The phrase “big al’s muffler” represents a specific product or service, most likely related to automotive exhaust systems. It refers to a component used in vehicles to reduce engine noise and emissions. For example, an individual might state, “I need to replace my car’s exhaust; I think I’ll go to Big Al’s Muffler shop.”

Properly functioning exhaust components are critical for vehicle performance, fuel efficiency, and adherence to environmental regulations. The availability of specialized services, such as those suggested by the keyword, ensures that vehicle owners have access to the necessary maintenance and repairs. The historical context involves the evolution of automotive technology and the increasing importance of noise and emission control.

The subsequent sections of this article will delve into the specifics of automotive exhaust systems, the types of mufflers available, and the factors to consider when choosing a service provider for exhaust system maintenance. The analysis will also include aspects such as product quality, service reliability, and potential cost implications.

Exhaust System Maintenance Tips

Maintaining a vehicle’s exhaust system is crucial for optimal performance, fuel efficiency, and regulatory compliance. This section outlines several key considerations for ensuring the longevity and effectiveness of exhaust components.

Tip 1: Regular Visual Inspections: Periodically inspect the exhaust system for signs of corrosion, damage, or leaks. Pay close attention to the muffler, exhaust pipes, and catalytic converter. Early detection of issues can prevent more extensive and costly repairs.

Tip 2: Listen for Unusual Noises: Changes in the exhaust note, such as excessive loudness or rattling sounds, may indicate a problem. These noises can signify a damaged muffler, a leak in the system, or a loose component.

Tip 3: Address Rust Promptly: Rust is a common problem in exhaust systems, particularly in regions with harsh weather conditions. Address rust spots immediately by cleaning and applying a rust inhibitor or protective coating. This helps prevent further corrosion and prolong the life of the components.

Tip 4: Check for Leaks: Exhaust leaks can lead to decreased fuel efficiency, increased emissions, and potential health hazards. Inspect all joints and connections for signs of leaks, such as black soot or excessive noise. If a leak is detected, have it repaired by a qualified technician.

Tip 5: Ensure Proper Mounting: Check the exhaust system’s mounting hardware to ensure that all components are securely attached to the vehicle. Loose or damaged hangers can cause the system to vibrate excessively, leading to premature wear and potential damage to other parts of the vehicle.

Tip 6: Periodic Professional Inspection: Schedule regular inspections of the exhaust system with a qualified mechanic. A professional can identify potential issues that may not be readily apparent during a visual inspection and perform necessary maintenance or repairs.

Adhering to these maintenance tips can significantly extend the lifespan of an exhaust system and ensure that it operates efficiently. Proactive care and regular inspections contribute to improved vehicle performance and reduced environmental impact.

The following sections will elaborate on the replacement and repair of exhaust systems, including the selection of suitable replacement parts and the diagnosis of common exhaust system problems.

1. Exhaust Noise Reduction

Exhaust noise reduction is a primary function of a vehicle’s muffler. In the context of “big al’s muffler,” this aspect defines a core service offering, involving the provision, installation, and maintenance of components designed to mitigate engine noise. The effectiveness of this service directly impacts driver comfort and community noise levels.

- Muffler Design and Functionality

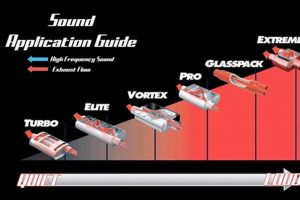

The design of a muffler fundamentally dictates its noise reduction capabilities. Baffle systems, resonance chambers, and sound-absorbing materials are employed to attenuate exhaust pulses. Big Al’s Muffler, as a hypothetical or actual business, would presumably stock and install a variety of muffler designs suited to different vehicles and noise reduction preferences. The performance of these designs directly correlates to customer satisfaction and regulatory compliance.

- Material Composition and Longevity

The materials used in muffler construction influence its durability and noise reduction effectiveness over time. Steel, stainless steel, and aluminized steel are common choices, each offering different levels of corrosion resistance and sound dampening properties. “big al’s muffler” should consider the material composition when advising customers, ensuring the selected muffler aligns with the vehicle’s operating environment and expected lifespan.

- Installation Techniques and Precision

Proper installation is critical to achieving optimal noise reduction. Incorrectly installed mufflers can leak, vibrate excessively, and ultimately fail prematurely. “big al’s muffler” should prioritize skilled installation practices, including proper welding, secure mounting, and the use of appropriate sealing materials. Precise installation ensures the muffler functions as designed and maximizes its noise reduction potential.

