A device designed to reduce the noise emitted from an internal combustion engine, specifically targeting certain motorcycle models. These aftermarket components alter the exhaust note and flow characteristics compared to stock systems.

The primary advantage often cited is an increase in engine performance, achieved through reduced backpressure. Furthermore, these components contribute to a distinctive sound profile, appealing to riders seeking a more aggressive or customized auditory experience. Historically, modifications to exhaust systems have been popular among motorcycle enthusiasts, driven by a desire for both enhanced performance and aesthetic personalization.

The following sections will delve into the specific design elements, installation procedures, and performance characteristics, as well as any regulatory considerations surrounding aftermarket exhaust modifications.

Guidance on Aftermarket Exhaust Systems

The following points offer practical advice concerning aftermarket motorcycle exhaust components. These considerations aim to maximize performance, ensure legality, and promote long-term reliability.

Tip 1: Research Compatibility. Prior to purchase, verify compatibility with the specific motorcycle model. Conflicting specifications can result in diminished performance or installation difficulties.

Tip 2: Assess Material Quality. Opt for components constructed from durable materials such as stainless steel or titanium. This choice provides resistance to corrosion and extends service life.

Tip 3: Evaluate Noise Levels. Be cognizant of local noise regulations. Excessive decibel levels can result in fines and legal repercussions. Some aftermarket systems include sound inserts for adjustability.

Tip 4: Consider Backpressure Implications. Modifications to the exhaust system impact engine backpressure. Improper backpressure can negatively affect engine performance; consult with a qualified technician if necessary.

Tip 5: Employ Professional Installation. Installation requires specific tools and mechanical aptitude. Professional installation ensures proper fitment and reduces the risk of damage to the motorcycle.

Tip 6: Conduct Periodic Inspections. Routinely inspect exhaust components for signs of corrosion, leaks, or damage. Early detection prevents escalation of issues and maintains optimal performance.

Tip 7: Monitor Engine Performance. Following installation, monitor engine performance indicators such as fuel efficiency and throttle response. Any irregularities warrant further investigation.

Adherence to these recommendations promotes responsible modification practices and enhances the long-term ownership experience. Proper selection, installation, and maintenance are paramount.

The subsequent section will address legal considerations and environmental impact associated with these components.

1. Sound Attenuation

Sound attenuation is a critical design consideration for aftermarket motorcycle exhaust systems. These components directly influence the noise level emitted by the motorcycle, impacting both rider experience and regulatory compliance.

- Baffle Design and Implementation

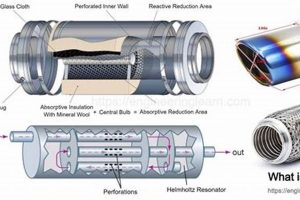

Baffles are internal structures within the exhaust that disrupt sound waves, reducing their amplitude. Variations in baffle designincluding perforated cores, reverse cones, and multi-chamber systemsdirectly correlate with the degree of sound attenuation achieved. For example, a dense, multi-chamber baffle system offers greater noise reduction compared to a straight-through perforated core design, though often at the expense of exhaust flow.

- Material Composition and Acoustic Properties

The materials used in exhaust construction contribute to sound attenuation. Certain materials, such as fiberglass packing or specialized sound-absorbing wool, are strategically placed within the muffler to dampen acoustic energy. The effectiveness of these materials degrades over time due to heat and exhaust gases, necessitating periodic replacement to maintain optimal sound attenuation.

- Decibel Level Compliance and Legal Requirements

Aftermarket exhaust systems must adhere to noise regulations established by governing bodies. These regulations specify maximum permissible decibel levels at various engine speeds and distances from the motorcycle. Non-compliance can result in fines, vehicle impoundment, and legal repercussions. Consequently, effective sound attenuation is not merely a matter of personal preference but a legal obligation.

- Impact on Engine Performance and Backpressure

Sound attenuation measures influence engine performance characteristics, particularly exhaust backpressure. Highly restrictive baffles, while effective at reducing noise, can increase backpressure, potentially hindering engine output. Conversely, a less restrictive design, while maximizing performance, may result in unacceptable noise levels. A balance between sound attenuation and performance optimization is therefore crucial in aftermarket exhaust design.

Effective management of sound through strategic design and materials directly dictates overall product performance and legal acceptance of the component. The implementation of durable, noise reducing mechanisms and the adherence to industry decibel level standards are the foundations of product satisfaction.

2. Performance Enhancement

Performance enhancement is a primary driver behind the adoption of aftermarket motorcycle exhaust components. Modifications to the exhaust system can alter engine operating characteristics, influencing power output, throttle response, and overall riding experience. This section explores the connection between performance enhancement and the application of these components.

- Exhaust Flow Optimization

These systems are often designed to reduce exhaust backpressure, allowing for more efficient scavenging of combustion gases from the engine cylinders. Improved exhaust flow contributes to increased horsepower and torque, particularly at higher engine speeds. For example, a system with a larger diameter pipe and less restrictive muffler can significantly improve airflow compared to a stock system, resulting in a noticeable performance gain.

