The phrase identifies a specific aftermarket automotive component designed to modify a truck’s exhaust note, enhancing its auditory characteristics to meet the owner’s preference. For instance, an individual might seek a product that produces a deep, resonant rumble rather than the factory-installed muffler’s more subdued sound.

Selecting such a component can significantly impact the perceived quality and enjoyment of the vehicle. It can also provide a sense of personalization and reflect the owner’s taste. The market for these products has evolved over time, with increasing options in materials, designs, and technologies aimed at achieving particular sound profiles.

Subsequently, understanding the factors that contribute to the sound characteristics, exploring various types available, and considering the practical aspects of installation and legal compliance become essential when selecting an appropriate aftermarket truck component. This allows for a knowledgeable purchase that meets individual needs and preferences.

Selecting a Performance Muffler

Choosing a performance muffler involves careful consideration of various factors to achieve the desired sound and performance characteristics. The following tips provide guidance in making an informed decision.

Tip 1: Research Sound Preferences: Determine the desired sound profile before exploring options. Consider factors such as loudness, tone (deep rumble versus aggressive rasp), and presence of drone at highway speeds. Listen to sound clips online or, ideally, in person.

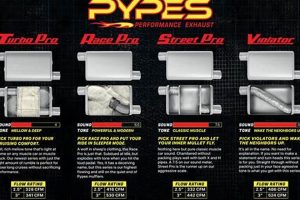

Tip 2: Understand Muffler Types: Different muffler designs produce distinct sound characteristics. Chambered mufflers tend to generate louder, more aggressive tones, while straight-through designs provide improved flow with a more moderate sound. Turbo mufflers offer a balance of both.

Tip 3: Consider Material Quality: The muffler’s material impacts its durability and sound. Stainless steel offers superior corrosion resistance and a brighter sound compared to aluminized steel.

Tip 4: Evaluate Vehicle Compatibility: Ensure the selected muffler is compatible with the truck’s exhaust system specifications. Check inlet/outlet diameter, overall length, and mounting configuration. Modifications may be required for incompatible systems.

Tip 5: Assess Noise Regulations: Verify local and state noise regulations before installing a performance muffler. Excessive noise can result in fines or legal action. Choose a muffler that complies with applicable laws.

Tip 6: Read Reviews and Seek Recommendations: Gather information from online reviews and forums to gauge the performance and sound quality of different mufflers. Solicit recommendations from experienced truck enthusiasts or automotive professionals.

Tip 7: Professional Installation: Consider professional installation to ensure proper fitment and optimal performance. Improper installation can lead to exhaust leaks, reduced performance, and potential damage to the exhaust system.

Selecting the correct performance muffler requires a comprehensive approach, balancing sound preferences, performance considerations, and legal compliance. Thoughtful research and informed decision-making contribute to a satisfying and beneficial upgrade.

These tips offer a foundation for understanding the key aspects of performance muffler selection, facilitating a smoother transition into further explorations of specific brands, models, and installation techniques.

1. Sound Preference

Sound preference forms the foundational element in the pursuit of an optimal aftermarket exhaust enhancement for a truck. This subjective consideration dictates the direction of the selection process, steering choices toward specific muffler types and configurations designed to align with individual auditory expectations.

- Desired Tone Characteristics

The fundamental aspect of sound preference involves the desired tone. This encompasses considerations such as the depth (bass-heavy rumble vs. high-pitched rasp), aggressiveness (moderate vs. very loud), and overall timbre. For example, some individuals might prefer a deep, throaty exhaust note reminiscent of classic muscle cars, while others might seek a more refined and modern sound. The selected muffler must therefore be capable of producing the target tonal qualities.

- Acceptable Volume Levels

Volume represents a critical parameter, as excessive noise can lead to legal repercussions or detract from the driving experience. Sound preference must, therefore, reconcile the desire for an enhanced exhaust note with the practical limitations imposed by noise regulations and personal tolerance levels. A quieter muffler might be preferable in urban environments or during long-distance driving, while a louder option might be suitable for off-road or recreational use.

