A specialized exhaust system component, typically fabricated or modified to meet specific vehicle performance or aesthetic requirements, can significantly alter a vehicle’s sound profile and exhaust flow characteristics. Examples range from systems designed for increased horsepower in racing applications to those prioritizing a unique tonal quality for personal enjoyment.

The advantages of this type of modification include optimized engine performance, a distinctive sound, and a customized appearance. Historically, the practice of altering exhaust systems has been driven by both competitive racing needs and a desire for personalized vehicle aesthetics, leading to a diverse range of materials and construction techniques.

The following discussion will delve into the considerations involved in selecting a tailored exhaust system, the performance implications of such modifications, and the regulatory landscape governing exhaust system alterations for street-legal vehicles.

Expert Guidance on Tailored Exhaust Systems

The selection and implementation of bespoke vehicle exhaust solutions require careful consideration. The following tips offer essential guidance for optimal results.

Tip 1: Assess Performance Goals: Clearly define the desired performance improvements. Increased horsepower, torque, or fuel efficiency will influence the design and materials chosen.

Tip 2: Material Selection is Critical: Opt for high-quality materials such as stainless steel or titanium to ensure longevity and resistance to corrosion. Material selection impacts both sound and durability.

Tip 3: Consider Sound Characteristics: Exhaust note is a subjective preference. Investigate sound clips and consult with experienced fabricators to achieve the desired auditory experience. Legal sound level restrictions must be observed.

Tip 4: Proper Installation is Paramount: Professional installation is strongly recommended. Improper installation can lead to leaks, reduced performance, and potential damage to the vehicle.

Tip 5: Ensure Regulatory Compliance: Verify that the modified exhaust system complies with all applicable local and federal regulations. This includes emissions standards and noise restrictions.

Tip 6: Regular Maintenance is Necessary: Inspect the exhaust system periodically for leaks, corrosion, and damage. Timely repairs will prevent further issues and maintain optimal performance.

Tip 7: Consult with Experts: Seek advice from experienced exhaust system specialists. They can provide valuable insights and guidance based on specific vehicle and performance requirements.

Adhering to these guidelines will contribute to the successful integration of a tailored exhaust solution, maximizing performance benefits while ensuring regulatory compliance.

The subsequent sections will explore specific exhaust system designs and their impact on vehicle dynamics and overall driving experience.

1. Performance Optimization

Performance optimization in exhaust systems, including specialized mufflers, directly influences engine efficiency and power output. The design and construction of these systems can be tailored to enhance various aspects of vehicle performance.

- Exhaust Flow Dynamics

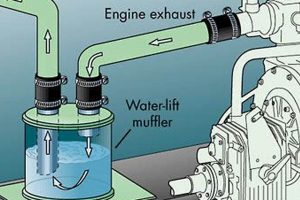

Optimized exhaust flow reduces backpressure, allowing the engine to expel exhaust gases more efficiently. This results in increased horsepower and torque, particularly at specific RPM ranges. Specialized mufflers are designed with internal geometries that minimize flow restriction while effectively attenuating sound.

- Engine Tuning Synergies

A customized muffler can be designed to work in conjunction with engine tuning modifications, such as ECU remapping or camshaft upgrades. These synergistic effects can further amplify performance gains. For example, a muffler designed for high-RPM flow can complement a camshaft profile optimized for top-end power.

- Weight Reduction Contributions

Lighter muffler materials, such as titanium or thin-gauge stainless steel, contribute to overall vehicle weight reduction. This can improve acceleration, braking, and handling. The reduction in weight also indirectly improves fuel efficiency.

- Thermal Management Considerations

High-performance mufflers are often designed to dissipate heat more effectively, reducing thermal stress on surrounding components. This can improve the reliability and longevity of the exhaust system and adjacent parts. Proper thermal management is especially crucial in forced-induction applications.

In summary, performance optimization of exhaust systems, particularly through specialized mufflers, involves a multifaceted approach encompassing flow dynamics, engine tuning synergies, weight reduction, and thermal management. The effectiveness of these optimizations depends on the specific design and application of the system.

2. Sound Customization

The acoustic profile of a vehicle’s exhaust system represents a critical element in the overall driving experience. Sound customization, therefore, constitutes a significant component when considering a bespoke exhaust solution. The properties of the muffler directly influence the frequency and amplitude of the sound waves produced. The intended outcome ranges from a subtle reduction in harsh tones to a more pronounced, aggressive exhaust note, predicated upon individual preference and application. For example, performance vehicles often incorporate mufflers designed to produce a deep, resonant sound at higher engine speeds, signifying power and performance capabilities. Conversely, luxury vehicles might prioritize mufflers that minimize noise levels, ensuring a quiet and comfortable ride. The shape, size, and internal baffling of the muffler all contribute to the final sound characteristics.

