The systems responsible for engine temperature regulation and exhaust noise reduction in vehicles operating within the Fairbanks, Alaska, region are the central topic. Components crucial for maintaining optimal engine performance and minimizing environmental noise pollution are integral to the operation of these automotive systems. Examples include cooling system components designed to dissipate heat generated by the engine and exhaust system devices engineered to dampen sound produced during combustion.

Efficient heat management and noise suppression are paramount in the challenging climatic conditions and regulatory environment of interior Alaska. Effective engine cooling prevents overheating, extending engine lifespan and ensuring reliable performance. Conversely, regulated exhaust systems contribute to noise abatement, adherence to environmental regulations, and enhanced community quality of life. The evolution of these systems reflects ongoing advancements in automotive engineering and environmental awareness.

The following sections will delve into the specifics of cooling system technologies, exhaust system designs, and the critical role these components play in vehicle maintenance and operation. Material will be explored that focuses on both standard practices and innovative solutions for the unique challenges presented by the regional environment.

Maintenance and Longevity Recommendations

The following guidelines are provided to assist in the proper maintenance and extended service life of vehicle cooling and exhaust systems operating within the specific environmental conditions of interior Alaska.

Tip 1: Regular Coolant Flush and Fill: Consistent replacement of engine coolant is critical. Coolant degrades over time, losing its ability to effectively transfer heat and prevent corrosion. It is advised to adhere to manufacturer-specified intervals or, in severe operating conditions, shorten these intervals by up to 50%.

Tip 2: Visual Inspection of Radiator: Periodically examine the radiator core for debris accumulation, bent fins, and evidence of leaks. Clean debris using a soft brush or low-pressure air. Address bent fins carefully to maintain airflow. Promptly repair or replace leaking radiators to prevent engine overheating.

Tip 3: Hose and Belt Inspection: Cooling system hoses and drive belts should be inspected for cracks, swelling, or fraying. Replace compromised components immediately to avert system failure and potential engine damage.

Tip 4: Exhaust System Corrosion Prevention: In regions with high road salt usage, apply corrosion-resistant coatings to exhaust system components. Regularly wash the undercarriage of the vehicle to remove accumulated salt and debris.

Tip 5: Muffler Drain Hole Maintenance: Ensure the drain hole in the muffler remains clear of obstructions. This allows condensation to escape, preventing internal corrosion and extending muffler lifespan.

Tip 6: Professional System Evaluation: Schedule periodic professional inspections of both the cooling and exhaust systems. Certified technicians possess the expertise and equipment to identify potential issues before they escalate into major repairs.

Tip 7: Monitor Engine Temperature: Pay close attention to the vehicle’s engine temperature gauge. Any indication of overheating should be addressed immediately to prevent catastrophic engine damage.

These maintenance procedures are essential for ensuring the reliable and efficient operation of vehicles within the demanding environment. Consistent adherence to these recommendations will contribute to minimizing downtime, reducing repair costs, and maximizing vehicle longevity.

The subsequent section provides an overview of common problems and troubleshooting techniques for cooling and exhaust systems.

1. Coolant Composition and Fairbanks Radiator and Muffler

Coolant composition is inextricably linked to the functionality and longevity of cooling systems within the Fairbanks, Alaska, region. The engine coolant serves as the primary heat transfer medium, circulating through the engine block and radiator to dissipate heat generated during combustion. Inadequate coolant composition, specifically regarding freeze protection and corrosion inhibitors, directly impacts the performance and lifespan of the radiator and, indirectly, the muffler. The extreme winter temperatures prevalent in Fairbanks necessitate a coolant mixture that prevents freezing and subsequent expansion, which can rupture radiator cores and engine blocks.

Furthermore, the presence of effective corrosion inhibitors within the coolant is paramount. These additives mitigate the electrochemical reactions between dissimilar metals within the cooling system (e.g., aluminum cylinder heads and cast iron engine blocks). Without adequate corrosion protection, galvanic corrosion accelerates, leading to the formation of scale and sludge. This buildup reduces heat transfer efficiency, potentially causing engine overheating. It also compromises the structural integrity of the radiator, leading to leaks and premature failure. The muffler is indirectly affected because an overheated engine can lead to inefficient combustion and excessive backpressure, potentially damaging the exhaust system components.

In summary, selecting and maintaining the correct coolant composition is not merely a routine maintenance task; it is a critical preventative measure essential for preserving the operational integrity of automotive cooling systems. The harsh operating conditions of Fairbanks amplify the significance of this practice. Neglecting coolant composition leads to reduced efficiency, increased maintenance costs, and potentially catastrophic engine damage, underscoring the direct connection between this fluid and the performance of the radiator and, consequentially, the overall vehicle health.