- Resonance and Drone Considerations

Resonance, often referred to as drone, signifies a low-frequency humming sound that can occur at specific engine speeds. This phenomenon can prove distracting and uncomfortable, particularly on extended drives. Sound preference must include an evaluation of the potential for drone and the selection of mufflers incorporating technologies designed to mitigate this issue. For instance, some mufflers utilize Helmholtz resonators or other internal structures to cancel out unwanted frequencies.

- Application-Specific Considerations

The intended application of the truck influences sound preference. A work truck might benefit from a muffler that enhances performance without generating excessive noise, while a show truck might prioritize aesthetics and a bold exhaust note. Similarly, trucks used for towing might require mufflers that maintain optimal exhaust flow to avoid compromising engine performance. Therefore, sound preference must align with the practical requirements of the vehicle’s intended use.

In conclusion, sound preference is not merely an aesthetic choice but a multifaceted consideration encompassing tone, volume, resonance, and application-specific requirements. A successful selection of a muffler for a truck necessitates a thorough understanding of these factors and their interplay to achieve an exhaust note that satisfies individual preferences while adhering to practical and legal constraints.

2. Muffler Design

Muffler design constitutes a primary determinant of the acoustic properties associated with an exhaust system. Consequently, its understanding is crucial in the selection of an aftermarket component intended to produce a preferred auditory signature.

- Chambered Mufflers

Chambered mufflers utilize a series of internal baffles to redirect exhaust gases, creating sound wave cancellation and reduction. This design typically yields a louder, more aggressive sound profile. The number, size, and arrangement of chambers influence the specific tone produced. In the context of selecting an aftermarket truck exhaust, chambered designs are often chosen by individuals seeking a pronounced, noticeable exhaust note.

- Straight-Through Mufflers

Straight-through mufflers employ a perforated core surrounded by sound-absorbing material, allowing exhaust gases to flow with minimal restriction. This configuration typically results in a less restrictive exhaust flow, potentially enhancing engine performance. The sound produced tends to be smoother and less aggressive compared to chambered designs. Truck owners prioritizing performance gains alongside a moderate sound enhancement frequently consider straight-through designs.

- Turbo Mufflers

Turbo mufflers represent a hybrid design, incorporating elements of both chambered and straight-through approaches. They generally feature a series of S-shaped passages and sound-absorbing materials. This design aims to provide a balance between sound attenuation and exhaust flow. The resulting sound is often characterized as a moderate tone with reduced drone. Turbo mufflers can be a suitable option for individuals seeking a balance between sound enhancement and comfortable driving characteristics.

- Baffled Mufflers

Baffled mufflers employ strategically placed baffles to redirect exhaust flow and cancel out specific sound frequencies, achieving a targeted sound profile. This design enables more precise control over the exhaust note and can be tailored to minimize unwanted drone or maximize desired tones. Baffled mufflers are used on a lot of stock muffler design but performance muffler has a great advancement.

Therefore, the choice of muffler design directly influences the resultant sound characteristics of a truck’s exhaust system. Consideration of the design principles inherent in each type is vital in achieving the desired aural experience. Informed selection necessitates careful evaluation of individual sound preferences and the trade-offs associated with each design configuration.

3. Material Quality

Material quality exerts a substantial influence on the sound characteristics and longevity of a truck’s exhaust component. The specific material used in construction directly affects the resonance, tone, and overall durability, thus playing a critical role in achieving the desired auditory experience and ensuring long-term performance.

- Stainless Steel Composition

Stainless steel, particularly grades like 304 and 409, provides superior corrosion resistance compared to aluminized steel. This inherent property extends the lifespan of the muffler, preventing rust and degradation that can negatively impact sound quality over time. Stainless steel also tends to produce a brighter, more resonant sound compared to other materials. The choice of stainless steel is often preferred in environments where exposure to road salt and corrosive elements is prevalent.

- Aluminized Steel Characteristics

Aluminized steel presents a more cost-effective alternative to stainless steel. It offers a degree of corrosion resistance due to its aluminum coating, although it is less robust than stainless steel in harsh conditions. Mufflers constructed from aluminized steel typically exhibit a mellower, less resonant sound profile. This material choice can be suitable for individuals seeking a balance between affordability and moderate sound enhancement.

