This component, crucial for vehicle exhaust systems, plays a significant role in reducing noise pollution. Functioning as a sound dampener, it utilizes chambers and baffles to attenuate the high-pressure, rapidly expanding gases emitted from the engine. For example, without this device, the operation of internal combustion engines would generate disruptive sound levels, exceeding acceptable environmental standards.

The significance of this device extends beyond mere noise reduction. Its proper functioning contributes to improved engine efficiency by optimizing exhaust flow. Furthermore, historical context reveals that early iterations were rudimentary, but modern designs incorporate sophisticated engineering principles to achieve optimal performance and durability. This evolution underscores its enduring importance in automotive technology.

The subsequent sections will delve into specific aspects such as maintenance requirements, common failure modes, and selection criteria, providing a comprehensive understanding of this essential automotive element and its impact on vehicle operation and environmental considerations.

Guidance for Optimal Exhaust System Performance

The following recommendations are designed to promote the longevity and operational efficiency of your vehicle’s exhaust system, minimizing potential disruptions and maximizing performance.

Tip 1: Routine Visual Inspection: Conduct regular visual checks for signs of corrosion, physical damage, or leaks. Early detection of these issues can prevent more extensive and costly repairs.

Tip 2: Prompt Addressing of Unusual Noises: Investigate any unusual sounds emanating from the exhaust system. Rattling, hissing, or booming noises often indicate underlying problems such as loose components or exhaust leaks.

Tip 3: Monitor Fuel Efficiency: A noticeable decrease in fuel economy can be a symptom of exhaust system inefficiency, potentially caused by a clogged or damaged component. Address this promptly.

Tip 4: Avoid Short Trip Driving: Frequent short trips can lead to moisture accumulation within the exhaust system, accelerating corrosion. Allow the system to fully heat up during longer journeys.

Tip 5: Utilize Quality Replacement Parts: When replacement is necessary, opt for components manufactured to original equipment specifications. Inferior parts may compromise performance and durability.

Tip 6: Professional Installation: Ensure that any repairs or replacements are performed by a qualified technician. Improper installation can lead to exhaust leaks and other performance issues.

Tip 7: Regular Undercoating Application: In regions with harsh weather conditions, consider applying an undercoating to protect the exhaust system from road salt and other corrosive elements.

Adherence to these guidelines will contribute to the overall health of the vehicle’s exhaust system, resulting in improved performance, reduced emissions, and extended component lifespan.

The final segment of this article will provide a concluding overview of the presented information and offer perspectives on the future of exhaust system technology.

1. Sound Attenuation

Sound attenuation is a primary function of this critical exhaust system component. The effectiveness of this component in reducing noise directly correlates to its internal design and the materials used in its construction.

- Chamber Design and Resonance

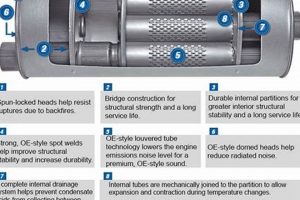

Internal chambers are strategically designed to reflect and cancel out sound waves. These chambers operate on principles of destructive interference, minimizing the amplitude of sound waves that pass through the component. Resonance within the chambers targets specific frequencies, reducing overall noise levels. Ineffective chamber design results in diminished sound reduction capabilities.

- Baffle Configuration and Sound Wave Disruption

Baffles, internal partitions within the component, force exhaust gases to change direction, disrupting the propagation of sound waves. The number, angle, and material of the baffles influence the degree of sound attenuation achieved. Suboptimal baffle configuration may lead to increased backpressure and reduced engine performance.

- Insulation Materials and Sound Absorption

Certain materials, such as fiberglass or mineral wool, are used to line the internal surfaces to absorb sound energy. These materials convert sound energy into heat, further reducing noise levels. The density and composition of the insulation material are critical factors in determining its sound absorption efficiency. Degradation of these materials over time reduces sound attenuation performance.

- Construction Integrity and Leak Prevention

Sealed construction is essential to prevent exhaust leaks, which can significantly increase noise levels and compromise sound attenuation effectiveness. Corrosion or damage to the component’s housing can create pathways for sound to escape, negating the effects of internal sound-dampening mechanisms. Regular inspection and maintenance are vital for preserving the structural integrity.

The interplay of these design elements and materials dictates the component’s overall sound attenuation performance. Effective sound attenuation not only contributes to a quieter driving experience but also ensures compliance with noise regulations and minimizes environmental noise pollution.