- Regulatory Compliance and Legal Considerations

Vehicles are subject to noise regulations at both the state and local levels. Mufflers must meet specific noise emission standards to ensure legal operation. “big al’s muffler” has a responsibility to ensure that the mufflers they install comply with these regulations, providing customers with products that are both effective and legally compliant. Non-compliance can result in fines and penalties for both the vehicle owner and the installer.

In conclusion, exhaust noise reduction is a multifaceted aspect of muffler design, installation, and regulatory adherence. A business operating under the name “big al’s muffler” would ideally provide expertise and services encompassing these considerations, ensuring customer satisfaction, environmental responsibility, and legal compliance. The selection and proper installation of suitable mufflers directly impact the overall driving experience and community well-being.

2. Emission Control Standards

Emission Control Standards represent a critical regulatory framework influencing the automotive industry. These standards mandate specific limits on the pollutants vehicles can release into the atmosphere. The relevance to a business such as “big al’s muffler” lies in the fact that it must provide services and products that enable vehicles to meet these stringent requirements.

- Catalytic Converter Functionality

The catalytic converter is a key component in modern exhaust systems, designed to reduce harmful emissions such as hydrocarbons, carbon monoxide, and nitrogen oxides. Its proper functioning is essential for vehicles to pass emission tests. “big al’s muffler” is directly involved in ensuring this functionality by offering catalytic converter replacements and inspections, aligning services with emission control standards.

- Oxygen Sensor Accuracy

Oxygen sensors monitor the amount of oxygen in the exhaust stream, providing feedback to the engine control unit (ECU) to optimize the air-fuel mixture. Faulty oxygen sensors can lead to increased emissions and decreased fuel efficiency. “big al’s muffler” needs to ensure the functionality of oxygen sensor as it plays a part of reducing environmental pollutions.

- Exhaust Leak Mitigation

Exhaust leaks compromise the effectiveness of the emission control system, allowing uncombusted hydrocarbons to escape into the atmosphere. Addressing exhaust leaks through welding, pipe replacement, or component sealing is a crucial service. “big al’s muffler” would thus ensure the system’s structural integrity in line with emission standards.

- Diagnostic Testing and Repair

Modern vehicles are equipped with on-board diagnostic (OBD) systems that monitor emission control components. When a problem is detected, the OBD system illuminates the “check engine” light and stores diagnostic trouble codes (DTCs). “big al’s muffler” must possess the capability to accurately diagnose these codes and perform the necessary repairs to restore the vehicle’s emission control system to proper working order.

In summary, “big al’s muffler’s” role in adhering to Emission Control Standards encompasses a range of services, from component replacement to diagnostic testing and repair. Ensuring that vehicles meet these standards is not only a legal requirement but also a significant contribution to environmental protection. Failure to comply with these standards can result in fines and penalties for vehicle owners, as well as negative consequences for the environment.

3. Fuel Efficiency Impact

The integrity of a vehicle’s exhaust system directly correlates with its fuel efficiency. Compromised exhaust components, such as leaks or restrictions, can significantly impede engine performance, thereby increasing fuel consumption. A service provider, as embodied by “big al’s muffler”, plays a crucial role in maintaining exhaust system health, indirectly impacting fuel economy. For instance, a deteriorated muffler can create back pressure, forcing the engine to work harder and consume more fuel. Similarly, a malfunctioning catalytic converter can restrict exhaust flow, leading to decreased efficiency. By offering exhaust system inspections, repairs, and replacements, a business analogous to “big al’s muffler” contributes to optimizing engine performance and minimizing fuel wastage. The cause-and-effect relationship is clear: exhaust system integrity directly affects fuel efficiency, and the services provided by businesses such as “big al’s muffler” maintain this integrity.

Furthermore, the choice of exhaust components, particularly mufflers, can also influence fuel economy. Some aftermarket mufflers are designed to reduce back pressure, potentially improving engine breathing and fuel efficiency. However, it is crucial to select components that are appropriately matched to the vehicle’s engine and intended use. An ill-suited muffler can actually decrease fuel efficiency. “big al’s muffler” should provide informed guidance on component selection, considering factors such as engine size, vehicle weight, and driving style. Practical applications include advising customers on the benefits of low-restriction mufflers for high-performance vehicles or recommending stock replacement mufflers for standard passenger cars. These informed recommendations ensure that exhaust system maintenance and upgrades contribute to optimal fuel efficiency.

