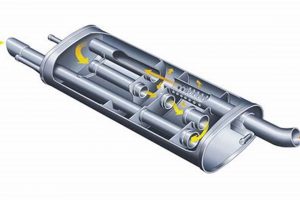

The component in question, typically found in motor vehicles, serves as a critical part of the exhaust system. Its primary function involves the reduction of noise generated by the engine’s combustion process. As exhaust gases exit the engine, they pass through this device, which utilizes a series of chambers and baffles to dampen sound waves before they are released into the atmosphere. A damaged or inefficient component can result in increased noise pollution and potential regulatory violations.

The effectiveness of this device is paramount for both environmental considerations and driver comfort. Historically, these systems have evolved from simple, straight-through designs to more complex configurations that optimize both sound reduction and exhaust flow. Improved designs contribute to quieter operation, reduced backpressure on the engine (potentially enhancing fuel efficiency), and adherence to increasingly stringent noise emission standards. Its proper functioning is directly linked to a vehicle’s overall acoustic profile and regulatory compliance.

With a basic understanding of the general component’s function and importance, the main body of the article will delve into specific aspects, like diagnosing common issues, considering different brands and types, and detailing the process of replacement or repair. The following sections will also explore the impact of aftermarket options on performance and sound characteristics.

Essential Considerations

The following points offer valuable insights into the selection, maintenance, and troubleshooting of this critical exhaust system component.

Tip 1: Identify Accurate Compatibility: Ensure the replacement part is designed specifically for the vehicle’s make, model, and year. Incorrect fitment can compromise performance and potentially damage the exhaust system.

Tip 2: Conduct Regular Visual Inspections: Periodically examine the undercarriage for signs of corrosion, rust, or physical damage. Early detection can prevent costly repairs.

Tip 3: Listen for Abnormal Sounds: Changes in exhaust noise, such as rattling, hissing, or excessive loudness, may indicate a leak or internal damage.

Tip 4: Consider Material Quality: Opt for components constructed from durable materials like stainless steel or aluminized steel, which offer superior resistance to corrosion and prolonged lifespan.

Tip 5: Understand Regional Regulations: Be aware of local noise emission standards and ensure any modifications or replacements comply with applicable laws.

Tip 6: Employ Professional Installation: While DIY replacement is possible, professional installation ensures proper alignment, sealing, and torque specifications, minimizing the risk of future issues.

Tip 7: Review Warranty Coverage: Prior to purchase, carefully review the warranty terms and conditions offered by the manufacturer or retailer, safeguarding against premature failure.

These tips highlight proactive steps for responsible vehicle maintenance and optimized performance. Addressing these aspects contributes to a safer and more efficient driving experience.

With these foundational considerations in mind, the concluding section will summarize the key points and offer guidance on seeking professional assistance.

1. Sound dampening effectiveness

Sound dampening effectiveness, in the context of this automotive component, refers to its capability to reduce the noise produced by the engine’s exhaust. This effectiveness is achieved through internal baffling and chamber designs that manipulate sound waves, diminishing their amplitude before exiting the vehicle. A direct correlation exists between the component’s internal structure and the level of noise reduction. Insufficient baffling or deterioration of internal components directly reduces sound dampening capacity, resulting in increased exhaust noise. For instance, a vehicle experiencing a noticeable increase in exhaust volume after several years of operation may indicate a degradation of the internal dampening materials.

The importance of the component’s sound dampening capacity extends beyond mere comfort. Regulatory bodies globally impose noise emission standards for vehicles, and a malfunctioning or poorly designed component can lead to non-compliance. Automotive workshops perform regular noise level checks to ensure the component’s sound dampening falls within acceptable limits. Moreover, it plays a role in the acoustic environment of communities, reducing noise pollution and improving the quality of life for residents in urban settings. Compromised dampening can result in fines, failed vehicle inspections, and potentially negative community impact.

