint between the muffler and other exhaust system components. It must withstand high temperatures, vibration, and corrosive elements, ensuring efficient exhaust gas channeling.

Question 2: What materials are commonly used in the manufacturing of muffler connectors, and why?

Common materials include stainless steel, aluminized steel, and, in some cases, galvanized steel. Stainless steel offers superior corrosion resistance, while aluminized steel provides a cost-effective alternative with moderate corrosion protection. Galvanized steel is less common due to its limited lifespan in high-temperature environments.

Question 3: What are the signs of a failing muffler connector?

Signs of failure include exhaust leaks (audible as a hissing or roaring sound), visible corrosion or rust, decreased fuel efficiency, increased engine noise, and the presence of exhaust fumes inside the vehicle cabin. A visual inspection can often reveal physical damage, such as cracks or broken welds.

Question 4: How critical is proper sizing during the installation of a muffler connector?

Proper sizing is crucial. A mismatch in diameter can create turbulence in the exhaust flow, increasing backpressure and reducing engine performance. It also makes achieving a secure, leak-proof seal significantly more difficult. Incorrect dimensions will compromise functionality.

Question 5: Can a damaged muffler connector be repaired, or does it require replacement?

Minor surface rust may be addressed with rust converters and protective coatings. However, significant corrosion, cracks, or structural damage typically necessitate replacement. Attempting to repair severely damaged components is generally not recommended due to safety concerns and the potential for recurring failure.

Question 6: What are the potential safety hazards associated with a faulty muffler connector?

A faulty connector can lead to exhaust leaks, potentially exposing occupants to harmful gases such as carbon monoxide. It can also increase the risk of fire due to the presence of hot exhaust gases near flammable materials. A detached muffler can create a road hazard, posing a risk to other drivers.

Understanding the importance of these frequently asked questions will result in extending the lifespan of the exhaust and improving drive quality.

This concludes the frequently asked questions section. The following segment will cover best practices.

Conclusion

Throughout this exploration, the function, materials, maintenance, and potential issues associated with the muffler connector have been detailed. The necessity of proper selection based on material compatibility, diameter matching, and corrosion resistance has been emphasized. The consequences of neglecting the component’s integrity, which range from reduced engine efficiency to potential safety hazards, have also been thoroughly examined.

The muffler connector, while seemingly a minor element, is integral to the exhaust system’s overall performance and the vehicle’s safe operation. A continued focus on regular inspection and proactive maintenance of the muffler connector is essential for vehicle owners and technicians alike, ensuring long-term reliability and minimizing potential risks.