An abnormal noise emanating from a vehicle’s exhaust system, characterized by a louder, often raspy or sputtering tone, can indicate a compromise in the integrity of the muffler. This auditory symptom frequently arises from corrosion or physical damage creating an aperture in the exhaust system’s component designed for sound attenuation. A common manifestation is an increased volume and altered timbre of the engine’s operation, particularly noticeable during acceleration.

The presence of this abnormal exhaust note signifies more than just an auditory nuisance; it can suggest underlying issues impacting vehicle performance and safety. Compromised exhaust systems can lead to reduced fuel efficiency due to altered backpressure, potentially impacting engine operation. Historically, addressing such issues promptly has been considered essential for maintaining vehicle operational standards and minimizing potential environmental impact through unregulated emissions.

The subsequent discussion will delve into the diagnostic methods for identifying the source of exhaust system anomalies, the range of repair options available, and preventative measures that can be implemented to prolong the lifespan of the exhaust system and mitigate the risk of future incidents related to muffler integrity.

Mitigating Exhaust System Degradation

The following are preventative measures designed to minimize the risk of exhaust system damage and the subsequent development of acoustic anomalies indicative of component failure.

Tip 1: Regular Visual Inspections: Conduct routine examinations of the exhaust system, focusing on welds, seams, and surfaces susceptible to corrosion. Early detection of rust or physical damage can facilitate timely repairs and prevent escalation of the issue.

Tip 2: Prompt Addressing of Corrosion: If surface rust is observed, immediate treatment with rust inhibitors can prevent further degradation. Severely corroded components may necessitate replacement to maintain system integrity.

Tip 3: Careful Driving Practices: Avoid driving habits that expose the exhaust system to undue stress, such as traversing rough terrain or driving through deep water, which can cause physical damage.

Tip 4: Scheduled Professional Inspections: Incorporate exhaust system inspections into routine vehicle maintenance schedules. Qualified technicians can identify subtle issues that may be missed during visual inspections.

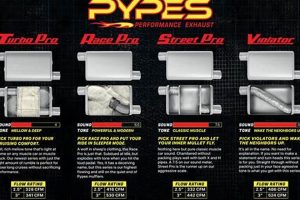

Tip 5: Proper Exhaust Component Selection: When replacing exhaust components, opt for high-quality materials and reputable brands. Durable materials can better withstand the harsh conditions within the exhaust system and prolong its lifespan.

Tip 6: Avoid Short Trips: Short trips do not allow the exhaust system to reach optimal operating temperature, which can lead to moisture buildup and accelerated corrosion. Longer trips allow the system to burn off accumulated moisture.

Implementing these measures can significantly reduce the probability of exhaust system failures and the manifestation of unusual exhaust sounds, contributing to a more reliable and efficient vehicle operation.

By adhering to these guidelines, vehicle owners can actively manage the health of their exhaust systems, mitigating the risks associated with degradation and ensuring optimal performance. This proactive approach ensures cost-effective maintenance and prolongs the lifespan of critical vehicle components.

1. Increased Volume

The escalation of exhaust noise is a primary indicator of structural compromise within the muffler. This augmentation in sound pressure level directly correlates with a breach in the muffler’s sound attenuation capabilities, warranting investigation.

- Compromised Sound Attenuation

The muffler’s primary function is to dampen the sound waves generated by engine combustion. A physical opening bypasses the internal chambers and baffles designed to absorb and cancel out these sound waves. This results in a far less restricted path for the exhaust gases, allowing sound to escape with significantly reduced dampening.

- Direct Proportionality to Aperture Size

The magnitude of the volume increase is generally proportional to the size of the opening. A small perforation may result in a subtle increase in noise, while a larger rupture can produce a substantial and immediately noticeable difference. The correlation is not perfectly linear, as the location and shape of the opening also influence the sound characteristics.

- Impact on Acoustic Frequency Profile

Beyond a simple increase in loudness, the acoustic frequency profile of the exhaust is altered. The muffler is designed to target specific frequencies, reducing the overall noise level. With a hole, untamed frequencies escape, leading to a harsher, less refined sound quality in addition to the increased amplitude. This change in tone, often described as raspy or sputtering, further contributes to the perceived increase in volume.

- Environmental Noise Pollution Considerations

Elevated vehicle noise contributes to overall environmental noise pollution, particularly in urban environments. Vehicles operating with compromised mufflers exceed permissible noise level standards in many jurisdictions, leading to potential fines and regulatory consequences. The increased volume represents not only a mechanical issue, but also a tangible contribution to community noise levels.