2. Exhaust Flow

Exhaust flow, the movement of spent gases from the engine through the exhaust system, exerts a significant influence on engine performance, fuel efficiency, and component longevity. The characteristics of this flow, including its velocity and pressure, are directly affected by the design and condition of the exhaust components, specifically the component discussed previously. Restricting exhaust flow can lead to reduced engine power, increased fuel consumption, and potential engine damage.

- Backpressure Generation

Internal design, characterized by chambers and baffles intended to attenuate sound, inherently creates backpressure. Excessive backpressure impedes the efficient evacuation of exhaust gases from the cylinders, hindering the engine’s ability to intake fresh air and fuel. Inefficiently designed components generate disproportionately high backpressure, negatively impacting engine performance. Conversely, an overly free-flowing system may diminish low-end torque.

- Diameter and Pipe Configuration

The diameter of the exhaust piping and the configuration of bends and curves influence flow dynamics. Constricted diameters or sharp bends generate turbulence and increase resistance to flow. Optimal design necessitates a balance between maintaining adequate exhaust velocity and minimizing pressure drop. Replacement with inappropriately sized piping can compromise engine performance.

- Internal Obstructions and Debris Accumulation

Internal obstructions, such as catalytic converter failure or debris accumulation, impede exhaust flow and increase backpressure. Corrosion and internal deterioration can lead to the detachment of materials that obstruct the exhaust passageway. Regular inspection and maintenance are essential to mitigate the risk of internal obstructions.

- System Matching and Engine Characteristics

The exhaust system should be carefully matched to the engine’s characteristics. An improperly sized or designed system can negate the benefits of engine modifications intended to improve performance. Consideration should be given to engine displacement, horsepower output, and intended operating range when selecting components.

Optimizing exhaust flow through careful design and maintenance enhances engine performance, improves fuel economy, and extends component lifespan. Understanding the interplay between exhaust flow dynamics and component characteristics is paramount for ensuring optimal vehicle operation.

3. Material Durability

Material durability constitutes a critical element in the overall performance and longevity of exhaust components. The selection of appropriate materials and manufacturing processes directly affects resistance to corrosion, thermal stress, and mechanical fatigue, all prevalent factors impacting the lifespan of such components. Premature failure due to inadequate material selection can result in increased noise pollution, reduced engine efficiency, and potential safety hazards. Examples include the use of aluminized steel, stainless steel, and titanium alloys, each offering varying levels of resistance to corrosive elements encountered in exhaust systems. The practical significance lies in minimizing replacement frequency, reducing maintenance costs, and ensuring reliable vehicle operation.

Environmental factors significantly influence material degradation. Exposure to road salt, moisture, and extreme temperature fluctuations accelerates corrosion processes. Internal condensation, generated during short trips, contributes to accelerated degradation of the exhaust system from within. Furthermore, mechanical stress, induced by engine vibrations and road impacts, can lead to fatigue cracking, particularly at weld joints and mounting points. Proper material selection, coupled with protective coatings, mitigates the adverse effects of these environmental stressors. For instance, stainless steel exhibits superior corrosion resistance compared to mild steel, making it a preferred choice for environments prone to high levels of salt exposure.

In conclusion, material durability stands as a cornerstone of reliable vehicle operation and environmental stewardship. The careful selection of materials, informed by a thorough understanding of operating conditions and degradation mechanisms, translates directly into extended component lifespan and reduced maintenance burden. Addressing material durability challenges proactively through robust design and manufacturing practices ensures optimal performance and mitigates the potential for premature failure, aligning with broader goals of sustainability and vehicle reliability.

4. Vehicle emissions

The reduction of harmful vehicle emissions represents a critical imperative in contemporary automotive engineering and environmental protection. Exhaust systems, particularly the component designed for sound attenuation, play an integral role in influencing the composition and volume of pollutants released into the atmosphere. The efficiency of this component, in conjunction with other emission control devices, directly impacts compliance with stringent regulatory standards and overall air quality.

- Catalytic Converter Integration

The presence or absence of a catalytic converter, often integrated within the exhaust system near this component, profoundly affects emission levels. Catalytic converters utilize chemical reactions to transform harmful gases, such as hydrocarbons, carbon monoxide, and nitrogen oxides, into less harmful substances like carbon dioxide, water, and nitrogen. In systems lacking a functional catalytic converter, this component provides minimal impact on reducing pollutant output, potentially leading to non-compliance with emissions regulations.

