The phrase indicates a period when automotive exhaust systems, specifically mufflers, typically require inspection, maintenance, or replacement. For example, seasonal changes or increased vehicle usage might lead to a higher incidence of exhaust system issues, prompting the declaration of this specific period.

The significance lies in preventative vehicle care, ensuring optimal performance, fuel efficiency, and adherence to environmental regulations regarding emissions. Historically, this period might have coincided with pre-winter vehicle check-ups or preparations for long-distance travel during specific seasons. Addressing potential muffler problems at this designated juncture can prevent more extensive and costly repairs down the line, contributing to vehicle longevity and driver safety.

Given the importance of vehicle maintenance, subsequent sections will elaborate on identifying common muffler problems, selecting appropriate replacement parts, and outlining best practices for exhaust system care. Furthermore, the impact of a properly functioning muffler on overall vehicle performance and regulatory compliance will be examined.

Exhaust System Maintenance Guidelines

This section provides essential guidelines for maintaining a vehicle’s exhaust system, focusing on preventative measures and early detection of potential issues.

Tip 1: Conduct Regular Visual Inspections: Examine the muffler and exhaust pipes for signs of rust, corrosion, holes, or physical damage. Early detection can prevent minor issues from escalating into major repairs.

Tip 2: Listen for Unusual Noises: Pay attention to any changes in exhaust sound, such as rattling, hissing, or excessive loudness. These noises often indicate leaks or internal damage within the exhaust system.

Tip 3: Check for Exhaust Leaks: With the engine running, carefully inspect the exhaust system connections for leaks. A mechanic can use specialized equipment to detect even small leaks.

Tip 4: Monitor Fuel Efficiency: A decrease in fuel economy can sometimes be attributed to a malfunctioning exhaust system, particularly a clogged catalytic converter or damaged muffler.

Tip 5: Address Issues Promptly: If any problems are detected during inspection, schedule a professional repair or replacement as soon as possible. Delaying repairs can lead to further damage and increased costs.

Tip 6: Consider Environmental Factors: Driving in areas with harsh weather conditions or salted roads can accelerate exhaust system corrosion. Increase inspection frequency under these circumstances.

Tip 7: Review Vehicle Maintenance Records: Keep track of all exhaust system maintenance and repairs. This record provides a valuable history for future diagnostics and repairs.

Adhering to these maintenance guidelines ensures optimal exhaust system performance, prolongs component lifespan, and contributes to responsible vehicle operation. Consistent attention to these details minimizes the risk of unexpected breakdowns and ensures adherence to environmental regulations.

The subsequent section will offer insights into selecting appropriate replacement mufflers and related exhaust system components, ensuring optimal vehicle performance and compliance with emissions standards.

1. Inspection Frequency

Inspection frequency directly impacts the efficacy of preventative maintenance regarding vehicle exhaust systems, particularly during periods when heightened attention to muffler condition is warranted. Consistent monitoring allows for the early identification and mitigation of potential issues, thereby preventing costly repairs and ensuring regulatory compliance.

- Seasonal Variations Impact:

Seasonal changes, such as winter salting of roads, accelerate corrosion of exhaust components. Increased inspection frequency during and after these periods is necessary to detect early signs of rust and deterioration. Failure to do so can result in significant damage and potential system failure.

- Mileage-Based Assessment:

Exhaust system components experience wear and tear proportional to vehicle usage. Establishing a mileage-based inspection schedule, independent of seasonal factors, ensures timely detection of issues related to normal wear and tear. High-mileage vehicles benefit significantly from increased inspection frequency.

- Age of Components Correlation:

The age of the muffler and related exhaust system components is a critical factor in determining inspection frequency. Older components are inherently more susceptible to failure due to material degradation. A proactive approach involves more frequent inspections as components approach their expected lifespan, preventing unexpected breakdowns.

- Driving Conditions Influence:

Operating a vehicle in harsh environments, such as off-road or in areas with poor road conditions, increases the risk of physical damage to the exhaust system. Regular inspections following exposure to such conditions are crucial to identify and address any impact-related damage. Neglecting these inspections may lead to leaks or system malfunctions.

The integration of seasonal considerations, mileage tracking, component age, and driving conditions into a comprehensive inspection schedule ensures optimal exhaust system maintenance. This proactive approach not only prevents costly repairs but also promotes vehicle safety and environmental responsibility, underlining the importance of diligent monitoring during “its muffler time” and throughout the vehicle’s operational lifespan.