The selection of materials plays a crucial role in shaping the acoustic output. Stainless steel, known for its durability, often produces a brighter, more metallic sound, while aluminized steel tends to yield a deeper, more muted tone. Furthermore, the diameter and length of the exhaust piping leading to the muffler affect the resonant frequencies and overall volume. Sound customization also necessitates adherence to local noise regulations, requiring careful consideration of decibel levels and permissible modifications. The practical application of these principles is evident in aftermarket exhaust systems that offer adjustable valves or baffles, allowing drivers to modify the sound profile based on driving conditions or personal preferences. An informed understanding of these factors ensures that the final acoustic signature aligns with the desired characteristics.

Ultimately, the interplay between muffler design, material selection, and exhaust system configuration dictates the degree of sound customization achieved. This element is inseparable from the overall value proposition of a specialized exhaust system, impacting both the perceived performance and driving satisfaction. Challenges in achieving desired sound profiles often arise from balancing acoustic requirements with performance goals and regulatory constraints. Therefore, a comprehensive approach, encompassing careful planning and expert execution, is essential to realize the intended benefits of sound customization in exhaust systems.

3. Material Durability

Material durability directly impacts the lifespan and performance of a custom muffler. Exposure to extreme temperatures, corrosive road salts, and constant vibrations necessitates robust materials capable of withstanding harsh conditions. The selection of materials, therefore, is not merely an aesthetic choice but a critical engineering consideration that determines the long-term effectiveness and reliability of the component. Inferior materials will corrode, crack, or otherwise degrade, leading to exhaust leaks, reduced performance, and ultimately, premature failure of the entire system. For instance, a muffler constructed from low-grade steel will rapidly succumb to rust, particularly in regions with harsh winter climates where road salts are heavily used. This corrosion weakens the structural integrity of the muffler, potentially causing it to separate from the exhaust system and necessitating costly repairs or replacements.

Conversely, using high-quality materials like 304 stainless steel or titanium offers superior resistance to corrosion and high temperatures. Stainless steel forms a protective chromium oxide layer on its surface, preventing rust from forming. Titanium, while more expensive, provides exceptional strength-to-weight ratio and corrosion resistance, making it ideal for high-performance applications where weight reduction is a priority. The implementation of these materials translates to increased longevity of the muffler, reduced maintenance requirements, and sustained performance over time. A custom muffler fabricated from stainless steel, for example, can easily last for ten years or more under normal driving conditions, while a comparable muffler made from aluminized steel may only last for two to three years.

In summary, material durability constitutes an indispensable factor in the overall value proposition of a custom muffler. The investment in durable materials translates directly into extended service life, reduced maintenance costs, and consistent performance, thereby enhancing the long-term satisfaction and economic viability of the exhaust system modification. The challenges lie in balancing the cost of premium materials with the desired performance characteristics and longevity expectations. However, the selection of appropriate materials for a custom muffler, coupled with proper installation and maintenance, will significantly improve the reliability and lifespan of the complete system.

4. Fabrication Precision

Fabrication precision constitutes a cornerstone in the quality and performance of any custom exhaust component. The degree of accuracy and meticulousness in the manufacturing process directly correlates with the overall functionality, longevity, and sound characteristics of a bespoke muffler.

- Dimensional Accuracy

Dimensional accuracy ensures a precise fit within the vehicle’s exhaust system. Deviation from specified dimensions can result in leaks, rattling, and reduced performance. Accurate measurements and adherence to design specifications are essential for seamless integration of the muffler.

- Welding Integrity

Welding integrity guarantees structural strength and prevents exhaust gas leaks. Precise welding techniques, such as TIG welding, create strong, durable joints that withstand high temperatures and vibrations. Defective welds compromise the integrity of the muffler and lead to premature failure.

- Material Forming Consistency

Consistent material forming maintains uniform wall thickness and internal geometry, which are critical for sound attenuation and exhaust flow. Inconsistent forming can result in uneven sound characteristics and reduced performance. Precision forming techniques, such as mandrel bending, preserve the internal diameter of the tubing, optimizing exhaust flow.

- Surface Finish Quality

Surface finish quality enhances corrosion resistance and aesthetic appeal. Smooth, consistent surface finishes minimize corrosion initiation points and provide a professional appearance. Proper surface preparation and coating techniques, such as polishing or powder coating, improve the long-term durability and visual appeal of the muffler.