Therefore, the performance of the component hinges on its ability to attenuate engine noise, and its effectiveness is gauged by its design and structural integrity. As a critical part of a vehicle’s exhaust system, the failure to maintain or replace the component contributes to noise pollution, regulatory breaches, and decreased overall acoustic comfort. Therefore, understanding the device’s contribution to sound mitigation is key for a safer and quieter driving experience.

2. Material corrosion resistance

Material corrosion resistance is a critical factor determining the longevity and effectiveness of the vehicle exhaust component. This characteristic refers to the ability of the material to withstand degradation caused by exposure to corrosive elements inherent in the exhaust stream and the external environment. The material’s capacity to resist corrosion directly affects its structural integrity, performance, and overall lifespan.

- The Role of Condensation and Acids

During engine operation, combustion byproducts, including water vapor and acidic compounds like sulfuric and nitric acid, are generated. When the exhaust system cools down, this water vapor condenses, creating a corrosive environment inside the exhaust component. Materials with poor corrosion resistance are susceptible to degradation from these acids, leading to rust, pitting, and eventual structural failure. For example, untreated steel will quickly corrode in this environment, significantly reducing its lifespan.

- Impact on Performance and Emissions

Corrosion can compromise its ability to effectively dampen sound. Rust weakens the metal, creating holes and leaks that allow exhaust gases to escape prematurely. This results in increased noise levels and can lead to the release of harmful emissions into the atmosphere. A corroded component also restricts exhaust flow, negatively affecting engine performance and fuel efficiency. Consequently, degradation of the material leads to a cascade of adverse effects impacting both vehicle operation and environmental impact.

- Material Selection and Manufacturing Processes

Material selection and manufacturing processes play a pivotal role in determining its corrosion resistance. Stainless steel, aluminized steel, and ceramic coatings are commonly employed to enhance resistance to corrosion. Stainless steel offers inherent corrosion resistance, while aluminized steel provides a protective coating. Manufacturing processes like welding and coating application must be carefully controlled to ensure integrity and prevent weak points where corrosion can initiate. For example, poorly executed welds can create crevices that trap corrosive substances, accelerating degradation.

- Environmental Factors and Road Conditions

External environmental factors such as road salt, humidity, and temperature fluctuations also contribute to the corrosion process. In regions with harsh winters, road salt accelerates corrosion, particularly on exposed undercarriage components. Similarly, high humidity levels and extreme temperature variations promote the formation of condensation and accelerate the rate of corrosion. Protective coatings and regular washing are recommended to mitigate the impact of these external factors. Frequent driving on gravel roads increases the likelihood of physical damage, compromising protective layers and exposing the underlying material to corrosion.

The correlation between “material corrosion resistance” and the performance of the device is undeniable. Selection of corrosion-resistant materials and adherence to proper manufacturing practices are crucial for ensuring longevity, maintaining optimal performance, and minimizing environmental impact. The effects of environmental conditions, driving habits, and maintenance influence the integrity of the component, underscoring the necessity for both manufacturers and vehicle owners to understand the consequences of poor corrosion resistance on this vital exhaust system element.

3. Exhaust flow optimization

Exhaust flow optimization, within the context of this exhaust component, refers to the design and engineering principles employed to minimize backpressure and turbulence within the exhaust system. This optimization directly impacts engine efficiency, power output, and fuel economy. The internal structure, including the arrangement of baffles, chambers, and pipe diameters, plays a critical role in facilitating the smooth and efficient passage of exhaust gases from the engine. A poorly designed component can create excessive backpressure, impeding the engine’s ability to expel exhaust gases effectively. This increased backpressure results in reduced horsepower, lower fuel efficiency, and increased engine wear. Real-life examples include aftermarket components specifically designed to reduce backpressure in high-performance vehicles, resulting in dyno-verified horsepower gains. Understanding the flow dynamics within this component is therefore paramount for both manufacturers and vehicle owners seeking to maximize engine performance.