2. Corrosion Prevention

Corrosion prevention assumes a pivotal role during periods designated as “its muffler time,” reflecting the vulnerability of exhaust systems to environmental factors that accelerate degradation. Implementing strategies to mitigate corrosion during this period extends component lifespan and sustains optimal vehicle performance.

- Protective Coatings Application

The application of protective coatings, such as high-temperature paints or ceramic coatings, forms a primary defense against corrosion. These coatings create a barrier between the metallic components and corrosive agents, including road salt, moisture, and acidic compounds. Vehicles operating in regions with harsh winter conditions benefit significantly from the preventative application of these coatings, especially during inspection and maintenance cycles.

- Material Selection Considerations

The material composition of exhaust system components directly influences their susceptibility to corrosion. Stainless steel, aluminized steel, and other corrosion-resistant alloys offer enhanced durability compared to traditional carbon steel. Replacement or upgrade of existing components with these materials provides a long-term solution for mitigating corrosion risks. This consideration becomes particularly relevant when addressing existing corrosion issues during inspection intervals.

- Drainage Optimization Strategies

Effective drainage of condensation and moisture from within the exhaust system reduces the prolonged exposure of metallic surfaces to corrosive liquids. Implementing design modifications or ensuring the proper functionality of existing drainage points minimizes internal corrosion. Routine inspection and maintenance of drainage systems are essential to prevent the accumulation of corrosive fluids and extend the life of the muffler and related components.

- Regular Cleaning Protocols

Periodic cleaning of the exhaust system removes accumulated road salt, dirt, and other corrosive debris, preventing the formation of localized corrosion cells. This process involves washing the undercarriage of the vehicle, particularly the exhaust system, with appropriate cleaning solutions. Regular cleaning, especially after exposure to harsh environmental conditions, significantly reduces the rate of corrosion and prolongs the lifespan of exhaust components. This protocol should be an integral part of any seasonal maintenance strategy.

Addressing corrosion prevention through a multifaceted approach during “its muffler time,” including protective coatings, optimized material selection, improved drainage, and regular cleaning, ensures the long-term integrity of the exhaust system. These measures, when implemented proactively, minimize the risk of premature component failure, contribute to optimal vehicle performance, and enhance overall vehicle longevity, justifying the focused attention during these designated maintenance periods.

3. Performance Degradation

The phrase “its muffler time” inherently acknowledges the potential for performance degradation stemming from a compromised exhaust system. Performance degradation manifests as a reduction in engine power, decreased fuel efficiency, and increased emissions. A malfunctioning muffler, often due to internal corrosion or physical damage, restricts the efficient expulsion of exhaust gases. This restriction creates backpressure within the engine, hindering optimal combustion and reducing overall performance. For example, a vehicle struggling to maintain speed on inclines or exhibiting a noticeable drop in miles per gallon may be experiencing performance degradation directly linked to a failing muffler. This degradation not only affects the driving experience but also increases the vehicle’s environmental impact.

The importance of addressing performance degradation during the designated period lies in its direct correlation with long-term engine health. Unresolved exhaust system issues place undue stress on other engine components, potentially leading to more severe and costly repairs. Furthermore, the increased emissions resulting from incomplete combustion contribute to air pollution and may result in failed emissions tests, leading to fines or restrictions on vehicle operation. Understanding the practical significance of addressing performance degradation involves recognizing the interconnectedness of vehicle systems and the cumulative effect of seemingly minor issues. Neglecting a failing muffler can trigger a cascade of problems, ultimately diminishing the vehicle’s value and reliability.

In summary, the connection between “its muffler time” and performance degradation underscores the necessity of proactive maintenance. Timely inspection and repair or replacement of a compromised muffler mitigate the negative impacts on engine performance, fuel efficiency, and emissions. By recognizing the early signs of performance degradation and addressing them promptly, vehicle owners can ensure optimal vehicle operation, minimize environmental impact, and avoid costly repairs in the long term. The challenge lies in educating drivers about the subtle indicators of exhaust system problems and emphasizing the long-term benefits of preventative maintenance.

