A component employed in vehicle exhaust systems serves to provide structural support and stability. It is typically a metal component designed to connect the exhaust system, specifically the silencer, to the vehicle’s chassis or frame. This ensures that the silencer remains securely positioned and does not vibrate excessively or become detached during vehicle operation. As an example, consider a U-shaped metal bracket bolted to the silencer and then attached to a secure point on the vehicle’s undercarriage.

The primary function of this support mechanism is to reduce stress on the exhaust system components, thereby preventing premature wear and potential damage. By minimizing vibration and movement, it contributes to a quieter and more efficient vehicle operation. Historically, these supports have evolved in design and materials, adapting to increasingly stringent noise regulations and vehicle performance standards. Their presence is crucial for maintaining the integrity and longevity of the exhaust system, particularly in environments where vehicles are subjected to rough terrain or high levels of vibration.

The following sections will delve into the specific types of these supporting structures, the materials used in their construction, common failure modes, and best practices for inspection and replacement. Understanding these elements is essential for ensuring the continued reliability and optimal performance of the vehicle’s exhaust system.

Essential Considerations for Exhaust System Support

The following points provide critical insights into maintaining and optimizing the performance and lifespan of exhaust system supports.

Tip 1: Regular Visual Inspection: Conduct routine visual inspections of the support. Look for signs of rust, cracks, or any deformation. Early detection of these issues can prevent more significant problems.

Tip 2: Torque Specification Adherence: When installing or tightening the fasteners associated with the support, strictly adhere to the manufacturer’s specified torque settings. Over-tightening can lead to component failure, while under-tightening can result in loosening and vibration.

Tip 3: Material Compatibility: Ensure that the support material is compatible with the exhaust system’s material. Dissimilar metals can lead to galvanic corrosion, weakening the structure over time.

Tip 4: Vibration Dampening: Utilize vibration dampening materials or techniques, particularly in high-vibration environments. This can involve using rubber isolators or specialized coatings to reduce the transmission of vibrations to the surrounding components.

Tip 5: Replacement Schedule: Establish a preventative maintenance schedule that includes periodic replacement of the support, especially in harsh operating conditions or after prolonged use. This proactive approach minimizes the risk of unexpected failures.

Tip 6: Professional Installation: When replacing a support, consider seeking professional installation. A qualified technician can ensure proper alignment, tightening, and overall integration with the exhaust system.

Implementing these measures will contribute to the enhanced durability, safety, and overall performance of the exhaust system.

The next section will address common issues and troubleshooting techniques related to exhaust system supports.

1. Material Strength

Material strength is a paramount characteristic governing the durability and operational effectiveness of any support component within an exhaust system. The primary function of this support is to withstand continuous exposure to mechanical stress induced by vehicle operation, exhaust system vibration, and thermal cycling. Insufficient material strength directly translates to premature failure, characterized by cracking, yielding, or complete fracture of the support. For instance, if a low-grade steel is utilized in the construction of a supporting bracket, its susceptibility to fatigue and corrosion will compromise its load-bearing capacity, ultimately leading to exhaust system instability and potential detachment. Conversely, employing high-strength alloys or reinforced composites significantly enhances the component’s ability to endure demanding operational conditions.

The selection of appropriate materials with adequate strength is further influenced by the specific application and environmental conditions. Vehicles operating in regions with high levels of road salt exposure necessitate the use of corrosion-resistant alloys like stainless steel, which exhibit superior mechanical properties compared to standard carbon steel under corrosive attack. Similarly, for high-performance vehicles or those subjected to extreme vibration, the implementation of specialized vibration-dampening materials, integrated within the support structure, mitigates stress concentrations and prolongs component life. Real-world examples include the utilization of high-tensile strength steel in heavy-duty trucks and specialized polymer composites in racing vehicles, each tailored to optimize performance and reliability within specific operating parameters.

In conclusion, the correlation between material strength and the overall performance of exhaust system supports is undeniable. Choosing materials exhibiting adequate tensile strength, yield strength, and fatigue resistance is crucial for ensuring structural integrity, preventing failures, and maintaining optimal exhaust system function. A comprehensive understanding of material properties, coupled with careful consideration of the vehicle’s operating environment, forms the basis for informed decision-making in the selection and application of these critical components. Failures related to inadequate material strength can ultimately lead to costly repairs, safety hazards, and decreased vehicle performance, highlighting the practical significance of prioritizing robust material selection practices.

