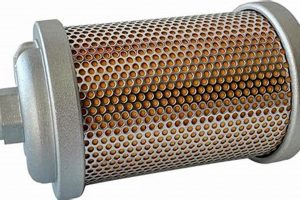

The term describes an automotive exhaust component designed to reduce engine noise. It is a vital part of a vehicle’s exhaust system, contributing to a quieter and more comfortable driving experience. This part functions by dampening sound waves generated by the engine’s combustion process as they travel through the exhaust system. An example would be the model of a component installed to ensure that a vehicle operates within permissible noise levels.

Its importance lies in its ability to mitigate noise pollution and comply with regulatory standards related to vehicle emissions and sound levels. Historically, the evolution of this component has been driven by advancements in materials science and acoustic engineering, leading to more efficient and durable designs. The benefits include reduced noise levels both inside and outside the vehicle, contributing to a more pleasant environment and adherence to legal requirements.

The following sections will explore different aspects related to vehicle exhaust systems and their maintenance. This includes detailed discussions about part selection, installation procedures, and troubleshooting common issues associated with these components. The longevity and optimal function of these components are key for the overall health of a vehicle.

Maintenance and Longevity Tips

Optimizing the lifespan and functionality of exhaust systems requires adherence to specific maintenance protocols and preemptive measures. The following tips outline critical considerations for ensuring sustained performance and preventing premature failure.

Tip 1: Regular Inspection: Conduct routine visual inspections for signs of corrosion, damage, or leaks. Early detection can prevent minor issues from escalating into costly repairs.

Tip 2: Address Rust Promptly: Apply rust inhibitors or protective coatings to exposed surfaces. This proactive approach mitigates the damaging effects of environmental factors.

Tip 3: Avoid Short Trips: Minimize short trips that do not allow the exhaust system to reach optimal operating temperature. Condensation buildup within the system can accelerate corrosion.

Tip 4: Proper Installation: Ensure that replacements are installed correctly according to manufacturer specifications. Improper installation can introduce stress points and compromise the integrity of the system.

Tip 5: Check for Exhaust Leaks: Monitor for unusual exhaust noises or odors, which may indicate leaks. Addressing leaks promptly can prevent performance degradation and safety hazards.

Tip 6: Be Careful With Speed Bumps and Rough Roads: Drive with caution over speed bumps and rough roads. Bumps in the road can damage exhaust components and lead to costly repair.

Tip 7: Maintain the Engine: A well-maintained engine reduces stress on the exhaust system. Properly functioning engine produces less exhaust, contributing to overall exhaust system health.

Implementing these tips will contribute to the extended lifespan and reliable operation of this critical automotive component. Consistent maintenance reduces the likelihood of unexpected failures and ensures compliance with emission standards.

The subsequent sections will provide further insights into troubleshooting common exhaust system issues and selecting suitable replacement parts based on vehicle specifications and performance requirements.

1. Noise Reduction

Effective noise reduction is a primary function of automotive exhaust systems. The design and functionality of the component directly influences a vehicle’s acoustic profile and its compliance with noise pollution regulations. This section explores key facets of this relationship.

- Internal Baffle Design

Internal baffle design is the cornerstone of sound attenuation. Baffles strategically redirect and disrupt sound waves within the component, causing them to collide and cancel each other out, reducing the overall noise output. Different baffle configurations (e.g., straight-through, S-shaped) yield varying degrees of noise reduction, impacting vehicle performance and noise levels. A straight-through design could prioritize performance, offering less noise reduction, while an S-shaped design emphasizes noise dampening.

- Sound Absorption Materials

Materials such as fiberglass, steel wool, and ceramic packing are incorporated to absorb sound energy. These materials convert acoustic energy into heat, further reducing noise propagation through the exhaust system. The type and density of the chosen material directly influence the component’s noise reduction capabilities and its resistance to degradation over time. For instance, ceramic packing has a longer lifespan at high temperatures but may be more expensive than fiberglass.

- Resonator Integration

Resonators are additional chambers within the exhaust system designed to cancel out specific sound frequencies. They operate on the principle of destructive interference, where sound waves of a particular frequency are reflected and phase-shifted to negate the original sound wave. Integrating resonators allows for targeted noise reduction without significantly restricting exhaust flow. A common example involves targeting low-frequency engine drone.

- System Design and Tuning

The overall design of the exhaust system, including pipe diameter, length, and bend radius, affects its acoustic properties. Optimizing these parameters can improve noise reduction while maintaining engine performance. Tuned exhaust systems are designed to minimize backpressure while effectively dampening unwanted sounds, achieving a balance between noise levels and vehicle performance. This tuning may involve adjusting pipe lengths to create specific resonant frequencies.

These facets collectively determine the noise reduction effectiveness of the component. The design must balance noise suppression with performance considerations, ensuring the vehicle operates within acceptable noise level limits while maintaining engine efficiency. Different designs prioritize these competing objectives, resulting in various trade-offs in performance and noise reduction. Understanding these facets is crucial for selecting the correct component and ensuring optimal vehicle operation.

