This automotive component plays a critical role in reducing the noise emitted from an internal combustion engine. It achieves this by incorporating a series of chambers and tubes designed to dampen sound waves, effectively minimizing the loud exhaust noises typically associated with vehicle operation. As an example, consider a vehicle experiencing increased sound levels; inspection often reveals a compromise to this part, potentially indicating internal corrosion or physical damage requiring replacement.

The importance of this device extends beyond mere noise reduction. Its proper functioning contributes to compliance with noise pollution regulations, promoting a quieter environment. Moreover, a well-maintained system can positively impact engine performance and fuel efficiency by ensuring proper exhaust flow. Historically, advancements in material science and engineering have led to significant improvements in the durability and effectiveness of these systems, resulting in longer lifespans and enhanced acoustic performance.

The following sections will delve into specific aspects of this component, including its construction, different types available, maintenance procedures, and factors to consider when selecting a replacement. Understanding these elements will provide a comprehensive perspective on its functionality and contribution to overall vehicle operation.

Essential Maintenance Guidelines

The following outlines critical maintenance guidelines to ensure optimal functionality and longevity. Adherence to these recommendations can prevent costly repairs and maintain desired operational parameters.

Tip 1: Routine Visual Inspections: Conduct regular visual checks for signs of corrosion, rust, or physical damage. Early detection can prevent minor issues from escalating into major problems.

Tip 2: Addressing Abnormal Noises: Investigate any unusual rattling, hissing, or booming sounds emanating from the exhaust system. These noises often indicate a leak or internal deterioration.

Tip 3: Preventing Moisture Buildup: Short trips can lead to moisture accumulation within the system, accelerating corrosion. Ensure adequate warm-up periods and occasional longer drives to evaporate excess moisture.

Tip 4: Proper Mounting and Support: Verify that all mounting brackets and hangers are secure and in good condition. Loose or damaged supports can cause undue stress on the system, leading to premature failure.

Tip 5: Prompt Leak Repair: Address any exhaust leaks immediately. Leaks can compromise engine performance, reduce fuel efficiency, and pose safety hazards.

Tip 6: Material Consideration for Replacement: When replacement becomes necessary, consider the material used in the new component. Stainless steel typically offers superior durability compared to aluminized steel, although it may come at a higher initial cost.

Tip 7: Professional Installation: Ensure that any replacement or repair work is performed by a qualified technician. Proper installation is crucial for optimal performance and longevity.

Following these preventative measures will significantly extend the lifespan, maintain its efficiency, and guarantee compliance with noise regulations.

The next segment will explore frequently asked questions regarding troubleshooting and selection of appropriate replacement options.

1. Noise Reduction

Noise reduction stands as a fundamental requirement in automotive engineering and operation. Within the context of exhaust systems, this principle is intrinsically linked to the functionality of an exhaust sound dampening device. Its ability to attenuate exhaust noise is paramount for both regulatory compliance and environmental considerations.

- Internal Chamber Design

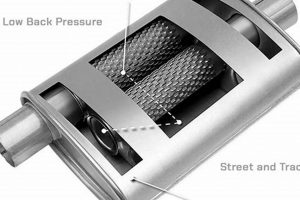

The effectiveness of sound attenuation largely depends on the internal configuration of chambers and baffles. These elements are strategically designed to reflect and cancel out sound waves, thereby diminishing noise levels. Variations in chamber size, shape, and placement influence the specific frequencies that are most effectively suppressed. For example, a complex multi-chamber design targets a broader range of frequencies, while a simpler configuration may focus on reducing specific resonant frequencies.

- Material Properties

The materials employed in construction play a crucial role in noise absorption and vibration dampening. Certain materials, such as fiberglass packing or specialized acoustic composites, are incorporated to absorb sound energy and minimize vibrations that contribute to noise generation. The selection of materials must balance acoustic performance with durability and resistance to high temperatures and corrosive exhaust gases. For instance, stainless steel offers excellent corrosion resistance but may require additional sound-absorbing materials to achieve desired noise reduction levels.