2. Radiator Integrity

Radiator integrity represents a foundational requirement for reliable vehicle operation, particularly within the context of automotive services offered under the rubric of “fairbanks radiator and muffler.” The radiator functions as the primary heat exchanger within the engine cooling system, dissipating thermal energy generated during combustion. Structural compromise of the radiator, resulting from corrosion, impact damage, or material fatigue, directly impairs its ability to regulate engine temperature effectively. This functional degradation leads to engine overheating, a condition that can induce severe mechanical damage, including cylinder head warping, piston seizure, and complete engine failure.

The significance of maintaining radiator integrity in Fairbanks stems from the region’s extreme climatic conditions. Sub-zero temperatures amplify the corrosive effects of road salts and de-icing agents, accelerating the deterioration of radiator materials, especially at welded seams and tube-to-header joints. Furthermore, the thermal cycling experienced by vehicles operating in this environment, characterized by frequent temperature fluctuations, induces stress on the radiator core, predisposing it to cracking and leakage. Consider, for example, a vehicle routinely driven on the Dalton Highway. The harsh conditions prevalent on this route increase the likelihood of rock impacts to the radiator, which creates punctures and compromises its structural integrity. Such occurrences lead to reduced cooling efficiency, increasing the risk of overheating under sustained high-load operation or during summer months.

In conclusion, radiator integrity is not merely a matter of routine maintenance; it is a critical determinant of vehicle reliability and longevity in demanding environments. Neglecting to address potential radiator weaknesses can result in costly repairs and vehicle downtime, ultimately undermining the operational efficiency of vehicles. Therefore, regular inspection, proper coolant maintenance, and prompt repair of any identified damage are essential practices for those seeking to optimize vehicle performance and mitigate the risks associated with operating in challenging environments.

3. Exhaust Integrity

Exhaust integrity is a crucial component, indirectly yet significantly, influencing the domain denoted by “fairbanks radiator and muffler.” A compromised exhaust system, characterized by leaks, corrosion, or blockages, leads to increased engine backpressure. Elevated backpressure negatively impacts engine performance, reducing fuel efficiency and increasing engine operating temperature. This rise in temperature places added stress on the engine cooling system, demanding greater heat dissipation from the radiator. A failing exhaust system, therefore, indirectly forces the radiator to operate beyond its design parameters, potentially accelerating wear and reducing its lifespan.

The connection extends further. A malfunctioning exhaust system, specifically one lacking proper catalytic converters, results in incomplete combustion and increased pollutant emissions. The byproducts of incomplete combustion, such as carbon monoxide and unburnt hydrocarbons, contribute to air pollution. While seemingly disconnected, this pollution directly impacts radiator efficiency. Airborne particulate matter accumulates on the radiator fins, reducing airflow and diminishing the radiator’s ability to effectively transfer heat. Therefore, maintaining exhaust integrity is crucial not only for emissions compliance but also for optimizing the performance and longevity of the engine cooling system. An example is a fleet vehicle operating in Fairbanks during winter. A corroded exhaust system allows exhaust gas to escape near the engine compartment, raising the ambient temperature around the radiator. This reduces the radiator’s effectiveness, forcing the cooling system to work harder to maintain optimal engine temperature, placing additional stress on the radiator and associated components.

In summary, while not a direct component of the cooling system, exhaust integrity significantly influences the performance and lifespan of the radiator, a core element of “fairbanks radiator and muffler.” Compromised exhaust systems indirectly burden the cooling system, accelerate radiator wear, and contribute to environmental pollution that further diminishes cooling efficiency. Prioritizing both exhaust and radiator maintenance is paramount for ensuring optimal engine performance, minimizing environmental impact, and maximizing the longevity of vehicles.

4. Corrosion Prevention

Corrosion prevention is an indispensable aspect of maintaining the operational efficacy and extending the service life of cooling and exhaust systems, key elements addressed by services related to “fairbanks radiator and muffler.” The harsh environmental conditions characteristic of interior Alaska, particularly the prolonged exposure to road salts and de-icing agents during winter, accelerate corrosive processes on metallic components. Radiators, constructed from aluminum and copper alloys, are susceptible to galvanic corrosion, where electrochemical reactions between dissimilar metals cause material degradation and eventual failure. Similarly, exhaust systems, typically fabricated from steel, are prone to oxidation and corrosion due to exposure to exhaust gases, moisture, and road salts. Consider a commercial vehicle regularly traversing the Elliott Highway during winter months. The constant bombardment of road salts on the vehicle’s undercarriage significantly increases the risk of corrosion to both the radiator and muffler, leading to potential leaks, reduced efficiency, and costly repairs. Proper corrosion prevention is paramount to prevent these issues.