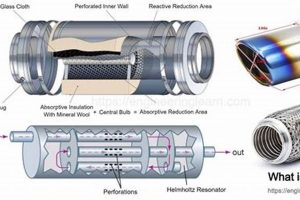

2. Vibration Dampening

Effective operation of an exhaust system support relies heavily on the incorporation of adequate vibration dampening mechanisms. Undamped vibrations transmitted through the exhaust system can accelerate wear and fatigue, ultimately leading to premature failure of the support. The following outlines key facets of vibration dampening relevant to exhaust system supports.

- Material Selection for Vibration Absorption

The choice of material significantly influences the support’s ability to attenuate vibrations. Materials with high damping coefficients, such as specialized elastomers or composite materials, absorb vibrational energy, converting it into heat and reducing its transmission to the vehicle’s chassis. For instance, using a support constructed from a steel core encapsulated in a layer of vibration-absorbing rubber minimizes the propagation of resonant frequencies that would otherwise induce stress concentrations at weld points or mounting locations.

- Design and Geometry Considerations

The structural design of the support itself can contribute to vibration dampening. Incorporating features like flexible joints, strategically placed slots, or variations in cross-sectional area alters the component’s natural frequencies, effectively decoupling it from the primary excitation frequencies of the exhaust system. Consider a support with a “tuning fork” design; its geometry is engineered to vibrate out-of-phase with the exhaust system, thereby canceling out a portion of the transmitted vibrations. This geometric optimization complements the material properties to enhance overall damping effectiveness.

- Isolators and Bushings

The use of isolators and bushings provides a physical barrier between the exhaust system and the vehicle’s chassis, further reducing the transmission of vibrations. These components, typically made from resilient materials like rubber or polyurethane, act as mechanical filters, attenuating high-frequency vibrations while allowing for necessary movement of the exhaust system due to thermal expansion. A common example involves using rubber bushings at the mounting points of the support; these bushings deform under vibrational stress, dissipating energy and preventing it from reaching the chassis, thus minimizing noise and structural fatigue.

In summary, effective vibration dampening in exhaust system supports is achieved through a multi-faceted approach that encompasses material selection, geometric design, and the strategic implementation of isolators. These elements work in concert to minimize the transmission of vibrational energy, prolonging the life of the support and contributing to a quieter and more comfortable vehicle experience. Neglecting vibration dampening considerations can lead to accelerated wear, increased noise levels, and ultimately, compromised exhaust system performance.

3. Corrosion Resistance

Corrosion resistance is a critical attribute dictating the lifespan and functional integrity of any exhaust system support. Exhaust systems, including the supporting structures, are consistently exposed to a harsh environment characterized by high temperatures, condensation, road salts, and exhaust gases. The material’s ability to withstand these corrosive agents directly impacts the support’s structural integrity. The absence of adequate corrosion protection leads to accelerated degradation, weakening the support structure and increasing the risk of failure. A typical example is a support fabricated from unprotected carbon steel; exposure to winter road salt will initiate rapid oxidation, resulting in rust formation and eventual structural compromise. This degradation undermines the support’s ability to maintain the exhaust system’s position, leading to increased vibration, noise, and potential damage to other vehicle components. Therefore, corrosion resistance is not merely a desirable feature but a necessity for ensuring the reliable operation and longevity of the exhaust system.

The implementation of corrosion-resistant materials and coatings constitutes a vital strategy in mitigating the adverse effects of environmental exposure. Stainless steel, aluminized steel, and specialized protective coatings are commonly employed to enhance the durability of exhaust system supports. For instance, an exhaust support constructed from 304 stainless steel offers superior corrosion resistance compared to mild steel, providing extended service life even in harsh environments. Similarly, the application of a ceramic-based coating can create a protective barrier against corrosive elements, preventing direct contact with the underlying metal. These practical applications of corrosion-resistant materials directly translate to reduced maintenance costs, improved vehicle safety, and extended component lifespan. Understanding the specific corrosive agents present in the vehicle’s operating environment guides the selection of appropriate materials and protective measures, ensuring optimal performance and reliability.