In summary, the relationship between increased exhaust volume and structural compromise within the muffler is direct and significant. Analyzing the magnitude and characteristics of this volume increase, alongside other indicators, is crucial for accurately diagnosing and addressing the underlying problem, ensuring vehicle compliance and minimizing noise pollution.

2. Altered Tone

A discernible shift in the characteristic sound emitted from a vehicle’s exhaust system represents a significant indicator of muffler compromise. The factory-engineered exhaust system, particularly the muffler, is meticulously designed to attenuate specific sound frequencies, resulting in a predictable tonal quality. The introduction of an aperture, whether due to corrosion or physical damage, fundamentally disrupts this carefully calibrated acoustic profile. The resultant “altered tone” often manifests as a raspy, sputtering, or hollow sound, a marked departure from the standard, more subdued exhaust note. This tonal shift arises because the aperture allows exhaust gases to bypass the muffler’s internal chambers, where sound-dampening processes occur. A classic example is the transformation from a low rumble to a higher-pitched, tinny sound, directly attributable to a compromised muffler diverting exhaust flow.

The identification of altered tone is not merely a qualitative assessment; it holds practical significance in automotive diagnostics. The frequency and timbre of the aberrant sound can provide clues as to the size, shape, and location of the compromise within the exhaust system. For instance, a sharp, whistling sound may indicate a small, localized leak, while a deeper, rumbling sound frequently suggests a larger, more significant rupture in the muffler casing. Technicians skilled in acoustic diagnostics can use these auditory cues to pinpoint the area of concern, often streamlining the repair process and minimizing unnecessary component replacements. Moreover, changes in exhaust tone can serve as an early warning sign of impending muffler failure, allowing for proactive maintenance and preventing potentially costly repairs to other engine components.

In summary, altered exhaust tone is a critical diagnostic indicator of potential muffler compromise. Its detection and accurate interpretation enable proactive maintenance and efficient troubleshooting, helping prevent further damage and ensuring optimal vehicle performance. The altered sound’s inherent acoustic characteristics provide invaluable information for pinpointing the location and severity of the breach, and serve as a powerful tool for automotive technicians and discerning vehicle owners alike. The challenges lie in accurately differentiating between normal engine variations and genuine exhaust system anomalies, requiring experience and familiarity with the specific vehicle’s acoustic signature.

3. Engine Backfire

Engine backfire, characterized by an explosive sound emanating from the exhaust system, frequently indicates an imbalance in the air-fuel mixture within the engine’s combustion chambers. Uncombusted fuel may enter the exhaust system, igniting within the muffler or exhaust pipes. This combustion event is often exacerbated by the presence of an aperture in the muffler. The compromised structural integrity of the muffler provides an escape route for the expanding gases produced during a backfire, resulting in a pronounced and atypical sound. The size and location of the muffler aperture directly influence the intensity and tonal quality of the backfire.

The presence of a muffler breach can alter the dynamics of the exhaust system, potentially leading to more frequent or intense backfire events. A damaged muffler may not effectively dampen the pressure waves generated by the engine, contributing to increased turbulence and facilitating the ignition of unburnt fuel. For example, a vehicle with a severely corroded muffler may exhibit repeated backfiring, especially during deceleration when the air-fuel mixture is more prone to imbalance. The absence of a properly functioning muffler creates an environment conducive to explosive combustion, underscoring the importance of maintaining the exhaust system’s integrity.

In summation, engine backfire, when associated with an atypical exhaust sound, serves as a critical indicator of both engine performance issues and potential muffler damage. Addressing the underlying cause of the backfire, along with promptly repairing or replacing the compromised muffler, is essential for restoring optimal engine function and preventing further damage to the exhaust system. The auditory manifestation of the backfire, modulated by the presence of a muffler aperture, provides valuable diagnostic information for automotive technicians. Correcting these dual issues restores engine efficiency, reduces harmful emissions, and maintains safe operating conditions.

4. Exhaust Leaks

Exhaust leaks, the unintended escape of exhaust gases from the vehicle’s exhaust system, are frequently associated with audible changes, including those symptomatic of a compromised muffler. The correlation stems from the interconnected nature of the exhaust system and the impact of leaks on sound attenuation.

- Aperture Formation

Exhaust leaks often arise from corrosion, mechanical stress, or weld failures within the exhaust system. When these breaches occur in the muffler itself, the intended sound dampening mechanisms are bypassed. This results in a louder, often distorted, exhaust note, characteristic of a “hole in the muffler sound.” The leak acts as an additional exit point for exhaust gases, negating the muffler’s internal baffling and resonance chambers.