4. Emission Compliance

The phrase “its muffler time” often implicitly acknowledges the link between exhaust system integrity and emission compliance. Mufflers, as components of the larger exhaust system, play a crucial role in mitigating noise pollution and facilitating proper catalytic converter function. A degraded or malfunctioning muffler can compromise the efficiency of the catalytic converter, leading to increased emissions of harmful pollutants, such as hydrocarbons, carbon monoxide, and nitrogen oxides. For instance, a corroded muffler may allow exhaust gases to escape prematurely, disrupting the optimal temperature and chemical reactions within the catalytic converter. This, in turn, can result in a vehicle failing emissions tests, potentially incurring fines and requiring costly repairs to achieve compliance. The importance of emission compliance within the context of “its muffler time” is amplified by stringent environmental regulations in many jurisdictions, which mandate regular vehicle inspections and adherence to specific emission standards.

Further examination reveals that “its muffler time” provides an opportunity to proactively address potential emission non-compliance issues. A comprehensive inspection of the exhaust system during this period allows for the early detection of muffler damage, leaks, or other issues that could negatively affect emissions. By addressing these problems promptly, vehicle owners can prevent further degradation of the exhaust system and ensure that their vehicles continue to meet the required emission standards. Practical application of this understanding involves scheduling regular exhaust system checks, particularly during periods when environmental factors, such as road salt exposure, are likely to accelerate corrosion. Additionally, selecting high-quality replacement mufflers and exhaust components can improve the system’s durability and enhance its ability to maintain optimal catalytic converter function over an extended period.

In summary, the connection between “its muffler time” and emission compliance highlights the critical role of the exhaust system in reducing vehicle emissions. Proactive maintenance and timely repairs, particularly during periods when muffler inspection and replacement are emphasized, are essential for achieving and maintaining emission compliance. The challenge lies in increasing awareness among vehicle owners regarding the environmental and financial consequences of neglecting exhaust system maintenance. By prioritizing emission compliance within the context of “its muffler time,” individuals can contribute to cleaner air quality, avoid regulatory penalties, and ensure the long-term operational efficiency of their vehicles.

5. Noise Reduction

The concept of noise reduction is intrinsically linked to the phrase “its muffler time.” The muffler, a primary component of the exhaust system, is specifically designed to attenuate engine noise, contributing to a quieter and more environmentally considerate operation. Addressing muffler issues during a designated maintenance period directly impacts the level of noise produced by a vehicle.

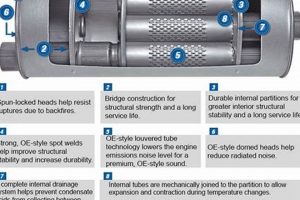

- Muffler Design and Function

The internal design of a muffler incorporates a series of chambers and baffles that redirect and dampen sound waves generated by the engine’s combustion process. These elements disrupt the propagation of sound, reducing its amplitude and perceived loudness. A properly functioning muffler effectively minimizes exhaust noise, ensuring compliance with noise pollution regulations and contributing to a more pleasant driving experience. During “its muffler time,” inspecting the integrity of these internal components is crucial.

- Acoustic Impact of Muffler Degradation

As a muffler ages or sustains damage, its noise reduction capabilities diminish. Corrosion, physical impacts, or internal baffle failure can compromise the muffler’s ability to attenuate sound effectively. This degradation results in increased exhaust noise, often characterized by rattling, hissing, or a general increase in loudness. The acoustic impact of muffler degradation is particularly noticeable during acceleration or when operating at higher engine speeds. “Its muffler time” serves as a reminder to address these acoustic changes before they escalate.

- Regulatory Noise Standards

Many jurisdictions enforce noise emission standards for vehicles, aiming to minimize noise pollution in urban and residential areas. These standards typically specify maximum permissible noise levels at various engine speeds and driving conditions. A properly functioning muffler is essential for meeting these regulatory requirements. During “its muffler time,” ensuring the muffler’s effectiveness in reducing noise is critical for maintaining compliance with local noise ordinances. Neglecting this aspect can result in fines and mandatory repairs.

- Subjective Noise Perception and Comfort

Beyond regulatory compliance, the effectiveness of a muffler in reducing noise directly impacts the subjective experience of driving and the comfort of passengers. Excessive engine noise can be distracting and fatiguing, particularly during long journeys. A well-maintained muffler contributes to a quieter cabin environment, enhancing the overall driving experience and reducing driver stress. “Its muffler time” emphasizes the importance of addressing noise levels for both regulatory compliance and personal comfort.

The facets described above illustrate the interconnectedness of noise reduction and the concept of “its muffler time.” By proactively addressing muffler issues during designated maintenance periods, vehicle owners can ensure compliance with noise regulations, minimize noise pollution, and enhance the overall driving experience. The objective assessment of muffler condition and acoustic output during these intervals proves crucial for maintaining both vehicle performance and environmental responsibility.

