This automotive component is a key element in exhaust systems designed to enhance vehicle performance. Specifically engineered to reduce backpressure and optimize exhaust flow, it contributes to increased horsepower and torque. This type of muffler often incorporates a straight-through design and high-flow internals, differing significantly from conventional baffled mufflers commonly found in stock exhaust systems.

The importance of this aftermarket exhaust upgrade lies in its potential to unlock hidden power within the engine. Improved exhaust flow allows the engine to breathe more efficiently, resulting in better fuel economy and a more responsive driving experience. Historically, the development of such systems has been closely tied to the evolution of motorsports, where maximizing engine output is paramount. The technology has since trickled down to consumer vehicles, allowing enthusiasts to enjoy performance gains in their daily drivers.

The subsequent sections will delve into specific aspects related to these performance-oriented components, including materials, construction techniques, sound characteristics, installation considerations, and comparisons with other available options in the aftermarket exhaust industry.

Guidance on Performance Exhaust Optimization

The following recommendations are designed to inform individuals considering enhancements to their vehicle’s exhaust system. Proper selection and maintenance are essential for optimal performance and longevity.

Tip 1: Material Selection. Prioritize stainless steel construction for enhanced corrosion resistance, particularly in regions with harsh winter conditions or coastal environments. The increased durability justifies the higher initial investment.

Tip 2: Diameter Considerations. Match the exhaust system diameter to the engine’s output and intended use. Oversizing can lead to reduced exhaust velocity and diminished low-end torque, while undersizing restricts high-RPM power.

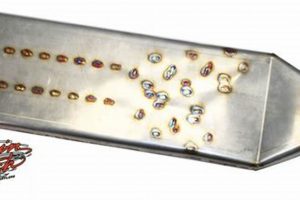

Tip 3: Weld Integrity. Inspect welds meticulously before installation. Consistent, clean welds are crucial for preventing exhaust leaks and ensuring structural integrity under thermal stress.

Tip 4: Sound Profile Evaluation. Research sound clips and reviews to understand the exhaust’s sound characteristics. Select a system that aligns with personal preferences and complies with local noise ordinances.

Tip 5: Professional Installation. Engage a qualified technician for installation. Proper alignment and secure mounting are critical for preventing leaks, vibration, and premature component failure.

Tip 6: Periodic Inspection. Conduct routine inspections for signs of damage, corrosion, or loose connections. Address any issues promptly to maintain optimal performance and prevent further degradation.

Tip 7: Heat Shielding. Consider heat shielding to mitigate radiant heat transfer to surrounding components. This protects sensitive parts and reduces the risk of heat-related damage.

Adhering to these guidelines will help ensure optimal performance, longevity, and satisfaction with the selected exhaust system upgrade. These considerations are paramount for maximizing the benefits derived from enhanced exhaust flow.

The subsequent sections will explore specific maintenance procedures and troubleshooting techniques related to performance exhaust systems.

1. Sound characteristics

The sound characteristics of an automotive performance muffler are a critical consideration for consumers seeking to enhance their vehicle’s auditory profile alongside potential performance gains. These characteristics are a direct result of the internal design and materials employed in the muffler’s construction.

- Internal Configuration and Tone

The internal design significantly shapes the exhaust note. Straight-through mufflers typically produce a louder, more aggressive sound, while chambered designs offer a more controlled and refined tone. The geometry of the internal passages directly influences the frequencies that are amplified or attenuated, resulting in distinct sonic signatures.

- Material Composition and Resonance

The materials used in the muffler’s construction affect its resonant properties. Stainless steel, for example, tends to produce a brighter, more metallic tone compared to aluminized steel. The gauge (thickness) of the material also contributes to the overall sound, with thicker materials often resulting in a deeper, more robust exhaust note.

- Sound Frequency and Perceived Loudness

The frequency range of the exhaust sound influences its perceived loudness and overall character. Lower frequencies contribute to a deep, rumbling tone, while higher frequencies result in a raspier, more aggressive sound. The balance between these frequencies determines the overall sonic experience.

- Sound Volume and Regulatory Compliance

Exhaust volume is a critical aspect, particularly in the context of legal compliance. Many jurisdictions have regulations regarding maximum permissible sound levels for vehicles. Performance mufflers must strike a balance between delivering an enhanced auditory experience and adhering to these regulations.

These facets, combined, define the acoustic signature delivered. Careful consideration of these aspects ensures that the selected performance muffler aligns with the driver’s sonic preferences and meets applicable regulatory requirements. Furthermore, understanding these principles allows for informed comparisons between different models and brands.