- Weight Reduction

Aftermarket exhaust systems frequently utilize lighter materials, such as titanium or carbon fiber, compared to the stock steel components. This weight reduction contributes to improved handling and acceleration. A lighter motorcycle requires less energy to accelerate and decelerate, enhancing overall agility and responsiveness. Some riders report significant improvements in handling characteristics simply from switching to a lighter exhaust system.

- Engine Tuning and Mapping

Changes to the exhaust system often necessitate adjustments to the engine’s fuel injection or carburetion system to optimize performance. Altering the air/fuel mixture ensures that the engine is operating at its peak efficiency and prevents lean or rich conditions that can damage the engine. A professionally tuned motorcycle, following exhaust modification, typically exhibits improved throttle response and overall power delivery.

- Impact on Torque and Power Curves

Aftermarket exhaust systems can alter the shape of the engine’s torque and power curves. Some systems are designed to enhance low-end torque, providing improved acceleration from a standstill. Other systems prioritize peak horsepower at higher RPMs, catering to riders who favor high-speed performance. The selection of an appropriate exhaust system depends on the rider’s preferred riding style and the intended application of the motorcycle.

The pursuit of performance enhancement through exhaust modification requires careful consideration of several factors, including exhaust flow, weight reduction, and engine tuning. Proper implementation of these modifications can yield tangible improvements in engine performance and overall riding experience. However, it’s crucial to ensure that any modifications comply with local noise regulations and do not negatively impact engine reliability.

3. Material Durability

Material durability is a paramount consideration in the context of aftermarket motorcycle exhaust components, dictating longevity, resistance to environmental factors, and overall value. The selection of appropriate materials significantly impacts the exhaust system’s performance and operational lifespan.

- Corrosion Resistance

Exposure to exhaust gases, road salts, and moisture makes corrosion resistance a critical attribute. Materials such as stainless steel and titanium exhibit superior resistance to corrosion compared to mild steel, thereby extending the component’s lifespan and maintaining its aesthetic appearance. For instance, a stainless-steel exhaust is likely to maintain structural integrity and appearance over several years, while a mild steel counterpart would exhibit rust and degradation much sooner, especially in regions with harsh winter climates.

- Thermal Stability

Exhaust systems are subjected to extreme temperature fluctuations. Materials must maintain their structural integrity and mechanical properties at elevated temperatures to prevent warping, cracking, or failure. High-quality stainless steel alloys and titanium are known for their thermal stability, making them suitable for this demanding application. Cheaper materials are prone to deformation from this constant expanding and contracting.

- Resistance to Mechanical Stress

Vibration and physical impacts from road debris can induce mechanical stress on the exhaust system. Durable materials with high tensile strength and fatigue resistance are necessary to withstand these stresses and prevent premature failure. Thicker gauge metals and strategic reinforcement in high-stress areas contribute to improved resistance. A thin walled system will quickly become damaged.

- Weld Integrity and Joint Strength

The welds connecting various components of the exhaust system are critical points of potential failure. Welding processes must be carefully controlled to ensure strong, durable joints that can withstand thermal cycling and mechanical stress. The use of high-quality welding wire and proper welding techniques are essential for maintaining the integrity of the exhaust system. For example, a poorly executed weld on an exhaust flange can lead to leaks and eventual component separation.

The material composition and construction methods of an aftermarket exhaust directly influence its durability and resistance to environmental factors. Investing in components constructed from high-quality materials and fabricated with precise welding techniques ensures long-term reliability and performance, minimizing the need for frequent replacements and reducing overall ownership costs.

4. Compatibility Verification

Compatibility verification is a crucial step in the selection and installation of any aftermarket motorcycle exhaust component. It directly addresses the potential for mismatch between the exhaust system and the specific motorcycle model. Failure to verify compatibility can lead to a range of adverse consequences, including compromised engine performance, physical fitment issues, and potential damage to the motorcycle. The cause-and-effect relationship is straightforward: an incompatible exhaust system will not function as intended, potentially degrading the overall performance of the motorcycle. A real-life example would be attempting to install an exhaust designed for a twin-cylinder engine on a single-cylinder motorcycle; the exhaust port shapes, pipe diameters, and mounting points will invariably differ, rendering the installation impossible without extensive modifications.

The importance of compatibility verification extends beyond simple physical fitment. The engine control unit (ECU) relies on specific exhaust backpressure characteristics for optimal operation. An exhaust system designed for a different engine displacement or configuration can disrupt these characteristics, leading to improper fuel delivery and potentially causing engine damage over time. The practical significance of understanding this lies in preventing costly repairs and ensuring the motorcycle operates within its intended performance parameters. Manufacturers typically provide compatibility charts or lists that specify the motorcycle models with which a given exhaust system is compatible. Consulting these resources prior to purchase is essential.

In summary, compatibility verification is not merely a formality but a critical step in the process of selecting and installing an aftermarket exhaust component. Overlooking this step can result in a cascade of problems, ranging from simple fitment issues to severe engine damage. By prioritizing compatibility verification, motorcycle owners can ensure that the exhaust system performs as intended, enhances the riding experience, and safeguards the long-term health of their motorcycles.