- Exhaust Gas Flow Dynamics

The design impacts the flow of exhaust gases. While prioritizing noise reduction, it is crucial to minimize backpressure, which can negatively affect engine performance. Engineers carefully balance acoustic attenuation with flow dynamics to ensure efficient exhaust evacuation. For instance, a design with excessive internal restrictions may effectively reduce noise but also increase backpressure, leading to reduced power output and fuel efficiency.

- Regulatory Standards

Stringent noise regulations mandate that vehicles adhere to specific noise emission limits. Sound dampening devices are designed and tested to comply with these standards. Failure to meet these regulations can result in penalties and restrictions on vehicle sales. Examples include EU noise directives and EPA regulations in the United States, which specify maximum permissible noise levels for various vehicle categories and operating conditions.

The aforementioned facets collectively underscore the complex interplay between noise reduction and the design and function of an exhaust sound dampening device. Optimizing noise reduction while maintaining engine performance and regulatory compliance represents a significant challenge in automotive engineering.

2. Exhaust Flow

Efficient exhaust flow is a critical performance parameter directly affected by the condition and design of an automotive exhaust sound dampening device. An obstruction to exhaust flow within the device, such as corrosion buildup or a collapsed internal baffle, creates backpressure. Elevated backpressure impedes the engine’s ability to expel exhaust gases effectively. This restriction negatively impacts volumetric efficiency, reducing the amount of fresh air and fuel mixture drawn into the cylinders during the intake stroke. Consequently, engine power output is diminished, and fuel consumption increases. As an example, a vehicle exhibiting sluggish acceleration and reduced fuel economy may indicate a compromised system restricting optimal passage of gases.

The internal design of the exhaust sound dampening device must balance sound attenuation with the requirement for unrestricted exhaust flow. Straight-through designs, commonly found in performance applications, prioritize flow optimization at the expense of some noise reduction capability. Conversely, baffled designs offer superior noise reduction but can potentially introduce more backpressure if not engineered carefully. Computational fluid dynamics (CFD) modeling is frequently employed during the design process to simulate exhaust gas flow patterns and optimize the internal geometry to minimize flow restrictions. The choice of materials and manufacturing processes also influences flow characteristics. Smooth internal surfaces and properly aligned welds reduce turbulence and pressure drop.

In summary, the relationship between exhaust flow and exhaust sound dampening device is characterized by a necessary trade-off between noise reduction and engine performance. Design choices must carefully consider the impact on backpressure and exhaust gas velocity to ensure optimal engine efficiency and power output. Monitoring performance indicators, such as fuel economy and engine responsiveness, can provide valuable insight into the condition of the exhaust system and the potential need for inspection or repair to maintain unimpeded exhaust flow.

3. Material Durability

Material durability is a paramount consideration in the context of an exhaust sound dampening device. Its longevity and effectiveness are directly correlated with the material’s ability to withstand the harsh operating conditions within an exhaust system. These conditions include exposure to high temperatures, corrosive exhaust gases, and physical stresses caused by vibration and road debris.

- Corrosion Resistance

The exhaust system is subjected to a constant barrage of corrosive elements, including water vapor, acids, and salts. Materials must exhibit high resistance to these substances to prevent rust and degradation. For example, stainless steel alloys, particularly those containing chromium and nickel, provide superior protection against corrosion compared to aluminized steel. The selection of corrosion-resistant materials directly impacts the lifespan and performance of the system, minimizing the risk of leaks and structural failure.

- Thermal Stability

Exhaust gases can reach extremely high temperatures, particularly under heavy engine load. Materials must maintain their structural integrity and mechanical properties at these elevated temperatures. Thermal fatigue, caused by repeated heating and cooling cycles, can lead to cracking and failure. High-quality materials with high melting points and low coefficients of thermal expansion are essential for resisting thermal degradation. An example is the use of Inconel alloys in high-performance exhaust systems to withstand extreme temperatures.