The cumulative effect of these facets underscores the importance of fabrication precision in the production of custom mufflers. Achieving optimal performance, longevity, and aesthetic appeal necessitates a commitment to meticulous manufacturing processes and adherence to stringent quality control standards. The value of a tailored muffler is directly proportional to the precision employed during its fabrication.

5. Regulatory Compliance

Regulatory compliance is a critical aspect of custom exhaust system modifications. The installation of a non-compliant system can result in legal penalties, vehicle inspection failures, and potential environmental damage. The following points outline key considerations.

- Noise Emission Standards

Many jurisdictions enforce noise emission standards for vehicles, often measured in decibels (dB). Custom mufflers must comply with these limits to be street legal. Exceeding the specified dB level can result in fines or the requirement to revert to a compliant exhaust system. For example, California mandates specific noise limits for aftermarket exhaust systems, requiring them to be no louder than the original equipment manufacturer (OEM) system.

- Emissions Control Regulations

Exhaust systems are integral to a vehicle’s emissions control system. Altering or removing catalytic converters or other emissions control devices is illegal in many countries and states. Custom mufflers must be designed to work in conjunction with existing emissions control systems to maintain compliance with regulations such as the Clean Air Act in the United States. Failure to comply can lead to substantial fines and legal action.

- Safety Standards and Inspections

Exhaust systems must adhere to safety standards to prevent hazards such as carbon monoxide leaks or fire risks. Custom mufflers must be properly installed and maintained to ensure safe operation. Vehicle inspections often include checks for exhaust leaks, proper mounting, and compliance with safety regulations. Non-compliant installations can result in inspection failures and the requirement for corrective action.

- Labeling and Certification Requirements

Some jurisdictions require custom mufflers to be labeled with specific information, such as the manufacturer’s name, model number, and compliance certifications. This labeling provides assurance to vehicle owners and enforcement agencies that the system meets applicable regulatory requirements. Failure to properly label or certify a custom muffler can result in fines and the requirement to remove the system from the vehicle.

Adherence to these regulatory requirements is essential for the legal operation of vehicles equipped with custom exhaust systems. It also contributes to environmental protection and public safety. Consulting with experienced exhaust system specialists and verifying compliance with local regulations are crucial steps in selecting and installing a custom muffler.

Frequently Asked Questions About Custom Muffler Systems

This section addresses common inquiries regarding tailored exhaust systems, providing objective and informative answers.

Question 1: Does modifying a vehicle’s exhaust system automatically void its warranty?

The impact on a vehicle’s warranty depends on the specific terms outlined by the manufacturer and the nature of the modification. An aftermarket system that doesn’t cause damage to related components is unlikely to void the entire warranty, but the altered components are generally not covered.

Question 2: How does a custom muffler affect vehicle emissions?

A properly designed custom muffler should not negatively impact emissions. It is crucial that modifications do not remove or alter any emissions control devices, such as catalytic converters. Maintaining compliance with emissions regulations is the owner’s responsibility.

Question 3: What are the primary benefits of a performance-oriented exhaust system?

Performance-oriented systems aim to enhance engine efficiency by reducing backpressure. This can lead to increased horsepower and torque, particularly at specific engine speeds. Additional benefits may include weight reduction and improved exhaust note.

Question 4: Are all “stainless steel” exhaust systems created equal?

No. The grade of stainless steel significantly affects durability and corrosion resistance. Higher grades, such as 304 stainless steel, offer superior protection against rust and are recommended for long-term performance.

Question 5: How important is professional installation for a custom exhaust system?

Professional installation is highly recommended. Proper installation ensures correct fitment, prevents leaks, and optimizes performance. Improper installation can lead to reduced efficiency and potential damage to the vehicle.

Question 6: How can one ensure that a custom muffler complies with local noise ordinances?

Research local noise regulations prior to selecting and installing an aftermarket exhaust system. Consult with experienced fabricators and consider systems that include sound level adjustability. Compliance is the responsibility of the vehicle owner.

Custom exhaust systems provide options for performance enhancement and personalized sound, provided that modifications are carefully considered and implemented responsibly.

The subsequent section will provide insights into troubleshooting common exhaust system issues.

Concluding Remarks on Tailored Exhaust Systems

This exploration has illuminated the critical factors surrounding specialized exhaust solutions. Considerations of performance optimization, sound customization, material durability, fabrication precision, and regulatory compliance are paramount in achieving desired outcomes. Suboptimal choices in any of these areas can compromise the system’s overall effectiveness and longevity.

The value of expertly crafted exhaust systems extends beyond mere aesthetic enhancement. When properly engineered and installed, such systems can contribute to improved engine efficiency, a more engaging driving experience, and adherence to environmental standards. A thorough understanding of these principles is essential for making informed decisions and realizing the full potential of custom exhaust technology.