- Exhaust Leak Prevention

The structural integrity of this component is crucial for preventing exhaust leaks. Leaks occurring upstream or downstream of emission control devices diminish their effectiveness, allowing untreated exhaust gases to escape into the atmosphere. Even minor leaks can contribute significantly to increased emissions, especially in older vehicles with less sophisticated emission control systems. Regular inspection and maintenance are essential to ensure the integrity of the entire exhaust system.

- Backpressure Effects on Combustion

The level of backpressure generated by this component can influence engine combustion efficiency, which in turn affects emission levels. Excessive backpressure impedes the efficient evacuation of exhaust gases, potentially leading to incomplete combustion and increased levels of hydrocarbons and carbon monoxide. Optimizing this component’s design to minimize backpressure can improve combustion efficiency and reduce emissions.

- Material Composition and Chemical Reactions

The materials used in the construction of this component may, under certain operating conditions, contribute to or inhibit chemical reactions that impact emission levels. Some materials may catalyze unwanted reactions, while others may be inert. The selection of appropriate materials is crucial for ensuring that the component does not inadvertently increase pollutant output.

In summary, this automotive component’s contribution to vehicle emissions is multifaceted, encompassing catalytic converter integration, leak prevention, backpressure regulation, and material composition. A comprehensive approach to emission control necessitates considering the interplay of these factors to minimize environmental impact and ensure regulatory compliance.

5. Installation integrity

The operational effectiveness and longevity of vehicle exhaust components, particularly those designed for sound attenuation, are inextricably linked to installation integrity. Deviations from prescribed installation procedures, encompassing improper alignment, inadequate support, or the use of incompatible hardware, directly compromise component performance and accelerate degradation. A misaligned component, for instance, induces stress concentrations at mounting points, leading to premature cracking and failure. Insufficient support amplifies vibrations, further exacerbating stress-related damage. These seemingly minor oversights precipitate significant functional impairments and necessitate costly repairs. Real-world examples reveal that exhaust leaks, a common consequence of faulty installation, not only increase noise pollution but also diminish fuel efficiency and potentially expose vehicle occupants to harmful exhaust gases. This underscores the critical importance of adhering to stringent installation protocols to ensure optimal component performance and vehicle safety.

Further ramifications of compromised installation integrity extend to the vehicle’s broader emission control system. Misaligned or improperly sealed exhaust joints disrupt the intended flow of exhaust gases, impairing the catalytic converter’s efficiency in reducing harmful emissions. This leads to increased levels of pollutants released into the atmosphere, potentially violating environmental regulations. Furthermore, improper installation can compromise the structural integrity of adjacent exhaust components, triggering a cascading effect of failures and escalating repair costs. Consider a scenario where a component is installed with excessive torque on the mounting bolts. This can distort the component’s flange, creating a leak path and subjecting the component to undue stress, ultimately shortening its service life. Adherence to manufacturer-specified torque values and installation procedures is therefore paramount for maintaining the integrity of the entire exhaust system and ensuring compliance with emissions standards.

In summary, installation integrity serves as a foundational pillar for ensuring the reliable and environmentally responsible operation of vehicle exhaust components. The consequences of neglecting proper installation practices range from increased noise pollution and reduced fuel efficiency to compromised emission control and accelerated component failure. Prioritizing adherence to manufacturer specifications, employing qualified technicians, and conducting thorough post-installation inspections are essential steps in safeguarding component performance, vehicle safety, and environmental integrity.

6. System compatibility

System compatibility, with respect to the exhaust component in question, dictates its seamless integration with existing vehicle architecture. Deviations from established standards or a mismatch in design parameters can precipitate performance degradation, induce mechanical stress, and ultimately compromise the vehicle’s operational integrity.

- Flange Interface and Dimensional Accuracy

The flange, serving as the primary interface for component attachment, must exhibit precise dimensional accuracy to ensure a secure and leak-free connection. Discrepancies in bolt hole patterns, flange diameter, or surface flatness can lead to exhaust leaks, diminished sound attenuation, and potential damage to adjacent components. Mismatched flange dimensions necessitate costly modifications or replacement of mating parts. The implications extend to increased noise pollution and reduced fuel efficiency.