In summary, corrosion resistance is an indispensable factor in the design and material selection of exhaust system supports. The selection of corrosion-resistant materials, such as stainless steel and the application of protective coatings, is of utmost importance. Its role in preventing structural degradation and ensuring long-term reliability cannot be overstated. Overcoming challenges associated with corrosion requires a thorough understanding of the operating environment and the implementation of appropriate material selection strategies. Failure to prioritize corrosion resistance results in diminished component lifespan, increased maintenance expenses, and compromised vehicle safety.

4. Proper Installation

The service life and effectiveness of an exhaust support are intrinsically linked to the quality of its installation. A misaligned, loosely secured, or improperly torqued support negates the benefits of even the most robust materials and advanced designs. The intended load distribution and vibration dampening characteristics of the component are compromised without correct installation. The connection points between the support and the exhaust system or the vehicle’s chassis become focal points for stress concentration, leading to accelerated fatigue and potential catastrophic failure. Consider a scenario where a support is attached using incorrect fasteners; the resulting play allows for excessive movement, causing the silencer to impact nearby components and potentially sever the exhaust system at its joints. Consequently, a systematic and meticulous installation process is not merely a recommendation, but an essential prerequisite for achieving the designed performance and reliability.

Correct installation protocols extend beyond simple bolting procedures. It encompasses the precise alignment of the exhaust system to minimize stress on individual components, the application of appropriate torque specifications to fasteners to ensure secure attachment without over-stressing the materials, and the verification of clearances to prevent contact with other vehicle parts. An example of effective installation includes the use of a torque wrench to tighten mounting bolts to the manufacturer’s specified value; this prevents both over-tightening, which can damage the support or surrounding components, and under-tightening, which can lead to loosening and vibration. Furthermore, applying anti-seize compound to threaded fasteners ensures that they can be removed without damage during subsequent maintenance procedures. These installation steps enhance the performance and increase the support’s lifespan.

In conclusion, proper installation is not an isolated activity, but an integral element in achieving exhaust system support reliability. It ensures that the component functions as designed, effectively dampening vibrations, distributing loads, and withstanding environmental stresses. Neglecting correct installation practices can negate the benefits of advanced materials and designs, leading to premature failure, increased noise, and potential safety hazards. A comprehensive understanding of the installation process, combined with adherence to manufacturer’s specifications, is crucial for maximizing the effectiveness and lifespan of an exhaust system support.

5. Exhaust Alignment

Proper exhaust alignment is intrinsically linked to the function and longevity of the silencer support structure. Misalignment introduces undue stress on the support, leading to premature fatigue and potential failure. The support is designed to bear the weight of the silencer and dampen vibrations within a specific range of motion. If the exhaust system is not correctly aligned, the support experiences forces beyond its design parameters. This may manifest as excessive bending, twisting, or shearing stresses, accelerating the degradation of the support material and its connecting hardware. As an example, consider an exhaust system that is forced to bend sharply due to a mispositioned catalytic converter; the resulting strain on the silencer support causes it to crack prematurely near the welding points. Thus, exhaust alignment is a prerequisite for optimal support performance.

The relationship between alignment and support effectiveness extends to noise reduction and overall vehicle operation. An exhaust system that is improperly aligned can vibrate excessively, generating unwanted noise and potentially contacting other vehicle components. This contact can cause further damage and create additional stress points within the system. The support, if functioning correctly, helps to mitigate these vibrations. However, if the underlying alignment issues are not addressed, the support is forced to work beyond its capacity, ultimately compromising its structural integrity. Routine inspection of the exhaust system, including verifying proper alignment and the condition of the support, is crucial. If the support shows signs of stress or damage, it should be replaced after the alignment issues are corrected. Neglecting alignment problems shortens the life of the replaced component.

In summary, exhaust alignment is a critical factor influencing the performance and durability of the silencer support. Misalignment introduces stresses that can lead to premature failure of the support structure, increased noise levels, and potential damage to other vehicle components. Regular inspections and prompt correction of alignment issues are essential for maintaining the integrity of the exhaust system and ensuring the longevity of its supporting components. Prioritizing exhaust alignment as a standard maintenance procedure is vital for optimal vehicle performance and reduced repair costs in the long term.

