A crucial component in exhaust systems, this element seals the terminal point of a sound-dampening device. Constructed from durable materials like steel or aluminum, it withstands high temperatures and corrosive gases. It is often secured through welding, clamping, or bolting. A common example includes the circular or shaped piece visible at the rear of a vehicle’s exhaust assembly, which effectively closes off the muffler body.

The integrity of this terminal closure is paramount for optimal exhaust system performance and noise reduction. It prevents exhaust gas leakage, maintaining back pressure crucial for engine efficiency. Historically, improvements in its design and materials have significantly contributed to enhanced longevity and a reduction in exhaust system failures, minimizing costly repairs and environmental impact. Its secure fit also reduces unwanted vibrations, further contributing to noise abatement.

Understanding the functionality of this seemingly small piece is essential for those involved in automotive repair, performance tuning, and exhaust system manufacturing. The following sections will delve into specific aspects such as material selection, design variations, installation techniques, and potential failure modes, providing a detailed overview of this vital component.

Essential Considerations for Exhaust Terminal Closure

The following tips highlight key considerations to ensure the proper function and longevity of this crucial component within the exhaust system.

Tip 1: Material Selection: Opt for materials resistant to high temperatures and corrosion. Stainless steel and aluminized steel offer enhanced durability compared to standard steel, extending the component’s lifespan.

Tip 2: Proper Welding Techniques: When welding is required, ensure a complete and airtight seal. Porous welds can lead to exhaust leaks and premature failure. Consider professional welding services for optimal results.

Tip 3: Secure Attachment: Whether using clamps or bolts, verify a tight and secure fit. Loose attachments allow exhaust gas leakage and create unwanted noise. Regularly inspect and tighten as needed.

Tip 4: Regular Inspection: Periodically inspect for signs of rust, corrosion, or physical damage. Early detection of these issues allows for timely repairs, preventing more significant problems.

Tip 5: Consider Aftermarket Options: For performance enhancements or aesthetic improvements, explore aftermarket options. However, ensure compatibility with the existing exhaust system and adhere to all applicable regulations.

Tip 6: Address Damage Promptly: Any dents, cracks, or perforations should be addressed immediately. Damaged components compromise exhaust system performance and may pose safety hazards.

Maintaining the integrity of the exhaust terminal closure is crucial for optimal engine performance, noise reduction, and environmental compliance. Adhering to these guidelines will promote a longer lifespan and prevent costly repairs.

The subsequent sections will explore common problems and troubleshooting techniques related to this critical element, providing further insights into its maintenance and repair.

1. Material Durability

Material durability is a paramount consideration in the design and manufacture of the exhaust terminal closure. Its exposure to high temperatures, corrosive gases, and physical stress necessitates robust material selection to ensure prolonged functionality and prevent premature failure. The choice of material directly impacts the component’s lifespan and the overall efficiency of the exhaust system.

- Resistance to Thermal Fatigue

The exhaust terminal closure experiences significant temperature fluctuations during vehicle operation, leading to thermal stress and potential fatigue. Materials with high thermal fatigue resistance, such as certain grades of stainless steel, can withstand repeated heating and cooling cycles without cracking or weakening. This is critical for maintaining a secure seal and preventing exhaust leaks.

- Corrosion Resistance

Exhaust gases contain corrosive byproducts of combustion, including acids and water vapor. Materials must exhibit exceptional corrosion resistance to prevent degradation and subsequent failure. Stainless steel, aluminized steel, and certain alloys are commonly employed due to their ability to resist corrosion in this harsh environment. Coatings can also be used to enhance corrosion protection.

- Mechanical Strength at Elevated Temperatures

The exhaust terminal closure must maintain its structural integrity at high operating temperatures. Materials must possess sufficient tensile strength and yield strength to withstand the pressure and vibrations within the exhaust system. The reduction in mechanical properties at elevated temperatures must be carefully considered during material selection.

- Resistance to Physical Impact and Abrasion

The exhaust terminal closure is susceptible to physical damage from road debris and other external factors. Materials with high hardness and impact resistance are desirable to prevent dents, punctures, and other forms of physical degradation. The choice of material should also consider its resistance to abrasion from particulate matter in the exhaust stream.

The careful selection of materials with appropriate durability characteristics is essential for ensuring the long-term reliability and performance of the exhaust system. The interplay between thermal fatigue resistance, corrosion resistance, mechanical strength, and resistance to physical impact determines the lifespan of the part and its ability to maintain a secure and leak-free seal. Compromising on material durability will inevitably lead to premature failure and costly repairs.

2. Weld Integrity

Weld integrity is a crucial factor in the performance and longevity of the terminal closure on an exhaust muffler. The weld joint represents a critical point of vulnerability where failure can lead to exhaust leaks, noise pollution, and reduced engine efficiency. Therefore, the quality and strength of the weld are of paramount importance.