- Mechanical Strength

The system is subjected to constant vibration and physical impacts from road debris. Materials must possess sufficient mechanical strength to withstand these stresses without cracking or fracturing. The thickness and type of material used directly influence its ability to resist mechanical damage. Thicker gauge steel provides greater resistance to dents and punctures compared to thinner materials. Properly designed mounting brackets and hangers are also crucial for minimizing vibration and stress on the system.

- Weld Integrity

The construction of an exhaust sound dampening device involves numerous welds. The integrity of these welds is critical for ensuring structural integrity and preventing leaks. High-quality welding techniques and filler metals are essential for creating strong, durable joints that can withstand high temperatures and corrosive environments. Poorly executed welds are prone to cracking and failure, compromising the overall performance and lifespan of the system. Regular inspection of welds is recommended to identify and address potential issues before they escalate.

The selection of durable materials and robust construction techniques is essential for ensuring the long-term reliability and performance of an exhaust sound dampening device. By mitigating the effects of corrosion, thermal stress, and mechanical impacts, these considerations contribute to reduced maintenance costs, improved fuel efficiency, and compliance with environmental regulations.

4. Engine Performance

The operational efficiency and power output of an internal combustion engine are intrinsically linked to the characteristics of its exhaust system. An exhaust sound dampening device, a crucial component within this system, directly influences engine performance metrics, including horsepower, torque, and fuel economy. Its design and condition either facilitate or impede the effective removal of exhaust gases, thereby affecting the engine’s ability to operate optimally.

- Backpressure Effects

Excessive backpressure, a common consequence of a poorly designed or deteriorated exhaust system, directly restricts engine performance. The engine must expend additional energy to expel exhaust gases against this increased resistance, resulting in reduced power output and diminished fuel efficiency. For instance, a clogged exhaust system due to internal corrosion can significantly increase backpressure, leading to noticeable performance degradation. Conversely, a well-designed exhaust sound dampening device minimizes backpressure, allowing the engine to breathe freely and achieve its full potential.

- Scavenging Efficiency

The exhaust system plays a critical role in scavenging, the process of removing residual exhaust gases from the combustion chamber during the valve overlap period. A properly tuned exhaust system can create a negative pressure wave that assists in drawing out exhaust gases and promoting a more complete combustion process. An efficiently designed exhaust sound dampening device contributes to optimal scavenging by minimizing restrictions and promoting smooth exhaust flow. Improved scavenging results in increased volumetric efficiency and enhanced engine performance.

- Engine Tuning and Calibration

The characteristics of the exhaust system, including the exhaust sound dampening device, are essential considerations during engine tuning and calibration. Engine management systems are often calibrated to optimize performance based on the specific exhaust system configuration. Modifications to the exhaust system, such as replacing the factory exhaust sound dampening device with an aftermarket component, may necessitate recalibration of the engine management system to ensure optimal performance and prevent potential damage. Improper tuning can lead to reduced power output, increased emissions, and potential engine damage.

- Acoustic Performance and Design Trade-offs

The design of an exhaust sound dampening device involves inherent trade-offs between acoustic performance (noise reduction) and engine performance (exhaust flow). Aggressive noise reduction strategies can often lead to increased backpressure and reduced engine performance. Conversely, prioritizing exhaust flow optimization may result in increased noise levels. Engineers must carefully balance these conflicting requirements to achieve the desired levels of both acoustic and engine performance. Modern designs often incorporate sophisticated internal geometries and materials to optimize both aspects.

These facets collectively illustrate the intricate connection between engine performance and the attributes of an exhaust sound dampening device. Optimizing the exhaust system’s design and maintaining its condition is crucial for ensuring the engine operates efficiently and delivers its intended performance characteristics. A functional and appropriate exhaust sound dampening device is not merely a noise reduction component; it is an integral element that significantly influences the engine’s overall operational capabilities.