Further analysis reveals that optimized flow is not solely about reducing backpressure; it also involves managing the velocity and temperature of exhaust gases. Efficient flow helps maintain optimal catalytic converter operating temperatures, crucial for effective emission control. For instance, a well-designed component ensures that the gases reach the converter at a temperature conducive to chemical reactions, effectively reducing harmful pollutants. Practical applications of flow optimization extend to specialized vehicles like racing cars, where every fraction of a horsepower matters. These vehicles often utilize custom-designed exhaust systems to minimize flow restrictions and maximize engine output. The development of these specialized systems involves computational fluid dynamics simulations and extensive dyno testing to fine-tune the exhaust flow characteristics.

In conclusion, exhaust flow optimization is an integral aspect of component design and performance. It is a balancing act between noise reduction and minimizing restrictions to the airflow. The effects of flow restrictions are directly tied to the engine’s performance, the catalyst’s working temperatures, and the vehicle’s overall emissions. Understanding the flow properties and component design makes certain of correct selection, correct fitting, and improved engine operations.

4. Regulatory noise compliance

Regulatory noise compliance establishes the permissible sound levels emitted by vehicles, and this dictates the design parameters and performance criteria for specific vehicle exhaust components. Exceeding established noise limits subjects vehicle owners and manufacturers to penalties and legal consequences. The need to adhere to noise regulations compels the integration of effective sound-dampening technologies into exhaust systems. A component designed without adequate sound-dampening capabilities results in non-compliance, rendering the vehicle illegal for road use. Real-world instances include manufacturers recalling vehicles due to non-compliant exhaust systems, leading to significant financial losses and reputational damage. Therefore, a fundamental understanding of noise regulations is crucial in the design, manufacture, and maintenance of vehicle exhaust components.

Furthermore, the stringency of noise regulations varies across jurisdictions, necessitating that manufacturers tailor their exhaust systems to meet the specific requirements of different markets. For example, European Union noise standards may differ significantly from those in the United States, requiring distinct component designs for vehicles sold in those regions. Compliance also extends to aftermarket components; modifications to exhaust systems must adhere to local noise laws. Unapproved aftermarket components that increase noise levels can result in fines, vehicle impoundment, or failed inspections. These aftermarket considerations contribute to the importance of making sure vehicle compliance is a priority when considering non-factory additions or repairs.

In summary, regulatory noise compliance exerts a profound influence on the development and application of the exhaust systems, thus the component. The economic and legal repercussions of non-compliance necessitate adherence to established noise limits. Meeting this crucial requirement guarantees vehicles adhere to local jurisdiction. Comprehending regulations makes certain that performance and compliance are attained which is important for vehicle makers and vehicle owner.

5. Vehicle-specific compatibility

Vehicle-specific compatibility constitutes a critical consideration when selecting an exhaust component for any motor vehicle. It dictates the correct fitment, optimal performance, and adherence to manufacturer specifications. The appropriateness of this element depends directly on the vehicle’s make, model, year, and engine configuration. Failure to adhere to these specifications can result in significant functional and operational discrepancies.

- Physical Dimensions and Mounting Points

Physical dimensions and mounting points are fundamental to vehicle-specific compatibility. This component must match the vehicle’s exhaust system layout to ensure proper installation and secure attachment. Variations in exhaust pipe diameters, flange configurations, and hanger locations necessitate meticulous attention to these details. For example, a component designed for a compact car may not physically fit on a full-size truck due to length and mounting point differences. Attempting to force an incompatible component can damage the exhaust system or create exhaust leaks, compromising performance and safety.

- Engine Configuration and Exhaust Flow

Engine configuration dictates the required exhaust flow characteristics. Different engine types, such as inline, V-shaped, or turbocharged, generate varying exhaust volumes and pressures. The component must be designed to handle these specific flow rates to maintain optimal engine performance. A component with an incorrect internal diameter or baffling configuration can create excessive backpressure, reducing horsepower and fuel efficiency. Consider the example of a high-performance engine requiring a component with a larger diameter to accommodate increased exhaust flow, unlike a standard engine.