- Sound Wave Modification

Exhaust leaks disrupt the intended flow and pressure dynamics within the exhaust system. The escaping gases create turbulence and alter the frequencies of the sound waves propagating through the system. This can lead to a raspy, hissing, or sputtering sound, a clear deviation from the engineered exhaust tone. The location and size of the leak influence the specific auditory characteristics produced.

- Backpressure Disruption

Exhaust leaks alter the backpressure within the exhaust system. Backpressure is the resistance to exhaust flow, and it plays a critical role in engine performance. A leak reduces backpressure, potentially affecting fuel efficiency and engine responsiveness. This change in engine dynamics can further influence the sound produced by the exhaust system, compounding the auditory symptoms associated with a compromised muffler.

- Catalytic Converter Impact

Exhaust leaks upstream of the catalytic converter can allow uncombusted hydrocarbons to escape into the atmosphere, leading to increased emissions. Leaks near or within the muffler can contribute to localized corrosion due to the accumulation of moisture and exhaust byproducts. This accelerated corrosion further degrades the muffler, exacerbating the auditory symptoms and potentially leading to more significant structural damage.

The connection between exhaust leaks and the acoustic symptoms linked to a “hole in the muffler sound” lies in the fundamental disruption of the exhaust system’s intended functionality. The leaks create alternate pathways for exhaust gases, alter sound wave propagation, disrupt backpressure, and can accelerate component degradation. Addressing exhaust leaks promptly is essential for maintaining vehicle performance, minimizing emissions, and preventing further damage to the exhaust system, including the muffler.

5. Reduced Efficiency

A compromised muffler, particularly one exhibiting an aperture, directly correlates with diminished vehicle operational efficiency. This reduction stems from the alteration of exhaust backpressure. A properly functioning exhaust system, including an intact muffler, maintains a specific level of backpressure essential for optimal engine performance. An opening in the muffler disrupts this carefully engineered backpressure, altering the engine’s volumetric efficiency. This means the cylinders may not fill and empty as completely or efficiently as designed. The result is incomplete combustion, leading to a decrease in power output and increased fuel consumption. For instance, a delivery vehicle with a compromised muffler may experience a noticeable decline in miles per gallon, directly impacting operational costs.

The effect on catalytic converter function is also relevant. Uncontrolled exhaust leaks introduce excess oxygen into the system, potentially overloading or damaging the catalytic converter. The converter requires a specific exhaust gas composition to operate effectively and minimize harmful emissions. An inefficiently operating catalytic converter further reduces fuel efficiency as the engine management system attempts to compensate for the altered exhaust composition. This cycle of inefficiency compounds the initial problem caused by the muffler breach. Consider a scenario where a fleet of vehicles consistently displays higher-than-expected emissions readings; a compromised muffler may be a contributing factor, affecting the overall fleet’s environmental compliance.

In summary, the presence of a “hole in the muffler,” while seemingly a localized exhaust system issue, has far-reaching consequences on vehicle efficiency. The disruption of backpressure, the impact on combustion quality, and the potential damage to the catalytic converter collectively contribute to reduced fuel economy and increased emissions. Addressing the muffler issue promptly is, therefore, critical not only for mitigating noise pollution but also for optimizing vehicle performance and ensuring environmental responsibility. Overlooking a damaged muffler can lead to a cascade of operational inefficiencies and potential long-term damage to other critical vehicle components.

6. Component Degradation

Component degradation within a vehicle’s exhaust system is a primary precursor to acoustic anomalies, including those characterized as a “hole in the muffler sound.” This degradation typically involves material breakdown and structural compromise, directly impacting the system’s ability to effectively attenuate engine noise.

- Corrosion-Induced Perforation

Prolonged exposure to moisture, road salts, and acidic exhaust byproducts initiates corrosion, primarily affecting the muffler’s outer casing and internal baffles. This corrosion gradually weakens the metal, leading to perforations. The resulting aperture allows exhaust gases to escape without proper sound dampening, producing a louder, often raspy exhaust note. For instance, vehicles operating in regions with harsh winter conditions are particularly susceptible to this type of degradation.

- Thermal Stress Fractures

Repeated cycles of heating and cooling induce thermal stress in exhaust system components, particularly at weld points and areas of high stress concentration. Over time, these stresses can cause metal fatigue and the formation of cracks. When these fractures occur within the muffler, they create pathways for exhaust gas leakage, altering the sound profile. Performance vehicles, subjected to extreme temperature fluctuations, often exhibit this type of degradation.