- Gauge Thickness and Structural Integrity

The gauge thickness of the material impacts both the structural integrity and sound characteristics. Thicker gauge steel enhances durability and reduces the likelihood of damage from impacts or vibrations. It also contributes to a deeper, more substantial sound. Conversely, thinner gauge material may be more prone to developing leaks or distortions, which can negatively affect sound quality and overall performance.

- Internal Insulation and Sound Absorption

Some performance mufflers incorporate internal insulation or sound-absorbing materials, such as fiberglass packing or ceramic wool. These materials play a crucial role in attenuating high-frequency sounds and minimizing unwanted drone. The quality and density of these materials influence their effectiveness in sound absorption and their resistance to degradation from heat and exhaust gases. Over time, the degradation of these materials can lead to increased noise levels and a change in the overall sound profile.

In summary, material quality serves as a pivotal factor in determining the sound characteristics, durability, and longevity of a truck’s aftermarket exhaust component. A thorough understanding of the properties associated with different materials and their impact on sound quality enables a more informed selection process, aligning the choice with individual preferences, environmental conditions, and performance requirements.

4. Exhaust Flow

Exhaust flow represents a critical parameter in the pursuit of an optimized exhaust note. It significantly influences not only engine performance but also the sound characteristics of a truck’s exhaust system.

- Restriction and Tone

Excessive restriction within the muffler dampens the exhaust pulse, resulting in a muted and less aggressive sound. Conversely, minimal restriction allows for a more direct and forceful sound wave propagation, contributing to a louder and more pronounced exhaust note. A well-designed performance component balances the need for exhaust velocity with the desire for a specific sound profile.

- Backpressure Effects

Altering exhaust flow characteristics impacts engine backpressure, which can influence engine efficiency and performance. A component designed to minimize backpressure may enhance engine power, but also potentially increase exhaust volume. Careful consideration must be given to the trade-offs between performance gains and sound level when selecting an appropriate aftermarket component.

- Muffler Design and Flow Dynamics

Different muffler designs offer varying degrees of exhaust flow. Straight-through designs typically exhibit minimal restriction, while chambered designs introduce more complex flow paths. The internal structure and materials used within the component influence the velocity and turbulence of the exhaust gases, directly impacting the resultant sound. The selection of a muffler design should consider both the desired sound characteristics and the vehicle’s engine specifications to ensure optimal performance.

- Piping Diameter and System Matching

The diameter of the exhaust piping and the overall exhaust system configuration influence exhaust flow. A properly sized exhaust system complements the performance characteristics of the component, optimizing both sound and power output. Mismatched components, such as a component installed on an exhaust system with inadequate piping diameter, can negate potential performance gains and negatively impact the intended sound profile.

The optimization of exhaust flow represents an integral part of achieving a superior exhaust note. Understanding the interplay between restriction, backpressure, component design, and system matching enables a more informed selection, resulting in an aftermarket component that effectively balances performance enhancement with desired auditory characteristics.

5. Resonance Tuning

Resonance tuning plays a crucial role in achieving a desirable exhaust note. It involves manipulating the frequencies and amplitudes of sound waves produced by the engine to eliminate undesirable sounds, like drone, while amplifying more pleasing tones. Its application to a muffler directly impacts the perceived sound quality and overall driving experience.

A muffler design with poor resonance tuning may produce an excessively loud or irritating drone at certain engine speeds, even if the overall tone is initially appealing. Conversely, a well-tuned muffler can deliver a deep, throaty exhaust note without unwanted vibrations or noise. Manufacturers often incorporate Helmholtz resonators, strategically sized chambers, or specific internal baffling to counteract problematic frequencies. A real-world example includes high-performance trucks equipped with sophisticated exhaust systems utilizing electronically controlled valves to actively adjust resonance frequencies based on engine load and speed, effectively mitigating drone across the RPM range.

Understanding resonance tuning enables discerning consumers to prioritize mufflers that not only enhance the exhaust sound but also minimize undesirable side effects. This knowledge aids in making informed purchasing decisions, ensuring the selected component effectively contributes to a satisfying and comfortable driving experience. The practical significance lies in the ability to achieve a customized exhaust note that complements the vehicle’s performance and the driver’s preferences without compromising noise levels or driving comfort.