5. Regulatory Compliance

Regulatory compliance constitutes a critical aspect of aftermarket motorcycle exhaust components. These systems directly impact noise emissions and exhaust content, subjects of stringent regulations at the local, state, and federal levels. Adherence to these regulations is not optional; non-compliance can result in fines, legal repercussions, and operational restrictions.

- Noise Emission Standards

Governing bodies establish maximum permissible decibel levels for motorcycles. Aftermarket exhaust components must meet these standards at specified engine speeds and operating conditions. Failure to comply can result in citations and the rejection of vehicle inspections. For example, a community might have rules about how loud bikes can be at certain times. If an aftermarket component causes a bike to be louder than these levels, the owner could be fined.

- Emissions Control Regulations

Certain jurisdictions mandate emissions control devices, such as catalytic converters, to reduce harmful pollutants. Altering or removing these devices can violate emissions regulations, leading to substantial penalties. This can extend to aftermarket components if they remove the devices.

- Labeling and Certification Requirements

Some regions require aftermarket exhaust components to be labeled with a certification demonstrating compliance with applicable regulations. The absence of such labeling can result in the product being deemed illegal for use on public roads. Proper markings demonstrate verification of compliance and ensure legal operation.

- Enforcement and Inspection Procedures

Law enforcement agencies conduct routine inspections to ensure compliance with noise and emissions regulations. These inspections can involve sound level measurements, visual inspections of exhaust components, and review of certification documentation. Vehicles found in violation are subject to corrective actions and financial penalties. Because of this, an owner should routinely monitor their bikes.

The implications of regulatory compliance for aftermarket motorcycle exhaust systems are multifaceted. Manufacturers and consumers alike bear the responsibility of ensuring that these components meet applicable legal requirements. Ignoring this responsibility can lead to legal and financial ramifications, undermining the benefits sought from aftermarket modifications.

Frequently Asked Questions Regarding Aftermarket Motorcycle Exhaust Components

The following questions and answers address common concerns and misconceptions surrounding aftermarket motorcycle exhaust systems, specifically focusing on design, performance, and regulatory aspects. The information provided is intended to offer clarity and promote informed decision-making.

Question 1: To what extent do aftermarket exhaust systems genuinely enhance engine performance?

The degree of performance enhancement varies based on system design and engine configuration. Performance gains, attributable to reduced backpressure and optimized exhaust flow, are often most noticeable at higher engine speeds. However, overall performance improvements depend on proper engine tuning and system compatibility.

Question 2: What are the primary considerations in selecting an exhaust system?

Key considerations include intended application, engine characteristics, material durability, noise level compliance, and regulatory adherence. The specific use case of the motorcycle dictates the ideal system configuration, balancing performance objectives with noise and emissions restrictions.

Question 3: How does exhaust backpressure influence engine performance?

Exhaust backpressure significantly impacts engine efficiency. While some backpressure is necessary for proper scavenging, excessive backpressure restricts exhaust flow and diminishes power output. Aftermarket systems aim to optimize backpressure for improved engine performance.

Question 4: What materials are commonly employed in the construction of aftermarket exhaust systems, and what are their respective advantages?

Common materials include stainless steel, titanium, and carbon fiber. Stainless steel offers a balance of durability, corrosion resistance, and cost-effectiveness. Titanium provides exceptional strength-to-weight ratio and corrosion resistance, but at a higher cost. Carbon fiber reduces weight and offers aesthetic appeal but may be less durable than metallic options.

Question 5: What are the legal ramifications of installing an exhaust system that exceeds established noise level limits?

Installing a non-compliant exhaust system can result in fines, vehicle impoundment, and mandatory corrective actions. Local noise regulations vary, and it is the owner’s responsibility to ensure compliance. Legal ramifications vary widely, but all non-compliant activity bears the risk of consequences.

Question 6: How can the durability of an aftermarket exhaust system be maintained?

Durability is maintained through periodic inspections for corrosion, leaks, and damage. Cleaning and protective coatings help to prevent corrosion, particularly in regions with harsh environmental conditions. Regular maintenance extends system lifespan and ensures continued performance.

In summary, the selection and maintenance of aftermarket exhaust systems involve a complex interplay of performance objectives, regulatory considerations, and material properties. Careful evaluation and adherence to best practices are essential for maximizing system benefits and mitigating potential risks.

The following section will address troubleshooting common issues.

In Conclusion

This discussion has thoroughly explored aspects concerning these motorcycle components. Emphasis has been placed on performance implications, material selection, regulatory compliance, and overall design. Understanding these factors contributes to informed purchasing decisions and promotes responsible modification practices.

The ultimate success of any exhaust modification hinges on a balanced approach, considering not only performance gains but also environmental impact and legal ramifications. Continued diligence and adherence to best practices are essential to maximizing the benefits and mitigating the risks associated with alterations to motorcycle exhaust systems.