This specific type of exhaust system component is designed and manufactured to meet individual vehicle and performance requirements, often differing significantly from mass-produced, factory-installed units. Such components offer tailored acoustic properties and potential enhancements to engine efficiency.

The significance of a tailored exhaust solution lies in its ability to optimize engine performance characteristics, such as horsepower and torque, and to provide a distinct sound profile. Historically, such systems were primarily the domain of racing and high-performance vehicles, but their application has broadened to include a wider range of automotive applications where personalization and improved function are desired.

The subsequent discussion will delve into the various aspects of these specialized exhaust solutions, including material selection, design considerations, performance implications, and the process of custom fabrication and installation.

Optimization Strategies for Specialized Exhaust Systems

Implementing a tailored exhaust configuration necessitates careful consideration of several factors. These guidelines aim to provide a structured approach to enhance functionality and longevity.

Tip 1: Material Selection: Exhaust system materials significantly impact performance and lifespan. Stainless steel provides superior corrosion resistance compared to aluminized steel, while titanium offers weight reduction advantages in high-performance applications.

Tip 2: Diameter Optimization: Exhaust pipe diameter should be carefully calculated to match engine displacement and performance goals. Undersized pipes can restrict flow, while excessively large pipes can reduce exhaust velocity, both negatively affecting engine output.

Tip 3: Mandrel Bending Techniques: Employing mandrel bending during fabrication ensures consistent pipe diameter throughout bends, minimizing flow restriction and maintaining optimal exhaust velocity.

Tip 4: Weld Quality: Proper welding techniques are crucial for ensuring exhaust system integrity and preventing leaks. TIG welding is recommended for its precision and strength, particularly with stainless steel and titanium.

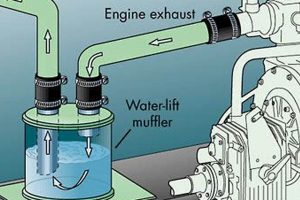

Tip 5: Sound Attenuation: Incorporating resonators and mufflers effectively manages exhaust noise levels. Selecting components with appropriate sound damping characteristics is essential for meeting regulatory requirements and personal preferences.

Tip 6: Proper Mounting and Support: Secure mounting and adequate support are necessary to prevent stress and vibration from damaging the exhaust system. Rubber isolators mitigate vibration transmission to the vehicle chassis.

Tip 7: Professional Installation: Exhaust system installation requires specialized tools and knowledge. Engaging a qualified technician ensures proper fitment, alignment, and leak-free performance.

Adhering to these best practices facilitates the construction and maintenance of a highly effective and durable tailored exhaust setup.

The following sections will elaborate on the various elements contributing to optimal exhaust system design and performance.

1. Performance

The performance characteristics of a vehicle are intrinsically linked to its exhaust system. A specifically designed component can significantly influence engine output, efficiency, and responsiveness. Careful optimization within the exhaust system can unlock a vehicle’s potential.

- Exhaust Gas Flow Optimization

The primary function impacting performance is the efficient evacuation of exhaust gases from the engine. A tailored exhaust component is designed to minimize backpressure, which can restrict engine performance. By reducing restriction, the engine can expel exhaust gases more readily, leading to improved combustion and increased power output. This optimization is particularly noticeable at higher engine speeds.

- Torque Curve Shaping

Beyond peak horsepower, a carefully designed exhaust system can alter the torque curve, affecting drivability across the engine’s operating range. Resonator and muffler design, along with pipe diameter, influence the characteristics of sound waves travelling through the exhaust. This influence can be used to optimize torque output at different RPMs, tailoring the vehicle’s performance to specific driving needs. A modified torque curve can improve acceleration and responsiveness in everyday driving scenarios.

- Fuel Efficiency Considerations

While primarily focused on power gains, a well-designed exhaust component can also contribute to improved fuel efficiency. By reducing backpressure and optimizing exhaust gas flow, the engine operates more efficiently, requiring less fuel to achieve the same level of performance. This effect is more pronounced during steady-state cruising than during aggressive acceleration.

- Weight Reduction Impact

Material selection directly impacts overall vehicle weight. Lighter materials, such as titanium or thin-gauge stainless steel, can reduce the exhaust system’s mass, contributing to improved handling and acceleration. This reduction, while often marginal compared to the overall vehicle weight, can be a factor in performance-oriented builds.