- Mechanical Impact Damage

Physical impacts from road debris, speed bumps, or off-road conditions can cause dents, punctures, or structural damage to the muffler. Even seemingly minor impacts can compromise the integrity of the metal, initiating corrosion or creating stress points that eventually lead to failure. A common scenario involves a vehicle striking a raised object, resulting in a compromised muffler casing and a subsequent alteration in exhaust acoustics.

- Internal Baffle Deterioration

The internal baffles within the muffler play a crucial role in sound attenuation. Over time, these baffles can corrode, crack, or detach, reducing their effectiveness. The degradation of these internal components alters the muffler’s sound-dampening characteristics, resulting in a louder and less refined exhaust note. Vehicles with high mileage are prone to this type of internal component failure, even if the outer casing appears relatively intact.

The interplay between these facets of component degradation and the emergence of a “hole in the muffler sound” highlights the importance of regular exhaust system inspections. Identifying and addressing these issues early can prevent further damage and maintain optimal vehicle performance.

Frequently Asked Questions

The following addresses common inquiries regarding atypical exhaust system sounds, particularly those indicative of muffler compromise.

Question 1: What specific factors contribute to the development of a “hole in the muffler sound?”

Several factors precipitate such auditory changes, including corrosion, physical impact, and thermal stress. Corrosion weakens the muffler material, while impacts create breaches. Thermal stress, resulting from temperature fluctuations, can cause fatigue and cracking, ultimately leading to structural failure.

Question 2: How does a breach in the muffler affect overall vehicle performance?

A compromised muffler disrupts exhaust backpressure, which influences engine volumetric efficiency. Altered backpressure can lead to reduced fuel economy, decreased power output, and potentially increased emissions. The extent of the performance impact depends on the size and location of the breach.

Question 3: What are the potential long-term consequences of ignoring a “hole in the muffler sound?”

Neglecting this symptom can lead to escalating issues. Increased emissions may result in regulatory penalties. The altered exhaust flow can damage other exhaust components, such as the catalytic converter. Moreover, prolonged operation with a compromised exhaust system can negatively impact engine performance and longevity.

Question 4: Can a “hole in the muffler sound” be temporarily repaired with DIY solutions?

While temporary solutions exist, they are not recommended as permanent fixes. Patches or sealants may provide short-term relief, but these are prone to failure due to the extreme temperatures and pressures within the exhaust system. A proper repair typically requires welding or component replacement.

Question 5: What is the estimated cost associated with addressing a compromised muffler?

The cost varies depending on the extent of the damage and the required repairs. A simple weld repair may be relatively inexpensive, while complete muffler replacement incurs higher costs. Furthermore, the cost fluctuates based on vehicle type and the selected aftermarket components.

Question 6: What preventative maintenance measures can be implemented to mitigate the risk of muffler damage?

Regular visual inspections of the exhaust system are crucial for detecting early signs of corrosion or damage. Promptly addressing surface rust with appropriate inhibitors can prevent further degradation. Avoiding driving habits that expose the exhaust system to undue stress, such as off-roading, is also beneficial.

Addressing exhaust system issues promptly is critical for maintaining optimal vehicle performance, ensuring environmental compliance, and preventing escalating repair costs. Regular maintenance and timely repairs are essential for preserving the integrity of the exhaust system.

The following section will provide a practical guide to diagnosing exhaust system anomalies.

Conclusion

The preceding analysis elucidates the complexities associated with the auditory phenomenon described as a “hole in the muffler sound.” This symptom is not merely an auditory nuisance but a diagnostic indicator of underlying exhaust system compromise. The discussion has highlighted the multifaceted nature of this issue, encompassing its impact on vehicle performance, environmental considerations, and potential economic consequences.

The integrity of the exhaust system is paramount for maintaining optimal vehicle operation and minimizing environmental impact. Consistent monitoring, timely intervention, and adherence to preventative maintenance protocols are essential for preserving the functionality of this critical component. Neglecting the symptoms associated with exhaust system degradation can lead to escalating complications and diminished vehicle performance. Vigilance and proactive maintenance are, therefore, indispensable for ensuring both vehicle longevity and environmental stewardship.

![Fix: Why Does One of My AirPods Sound Muffled? [SOLVED] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: Why Does One of My AirPods Sound Muffled? [SOLVED] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-396-300x200.jpg)

![Fix: Samsung TV Sound Is Muffled? [Solutions & Tips] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: Samsung TV Sound Is Muffled? [Solutions & Tips] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-328-300x200.jpg)