6. Load Distribution

The effectiveness of a silencer support is directly contingent upon balanced load distribution. The support’s function is to bear the weight of the silencer and mitigate vibrations generated by the exhaust system. If the load is not evenly distributed across the support’s mounting points and structural members, localized stress concentrations will occur. These concentrations lead to accelerated fatigue and potential failure of the component. For example, if one mounting bolt is significantly tighter than others, it will bear a disproportionate amount of the silencer’s weight, causing that specific point to weaken over time. Similarly, if the support’s design does not adequately distribute the load across its various sections, certain areas will be more susceptible to cracking or deformation. Therefore, proper load distribution is paramount to ensure the support functions as intended and maintains the integrity of the exhaust system.

Achieving optimal load distribution requires careful consideration of several factors, including the support’s design, the material properties, and the installation procedure. The support structure should be engineered to evenly distribute the weight and forces across all connection points. This may involve incorporating features such as reinforced sections, strategically placed gussets, or flexible joints to accommodate varying loads and vibrations. Additionally, the installation procedure must ensure that all mounting bolts are tightened to the manufacturer’s specified torque values to prevent uneven loading. Regular inspections should also be conducted to identify any signs of stress or damage that may indicate an imbalance in load distribution. Early detection of these issues allows for timely corrective action, preventing more severe problems from developing. One could see an issue, such as one portion cracking earlier than the rest of the support, therefore indicating bad load distribution.

In summary, balanced load distribution is crucial for maximizing the performance and lifespan of a silencer support. Proper design, material selection, and installation practices are essential for achieving optimal load distribution and preventing localized stress concentrations. By addressing load distribution concerns, it contributes to a reduction in support failures, improved vehicle safety, and reduced maintenance costs. An understanding of load distribution principles is therefore indispensable for engineers, technicians, and vehicle owners seeking to ensure the reliability and durability of exhaust systems.

Frequently Asked Questions

The following section addresses common inquiries regarding silencer support structures, their function, maintenance, and potential issues. This information aims to provide clarity and promote informed decision-making.

Question 1: What is the primary function of a silencer support?

The primary function is to provide structural support to the silencer, preventing excessive vibration, reducing stress on exhaust system components, and minimizing the risk of detachment during vehicle operation.

Question 2: What are the typical signs of a failing silencer support?

Common indicators include visible rust, cracks, deformation, excessive exhaust system vibration, unusual noises (rattling or clanging), and sagging of the silencer.

Question 3: What materials are commonly used in the manufacture of silencer supports?

Typical materials include carbon steel, stainless steel, aluminized steel, and, in some cases, reinforced polymers. The choice of material depends on factors such as cost, required strength, and corrosion resistance.

Question 4: How frequently should a silencer support be inspected?

Visual inspections are recommended during routine vehicle maintenance, ideally every 6 months or 12,000 miles, or more frequently under harsh operating conditions.

Question 5: Can a damaged silencer support be repaired, or is replacement always necessary?

While minor surface rust may be addressed, significant structural damage or corrosion necessitates replacement. Attempting to repair a severely compromised support can compromise its integrity and pose a safety risk.

Question 6: Does the type of vehicle or driving conditions influence the lifespan of a silencer support?

Yes. Vehicles operating in environments with road salt, rough terrain, or high vibration levels will generally experience shorter silencer support lifespans.

The information presented aims to clarify common questions regarding silencer support structures. Proper maintenance and timely replacement are crucial for ensuring vehicle safety and exhaust system longevity.

The next section will delve into advanced diagnostic techniques for identifying subtle issues affecting silencer support performance.

Muffler Brace

This exploration has highlighted the multifaceted role of the muffler brace within a vehicle’s exhaust system. Its function extends beyond simple support, encompassing vibration dampening, load distribution, and corrosion resistance. The selection of appropriate materials, adherence to proper installation techniques, and regular inspection protocols are crucial for maximizing the effectiveness and lifespan of this critical component. Failures in this area can lead to increased noise, compromised vehicle performance, and potential safety hazards.

Recognizing the significance of the muffler brace is paramount for both vehicle owners and maintenance professionals. Prioritizing its inspection and timely replacement contributes to overall vehicle reliability and minimizes the risk of costly exhaust system repairs. A proactive approach to maintenance, focused on early detection and correction of potential issues, ensures continued safe and efficient vehicle operation. The future of exhaust system design will likely see advancements in materials and support structures, further enhancing durability and performance in the face of increasingly stringent environmental regulations.