- Exhaust Pipe Diameter and Flow Characteristics

The diameter of the component’s inlet and outlet pipes must align with the existing exhaust system to maintain optimal flow characteristics. Variations in pipe diameter introduce turbulence and backpressure, negatively impacting engine performance and fuel economy. An undersized diameter restricts exhaust flow, while an oversized diameter can diminish exhaust scavenging effects. System compatibility requires adherence to established pipe diameter standards for the specific vehicle application. This ensures efficient evacuation of exhaust gases and proper engine operation.

- Mounting Point Alignment and Vibration Isolation

Mounting points must align precisely with existing vehicle frame or chassis attachment points to provide adequate support and minimize vibration transmission. Misaligned mounting points induce stress concentrations, leading to premature component failure and increased noise levels. Effective vibration isolation is crucial for preventing fatigue cracking and ensuring long-term durability. System compatibility mandates adherence to established mounting point configurations and the use of appropriate vibration dampening materials. This mitigates mechanical stress and prolongs component lifespan.

- Sensor Port Compatibility and Emission Control

Vehicles equipped with oxygen sensors or other emission control devices require compatible sensor ports on the exhaust component. Incompatible sensor ports disrupt the feedback loop between the engine control unit (ECU) and the emission control system, potentially leading to increased emissions and reduced fuel efficiency. System compatibility necessitates the inclusion of appropriately sized and positioned sensor ports to ensure proper functioning of the emission control system. This maintains compliance with environmental regulations and optimizes engine performance.

In summary, system compatibility constitutes a critical factor in determining the successful integration and performance of this crucial automotive component. Adherence to dimensional standards, flow characteristics, mounting configurations, and sensor port requirements ensures seamless integration with existing vehicle architecture, optimizing performance, minimizing mechanical stress, and ensuring compliance with environmental regulations. Neglecting system compatibility leads to compromised performance, increased maintenance costs, and potential environmental harm.

Frequently Asked Questions

The following questions address common inquiries regarding this crucial automotive component, aiming to clarify its function, maintenance, and performance characteristics.

Question 1: What is the primary function?

Its primary function is to attenuate exhaust noise generated by the internal combustion engine. This is achieved through internal chambers and baffles that disrupt sound wave propagation, reducing overall noise levels emitted from the vehicle.

Question 2: How does the component impact fuel efficiency?

A properly functioning system optimizes exhaust flow, minimizing backpressure and contributing to improved engine efficiency. Conversely, a damaged or obstructed component can increase backpressure, negatively impacting fuel economy.

Question 3: What are common signs of a failing component?

Common indicators include increased exhaust noise, rattling sounds emanating from beneath the vehicle, a noticeable decrease in fuel efficiency, and visible signs of corrosion or physical damage.

Question 4: What factors influence the component’s lifespan?

Lifespan is influenced by factors such as material quality, exposure to corrosive elements (road salt), driving conditions (short trips versus long distances), and the overall health of the vehicle’s engine.

Question 5: Does this automotive part affect vehicle emissions?

While primarily designed for sound attenuation, its functionality impacts emissions indirectly. Exhaust leaks compromise the effectiveness of catalytic converters, increasing harmful emissions. Furthermore, excessive backpressure reduces combustion efficiency, also affecting emissions.

Question 6: Is professional installation required?

Professional installation is highly recommended. Improper installation can lead to exhaust leaks, misalignment, and potential damage to adjacent components, compromising the overall performance and safety of the exhaust system.

In essence, understanding the function, maintenance requirements, and potential issues associated with this component ensures optimal vehicle performance, reduced emissions, and a quieter driving experience.

The subsequent section will delve into advanced diagnostics and troubleshooting techniques for this essential automotive component.

Conclusion

This exploration of “carolina muffler” has highlighted its multifaceted role in vehicle operation. From sound attenuation and exhaust flow management to material durability and system compatibility, the component’s significance extends beyond mere noise reduction. Its impact on fuel efficiency, vehicle emissions, and overall system integrity necessitates a comprehensive understanding of its design, function, and maintenance requirements.

The continued advancement in exhaust system technology demands ongoing attention to component optimization and integration. Emphasizing proactive maintenance, adherence to installation protocols, and informed component selection remains paramount for ensuring optimal vehicle performance, environmental responsibility, and long-term operational reliability. Prioritizing these factors will contribute to a more sustainable and efficient automotive future.