Effective corrosion prevention strategies encompass several key practices. The selection and maintenance of appropriate engine coolant with corrosion inhibitors are crucial for mitigating galvanic corrosion within the cooling system. These inhibitors create a protective barrier on metallic surfaces, preventing the electrochemical reactions that lead to material loss. Similarly, the application of corrosion-resistant coatings to exhaust system components, such as ceramic-based paints or undercoating sprays, provides a physical barrier against corrosive agents. Regular washing of vehicles to remove accumulated road salts and debris is also essential. Furthermore, the periodic inspection of cooling and exhaust systems for signs of corrosion, such as rust, pitting, or scale buildup, allows for early detection and preventative maintenance. Replacing corroded components proactively, rather than waiting for complete failure, minimizes the risk of collateral damage and reduces overall repair costs.

In summary, corrosion prevention is not merely an ancillary maintenance task; it represents a fundamental strategy for ensuring the reliable performance and longevity of cooling and exhaust systems operating in demanding environments. The proactive implementation of corrosion prevention measures, including proper coolant maintenance, protective coatings, regular cleaning, and periodic inspections, is essential for mitigating the detrimental effects of corrosion and maximizing the return on investment in vehicle maintenance. This approach supports the overall objective of services associated with “fairbanks radiator and muffler,” which is to provide dependable and cost-effective vehicle maintenance solutions.

5. Operational Temperature

Operational temperature exerts a profound influence on the functionality and lifespan of vehicular components, directly impacting services associated with “fairbanks radiator and muffler.” Deviation from optimal engine operating temperature, whether through overheating or insufficient warmth, engenders detrimental effects on engine performance, fuel efficiency, and emissions. Radiators, central to the cooling system, are tasked with maintaining this critical temperature range by dissipating excess heat generated during combustion. Conversely, mufflers, integral to the exhaust system, can experience accelerated degradation when subjected to excessively high exhaust gas temperatures resulting from inefficient combustion driven by temperature imbalances. A commercial truck traversing the Alaskan interior, for example, faces operational temperature challenges. During frigid winter conditions, the engine may struggle to reach optimal operating temperature, leading to increased fuel consumption and elevated emissions. Conversely, during summer or under heavy loads, the engine risks overheating, potentially damaging the radiator and exacerbating stress on the exhaust system. Understanding these temperature dynamics is critical for effective vehicle maintenance.

Effective management of operational temperature necessitates a multifaceted approach encompassing cooling system maintenance, exhaust system integrity checks, and the use of appropriate lubricants and fuel additives. Radiator efficiency must be regularly assessed and maintained through proper coolant selection, regular flushing, and inspection for blockages or leaks. Similarly, exhaust system integrity must be preserved to prevent backpressure increases that elevate engine temperature. Furthermore, the selection of engine oil viscosity and fuel additives plays a crucial role in optimizing engine performance and minimizing heat generation. Diagnostic tools are increasingly employed to monitor engine temperature in real-time, providing early warning of potential overheating or undercooling conditions. The proactive monitoring allows for timely intervention, preventing costly repairs and extending the lifespan of critical engine components.

In summary, operational temperature is a critical determinant of vehicular performance and durability, inextricably linked to the services provided under the banner of “fairbanks radiator and muffler.” Maintaining optimal engine temperature through diligent cooling and exhaust system maintenance, informed lubricant and fuel selection, and proactive diagnostic monitoring is essential for mitigating the risks associated with temperature extremes. This holistic approach ensures reliable vehicle operation, reduces maintenance costs, and minimizes environmental impact, underscoring the importance of a comprehensive understanding of temperature dynamics in automotive maintenance and repair.

6. Noise Regulation

Noise regulation establishes permissible sound levels emitted by vehicles, impacting exhaust system design and maintenance, areas intrinsically linked to “fairbanks radiator and muffler.” Compliance with these regulations necessitates mufflers and related components functioning within specified parameters to mitigate noise pollution. The intersection of noise regulation and automotive services underscores the importance of maintaining compliant and effective exhaust systems.