- Penetration and Fusion

Adequate weld penetration ensures that the weld metal fuses properly with the base metal, creating a strong and durable bond. Insufficient penetration results in a weak weld that is prone to cracking and failure under stress. For example, a complete penetration weld, achieved through techniques like Gas Tungsten Arc Welding (GTAW), ensures the closure is structurally sound and resistant to vibration-induced stress.

- Absence of Defects

Welds must be free from defects such as porosity, inclusions, and cracks. These defects can significantly weaken the weld joint and provide initiation points for failure. Quality control measures, including visual inspection and non-destructive testing methods like dye penetrant inspection, are essential to detect and eliminate weld defects. The presence of porosity, for instance, can reduce the effective cross-sectional area of the weld, diminishing its load-bearing capacity.

- Material Compatibility

The welding process must use filler metals that are compatible with the materials being joined. Using incompatible filler metals can lead to the formation of brittle intermetallic compounds, which weaken the weld joint. For instance, when welding stainless steel, a stainless steel filler metal with appropriate alloying elements should be used to ensure corrosion resistance and prevent dissimilar metal corrosion at the weld interface.

- Stress Relief

Welding introduces residual stresses into the material, which can contribute to cracking and distortion. Stress relief heat treatment can reduce these residual stresses, improving the weld’s resistance to fatigue and stress corrosion cracking. Post-weld heat treatment is particularly important for high-strength materials and critical applications where weld failure could have significant consequences.

The weld’s reliability directly influences the overall performance and lifespan of the exhaust terminal closure. Proper welding techniques, thorough inspection, and the use of appropriate materials are essential to ensure a strong and durable weld joint that can withstand the harsh operating conditions of the exhaust system, preventing leaks and maintaining optimal engine performance.

3. Secure Attachment

Secure attachment directly influences the functional integrity and longevity of an exhaust terminal closure. Its capacity to maintain a firm connection between the closure and the muffler body is paramount for preventing leaks, reducing noise, and preserving engine efficiency. The attachment method employed must withstand significant mechanical stress and environmental challenges.

- Clamping Force Distribution

Uniform distribution of clamping force is vital to prevent localized stress concentrations that can lead to premature failure. Clamps, for example, should exert equal pressure around the circumference of the closure to maintain a consistently tight seal. Uneven clamping can cause distortion and eventual separation, resulting in exhaust leaks and diminished noise reduction. Properly torqued band clamps ensure even pressure, while over-tightening can deform components and compromise the seal.

- Weld Bead Integrity

When welding is employed, the weld bead must exhibit complete fusion and penetration to ensure a robust and lasting bond. Porous welds or incomplete fusion sites create weak points prone to cracking under vibration and thermal stress. Proper welding techniques and qualified welders are essential for achieving a secure and reliable connection. The presence of porosity, for instance, significantly reduces the weld’s tensile strength and fatigue resistance.

- Mechanical Fastener Resilience

Bolts, screws, and rivets used for securing the closure must be resistant to loosening and corrosion. Locking mechanisms, such as lock washers or thread-locking compounds, are crucial for maintaining a secure connection under vibration. Corrosion-resistant materials are essential to prevent fastener degradation and subsequent loosening. For example, stainless steel fasteners are preferred in corrosive environments to prevent galvanic corrosion and ensure long-term reliability.

- Sealing Surface Preparation

The mating surfaces between the closure and the muffler body must be clean and free of imperfections to ensure a tight seal. Surface roughness, debris, or corrosion can create pathways for exhaust gas leakage. Proper surface preparation, such as cleaning, deburring, or the application of sealing compounds, is essential for achieving a reliable connection. The use of gaskets or sealants fills minor imperfections and enhances the sealing effectiveness.

The chosen attachment method, be it welding, clamping, or mechanical fastening, directly impacts the exhaust terminal closures ability to fulfill its intended purpose. A compromised connection leads to diminished performance, increased noise levels, and potential engine damage. Therefore, meticulous attention to detail and adherence to best practices during installation are critical for ensuring a secure and enduring attachment.

4. Corrosion Resistance

Corrosion resistance is a critical attribute of a exhaust terminal closure due to its continuous exposure to harsh conditions. Exhaust gases contain corrosive elements such as water vapor, acids, and chlorides, all of which accelerate material degradation. The effects of corrosion can range from surface rust to structural weakening, ultimately compromising the part’s ability to effectively seal the muffler and direct exhaust flow. For instance, a closure constructed from standard steel without protective coatings will rapidly corrode in regions with high road salt usage, leading to exhaust leaks and increased noise levels. Selecting materials with inherent corrosion resistance is paramount.

The selection of materials for a exhaust terminal closure often involves a trade-off between cost and corrosion resistance. Stainless steel, particularly grades like 304 and 316, offers excellent corrosion resistance but carries a higher price compared to aluminized steel or standard steel. Aluminized steel provides a cost-effective alternative, employing an aluminum coating to protect the underlying steel from corrosion. However, the aluminum coating can be compromised by physical damage, exposing the steel to corrosion. The implications of compromised corrosion resistance extend beyond component failure, potentially affecting vehicle emissions and requiring premature replacement of the muffler assembly.

