A component designed to reduce the noise emitted from internal combustion engines by dampening sound waves within the exhaust system. This device is typically constructed from materials resistant to high temperatures and corrosive gases, featuring a series of chambers and baffles to attenuate sound pressure levels. As an example, a vehicle’s system incorporates this element downstream from the catalytic converter to meet regulatory noise standards.

Its proper functioning is vital for maintaining environmental noise pollution at acceptable levels and contributing to vehicle operator and community comfort. Historically, improvements in its design have aimed to achieve a balance between noise reduction, exhaust flow efficiency, and overall system weight. The evolution of these components reflects advancements in material science and acoustic engineering.

The ensuing discussion will delve into the specific types available, their construction, performance characteristics, maintenance requirements, and the factors to consider when selecting one for a particular application. It will also address common issues, troubleshooting methods, and best practices for extending its service life.

Maintenance and Optimization Strategies

The following guidelines are presented to ensure optimal performance and longevity of noise reduction components within exhaust systems.

Tip 1: Conduct Regular Visual Inspections: Examine the exterior for signs of corrosion, physical damage (dents, cracks), or leaks. Early detection of such issues can prevent more significant problems and costly replacements.

Tip 2: Monitor Exhaust System Sounds: Changes in exhaust note, such as increased loudness or rattling, can indicate internal damage or deterioration of the internal baffling. Investigate any unusual noises promptly.

Tip 3: Address Corrosion Promptly: Apply rust inhibitors or protective coatings to exposed surfaces, especially in regions with harsh climates or road salt usage. Regular treatment can significantly extend service life.

Tip 4: Ensure Proper Mounting and Support: Verify that mounting brackets and hangers are secure and free from excessive vibration. Loose or damaged supports can lead to premature failure due to stress and fatigue.

Tip 5: Optimize Engine Tuning: Incorrect engine tuning can lead to increased exhaust gas temperatures, accelerating degradation of internal components. Ensure the engine operates within specified parameters.

Tip 6: Consider Material Upgrades: When replacing a worn-out unit, explore options with improved materials, such as stainless steel, for enhanced durability and resistance to corrosion.

Adherence to these maintenance and optimization strategies will contribute to a quieter vehicle operation, extended component lifespan, and reduced environmental impact.

The subsequent sections will cover troubleshooting common problems and provide guidance on selecting appropriate replacements when necessary.

1. Material Composition

The material composition of an exhaust noise reduction device directly dictates its performance, durability, and service life. The high temperatures and corrosive gases present within an exhaust system necessitate the use of materials that can withstand these harsh conditions without degradation. For instance, stainless steel alloys, commonly employed in premium models, offer superior resistance to rust and oxidation compared to lower-grade aluminized steel. This resistance translates to a longer operational lifespan, particularly in regions with high humidity or frequent exposure to road salts. The selection of appropriate materials also influences the device’s ability to effectively dampen sound waves; certain alloys possess inherent acoustic properties that enhance noise reduction capabilities.

The practical significance of understanding material composition lies in its impact on overall cost-effectiveness. While a less expensive component made from standard steel may offer a lower initial price point, its susceptibility to corrosion and premature failure can result in higher long-term replacement costs. Conversely, investing in a unit constructed from a high-grade alloy can yield significant savings over time by minimizing the frequency of replacements and reducing maintenance requirements. This decision is further complicated by considerations of weight; lighter materials, such as titanium alloys, can improve vehicle performance but often come at a considerably higher price. The design must balance cost, performance, and longevity.

In summary, material composition is a critical factor in determining the performance and reliability of exhaust noise reduction solutions. Selecting the appropriate materials based on specific application requirements and environmental conditions is essential for maximizing the return on investment and ensuring long-term operational efficiency. Neglecting this aspect can lead to premature component failure, increased maintenance costs, and potential environmental concerns related to excessive noise pollution.

2. Internal Baffle Design

Internal baffle design represents a critical determinant of performance within exhaust noise reduction devices. The configuration of these internal components directly impacts the attenuation of sound waves generated by the engine’s combustion process. A well-designed system of baffles strategically redirects and reflects sound waves, causing them to collide and cancel each other out, thereby reducing the overall noise level emitted from the exhaust system. Ineffective baffle design can lead to inadequate noise suppression and potential violations of noise regulations.