6. Drone Reduction

Drone reduction represents a key attribute when selecting an aftermarket muffler for a truck. It addresses the persistent, low-frequency humming sound generated within the exhaust system, particularly noticeable during steady-state driving conditions. Its efficacy determines the overall acoustic comfort within the vehicle’s cabin.

- Helmholtz Resonators

Helmholtz resonators involve the incorporation of a specifically sized chamber within the muffler body or exhaust system. This chamber is designed to counteract specific frequencies responsible for drone. By carefully calculating the dimensions of the resonator, engineers can effectively cancel out the targeted sound waves, mitigating the undesirable humming noise. For example, some aftermarket mufflers utilize tunable Helmholtz resonators, allowing users to fine-tune the system to address drone at various RPM ranges. Their precise engineering dictates their effectiveness, offering a targeted solution to specific drone frequencies.

- Quarter-Wave Tubes

Quarter-wave tubes operate on a similar principle to Helmholtz resonators, but employ a tube of a specific length (one-quarter of the wavelength of the target frequency) to create a pressure wave that cancels out the drone. These tubes are less bulky than Helmholtz resonators, making them suitable for applications where space is limited. A common application involves integrating quarter-wave tubes into the tailpipe section of the exhaust system. Their relative simplicity offers a cost-effective approach to drone reduction.

- Sound Absorption Materials

Sound absorption materials, such as fiberglass packing or ceramic wool, are commonly packed within the muffler body. These materials attenuate sound waves by converting acoustic energy into heat through friction. While they are effective at reducing overall noise levels, they also contribute to mitigating drone by dampening low-frequency vibrations. Over time, these materials can degrade, reducing their effectiveness and potentially increasing drone levels. Consequently, the quality and density of the packing material influence long-term performance.

- Muffler Chamber Design

The internal chamber design of the muffler itself can play a role in drone reduction. By carefully arranging baffles and flow paths within the muffler, engineers can disrupt the formation of standing waves that contribute to drone. More complex chamber designs often incorporate varying chamber sizes and shapes to address a wider range of frequencies. This holistic approach to muffler design integrates drone reduction as a fundamental aspect of the acoustic engineering process.

In conclusion, drone reduction is not merely an ancillary feature but a crucial element in the pursuit of an optimal aftermarket muffler for a truck. Effective drone reduction technologies, such as Helmholtz resonators, quarter-wave tubes, sound absorption materials, and optimized chamber designs, contribute to a more comfortable and enjoyable driving experience. The proper application of these techniques reflects a commitment to both sound enhancement and acoustic refinement.

7. Installation Quality

Installation quality significantly influences the performance and sound characteristics of an aftermarket muffler. Deviations from established installation procedures can compromise the intended acoustic properties and even damage the component or vehicle.

- Secure Mounting and Alignment

Proper mounting and alignment of the muffler within the exhaust system are paramount. Loose or misaligned components can generate vibrations and rattles, detracting from the desired sound. Furthermore, misalignment can create stress points, leading to premature wear or even system failure. Secure and properly aligned mounting ensures that the muffler operates as designed, delivering its intended sound characteristics without extraneous noises. For instance, using correct hangers and ensuring adequate clearance from the vehicle’s frame prevents unwanted contact and vibration.

- Leak-Free Connections

Exhaust leaks compromise both performance and sound quality. Leaks introduce disruptive air currents into the exhaust stream, altering the intended flow dynamics and producing undesirable hissing or whistling sounds. Moreover, leaks can allow harmful exhaust gases to enter the vehicle’s cabin. Achieving leak-free connections requires proper sealing techniques, such as using new gaskets and applying exhaust sealant where appropriate. Correctly torquing bolts and clamps to manufacturer specifications prevents leaks and ensures a tight, secure seal.

- Proper Welding Techniques

In cases where welding is necessary to adapt the muffler to the existing exhaust system, the quality of the welds directly impacts the system’s integrity and sound. Poor welds can create flow restrictions, leading to backpressure and negatively affecting engine performance. Moreover, weak or porous welds are prone to failure, potentially causing leaks or even complete separation of exhaust components. Employing skilled welders who utilize appropriate welding techniques and materials ensures strong, leak-free joints that maintain the intended exhaust flow and sound characteristics. Skilled welding helps adapt component to existing system.