2. Flow optimization

The design and functionality of the automotive performance muffler are intrinsically linked to flow optimization. This optimization, referring to the reduction of exhaust backpressure and the promotion of smooth gas passage, is a primary objective in the development and application of performance-oriented exhaust components. Specifically, a key mechanism involves replacing restrictive stock mufflers with designs that minimize obstructions, such as baffles and convoluted pathways. By facilitating a more direct path for exhaust gases, the engine experiences less resistance, leading to improved volumetric efficiency and, consequently, enhanced power output. This principle is evident in aftermarket applications where dyno testing frequently demonstrates measurable horsepower and torque gains attributable to reduced backpressure via optimized exhaust systems.

Consider, for example, the application of a straight-through muffler design. This design philosophy directly minimizes exhaust turbulence and maximizes the velocity of the exhaust gas as it exits the system. The result is a quicker evacuation of spent gases from the combustion chamber, allowing for a more complete intake charge during the subsequent intake cycle. In practical terms, this can translate to improved throttle response, particularly in the mid-range RPM band, and a reduction in exhaust gas recirculation, which can negatively impact engine efficiency. Another approach involves the use of larger diameter piping within the muffler and throughout the exhaust system. This increased cross-sectional area reduces the velocity of the exhaust gases, decreasing backpressure while still maintaining adequate scavenging effects at higher engine speeds.

In summary, flow optimization stands as a fundamental engineering principle underlying the performance benefits associated with enhanced exhaust systems. By minimizing restrictions and promoting efficient exhaust gas passage, the engine’s ability to breathe is significantly improved. This improvement leads to a more complete combustion cycle, resulting in increased power, torque, and overall engine efficiency. The practical significance of this understanding lies in the ability to select appropriate components that align with desired performance goals and engine characteristics. However, attention must be directed to preventing unrestricted flow to maintain enough exhaust velocity to help with scavenging, further optimizing performance.

3. Material durability

Material durability is a critical factor determining the longevity and overall value of an aftermarket exhaust component. The performance muffler is exposed to a harsh operating environment characterized by high temperatures, corrosive exhaust gases, road debris, and environmental contaminants. The selection of appropriate materials is, therefore, paramount for ensuring sustained performance and resistance to degradation.

- Stainless Steel Composition and Corrosion Resistance

Stainless steel is a frequently used material due to its inherent resistance to corrosion. The chromium content in stainless steel forms a passive layer that protects the underlying metal from oxidation and chemical attack. Higher grades of stainless steel, such as 304 or 409, offer superior corrosion resistance compared to lower grades, extending the service life of the muffler, particularly in regions with high salt exposure or harsh winter conditions. The investment into stainless steel is a trade for a long lasting muffler.

- Weld Quality and Structural Integrity

The quality of welds significantly impacts the overall durability of the muffler. Properly executed welds provide strong, leak-proof joints that can withstand the thermal stress and vibration associated with exhaust systems. Poorly executed welds can weaken the structure, leading to premature failure and exhaust leaks. TIG (Tungsten Inert Gas) welding is often preferred for its precision and strength, ensuring a robust and durable construction.

- Material Thickness and Resistance to Physical Damage

The thickness of the material used in the muffler’s construction directly influences its resistance to physical damage. Thicker gauge materials offer greater protection against dents, punctures, and other forms of physical degradation resulting from road debris or accidental impacts. This is especially important for vehicles that are frequently driven on unpaved roads or in environments where road hazards are prevalent. Increasing the thickness of the metal is good for increasing longevity.

- Internal Design and Resistance to Thermal Fatigue

The internal design of the muffler, including the arrangement of chambers and baffles, affects its susceptibility to thermal fatigue. Designs that minimize stress concentrations and promote uniform heat distribution reduce the risk of cracking or deformation due to repeated heating and cooling cycles. Straight-through designs generally exhibit better resistance to thermal fatigue compared to complex chambered designs. Designing the inner of muffler can enhance the longevity and performance of the part.

In conclusion, the selection of materials, weld quality, material thickness, and internal design collectively determine the durability and longevity of a high-performance muffler. The investment in a muffler constructed from high-quality materials and featuring robust construction techniques translates into a longer service life, reduced maintenance costs, and sustained performance benefits. The interplay of these factors underlines the importance of considering material durability as a primary criterion when selecting an aftermarket exhaust component.