These facets illustrate how a specific exhaust component influences various performance parameters. Optimizing these aspects requires careful consideration of engine characteristics, vehicle application, and desired performance goals. A tailored approach maximizes the benefits related to power, torque, fuel efficiency, and weight, ultimately contributing to a more responsive and efficient vehicle.

2. Sound Profile

The sound profile of a vehicle equipped with a specialized exhaust component represents a key area of customization, influencing the auditory experience for both the driver and surrounding environment. Tailoring the sound is a significant factor in selecting and designing such a component, aligning with individual preferences and potentially enhancing the perceived performance of the vehicle.

- Resonator Configuration

Resonators are integral components in shaping the exhaust note. Their design, including chamber size and internal structure, directly influences the frequencies that are attenuated or amplified. For example, a Helmholtz resonator can be tuned to cancel specific frequencies, reducing drone or unwanted noise. In the context of specialized exhaust solutions, resonator selection offers precise control over the exhaust’s tonal qualities, allowing for a deeper, more aggressive sound or a smoother, more refined note.

- Muffler Design and Construction

Mufflers play a crucial role in overall sound level reduction. Chambered mufflers utilize internal baffles to redirect and cancel sound waves, while absorption mufflers employ packing materials like fiberglass or steel wool to absorb sound energy. The choice between these designs, and the specific construction of each, significantly impacts the final sound profile. A chambered muffler might deliver a louder, more resonant tone, while an absorption muffler could provide a quieter, more subtle sound.

- Exhaust Tip Acoustics

The exhaust tip, while often considered an aesthetic element, also contributes to the sound profile. The shape, size, and angle of the exhaust tip can subtly alter the sound waves exiting the exhaust system, influencing the perceived loudness and tone. A larger diameter tip, for example, may amplify lower frequencies, resulting in a deeper sound. The tips design, therefore, can be considered as a final adjustment in fine-tuning the overall sound characteristics.

- Material Resonance

The material used in the construction of the exhaust system, including the component, influences the resonance and timbre of the exhaust note. Stainless steel, for example, tends to produce a brighter, more metallic sound compared to aluminized steel. The material’s thickness and density also play a role. A thinner-gauge material may be more prone to vibration, resulting in a different sound character. Therefore, material selection contributes to the unique auditory signature of a vehicle’s exhaust.

These factors underscore the intricate relationship between design choices and the resulting sound profile in specialized exhaust systems. Through careful manipulation of resonators, mufflers, exhaust tips, and material selection, a distinct auditory identity can be achieved, complementing the performance and aesthetic characteristics of the vehicle.

3. Material Choice

Material selection profoundly influences the performance, longevity, and sound characteristics of specialized exhaust components. The properties of the chosen material directly impact its resistance to corrosion, its ability to withstand high temperatures, and its contribution to the overall sound profile. In constructing custom exhaust systems, engineers and fabricators consider these factors to ensure the exhaust component meets the demands of the vehicle and the preferences of the owner. Stainless steel, for instance, offers superior corrosion resistance compared to aluminized steel, making it a preferred choice in regions with harsh climates or where the vehicle is exposed to road salt. This enhanced resistance translates to a longer lifespan and reduced maintenance requirements. Titanium, while more expensive, provides significant weight reduction advantages, crucial for high-performance applications where every pound matters. The choice of material is, therefore, a critical design consideration with direct consequences for the functionality and durability of the exhaust component.

The impact of material choice extends beyond structural integrity and weight. Different materials exhibit distinct resonance characteristics, influencing the exhaust note. Stainless steel tends to produce a brighter, more metallic sound compared to aluminized steel. The thickness of the material also affects the sound, with thinner-gauge materials potentially exhibiting more vibration and a different tonal quality. Consequently, the material selected plays a significant role in shaping the auditory experience. Consider, for example, a high-performance sports car where a deep, aggressive exhaust note is desired. Stainless steel might be the material of choice to achieve this sound profile. Conversely, in a luxury vehicle where a more refined and subtle sound is preferred, aluminized steel or a specialized alloy might be selected. These examples illustrate the intimate relationship between material choice and the desired sound characteristics of the exhaust component.

In summary, material selection constitutes a foundational element in the design and fabrication of specialized exhaust solutions. The material’s properties influence its durability, resistance to environmental factors, weight, and contribution to the sound profile. Understanding the trade-offs associated with different materials is essential for creating an exhaust component that meets specific performance, longevity, and acoustic requirements. While stainless steel offers corrosion resistance, and titanium provides weight reduction, the ultimate choice hinges on a holistic assessment of the vehicle’s application, the desired performance characteristics, and budgetary constraints. A well-informed material selection process is, therefore, paramount to the success of any custom exhaust project.