Consider, for example, a straight-through design with minimal baffling. Such a configuration might offer low exhaust backpressure, beneficial for engine performance, but would provide limited noise reduction. Conversely, a complex labyrinth of baffles can achieve substantial noise attenuation but may also increase backpressure, potentially hindering engine efficiency. Automotive engineers must therefore strike a delicate balance between noise reduction and performance optimization when designing internal baffle systems. The effectiveness of the internal baffle design is often validated through rigorous acoustic testing and computational fluid dynamics simulations.

In summary, the internal baffle design functions as a key element in achieving desired noise reduction levels. The configuration of these components directly influences the attenuation of sound waves and the overall performance of the system. Challenges arise in balancing noise reduction with potential increases in exhaust backpressure. Understanding the principles of acoustic design and the trade-offs involved is essential for developing exhaust systems that meet both regulatory requirements and performance expectations.

3. Sound Wave Attenuation

Sound wave attenuation is the fundamental principle upon which the function of an exhaust noise reduction device depends. The device is engineered to reduce the amplitude of sound waves generated by engine combustion before they are released into the environment. The effectiveness of this process directly correlates with the device’s ability to meet noise emission standards and contribute to a quieter operational environment. The primary purpose is to dissipate sound energy, converting it into other forms of energy, typically heat, through processes like absorption and interference.

The device employs various methods to achieve sound wave attenuation. These include: reflective baffling, which redirects sound waves and causes destructive interference; absorptive materials, which convert sound energy into heat; and expansion chambers, which reduce sound pressure by increasing the volume through which the waves propagate. Consider a passenger vehicle required to meet specific noise regulations. Its system incorporates a series of strategically placed baffles and chambers designed to cancel out specific frequencies of sound produced by the engine. Without effective attenuation, the vehicle would exceed acceptable noise limits.

The design and optimization of sound wave attenuation within an exhaust noise reduction device present ongoing challenges. Achieving optimal noise reduction often involves trade-offs with exhaust backpressure, which can negatively impact engine performance. Furthermore, the materials used must withstand high temperatures and corrosive gases while maintaining their acoustic properties over extended periods. Successful implementation requires a comprehensive understanding of acoustics, thermodynamics, and material science, alongside rigorous testing and validation procedures. In conclusion, sound wave attenuation is not merely a feature; it is the defining characteristic of effective exhaust noise control, crucial for environmental compliance and operational comfort.

4. System Backpressure

System backpressure, a critical parameter in exhaust system design, directly influences engine performance and the functional requirements of the noise reduction component. It refers to the resistance encountered by exhaust gases as they flow through the system, from the engine’s exhaust ports to the tailpipe. The design of the device significantly contributes to this backpressure, necessitating a carefully balanced approach to ensure optimal engine operation and noise attenuation.

- Impact on Engine Performance

Excessive backpressure restricts the efficient expulsion of exhaust gases from the engine cylinders, leading to reduced volumetric efficiency, decreased power output, and increased fuel consumption. The presence of a overly restrictive noise reduction device is a primary contributor to this phenomenon, particularly at higher engine speeds where exhaust gas flow rates are elevated. Conversely, insufficient backpressure can also negatively impact engine performance in certain applications, resulting in poor low-end torque and increased emissions.

- Design Trade-offs

Designing a noise reduction component involves inherent trade-offs between noise attenuation and backpressure. Effective noise reduction typically requires the incorporation of internal baffles, chambers, and absorptive materials, all of which increase flow resistance. Engineers must optimize the internal design to minimize backpressure while maintaining acceptable noise levels. Computational fluid dynamics (CFD) simulations and acoustic testing are frequently employed to evaluate and refine these designs.

- Material Selection and Flow Path

The choice of materials and the internal flow path significantly influence backpressure. Smooth, mandrel-bent tubing and lightweight materials such as stainless steel can reduce flow resistance compared to crimped tubing and heavier materials. The internal geometry, including the size and shape of perforations in baffles, plays a critical role in minimizing turbulence and pressure drop. A well-designed component minimizes sharp bends and constrictions in the exhaust gas flow path.

- Catalytic Converter Integration

The noise reduction component is often positioned downstream of the catalytic converter, and the combined backpressure of both components must be considered. A clogged or restrictive catalytic converter can significantly increase overall system backpressure, exacerbating the negative effects on engine performance. Periodic inspection and maintenance of the catalytic converter are therefore essential to ensure optimal exhaust system function.