2. Exhaust Flow

Exhaust flow is a critical determinant of engine performance, directly impacted by the design and function of the automotive exhaust component under consideration. Restriction of exhaust gases diminishes engine efficiency, increasing backpressure and reducing horsepower output. The internal structure of the component, including baffle configuration and pipe diameter, dictates the path and velocity of exhaust gases leaving the engine. An improperly designed component can create excessive backpressure, leading to decreased fuel economy and potential engine damage.

A well-engineered component optimizes exhaust flow while mitigating noise. Straight-through designs offer minimal restriction, maximizing horsepower potential but typically providing less noise reduction. Baffled designs, conversely, increase backpressure to reduce noise, but may compromise performance. For example, high-performance vehicles often utilize straight-through designs with strategically placed resonators to manage noise without significant power loss. Similarly, vehicles subject to stringent noise regulations may employ more restrictive designs, accepting some performance reduction to achieve compliance. Furthermore, the diameter of the piping is important for exhaust flow. Wider pipes offer less resistance but may affect exhaust velocity, which can affect engine performance. The effect is more prominent in high-performance engines.

Understanding the relationship between exhaust flow and the design of this component is crucial for selecting appropriate parts and maintaining vehicle performance. The ability to optimize exhaust flow depends on specific vehicle applications, performance goals, and regulatory requirements. Challenges include balancing noise reduction with power output and ensuring components adhere to emissions standards. Careful consideration of these factors ensures reliable operation and optimal engine performance.

3. Material Durability

Material durability constitutes a critical factor in the longevity and effectiveness of automotive exhaust components. Exposure to high temperatures, corrosive exhaust gases, road salts, and mechanical stress necessitate robust materials capable of withstanding these harsh conditions. A failure in material integrity directly impacts the operational lifespan and the component’s ability to perform its intended functionnoise reduction and exhaust flow management. For example, a component constructed from low-grade steel is susceptible to rapid corrosion, leading to premature failure, exhaust leaks, and increased noise levels. Conversely, components made from stainless steel or aluminized steel exhibit superior resistance to corrosion and heat, resulting in extended operational life and sustained performance.

The selection of materials directly influences the component’s ability to maintain structural integrity under extreme conditions. Consider the impact of road salt exposure in regions with harsh winters. Low-quality steel corrodes rapidly, weakening the structure and leading to leaks or complete failure. Stainless steel, due to its chromium content, forms a protective oxide layer that resists corrosion, making it a far more durable choice in such environments. In high-performance applications, where exhaust gas temperatures are significantly elevated, materials like titanium or Inconel may be employed to withstand the extreme heat and stress. The cost of materials needs to be balanced with long-term value and performance requirements. The higher initial cost of durable materials is offset by reduced replacement frequency and improved operational reliability.

In summary, material durability is not merely a desirable attribute but a fundamental requirement for effective long-term operation. The careful selection of materials, considering factors such as corrosion resistance, heat tolerance, and mechanical strength, directly impacts the components lifespan, performance, and compliance with noise regulations. While initial cost considerations may influence material choices, prioritizing durability ensures reduced long-term maintenance costs and enhanced vehicle reliability. Neglecting material durability risks premature failure, increased noise pollution, and potential engine damage, underscoring the practical significance of this aspect in the design and maintenance of automotive exhaust systems.

4. Vehicle Compatibility

Vehicle compatibility is a paramount consideration when selecting and installing a replacement exhaust component. The term denotes the precise alignment of the replacement part’s specifications with the original equipment manufacturer (OEM) standards or specified aftermarket requirements for a given vehicle make, model, and year. Failure to ensure compatibility results in a cascade of potential problems, ranging from reduced engine performance and increased noise levels to compromised emissions control and potential mechanical damage. This alignment extends beyond simple physical fitment; it encompasses factors such as exhaust flow characteristics, backpressure thresholds, and mounting point configurations.

The practical significance of vehicle compatibility is exemplified by considering a scenario where an exhaust component designed for a compact car is installed on a high-performance sports car. The smaller pipe diameter and restricted internal baffling of the compact car component would create excessive backpressure, hindering the sports car’s engine’s ability to expel exhaust gases efficiently. This, in turn, would lead to a reduction in horsepower and torque, decreased fuel economy, and potentially overheating. Conversely, installing a high-flow, low-restriction component designed for a high-performance engine on a fuel-efficient sedan could result in increased noise levels exceeding legal limits and decreased low-end torque, negatively impacting the sedan’s drivability. Moreover, the engine control unit (ECU) relies on specific backpressure characteristics to properly regulate fuel injection and ignition timing. Incompatible components disrupt these parameters, resulting in suboptimal engine operation and potentially triggering fault codes.