4. Craftsmanship

Craftsmanship, in the context of a specialized exhaust component, signifies the level of skill, precision, and attention to detail involved in its design, fabrication, and finishing. It directly impacts the component’s performance, durability, and aesthetic appeal, distinguishing it from mass-produced alternatives.

- Welding Precision

Welding is a critical aspect of exhaust component fabrication, requiring skilled execution to ensure structural integrity and prevent leaks. Precise welding techniques, such as TIG welding, are employed to create clean, strong joints that can withstand the stresses of heat, vibration, and pressure. The quality of the welds directly influences the component’s lifespan and its ability to maintain optimal performance over time. Inadequate welding can lead to premature failure and compromised exhaust gas flow.

- Fit and Finish

The fit and finish of an exhaust component reflect the care and attention invested in its fabrication. Precise measurements, accurate bending, and meticulous assembly are essential for ensuring a seamless integration with the vehicle’s exhaust system. A well-crafted component exhibits smooth surfaces, consistent dimensions, and a clean, professional appearance. Attention to detail in the finishing process enhances the component’s aesthetic appeal and contributes to its overall perceived value.

- Material Handling and Treatment

Proper handling and treatment of materials are crucial for preserving their integrity and ensuring optimal performance. Skilled craftsmen take precautions to avoid contamination, scratching, or damage to the materials during the fabrication process. Specialized techniques, such as passivation for stainless steel, may be employed to enhance corrosion resistance and extend the component’s lifespan. Attention to material handling reflects a commitment to quality and ensures that the component meets the highest standards of performance and durability.

- Design Execution and Adaptation

Craftsmanship extends beyond fabrication to encompass the design process itself. A skilled craftsman possesses the ability to translate conceptual designs into tangible realities, adapting the design as needed to optimize performance, fitment, and aesthetics. The ability to improvise and solve problems during the fabrication process is a hallmark of true craftsmanship. Effective design execution ensures that the final product meets the intended specifications and exceeds expectations.

These facets of craftsmanship highlight the importance of skill, precision, and attention to detail in the fabrication of specialized exhaust components. They underscore the value of investing in high-quality workmanship to ensure optimal performance, longevity, and aesthetic appeal. Craftsmanship is not merely a matter of technical skill; it represents a commitment to excellence and a dedication to creating a superior product.

5. Customization

The integration of “customization” within the context of a specialized exhaust component directly addresses the divergence between standardized, mass-produced exhaust systems and the specific performance or aesthetic requirements of individual vehicles and owners. This customization stems from a recognition that factory-installed exhaust systems are designed to meet broad regulatory requirements, cost constraints, and target audience preferences, often resulting in compromises that preclude optimal engine performance or personalized sound profiles. Therefore, a custom system represents a deliberate departure from this standardized approach, enabling precise tailoring of exhaust characteristics.

The practical implications of customization manifest in several critical areas. Firstly, engine tuning benefits from a precisely calibrated exhaust system. By optimizing exhaust gas flow and minimizing backpressure, a custom-designed component can unlock latent engine power, improving horsepower and torque output. Secondly, sound modulation provides users with the ability to define the vehicle’s auditory signature, ranging from aggressive, high-performance tones to subtle, refined notes. Consider a vintage automobile restoration project. A standardized exhaust system may not accurately replicate the original sound or meet the specific performance needs of the engine after restoration. Customization ensures both historical accuracy in sound and optimized performance relative to the engine’s restored specifications. Alternatively, consider a modern sports car owner seeking to enhance the vehicle’s auditory experience. A custom exhaust component, designed with specific resonators and muffler configurations, enables precise control over the exhaust note, aligning it with the owner’s preferences.

Ultimately, the value of customization lies in its ability to transcend the limitations of standardized components, enabling the creation of an exhaust system that perfectly aligns with specific performance objectives, aesthetic preferences, and vehicle requirements. Challenges inherent in this approach include the need for specialized design and fabrication expertise, along with a comprehensive understanding of engine dynamics and acoustic principles. The effectiveness of any customized exhaust system hinges on meticulous design, precise fabrication, and careful installation, underscoring the importance of engaging qualified professionals to ensure optimal results.