4. Vehicle compatibility

Vehicle compatibility is a fundamental aspect directly influencing the selection and performance of an aftermarket exhaust component. An improperly matched performance muffler will result in sub-optimal performance, fitment issues, and potential damage to the vehicle. The dimensions, mounting points, and exhaust system configuration must align precisely with the intended vehicle’s specifications. Failure to ensure this compatibility will negate the intended benefits of the enhanced exhaust system and can lead to significant complications. For instance, a muffler designed for a V8 engine will likely be incompatible with a four-cylinder engine, resulting in incorrect backpressure, diminished performance, and potential exhaust leaks due to mismatched pipe diameters and mounting locations. This is a critical determinant of the part’s utility.

The importance of confirming vehicle compatibility is further illustrated by the model-specific design considerations undertaken by manufacturers. Each vehicle model has a unique exhaust system layout, including pipe routing, hanger locations, and catalytic converter placement. Performance muffler manufacturers must account for these variations when designing their products. Online resources and manufacturer catalogs provide detailed compatibility information, including vehicle year, make, and model, to assist consumers in making informed decisions. Some manufacturers even offer vehicle-specific kits, ensuring a seamless installation process. Checking vehicle parameters such as engine type and exhaust configuration is crucial.

In conclusion, vehicle compatibility is an indispensable consideration when selecting an aftermarket performance muffler. It directly influences the installation process, performance benefits, and overall satisfaction with the product. Failing to verify compatibility can lead to significant complications, including diminished performance, installation difficulties, and potential damage to the vehicle. Therefore, careful attention to compatibility details is essential for achieving the desired performance enhancement and ensuring a trouble-free ownership experience. It is an integral element for realizing potential enhancements, and improper matching diminishes the advantage gained from the device’s specific construction.

5. Horsepower gains

Horsepower gains, as a performance metric, are a primary motivator for individuals considering aftermarket exhaust modifications. The connection between these gains and an enhanced exhaust system, specifically a performance muffler, arises from the reduction of exhaust backpressure. Stock mufflers, often designed to prioritize noise reduction, can impede exhaust flow, thereby limiting engine efficiency and power output. Replacing a stock muffler with a performance-oriented model designed for increased flow facilitates more efficient expulsion of exhaust gases, enabling the engine to operate with reduced pumping losses and improved volumetric efficiency. Real-world examples include dyno tests demonstrating measurable horsepower increases after the installation of such systems on various vehicle platforms. This understanding is significant because it allows vehicle owners to make informed decisions regarding exhaust modifications, balancing performance enhancements with considerations such as noise levels and regulatory compliance.

Further analysis reveals that the magnitude of horsepower gains achievable through performance muffler installation is contingent upon several factors, including engine displacement, existing exhaust system configuration, and the specific design characteristics of the aftermarket component. Smaller engines generally exhibit more pronounced gains due to the relatively greater restriction imposed by stock exhaust systems. Similarly, vehicles with heavily restricted catalytic converters may experience limited horsepower increases until the catalytic converters are also upgraded. Practical applications include selecting muffler designs that complement other performance modifications, such as cold air intakes and engine tuning, to maximize overall power output. Performance gains can vary from subtle improvements to substantial transformations dependent on the engine configuration and modifications.

In summary, the connection between horsepower gains and a performance muffler centers on the principle of reducing exhaust backpressure to improve engine efficiency. While the degree of gain varies depending on specific circumstances, the underlying concept remains consistent. Challenges include balancing performance enhancement with noise levels and ensuring compatibility with existing emission control systems. This understanding contributes to a broader theme of optimizing vehicle performance through targeted modifications and informed decision-making. The key insights underscore the importance of considering engine characteristics and overall system design when pursuing horsepower gains through exhaust modifications.

6. Installation ease

Installation ease is a significant consideration for consumers when evaluating aftermarket exhaust components. A straightforward installation process reduces labor costs, minimizes potential errors, and allows individuals with moderate mechanical skills to perform the upgrade themselves. The design and included hardware of the muffler system are critical determinants of the overall installation complexity.

- Direct-Fit Design and Vehicle-Specific Applications

Direct-fit systems are engineered to precisely match the mounting points and dimensions of the original equipment manufacturer (OEM) exhaust. This reduces the need for modifications such as cutting, welding, or bending. Vehicle-specific applications further streamline installation by providing pre-fabricated hangers, flanges, and adapters tailored to the target vehicle model. For example, a muffler system designed for a specific year and model of truck will likely include all necessary hardware for a bolt-on installation, eliminating the need for custom fabrication.