6. Component Integrity

The phrase “its muffler time” implicitly underscores the critical importance of component integrity within the exhaust system. The longevity, efficiency, and regulatory compliance of a vehicle are directly contingent upon the structural soundness and operational reliability of its individual exhaust components. Recognizing the period requiring focused maintenance signifies an acknowledgement of potential compromises to these integral parts.

- Structural Integrity of the Muffler Body

The muffler body, typically constructed from steel or aluminized steel, is subject to environmental stressors, including corrosion from road salt and thermal stress from exhaust gas temperatures. Structural breaches, such as rust-through or weld failures, compromise its ability to attenuate noise effectively and can lead to exhaust leaks. The “muffler time” designation serves as a crucial period for inspecting and addressing these structural weaknesses before they escalate into complete component failure, potentially causing safety hazards or regulatory violations. Leaks will reduce back pressure which reduces Engine efiiciency

- Integrity of Exhaust Piping Connections

Exhaust pipes are joined using flanges, clamps, or welds, each representing potential points of failure. Corrosion, vibration, and thermal expansion can weaken these connections, resulting in exhaust leaks and reduced system efficiency. Thorough inspection of these connections during “its muffler time” is essential to ensure a gas-tight seal and prevent the escape of harmful emissions. A compromised connection negatively impacts catalytic converter performance and contributes to increased noise levels, emphasizing the need for proactive maintenance of connecting structures.

- Internal Baffle Integrity

Within the muffler, a series of internal baffles directs and attenuates sound waves. These baffles are susceptible to fatigue, corrosion, and dislodgement over time. Failure of these internal components diminishes the muffler’s ability to reduce noise, resulting in increased exhaust volume. The inspection during “its muffler time” should include auditory assessment for rattling or unusual noises indicative of baffle degradation, prompting necessary replacement to restore the muffler’s acoustic function and maintain regulatory compliance regarding noise emission standards.

- Mounting Hardware Condition

Mufflers and exhaust pipes are supported by hangers and brackets, which prevent excessive vibration and stress on the exhaust system. Corrosion or fatigue of these mounting components can lead to sagging or detachment of the exhaust system, increasing the risk of damage and compromising system performance. The “muffler time” designation provides an opportunity to inspect and replace worn or damaged mounting hardware, ensuring the exhaust system remains securely attached to the vehicle and minimizing the potential for catastrophic failure or hazardous conditions.

The preceding facets coalesce to underscore the importance of meticulous attention to component integrity during “its muffler time.” Proactive inspection, maintenance, and replacement of compromised exhaust components are paramount for ensuring vehicle safety, regulatory compliance, and optimal performance. A failure to address these integral elements can result in a cascade of problems, ranging from increased noise pollution and decreased fuel efficiency to more severe environmental and safety hazards.

7. Cost Minimization

Cost minimization, when considered in relation to periods designated as “its muffler time,” signifies a proactive approach to vehicle maintenance aimed at reducing long-term expenses associated with exhaust system repairs and replacements. Strategic intervention during these designated periods can mitigate more extensive and costly damage.

- Preventative Maintenance Savings

Addressing minor exhaust system issues during “its muffler time” prevents them from escalating into major repairs. For example, replacing a partially corroded muffler before it develops a complete rupture avoids potential damage to other exhaust components, such as the catalytic converter. This preventative measure translates into lower overall repair costs compared to addressing multiple system failures concurrently.

- Extending Component Lifespan

Regular inspection and maintenance of the exhaust system, performed during “its muffler time,” prolongs the lifespan of individual components. Applying rust inhibitors or replacing worn mounting hardware prevents premature failure due to corrosion or stress. Extending the lifespan of exhaust components reduces the frequency of replacements, thereby minimizing long-term expenses.

- Optimizing Fuel Efficiency

A properly functioning exhaust system, maintained during “its muffler time,” contributes to optimal engine performance and fuel efficiency. A restricted or leaking exhaust system increases backpressure, reducing engine efficiency and increasing fuel consumption. Addressing exhaust system issues promptly restores optimal engine performance, resulting in fuel savings over time. For example, a faulty muffler which restricts exhaust flow will lead to increased fuel consumption and decreased engine performance, costing more in the long run.