The interplay between these facets underscores the importance of considering system backpressure when selecting or modifying a noise reduction component. A carefully chosen and properly maintained noise reduction component contributes to both effective noise control and optimal engine performance. Modifications to the exhaust system should be performed with a full understanding of their potential impact on backpressure and overall vehicle operation.

5. Thermal Resistance

Thermal resistance, a measure of a material’s opposition to heat flow, is a critical consideration in the design and operation of exhaust noise reduction devices. The extreme temperatures generated by internal combustion engines necessitate the use of materials and designs capable of withstanding prolonged exposure to high heat without compromising structural integrity or acoustic performance.

- Material Selection for High-Temperature Environments

The materials used in the construction of noise reduction devices must exhibit high thermal resistance to prevent warping, cracking, or melting under extreme operating conditions. Stainless steel alloys, commonly used in high-performance applications, offer superior thermal resistance compared to aluminized steel. The choice of material directly influences the device’s lifespan and its ability to maintain its acoustic properties over time. An example of this would be comparing a muffler made of 304 stainless steel versus one made of mild steel.

- Impact on Acoustic Performance

Elevated temperatures can alter the acoustic properties of materials used in the device, potentially affecting its noise reduction capabilities. Some absorptive materials may become less effective at high temperatures, leading to increased noise emissions. The design must account for these temperature-dependent variations in material properties to ensure consistent acoustic performance across a range of operating conditions. Such variation could require the use of specific high-temperature baffling or sound-dampening materials.

- Design Considerations for Heat Dissipation

Effective heat dissipation is essential to prevent localized overheating and premature failure. The design may incorporate features such as heat shields, air gaps, or strategically placed cooling fins to promote heat transfer away from critical components. These design elements help to maintain lower operating temperatures and extend the device’s service life. Consider the use of ceramic coatings as a further way of heat dissipation.

- Influence of Exhaust Gas Temperature

Variations in exhaust gas temperature directly impact the thermal stress experienced by the device. Engine tuning, operating conditions, and ambient temperature all contribute to fluctuations in exhaust gas temperature. The design must be robust enough to withstand these variations without compromising its structural integrity or acoustic performance. For example, a racing engine with significant modification may need a higher grade of thermal resistant material.

These facets highlight the intimate connection between thermal resistance and the design considerations of effective exhaust noise reduction devices. Selecting appropriate materials, implementing effective heat dissipation strategies, and accounting for the influence of exhaust gas temperature are crucial for ensuring long-term reliability and performance. Understanding these factors is essential for achieving both effective noise control and optimal engine operation.

6. Corrosion Protection

Effective corrosion protection is paramount in ensuring the longevity and optimal performance of exhaust noise reduction devices. Exposure to corrosive exhaust gases, moisture, and road salts creates a hostile environment that accelerates degradation of metallic components. Adequate corrosion protection is therefore essential for maintaining structural integrity, acoustic performance, and compliance with emissions regulations.

- Material Selection for Corrosion Resistance

The selection of corrosion-resistant materials is the first line of defense against degradation. Stainless steel alloys, particularly grades 304 and 316, offer superior resistance to rust and oxidation compared to aluminized steel or mild steel. Stainless steel’s chromium content forms a passive layer of chromium oxide on the surface, preventing further corrosion. In coastal regions or areas with heavy road salt usage, the use of stainless steel is particularly critical for extending the component’s lifespan. Furthermore, consider the addition of other alloys such as molybdenum and nickel to enhance corrosion resistance for certain applications.

- Protective Coatings and Surface Treatments

Even when using corrosion-resistant materials, the application of protective coatings or surface treatments can further enhance durability. Ceramic coatings, for example, provide a barrier against both corrosion and high temperatures, further extending the lifespan. Aluminizing, a process of coating steel with aluminum, provides a sacrificial layer that corrodes preferentially, protecting the underlying steel. These coatings can be applied to both the exterior and interior surfaces to provide comprehensive protection. Consider using a zinc phosphate coating for further protection.

- Design Considerations for Moisture Drainage

The design of the device can also play a significant role in mitigating corrosion. Incorporating drainage holes at low points allows moisture to escape, preventing the accumulation of corrosive fluids within the component. Proper sealing of joints and seams minimizes the ingress of moisture and exhaust gases into internal cavities. Design considerations can prevent moisture accumulation, leading to corrosion over time.