- Adherence to Manufacturer Specifications

Following the manufacturer’s installation instructions is essential for achieving optimal performance and sound quality. Deviations from specified procedures, such as incorrect pipe cutting or improper hanger placement, can compromise the system’s overall effectiveness. Manufacturer specifications are based on thorough engineering and testing, ensuring that the muffler functions as intended within the vehicle’s exhaust system. Adhering to these guidelines minimizes the risk of installation errors and maximizes the potential for achieving the desired sound profile and performance gains. Ignoring these specifications can lead to a suboptimal outcome.

In conclusion, installation quality directly influences the realized performance and sound of an aftermarket muffler. Proper mounting, leak-free connections, skilled welding, and adherence to manufacturer specifications are critical factors in ensuring that the component functions as intended. Neglecting these aspects can negate the benefits of even the most advanced component, resulting in a disappointing or even detrimental outcome. Prioritizing installation quality is paramount in achieving the best possible results when upgrading a truck’s exhaust system.

Frequently Asked Questions

The following section addresses common inquiries regarding the selection of an aftermarket muffler designed to enhance a truck’s exhaust note.

Question 1: How is “best sounding muffler for truck” defined?

The term represents a subjective assessment of an aftermarket exhaust component. The perceived quality is determined by individual preferences concerning tone, volume, and absence of undesirable resonance. Objective parameters, such as exhaust flow and material durability, also influence the evaluation.

Question 2: What muffler design is generally considered to produce the most aggressive sound?

Chambered mufflers typically yield a louder, more aggressive exhaust note due to their internal baffle design. However, straight-through designs can produce a similar volume if the sound-deadening material is minimized or absent.

Question 3: Does a more expensive muffler guarantee a superior sound?

Price does not definitively correlate with superior sound. Material quality, construction techniques, and brand reputation influence the cost. A careful assessment of specifications and reviews is necessary to ensure that the component aligns with individual sound preferences.

Question 4: How significant is the impact of exhaust piping on the resulting sound?

Exhaust piping diameter, material, and configuration significantly impact the resulting sound. A larger diameter pipe often enhances volume and alters the tone. Furthermore, pipe material affects resonance characteristics.

Question 5: Are there legal restrictions regarding muffler sound levels?

Many jurisdictions enforce noise regulations pertaining to motor vehicles. Exceeding established decibel limits can result in fines or legal action. It is incumbent upon the vehicle owner to verify local noise ordinances and select a muffler that complies with applicable laws.

Question 6: Can modifications to the exhaust system void the vehicle’s warranty?

Aftermarket modifications may potentially void certain aspects of the vehicle’s warranty. The Magnuson-Moss Warranty Act protects consumers, but manufacturers can deny warranty claims if the aftermarket part directly caused the failure. It is recommended to consult the vehicle’s warranty documentation and seek clarification from the manufacturer or dealership.

In conclusion, the selection of a muffler involves a multi-faceted evaluation encompassing subjective preferences, objective performance parameters, and legal considerations. Informed decision-making facilitates the identification of a component that effectively enhances the truck’s exhaust note while adhering to relevant regulations.

The subsequent section transitions into a summary of essential considerations for informed muffler selection.

Conclusion

The pursuit of the “best sounding muffler for truck” entails a comprehensive understanding of various interacting factors. Selection necessitates careful consideration of individual sound preferences, muffler design characteristics, material quality, exhaust flow dynamics, resonance tuning methodologies, drone reduction techniques, and the critical influence of installation quality. The optimal component effectively balances subjective auditory desires with objective performance parameters, while also ensuring compliance with applicable noise regulations.

Achieving a satisfying result requires diligent research, informed decision-making, and skilled installation practices. Prioritizing these elements enables truck owners to enhance their vehicle’s exhaust note while maintaining performance and complying with legal standards, ultimately leading to an optimized driving experience.

![Fix: Why Does One of My AirPods Sound Muffled? [SOLVED] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: Why Does One of My AirPods Sound Muffled? [SOLVED] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-396-300x200.jpg)

![Fix: Samsung TV Sound Is Muffled? [Solutions & Tips] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: Samsung TV Sound Is Muffled? [Solutions & Tips] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-328-300x200.jpg)