- Emission Control System Integration

Emission control system integration is essential for regulatory compliance. Modern vehicles incorporate catalytic converters and oxygen sensors that rely on precise exhaust gas composition and temperature. The component must be compatible with these systems to ensure proper function. An incompatible component can disrupt the emission control process, leading to increased pollutant levels and potential failure of emission tests. For instance, tampering with or removing catalytic converters is illegal in many jurisdictions and can result in significant fines.

- Acoustic Properties and Sound Dampening

Acoustic properties and sound dampening characteristics contribute to the vehicle’s overall noise profile. The component is designed to reduce exhaust noise to comply with regulatory limits and enhance driver comfort. Vehicle-specific components are engineered to meet these noise requirements while maintaining optimal performance. An improperly selected component can generate excessive noise levels, leading to regulatory violations or reduced driving pleasure. The difference between a quiet, factory-engineered device and an aftermarket component with aggressive sound characteristics demonstrates this consideration.

These facets underscore the paramount importance of vehicle-specific compatibility for exhaust components. Addressing the critical specifications concerning form, function, emission management and noise levels guarantees optimal system integration. Proper adherence results in reliability, compliance, and enhanced customer satisfaction.

Frequently Asked Questions About a Specific Exhaust Component

The following questions address common concerns and misconceptions about this component, its function, and related maintenance considerations.

Question 1: What are the primary indicators of a failing component?

The prominent symptoms of a failing system often encompass noticeable increases in exhaust noise, a rattling sound originating from the undercarriage, visible rust or corrosion, and a decrease in fuel efficiency. These indicators signify potential breaches in its structural integrity and diminished performance.

Question 2: How does this system affect vehicle performance?

A properly functioning system optimizes exhaust flow, reducing backpressure on the engine. This leads to enhanced fuel efficiency and power output. Conversely, a damaged or restricted system can impede exhaust flow, resulting in reduced performance and increased fuel consumption.

Question 3: What materials are commonly utilized in manufacturing this part, and what are their relative advantages?

Common materials include aluminized steel, stainless steel, and, less frequently, titanium. Aluminized steel offers a balance of cost-effectiveness and corrosion resistance, while stainless steel provides superior durability and longevity. Titanium, though lightweight and highly corrosion-resistant, carries a higher cost and is typically reserved for high-performance applications.

Question 4: Is it possible to replace only the system, or is it mandatory to replace the entire exhaust system?

In many cases, selective replacement of the system alone is feasible, provided the adjacent exhaust components are in good condition. However, if significant corrosion or damage is present in surrounding areas, replacing the entire exhaust system may be more prudent.

Question 5: How does the choice of an aftermarket system impact vehicle sound levels and performance?

Aftermarket systems can significantly alter vehicle sound levels and performance characteristics. Some are designed to enhance exhaust flow and power output, potentially increasing noise levels. Strict consideration of local noise regulations and personal preferences should guide the selection of aftermarket components.

Question 6: What is the recommended maintenance schedule for this component to ensure longevity?

Regular visual inspections, conducted during routine vehicle maintenance, are recommended. Addressing minor corrosion or damage promptly can prevent more extensive issues. Depending on environmental conditions and driving habits, professional inspection every two to three years may be beneficial.

These FAQs aim to offer clarity on key aspects of the component. Understanding these topics empowers responsible vehicle ownership and informed maintenance practices.

Moving forward, the next section will delve into specific diagnostic procedures for identifying common issues and potential solutions.

bj’s muffler

This exploration has detailed essential features, functionality, and implications related to “bj’s muffler” systems. Consideration has been given to key issues that affect both the efficiency and reliability of modern transportation. Areas such as regulatory obedience, material selection, acoustic properties, and exhaust flow efficiency were outlined to show how the item works.

Vehicle owners and maintenance specialists must understand all aspects when making decisions about this part’s replacement or maintenance to preserve road legal status, system efficiency, and lower environmental impact. A constant maintenance program for the product helps to maintain dependability and performance over the service life of the vehicle.