In conclusion, the fuel efficiency impact of exhaust system maintenance is substantial. Businesses such as “big al’s muffler” contribute to optimizing vehicle performance and minimizing fuel consumption. Addressing exhaust leaks, replacing deteriorated components, and providing informed guidance on component selection are crucial services that enhance fuel economy. The challenges involve accurately diagnosing exhaust system problems, selecting appropriate replacement parts, and ensuring proper installation. By addressing these challenges effectively, businesses akin to “big al’s muffler” play a significant role in promoting fuel efficiency and reducing environmental impact.

4. Component Longevity

Component longevity is a key factor in the operational costs and overall value proposition associated with vehicle maintenance. The relevance of this concept to a business such as “big al’s muffler” lies in the quality of products offered and the expertise in installation and maintenance practices, all of which directly impact the lifespan of exhaust system components.

- Material Selection and Corrosion Resistance

The materials used in the construction of exhaust components significantly influence their resistance to corrosion, a primary cause of failure. Stainless steel and aluminized steel offer superior corrosion protection compared to standard steel. “big al’s muffler” can impact component longevity by offering options with enhanced material properties, thereby extending the service life of the exhaust system. For example, a stainless steel muffler, while initially more expensive, can outlast a standard steel muffler by several years, reducing long-term replacement costs.

- Installation Quality and Joint Integrity

Proper installation techniques are essential for maximizing component lifespan. Secure welds, properly tightened fasteners, and the use of high-quality gaskets prevent leaks and vibrations that can accelerate wear and tear. “big al’s muffler” should employ skilled technicians who adhere to best practices in exhaust system installation. A poorly installed exhaust system, regardless of component quality, is prone to premature failure due to leaks, excessive stress, and improper alignment.

- Environmental Factors and Operating Conditions

The environment in which a vehicle operates can significantly affect the longevity of its exhaust components. Vehicles driven in areas with road salt or high humidity are at greater risk of corrosion. “big al’s muffler” can offer protective coatings and treatments to mitigate the effects of harsh environmental conditions. For instance, applying a rust inhibitor to exhaust components can prolong their lifespan in regions with significant salt usage.

- Maintenance Practices and Regular Inspections

Regular inspections and preventative maintenance can identify and address potential problems before they lead to component failure. Checking for leaks, tightening fasteners, and addressing minor rust spots can significantly extend the lifespan of the exhaust system. “big al’s muffler” can offer maintenance services and advise customers on best practices for maintaining their exhaust systems. Routine inspections can catch issues early, preventing costly repairs and extending the life of the components.

In conclusion, component longevity is a complex function of material quality, installation practices, environmental factors, and maintenance procedures. Businesses such as “big al’s muffler” play a critical role in influencing component lifespan by providing quality products, skilled installation services, and offering maintenance advice. By focusing on these aspects, “big al’s muffler” can offer customers enhanced value and reduce the long-term costs associated with exhaust system maintenance.

5. Installation Expertise

Installation expertise constitutes a core competency for any business providing automotive exhaust services, particularly those operating under the name “big al’s muffler.” It directly influences the performance, longevity, and safety of exhaust systems, representing a critical factor in customer satisfaction and business reputation.

- Welding Proficiency

Exhaust system installation often requires precise welding to ensure secure and leak-free connections between pipes and components. A skilled technician, representing “big al’s muffler,” must possess the ability to perform various welding techniques, including MIG and TIG welding, to accommodate different materials and configurations. Inadequate welding can lead to exhaust leaks, reduced engine performance, and potential safety hazards. For example, a poorly welded joint may crack under stress, releasing harmful emissions into the passenger cabin.

- Component Alignment and Secure Mounting

Proper alignment of exhaust components is essential for minimizing stress on joints and preventing premature wear. A technician from “big al’s muffler” must ensure that all components are correctly positioned and securely mounted to the vehicle’s chassis using appropriate hardware. Misalignment can cause vibrations, leaks, and damage to other vehicle systems. An example is an exhaust pipe that rubs against a suspension component due to incorrect positioning, leading to both exhaust system damage and potential suspension issues.