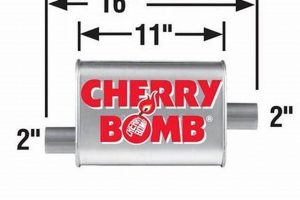

- Muffler Design and Performance Standards

Muffler design directly influences the sound attenuation properties of the exhaust system. Noise regulations mandate specific decibel limits for vehicles, forcing manufacturers to engineer mufflers that meet these standards. For example, a vehicle failing a noise inspection due to a deteriorated muffler requires replacement with a compliant unit. Failure to adhere to these performance standards can result in fines and operational restrictions. Regulations dictate the materials and design of mufflers to balance noise reduction with backpressure considerations, ensuring engine performance is not unduly compromised. Standards specify testing procedures to verify muffler effectiveness across different engine speeds and load conditions.

- Exhaust System Leaks and Noise Amplification

Exhaust system leaks compromise the muffler’s ability to attenuate noise effectively. Even minor leaks can significantly increase sound emissions, leading to violations of noise regulations. Routine inspections for exhaust system leaks, particularly at joints and connections, are crucial for maintaining compliance. For instance, a corroded exhaust manifold gasket can create a leak, amplifying engine noise and violating local ordinances. Addressing exhaust system leaks promptly is essential for both noise regulation adherence and optimal engine performance. Regulations often specify acceptable levels of exhaust leakage, with specific testing methods to detect and quantify leaks.

- Aftermarket Exhaust Systems and Compliance

Aftermarket exhaust systems, designed to enhance performance or aesthetics, must still comply with noise regulations. Installing a non-compliant aftermarket exhaust system can result in significant penalties. Many jurisdictions require aftermarket exhaust systems to be certified as meeting noise emission standards. Some aftermarket systems incorporate adjustable valves to control noise levels, allowing drivers to switch between compliant and performance-oriented modes. Regulations also dictate permissible modifications to factory exhaust systems, often prohibiting the removal of catalytic converters or other noise-reducing components.

- Enforcement and Penalties

Enforcement of noise regulations varies by locality but typically involves roadside inspections and noise level testing. Vehicles exceeding established noise limits are subject to fines, repair orders, and potential impoundment. Noise enforcement officers use calibrated sound level meters to measure vehicle emissions at specified distances and engine speeds. Penalties for noise violations can range from monetary fines to mandatory vehicle modifications. Repeat offenders may face more severe consequences, including license suspension or vehicle seizure. For example, a commercial vehicle consistently exceeding noise limits in a residential area might be subject to significant fines and operational restrictions.

These facets collectively illustrate the intricate relationship between noise regulation and the maintenance and repair services encapsulated by “fairbanks radiator and muffler.” Compliance with noise regulations necessitates diligent maintenance practices, including regular inspections, prompt repair of exhaust leaks, and the use of compliant exhaust system components. The economic and operational consequences of non-compliance underscore the importance of integrating noise regulation considerations into vehicle maintenance strategies.

7. System longevity

System longevity, referring to the extended operational lifespan of vehicle cooling and exhaust systems, is intrinsically linked to the services and expertise associated with “fairbanks radiator and muffler.” The ability of these systems to withstand the rigors of operation in the Fairbanks, Alaska region, characterized by extreme temperature fluctuations, corrosive road treatments, and demanding driving conditions, directly impacts vehicle reliability and overall cost of ownership. Cooling system failures, resulting from corrosion or component fatigue, lead to engine overheating and potentially catastrophic engine damage. Similarly, exhaust system degradation, stemming from rust or physical impacts, results in reduced fuel efficiency, increased emissions, and potential safety hazards. The preventative maintenance and repair services offered under the “fairbanks radiator and muffler” umbrella directly address these threats, aiming to prolong the functional lifespan of these critical systems. For instance, regular coolant flushes, radiator inspections, and exhaust system leak repairs are proactive measures that mitigate the risk of system failures and extend component longevity, thus impacting vehicle reliability and operational readiness.

The practical significance of understanding the connection between system longevity and “fairbanks radiator and muffler” extends beyond mere component replacement. A strategic approach to cooling and exhaust system maintenance requires a comprehensive assessment of operating conditions, material selection, and preventative maintenance schedules. The choice of corrosion-resistant materials, such as stainless steel exhaust components or specialized coolant formulations with enhanced corrosion inhibitors, contributes significantly to system longevity. Furthermore, tailored maintenance plans, developed in consideration of vehicle usage patterns and environmental factors, optimize component lifespan and minimize the risk of unexpected breakdowns. Consider the scenario of a local delivery vehicle operating extensively during the winter months. The vehicle’s cooling and exhaust systems are subjected to intense exposure to road salts, necessitating more frequent inspections and preventative maintenance compared to a vehicle used primarily during the summer. Adopting a maintenance schedule that accounts for these environmental factors directly contributes to extending system longevity and minimizing downtime.