- Avoiding Regulatory Fines

Compliance with emissions and noise regulations is often contingent on a properly functioning exhaust system. Neglecting exhaust system maintenance, especially during “its muffler time,” can lead to non-compliance and subsequent fines. Addressing potential issues proactively ensures adherence to regulatory standards, avoiding costly penalties and potential vehicle operation restrictions. For example, excessive noise due to a damaged muffler can result in fines, offsetting any short-term savings from deferred maintenance.

Integrating cost minimization strategies into “its muffler time” represents a pragmatic approach to vehicle ownership. The proactive measures undertaken during these designated periods yield tangible economic benefits through reduced repair costs, extended component lifespan, optimized fuel efficiency, and the avoidance of regulatory fines. This forward-thinking approach maximizes vehicle value and minimizes the overall financial burden associated with exhaust system maintenance.

Frequently Asked Questions Regarding Exhaust System Maintenance

This section addresses common inquiries and misconceptions surrounding exhaust system maintenance, particularly in relation to periods emphasizing muffler inspection and repair.

Question 1: What constitutes “its muffler time,” and how frequently should a vehicle’s exhaust system be inspected?

The phrase indicates a period, often tied to seasonal changes or mileage milestones, during which a vehicle’s exhaust system, particularly the muffler, requires focused inspection. The frequency of inspections varies depending on driving conditions, vehicle age, and environmental factors, but a minimum of twice annually is recommended, with increased frequency in regions experiencing harsh winter conditions or frequent exposure to salted roads.

Question 2: What are the primary indicators of a failing muffler or exhaust system?

Key indicators include a noticeable increase in exhaust noise, rattling sounds emanating from the undercarriage, visible rust or corrosion on exhaust components, a decrease in fuel efficiency, and the presence of exhaust leaks. A burning smell originating from beneath the vehicle may also suggest an exhaust system issue.

Question 3: Can a damaged muffler negatively impact a vehicle’s performance?

Yes, a damaged muffler can restrict exhaust flow, creating backpressure within the engine. This backpressure reduces engine efficiency, leading to decreased horsepower, reduced fuel economy, and potentially overheating. Addressing muffler issues promptly is crucial for maintaining optimal vehicle performance.

Question 4: Is it possible to replace a muffler without replacing the entire exhaust system?

In many cases, the muffler can be replaced independently of the entire exhaust system, provided the connecting pipes and catalytic converter are in good condition. However, a thorough inspection of the entire system is recommended to identify any other potential issues that may require attention.

Question 5: Does muffler replacement require specialized tools or expertise?

Muffler replacement typically requires specialized tools, including cutting torches, welding equipment, and exhaust pipe expanders. Furthermore, proper installation is crucial to ensure a gas-tight seal and prevent exhaust leaks. It is generally recommended to seek professional assistance for muffler replacement to ensure proper installation and avoid potential safety hazards.

Question 6: What are the environmental implications of neglecting exhaust system maintenance?

A malfunctioning exhaust system can lead to increased emissions of harmful pollutants, contributing to air pollution and potentially violating environmental regulations. Furthermore, excessive noise from a damaged muffler contributes to noise pollution. Regular maintenance is essential for minimizing a vehicle’s environmental impact.

These answers offer a basic understanding of exhaust system maintenance. Consultation with a qualified mechanic is always recommended for specific vehicle issues.

The subsequent section will discuss advanced diagnostic techniques for identifying complex exhaust system problems.

Concluding Observations on Vehicle Exhaust Systems

The preceding analysis underscores the critical role of preventative exhaust system maintenance, particularly during periods appropriately termed “its muffler time.” The explored facets, including inspection frequency, corrosion prevention, performance degradation, emission compliance, noise reduction, component integrity, and cost minimization, converge to emphasize the multifaceted benefits of a proactive approach. Neglecting these considerations incurs potential repercussions, ranging from diminished vehicle performance and increased operational costs to adverse environmental impacts and regulatory non-compliance.

The understanding of “its muffler time” transcends mere nomenclature, representing a paradigm shift toward responsible vehicle stewardship. A commitment to regular inspection, timely repair, and adherence to established maintenance protocols ensures sustained vehicle efficiency, mitigates environmental harm, and promotes safer operating conditions. Future endeavors should focus on enhancing public awareness regarding the long-term ramifications of deferred exhaust system maintenance and advocating for the integration of these principles into standard vehicle ownership practices. The sustained benefits derived from prioritizing exhaust system health significantly outweigh the consequences of neglect.