5. Regulatory Compliance

Compliance with noise emission regulations is a primary driver in the design and functionality of an automotive exhaust sound dampening device. Stringent legal standards mandate that vehicles operate within specific noise limits to mitigate noise pollution in urban and residential areas. Failure to adhere to these regulations can result in penalties for vehicle manufacturers and operators, underscoring the critical role of the exhaust sound dampening device in achieving compliance. Examples of such regulations include the European Union’s noise directives and the United States Environmental Protection Agency (EPA) noise standards, which define permissible sound levels for various vehicle types and operating conditions.

The design of an exhaust sound dampening device directly addresses these regulatory requirements through internal chambers and sound-absorbing materials intended to reduce exhaust noise to acceptable levels. Performance testing is a crucial step in the manufacturing process, ensuring that each device meets the necessary noise reduction targets before being installed in a vehicle. Any degradation or modification of the exhaust sound dampening device can compromise its ability to meet regulatory standards, potentially leading to legal repercussions and increased environmental noise. Real-world examples include vehicle inspections requiring sound level measurements and the potential for fines or repair orders for vehicles exceeding permissible noise limits.

In summary, regulatory compliance significantly shapes the design, manufacturing, and maintenance of an exhaust sound dampening device. Meeting and maintaining these standards is essential for legal vehicle operation, environmental protection, and preventing potential penalties. A thorough understanding of the relevant regulations and the role of the device in achieving compliance is crucial for both vehicle manufacturers and owners, underscoring its importance in the broader context of environmental responsibility and legal obligations.

Frequently Asked Questions

The following addresses common inquiries regarding exhaust sound dampening devices, providing concise and factual responses.

Question 1: What are the primary indicators of a failing exhaust sound dampening device?

Increased exhaust noise, rattling sounds from beneath the vehicle, and visible corrosion or physical damage are all potential indicators. A noticeable decline in fuel economy or engine performance may also suggest a problem.

Question 2: How does backpressure affect engine performance?

Excessive backpressure restricts exhaust flow, forcing the engine to work harder to expel exhaust gases. This reduces power output and decreases fuel efficiency.

Question 3: What materials are commonly used in the construction of an exhaust sound dampening device, and what are their relative advantages?

Aluminized steel and stainless steel are the most common materials. Aluminized steel offers a cost-effective solution but is less resistant to corrosion than stainless steel, which provides superior durability.

Question 4: Is it possible to repair a damaged exhaust sound dampening device, or is replacement always necessary?

Minor damages, such as small leaks, may be repairable through welding. However, significant corrosion or structural damage typically necessitates replacement to ensure optimal performance and compliance.

Question 5: How does the design of an exhaust sound dampening device affect its performance?

The internal configuration of chambers and baffles significantly influences noise reduction and exhaust flow. A well-designed device strikes a balance between minimizing noise and maximizing engine performance.

Question 6: What are the legal consequences of operating a vehicle with an excessively loud exhaust system?

Operating a vehicle that exceeds permissible noise levels can result in fines, repair orders, and potential vehicle impoundment, depending on local regulations.

Proper maintenance and timely replacement are essential for ensuring the device functions effectively, contributing to optimal engine performance and regulatory compliance.

The subsequent segment will offer a concluding summary.

bryant’s muffler

The preceding discourse has illuminated the pivotal role of automotive exhaust sound dampening devices in achieving a balance between engine performance, regulatory compliance, and environmental responsibility. Considerations surrounding noise reduction, exhaust flow optimization, material durability, and engine tuning coalesce to define the functional parameters of these components. A compromised or improperly designed system can negatively impact fuel efficiency, power output, and adherence to noise emission standards, underscoring the importance of both informed selection and consistent maintenance.

Given the stringent regulatory landscape and the growing societal awareness of noise pollution, proactive measures are warranted to ensure the continued efficacy of these systems. Vigilant monitoring, adherence to recommended maintenance schedules, and prompt replacement when necessary are essential for sustaining optimal vehicle operation and mitigating potential environmental impacts. The pursuit of quieter, more efficient transportation necessitates a comprehensive understanding of, and commitment to, these principles.