- Regular Inspection and Maintenance

Even with robust corrosion protection measures in place, regular inspection and maintenance are essential for identifying and addressing potential issues early on. Visual inspections can reveal signs of rust, pitting, or coating damage. Addressing these issues promptly with appropriate repair techniques or protective coatings can prevent further degradation and extend the component’s service life. For example, if rust is spotted, consider sanding down the affected area and applying a rust-inhibiting primer followed by a protective topcoat.

The effective implementation of these corrosion protection strategies contributes directly to the long-term reliability and cost-effectiveness of exhaust noise reduction devices. Neglecting corrosion protection can lead to premature component failure, increased maintenance costs, and potential environmental concerns related to increased noise emissions. A holistic approach to corrosion protection, encompassing material selection, protective coatings, design considerations, and regular maintenance, is essential for maximizing the lifespan and performance of these critical components.

Frequently Asked Questions Regarding the Exhaust Noise Reduction Device

The following section addresses common inquiries and clarifies misconceptions pertaining to the function, maintenance, and selection of exhaust noise reduction devices. This information is intended to provide a comprehensive understanding of these essential components and their impact on vehicle performance and environmental compliance.

Question 1: What is the primary function of an exhaust noise reduction device?

The primary function is to attenuate sound waves generated by the internal combustion engine, minimizing noise emissions and ensuring compliance with regulatory noise standards. It achieves this through a combination of reflective baffling, absorptive materials, and expansion chambers.

Question 2: How does the device affect engine performance?

The design influences exhaust backpressure, which can impact engine performance. Excessive backpressure restricts exhaust gas flow, potentially reducing power output and fuel efficiency. Optimizing the design to minimize backpressure while maintaining adequate noise reduction is crucial.

Question 3: What materials are commonly used in their construction?

Common materials include aluminized steel and stainless steel alloys. Stainless steel offers superior corrosion resistance and longer lifespan, particularly in harsh environments. The selection of material directly affects the device’s durability and performance.

Question 4: How often should the device be inspected?

Regular visual inspections are recommended to identify signs of corrosion, physical damage, or leaks. Inspecting the device at least annually, or more frequently in severe operating conditions, is prudent.

Question 5: What are the symptoms of a failing device?

Symptoms of failure may include increased exhaust noise, rattling sounds, decreased fuel efficiency, and visible signs of corrosion or damage. Addressing these symptoms promptly can prevent further damage and maintain vehicle compliance.

Question 6: Can the device be modified to improve performance?

Modifications should be approached with caution, as they can affect noise emissions and potentially violate regulations. Changes must be carefully considered to avoid compromising noise reduction capabilities or increasing exhaust backpressure excessively.

The information provided in this FAQ section should clarify the role and importance of exhaust noise reduction devices. It is essential to understand the device’s function, maintenance requirements, and the potential impact of modifications.

The succeeding segment will explore advanced technologies and emerging trends in exhaust noise control, shedding light on future developments in this field.

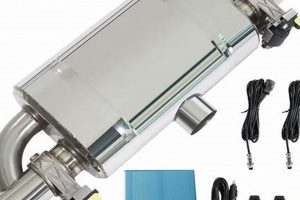

Brexhaust Muffler

This exploration has underscored the multifaceted importance of the brexhaust muffler. Its role extends beyond mere noise reduction; it is integral to maintaining environmental compliance, optimizing engine performance, and ensuring vehicle longevity. Key aspects examined include material composition, internal baffle design, sound wave attenuation, and the critical balance between backpressure and thermal resistance. The necessity of regular maintenance and informed material selection for corrosion protection has also been highlighted. The brexhaust muffler remains a key component in automotive engineering.

The ongoing evolution of brexhaust muffler technology, driven by stricter environmental regulations and the pursuit of enhanced vehicle efficiency, demands continuous assessment and adaptation. Investment in research and development will be crucial to meeting these future challenges and ensuring that brexhaust muffler designs continue to deliver optimal performance and environmental responsibility. Future innovations should focus on integrating noise reduction, thermal management, and backpressure optimization into a single, robust, and long-lasting solution for the automotive industry.

![Fix: AirPods Muffled on Calls? [Solutions & Tips] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: AirPods Muffled on Calls? [Solutions & Tips] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2025/12/th-403-300x200.jpg)