- Sensor Integration and Wiring Accuracy

Modern exhaust systems incorporate various sensors, such as oxygen sensors and catalytic converter monitors, which require precise integration and wiring. A qualified technician at “big al’s muffler” must be knowledgeable about sensor functionality and wiring diagrams to ensure proper sensor operation and data transmission. Incorrect wiring can lead to inaccurate sensor readings, engine performance problems, and emission control failures. For instance, an incorrectly wired oxygen sensor can cause the engine to run lean or rich, resulting in reduced fuel efficiency and increased emissions.

- Diagnostic Capabilities and Problem Solving

Installation expertise extends beyond the physical aspects of component replacement to encompass diagnostic capabilities and problem-solving skills. A skilled technician representing “big al’s muffler” must be able to diagnose existing exhaust system problems, identify potential issues during installation, and implement appropriate solutions. This includes the ability to interpret diagnostic trouble codes (DTCs) and use specialized tools to assess exhaust system performance. An example would be identifying a cracked exhaust manifold during a muffler replacement and advising the customer on the necessary repairs.

In conclusion, installation expertise encompasses a range of technical skills, diagnostic abilities, and problem-solving capabilities. A business such as “big al’s muffler” that prioritizes installation expertise enhances customer satisfaction, ensures the proper functioning of exhaust systems, and contributes to vehicle safety and environmental compliance. The absence of this expertise can lead to costly repairs, reduced vehicle performance, and potential safety hazards.

6. Rust Resistance Coating

Rust resistance coating, when considered in the context of an automotive exhaust service provider such as “big al’s muffler,” represents a proactive approach to mitigating corrosion, a primary cause of exhaust system failure. The application and availability of rust-resistant coatings directly impact component longevity and overall customer satisfaction.

- Types of Rust-Resistant Coatings

Various coating technologies are employed to enhance the corrosion resistance of exhaust components, including aluminized coatings, ceramic coatings, and specialized paints. Aluminized coatings provide a protective layer of aluminum that sacrifices itself to corrosion before the underlying steel. Ceramic coatings offer high-temperature resistance and enhanced protection against chemicals and abrasion. Specialized paints provide a barrier against moisture and salt. “big al’s muffler” might offer a range of these coatings, tailored to specific customer needs and environmental conditions. The selection of an appropriate coating is essential for maximizing its effectiveness.

- Application Methods and Preparation

The effectiveness of rust resistance coating depends heavily on proper application techniques. Surface preparation, including cleaning and degreasing, is critical for ensuring adequate adhesion. Application methods vary depending on the type of coating, ranging from spraying to dipping. “big al’s muffler” should employ trained technicians who are proficient in applying these coatings to ensure uniform coverage and optimal protection. Improper application can lead to premature coating failure and reduced corrosion resistance.

- Environmental Considerations and Salt Exposure

Vehicles operating in regions with high salt exposure, either due to road de-icing or proximity to marine environments, are particularly susceptible to corrosion. Rust resistance coatings provide an additional layer of protection in these harsh environments. “big al’s muffler” should advise customers in these regions on the benefits of rust resistance coatings and recommend appropriate coating types based on the severity of the environmental conditions. This proactive approach can significantly extend the lifespan of exhaust components in corrosive environments.

- Cost-Benefit Analysis and Customer Value

The application of rust resistance coating represents an additional cost to the customer. “big al’s muffler” should provide a clear cost-benefit analysis, highlighting the long-term savings associated with increased component longevity. While the initial investment may be higher, the reduced frequency of repairs and replacements can result in significant savings over the lifespan of the vehicle. Communicating the value proposition of rust resistance coatings is essential for customer acceptance and satisfaction.

In conclusion, rust resistance coating is a valuable service offering for businesses such as “big al’s muffler,” particularly in regions with corrosive environments. By providing a range of coating options, employing skilled technicians, and communicating the cost-benefit analysis, “big al’s muffler” can enhance customer satisfaction and promote long-term exhaust system reliability. The effective application of rust resistance coatings represents a proactive approach to minimizing corrosion and extending the lifespan of exhaust components.

7. Specialized Repair Services

The capacity to offer specialized repair services distinguishes a general automotive repair shop from an establishment focused on exhaust systems, exemplified by the phrase “big al’s muffler.” While a standard repair shop might replace a muffler, a specialized service addresses complex exhaust issues requiring specific expertise and equipment. For example, a vehicle with a custom exhaust configuration or an older model requiring fabrication of obsolete parts necessitates skills beyond basic replacement. “big al’s muffler,” in its ideal form, provides these advanced services, thereby catering to a wider range of customer needs.