- Included Hardware and Comprehensive Instructions

The inclusion of comprehensive installation instructions and all necessary hardware is essential for a smooth installation process. Detailed instructions with clear diagrams guide the installer through each step, minimizing the risk of errors. Complete hardware kits, including gaskets, bolts, clamps, and hangers, eliminate the need to source additional parts. A well-packaged kit ensures that the installer has everything required to complete the job efficiently.

- Welding Requirements and Skill Level

Some performance mufflers may require welding for installation, particularly those designed for universal fitment or custom exhaust systems. Welding necessitates specialized equipment and expertise, increasing the complexity and cost of the installation. Systems that minimize or eliminate the need for welding are generally preferred by consumers seeking a straightforward installation process. However, welding is frequently considered better for structural integrity, and so the option to weld a direct fit muffler is still valued.

- Potential Modifications and Adjustments

Even direct-fit systems may require minor modifications or adjustments to ensure proper alignment and clearance. These modifications can range from simple adjustments to the exhaust hangers to minor trimming of exhaust pipes. Systems that require minimal modifications are generally considered easier to install. Significant adjustments can introduce complexity and increase the likelihood of errors.

The emphasis on direct-fit designs, comprehensive instructions, and complete hardware packages contributes to the perception of “Installation ease.” The level of mechanical skill needed is a large determinant to the level of ease the consumer values. By minimizing the need for welding and potential modifications, the performance muffler becomes accessible to a wider range of consumers. This balance between performance benefits and installation convenience is a key consideration in the purchasing decision.

Frequently Asked Questions Regarding This Component

The following section addresses commonly encountered queries concerning performance exhaust upgrades. Accurate information is crucial for informed decision-making.

Question 1: What constitutes a tangible performance benefit resulting from the installation of this component?

Measurable improvements in horsepower and torque output are frequently observed. Reduced exhaust backpressure facilitates more efficient engine operation, resulting in enhanced acceleration and throttle response.

Question 2: Does the installation of this aftermarket system void the original vehicle warranty?

The impact on the original warranty depends on the specific terms and conditions outlined by the vehicle manufacturer. Generally, the installation of aftermarket components does not automatically void the entire warranty, but it may affect coverage for related components if the aftermarket part is determined to be the direct cause of a failure.

Question 3: What level of mechanical expertise is necessary for a successful installation?

Installation difficulty varies depending on the design of the aftermarket system. Some systems are designed for direct-fit installation, requiring basic hand tools and mechanical knowledge. Other systems may necessitate welding or custom fabrication, demanding advanced skills and specialized equipment.

Question 4: Is there an increase in exhaust noise associated with this component, and does it comply with noise regulations?

An increase in exhaust noise is typically observed. The degree of increase depends on the muffler design and internal configuration. Compliance with local noise regulations is the responsibility of the vehicle owner. It is advisable to verify compliance prior to installation.

Question 5: How does the material composition of this component influence its durability and lifespan?

Material selection is a critical factor. Stainless steel construction offers superior corrosion resistance compared to aluminized steel, extending the service life of the component. The gauge (thickness) of the material also contributes to its resistance to physical damage.

Question 6: Are there specific maintenance procedures required to ensure the longevity of this component?

Periodic inspections are recommended to identify signs of corrosion, damage, or loose connections. Promptly addressing any issues will help maintain optimal performance and prevent further degradation. Cleaning the exhaust tips and the body can help prevent rusting.

In summary, the decision to install an aftermarket performance exhaust component requires careful consideration of performance benefits, warranty implications, installation complexity, noise levels, material durability, and maintenance requirements.

The subsequent sections will discuss the various options for purchase.

Concluding Remarks on Component Selection

The preceding analysis has thoroughly explored key facets surrounding the selection and implementation of the `mbrp performance muffler`. Critical areas examined encompassed material durability, flow optimization, vehicle compatibility, potential horsepower gains, and installation considerations. The overarching theme underscores the importance of informed decision-making when considering aftermarket exhaust modifications. These components affect not only vehicle performance but also sound characteristics, regulatory compliance, and long-term maintenance requirements.

Therefore, a meticulous evaluation of individual needs, vehicle specifications, and component attributes is paramount. Prudent component selection, guided by a comprehensive understanding of the factors discussed, maximizes the potential for achieving desired performance enhancements while mitigating potential drawbacks. The ultimate goal is to ensure an optimal balance between improved vehicle dynamics, responsible environmental stewardship, and adherence to applicable regulations.

![Loudest Flowmaster Mufflers: Find Your Sound [Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Loudest Flowmaster Mufflers: Find Your Sound [Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-109-300x200.jpg)