In conclusion, vehicle compatibility is not merely a matter of convenience; it is a fundamental prerequisite for safe, efficient, and legal vehicle operation. The selection and installation of exhaust components must be guided by meticulous adherence to vehicle-specific requirements, as outlined by the manufacturer or qualified aftermarket suppliers. The challenges inherent in ensuring compatibility underscore the need for informed decision-making and professional installation to avoid detrimental consequences. Disregard for compatibility introduces risks to vehicle performance, longevity, and regulatory compliance, making it an indispensable consideration in exhaust system maintenance and repair.

5. Regulatory Compliance

Compliance with noise emission standards is inextricably linked to the design and functionality of exhaust systems. Governmental regulations dictate maximum permissible noise levels for vehicles, necessitating the integration of noise reduction technologies within the component. Non-compliance results in fines, legal penalties, and potentially the inability to operate the vehicle legally. The component, therefore, functions as a critical element in achieving and maintaining regulatory approval for vehicle operation. For example, California’s stringent noise regulations require vehicles to meet specific decibel limits at various speeds and operating conditions. Components sold in California must demonstrably meet these standards, often requiring certification and labeling to indicate compliance. The effectiveness of noise reduction is directly assessed through standardized testing procedures outlined in these regulations.

The design of the components is often dictated by the need to meet regulatory requirements. Internal baffling, sound-absorbing materials, and resonator configurations are strategically incorporated to attenuate noise without unduly restricting exhaust flow. Manufacturers invest in research and development to optimize these features, ensuring that their products meet the established noise limits. Furthermore, regulations may specify the testing methodologies and equipment used to measure noise emissions. Compliance testing typically involves placing microphones at designated distances from the vehicle and measuring sound levels under controlled conditions. The data obtained is then compared to the regulatory limits to determine whether the vehicle meets the required standards. Failure to meet these standards necessitates redesign or modification of the component to achieve compliance.

In summary, regulatory compliance constitutes a significant driver in the design and manufacturing of components, shaping their features and performance characteristics. Meeting noise emission standards is not merely a legal obligation but an integral aspect of responsible vehicle operation and environmental stewardship. Ignoring regulatory requirements risks financial penalties and jeopardizes a vehicle’s operational legality. Therefore, selecting and maintaining exhaust systems that adhere to established noise standards is crucial for both vehicle owners and manufacturers. The future development and innovation in this sector will continue to be strongly influenced by the evolution and tightening of these regulations.

Frequently Asked Questions About Penn Muffler

This section addresses common inquiries regarding automotive exhaust systems, with a focus on the selection, maintenance, and regulatory aspects of noise reduction components.

Question 1: What factors determine the lifespan of a vehicle’s noise reduction component?

Material composition, operating conditions, and maintenance practices significantly influence the lifespan. Exposure to road salts, high temperatures, and corrosive exhaust gases can accelerate degradation. Regular inspections and prompt repairs of any damage extend the component’s functional life.

Question 2: How does component design impact engine performance?

The internal baffling and pipe diameter of a component affect exhaust flow and backpressure. Excessive backpressure reduces engine efficiency, while insufficient backpressure can negatively impact low-end torque. Optimal designs balance noise reduction with exhaust flow characteristics to maximize engine performance.

Question 3: What are the key indicators of a failing component?

Increased exhaust noise, reduced fuel economy, and visible signs of corrosion are common indicators. Additionally, the presence of exhaust leaks, identified by unusual odors or hissing sounds, signifies a potential failure.

Question 4: Why is it important to select a component that is compliant with regulations?

Compliance with noise emission standards is legally mandated. Operating a vehicle with a non-compliant exhaust system results in fines and potential vehicle impoundment. Furthermore, non-compliant systems contribute to noise pollution, impacting the environment and public health.

Question 5: What materials are best suited for constructing a durable noise reduction component?

Stainless steel and aluminized steel are preferred due to their corrosion resistance and heat tolerance. These materials provide extended operational life and withstand harsh environmental conditions. Materials like titanium and Inconel are used for high-performance applications.

Question 6: How does component maintenance affect warranty coverage?

Failure to adhere to recommended maintenance schedules may void the warranty. Regular inspections, prompt repairs, and the use of approved replacement parts are essential for maintaining warranty coverage. Always consult the warranty documentation for specific requirements.

Selecting and maintaining a component that meets both performance and regulatory standards contributes to safe, efficient, and environmentally responsible vehicle operation.

The following section will address best practices for component replacement, including essential tools, installation procedures, and troubleshooting techniques.

Conclusion

The preceding discussion has elucidated the multifaceted aspects of the penn muffler, encompassing its role in noise reduction, exhaust flow management, material durability, vehicle compatibility, and regulatory compliance. Its proper selection, installation, and maintenance are paramount to ensuring vehicle performance, longevity, and adherence to established environmental standards. A comprehensive understanding of these factors enables informed decision-making and responsible vehicle operation.

The ongoing evolution of automotive technology and environmental regulations will undoubtedly shape the future development of noise reduction components. Continued research and innovation in materials science, acoustic engineering, and exhaust system design are essential to meet increasingly stringent requirements. The significance of investing in quality components and adhering to recommended maintenance practices cannot be overstated, contributing to both individual vehicle performance and the broader goal of environmental sustainability.