In conclusion, system longevity is a core objective of services offered under “fairbanks radiator and muffler.” Addressing system longevity requires a multifaceted approach encompassing proactive maintenance, strategic material selection, and tailored maintenance schedules that account for the demanding operating conditions prevalent in the Fairbanks region. Challenges remain in balancing cost considerations with the long-term benefits of enhanced system durability. However, a clear understanding of the factors influencing cooling and exhaust system lifespan, coupled with diligent preventative maintenance practices, is essential for maximizing vehicle reliability, minimizing operational costs, and ensuring the sustained performance of vehicles operating in challenging environments.

Frequently Asked Questions

This section addresses common inquiries regarding cooling and exhaust system maintenance, repair, and performance optimization, focusing on the unique challenges presented by the Fairbanks, Alaska environment.

Question 1: How frequently should engine coolant be replaced in vehicles operating in Fairbanks?

Coolant replacement frequency is influenced by operating conditions and coolant composition. Generally, adhering to manufacturer-specified intervals is recommended. However, in Fairbanks, where vehicles experience extreme temperature fluctuations and exposure to corrosive road treatments, shortening these intervals by up to 50% may be prudent. Regular coolant analysis is advised to determine its condition and effectiveness.

Question 2: What are the key indicators of a failing radiator?

Key indicators include visible coolant leaks, overheating engine, elevated engine temperature gauge readings, excessive steam emanating from the engine compartment, and a sweet odor emanating from the radiator area. Additionally, physical damage to the radiator core, such as bent fins or corrosion, can compromise its efficiency and indicate impending failure.

Question 3: How does road salt exposure affect exhaust system longevity?

Road salt accelerates corrosion of exhaust system components, particularly those constructed from steel. Salt penetrates protective coatings and promotes oxidation, leading to rust and eventual component failure. Regular vehicle washing, application of corrosion-resistant coatings, and prompt repair of any existing corrosion are essential for mitigating the damaging effects of road salt exposure.

Question 4: What are the potential consequences of neglecting exhaust system leaks?

Neglecting exhaust system leaks leads to increased noise pollution, reduced fuel efficiency, elevated emissions, and potential health hazards due to carbon monoxide exposure. Leaks also compromise the catalytic converter’s effectiveness, further increasing pollutant emissions. Prompt repair of exhaust system leaks is crucial for both environmental compliance and vehicle performance.

Question 5: Are aftermarket exhaust systems legal in Fairbanks?

The legality of aftermarket exhaust systems depends on their compliance with noise emission regulations. Aftermarket systems must meet established decibel limits and retain all required emission control devices, such as catalytic converters. Modifying exhaust systems in a manner that increases noise levels or removes emission controls is generally prohibited. Local regulations should be consulted for specific requirements.

Question 6: What are the benefits of using corrosion-resistant coatings on exhaust system components?

Corrosion-resistant coatings provide a protective barrier against moisture, road salts, and other corrosive agents, significantly extending the lifespan of exhaust system components. These coatings prevent oxidation and rust formation, maintaining structural integrity and preventing leaks. The investment in corrosion-resistant coatings translates to reduced repair costs and improved vehicle reliability over time.

Prioritizing preventative maintenance and addressing issues promptly are paramount for optimizing cooling and exhaust system performance and longevity in the demanding Fairbanks environment.

The subsequent section provides detailed information on troubleshooting common cooling and exhaust system problems.

Fairbanks Radiator and Muffler

This exploration has underscored the vital role that efficient cooling and exhaust systems play in maintaining vehicle reliability and longevity within the demanding environment of Fairbanks, Alaska. Key considerations discussed include the significance of proper coolant composition, radiator integrity, exhaust system integrity, corrosion prevention, operational temperature management, and noise regulation adherence. The integration of proactive maintenance strategies, combined with a comprehensive understanding of the unique challenges posed by the regional climate, is essential for mitigating the risk of system failures and optimizing vehicle performance.

Continued advancements in automotive engineering and material science offer opportunities for enhancing the durability and efficiency of cooling and exhaust systems. Prioritizing preventative maintenance, employing advanced diagnostic tools, and remaining informed about evolving industry best practices will contribute to minimizing downtime, reducing operational costs, and ensuring the sustained performance of vehicles operating in challenging environments. The long-term reliability of these systems remains a crucial factor in the operational effectiveness of both individual vehicles and commercial fleets within the Fairbanks region.