Real-world examples of such specialized services include custom exhaust bending, catalytic converter repair, and oxygen sensor diagnostic services. Custom exhaust bending allows for the creation of exhaust systems tailored to specific vehicle modifications or performance requirements. Catalytic converter repair involves addressing issues such as substrate damage or efficiency decline, potentially offering cost-effective alternatives to complete replacement. Oxygen sensor diagnostic services utilize advanced testing equipment to pinpoint sensor malfunctions, enabling precise repairs and optimal engine performance. The provision of these services elevates “big al’s muffler” from a simple parts replacer to a provider of comprehensive exhaust system solutions.

The practical significance of understanding this connection lies in recognizing the value proposition of a specialized service. Customers seeking exhaust system solutions often face complex problems that necessitate a higher level of expertise than general automotive shops can provide. By offering specialized repair services, “big al’s muffler” positions itself as a reliable source for addressing these needs, fostering customer loyalty and building a reputation for technical proficiency. The ability to diagnose and repair exhaust systems effectively contributes to improved vehicle performance, reduced emissions, and enhanced environmental responsibility.

Frequently Asked Questions – Exhaust Systems

This section addresses common inquiries regarding exhaust systems, maintenance, and associated services. The information provided aims to clarify technical aspects and inform decision-making related to vehicle exhaust systems.

Question 1: What are the primary functions of a vehicle’s muffler?

A muffler serves to reduce engine noise, control exhaust emissions, and optimize engine performance. It achieves noise reduction through internal baffles and chambers that attenuate sound waves. Emission control is facilitated by the catalytic converter, often integrated into the exhaust system.

Question 2: How often should a vehicle’s exhaust system be inspected?

Exhaust systems should be inspected at least annually, or more frequently in regions with harsh road conditions or high salt usage. Regular inspections can identify potential problems such as corrosion, leaks, or damaged components before they lead to more extensive and costly repairs.

Question 3: What are the signs of a failing catalytic converter?

Indicators of a failing catalytic converter include decreased fuel efficiency, a sulfurous or rotten egg smell emanating from the exhaust, a rattling noise from the undercarriage, and the illumination of the check engine light with codes related to catalytic converter inefficiency.

Question 4: Can a muffler be repaired, or does it always require replacement?

Minor muffler damage, such as small holes or surface rust, can sometimes be repaired through welding or patching. However, extensive corrosion, structural damage, or internal component failure typically necessitates complete muffler replacement to ensure proper functionality and noise reduction.

Question 5: What are the potential consequences of driving with an exhaust leak?

Driving with an exhaust leak can lead to reduced fuel efficiency, increased emissions, exposure to harmful gases, and potential engine damage. Exhaust leaks can also create excessive noise and may violate local noise ordinances. Prompt repair of exhaust leaks is essential for vehicle performance and safety.

Question 6: How does the material composition of an exhaust system affect its longevity?

Exhaust systems constructed from stainless steel or aluminized steel offer superior corrosion resistance and longevity compared to those made from standard steel. The choice of material significantly impacts the exhaust system’s ability to withstand exposure to moisture, salt, and high temperatures, thereby extending its service life.

This FAQ section provides a foundational understanding of exhaust systems and related maintenance. Understanding these points empowers vehicle owners to make informed decisions regarding their vehicles.

The subsequent section will provide information about contact and location information.

Conclusion

This article has explored the various facets of automotive exhaust systems, using “big al’s muffler” as a conceptual focal point. The analysis has encompassed the importance of noise reduction, adherence to emission control standards, the impact on fuel efficiency, the factors influencing component longevity, the necessity of installation expertise, the benefits of rust resistance coatings, and the value of specialized repair services. These elements collectively define the scope of services and expertise associated with a business dedicated to exhaust system maintenance and repair.

The integrity of a vehicle’s exhaust system is paramount for optimal performance, environmental responsibility, and compliance with regulatory requirements. Businesses specializing in this domain, such as “big al’s muffler,” play a critical role in ensuring that vehicles operate efficiently and safely. Maintaining a functional and compliant exhaust system is a responsibility that benefits both the individual vehicle owner and the broader community, contributing to a cleaner and quieter environment.