6. Durability

The lifespan of a specialized exhaust component is directly tied to its construction materials and fabrication methods, forming a critical element in its overall value proposition. The environment to which an exhaust system is subjected inherently promotes degradation. Exposure to extreme temperatures, corrosive road salts, moisture, and mechanical stresses from vibration collectively contribute to material fatigue and eventual system failure. Therefore, the durability of a custom exhaust system hinges on careful material selection and robust construction techniques designed to mitigate these adverse effects. An exhaust component constructed from low-grade steel, for instance, will exhibit a significantly shorter lifespan than one fabricated from high-grade stainless steel or titanium, particularly in regions where road salt is prevalent. This difference in material composition directly translates to a disparity in long-term maintenance costs and replacement frequency.

Welding quality and fabrication precision also exert a significant influence on an exhaust system’s longevity. Poorly executed welds can create points of stress concentration, accelerating fatigue and leading to premature cracking or failure. Similarly, improper fitment or inadequate support can induce excessive vibration, further exacerbating material fatigue. Consider the case of a custom exhaust system installed on an off-road vehicle. Such a system is subjected to increased mechanical stress due to rough terrain and potential impacts. A system fabricated with reinforced welds and robust mounting hardware will exhibit significantly greater durability than a system constructed with standard welding techniques and minimal support structures. In this scenario, the investment in enhanced fabrication techniques directly translates to extended service life and reduced risk of failure under demanding conditions.

Ultimately, the durability of a specialized exhaust component represents a critical factor in its overall economic viability. While a less durable system may offer a lower initial purchase price, the increased maintenance costs and reduced lifespan often outweigh the initial savings. Investing in a high-quality, durable exhaust system constructed from premium materials and fabricated with meticulous attention to detail ensures long-term reliability, reduced maintenance requirements, and sustained performance. In conclusion, the durability aspect should form a central consideration when evaluating the overall value of any specialized exhaust solution.

Frequently Asked Questions

This section addresses common inquiries and misconceptions concerning the design, performance, and application of specialized exhaust components.

Question 1: What constitutes a “specialized” exhaust component?

A specialized exhaust component deviates from mass-produced, factory-installed exhaust systems. It is engineered to meet specific performance criteria, acoustic preferences, or vehicle requirements, often involving custom design and fabrication processes.

Question 2: Does a tailored exhaust system universally improve engine performance?

Not necessarily. While a well-designed system can enhance engine output, an improperly designed or installed system can impede performance. Optimization requires careful consideration of engine characteristics and vehicle application.

Question 3: What are the primary material considerations for exhaust components?

Key material considerations include corrosion resistance, heat tolerance, weight, and acoustic properties. Stainless steel, aluminized steel, and titanium are common materials, each offering distinct advantages and disadvantages.

Question 4: What role does sound play in specialized exhaust systems?

Sound is a significant factor. The ability to control and shape the exhaust note is a primary motivation for selecting a specialized component. Resonators, mufflers, and pipe diameter are adjusted to achieve the desired sound profile.

Question 5: Is professional installation essential for a tailored exhaust system?

Professional installation is strongly recommended. Proper fitment, alignment, and welding are crucial for ensuring optimal performance, preventing leaks, and maximizing the system’s lifespan.

Question 6: How does an exhaust component’s durability relate to its long-term cost?

Durability is paramount. While a less expensive component may offer initial savings, the increased risk of failure and replacement often results in higher long-term costs. Investing in a durable system is generally more economical in the long run.

In summary, specialized exhaust systems offer the potential for enhanced performance and personalized sound, but careful design, material selection, and professional installation are crucial for realizing these benefits.

The next section will explore case studies and real-world applications of specialized exhaust components.

Conclusion

This exploration of the properties inherent in azteca custom muffler solutions has highlighted the critical parameters influencing performance, acoustic characteristics, material selection, fabrication quality, customization options, and durability. Careful evaluation of these elements is paramount when considering alternatives to standardized exhaust systems. Optimal outcomes are contingent upon a thorough understanding of engine dynamics, acoustic principles, and material science.

The integration of a tailored exhaust component represents a significant investment in vehicle performance and personalization. Prudent evaluation of needs, realistic expectations, and professional expertise are essential to realize the full potential of such endeavors. Future advancements in material science and fabrication techniques promise further refinements in the design and execution of specialized exhaust systems, underscoring the importance of informed decision-making and continuous learning.