Effective corrosion resistance strategies for exhaust terminal closures involve material selection, protective coatings, and design considerations. Regular inspections can identify early signs of corrosion, allowing for timely interventions to prevent further damage. Ultimately, ensuring the integrity of the closure against corrosion not only prolongs its lifespan but also contributes to vehicle longevity, reduced maintenance costs, and environmental protection by maintaining optimal exhaust system functionality.

5. Acoustic Performance

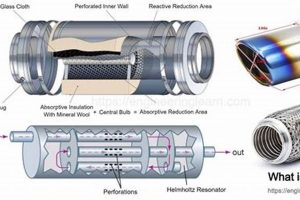

Acoustic performance is a critical factor in muffler design, and the terminal closure significantly influences the overall noise reduction effectiveness of the exhaust system. Its design, material composition, and installation directly affect the sound waves exiting the muffler, shaping the perceived noise signature of the vehicle.

- End Cap Geometry and Sound Reflection

The shape of the terminal closure impacts how sound waves reflect and diffract as they exit the muffler. Conical or angled designs can alter the sound directionality and frequency distribution compared to flat or rounded ends. For example, a flared exit may amplify certain frequencies, while a closed design redirects sound within the muffler, potentially increasing attenuation. Changes to the shape may cause a noticeable change to the vehicle’s exhaust note.

- Material Damping Characteristics

The material of the terminal closure influences the degree to which it absorbs or transmits sound vibrations. Materials with high damping characteristics, such as certain composite materials, can reduce resonance and dampen high-frequency noise. Conversely, rigid materials like thick steel may reflect sound waves, potentially increasing noise output. A higher grade material may cost more but have better reduction of noise.

- Seal Integrity and Noise Leakage

A compromised seal around the terminal closure allows exhaust gases, along with associated noise, to escape prematurely, bypassing the muffler’s intended sound attenuation pathways. Even small leaks can significantly increase the perceived noise level, particularly at higher engine speeds. Routine inspections should happen to ensure leaks are not present.

- Resonator Integration

Some terminal closures integrate resonator chambers or baffles to further attenuate specific frequencies. These integrated features can fine-tune the exhaust note and reduce unwanted noise components. The effectiveness of these resonators depends on their design, volume, and placement within the terminal closure assembly. Proper designs are important to have a good sound in vehicles.

The connection between acoustic performance and the exhaust muffler terminal closure involves complex interactions between sound wave propagation, material properties, and design features. Optimizing these factors is essential for achieving the desired noise reduction and sound quality characteristics in a vehicle’s exhaust system, while maintaining regulatory compliance.

Frequently Asked Questions

The following addresses common inquiries regarding this crucial component of a vehicle’s exhaust system.

Question 1: What is the primary function of the exhaust terminal closure?

The primary function is to seal the end of the muffler, directing exhaust gases through the designed pathways for optimal sound dampening and flow. It maintains backpressure vital for engine efficiency.

Question 2: What materials are commonly used in their construction, and why?

Common materials include steel, aluminized steel, and stainless steel. Stainless steel offers superior corrosion resistance, while aluminized steel provides a cost-effective balance of protection and affordability. Steel is generally coated for increased longevity.

Question 3: How does a damaged unit impact vehicle performance?

A damaged element can lead to exhaust leaks, reduced engine efficiency due to altered backpressure, increased noise levels, and potentially, failure to meet emission standards.

Question 4: What are the key indicators that a replacement is necessary?

Key indicators include visible rust or corrosion, exhaust leaks detected through sound or visual inspection, and physical damage such as dents or cracks.

Question 5: Are there different types available, and how do they affect exhaust sound?

Yes, designs vary, from simple flat caps to those with integrated resonators or directional outlets. Geometry and materials influence sound wave reflection and attenuation, impacting the final exhaust note.

Question 6: What is the recommended maintenance to prolong their lifespan?

Regular inspection for corrosion or damage is advised. Protective coatings can be applied to extend lifespan, particularly in regions with harsh weather conditions. Prompt repair of any observed damage is essential.

Properly functioning exhaust system parts are essential for vehicle operation and environmental compliance. Routine inspection and maintenance are highly recommended.

The subsequent section will provide information on diagnosing common problems associated with the item.

Muffler End Cap

This discussion has illuminated the critical role of the muffler end cap in exhaust systems. From material selection and weld integrity to secure attachment and corrosion resistance, each element contributes significantly to its overall performance. Its functionality directly impacts noise reduction, engine efficiency, and environmental compliance. Understanding the nuanced characteristics of this component is crucial for informed decision-making in vehicle maintenance and repair.

Given its multifaceted impact, prioritizing the integrity of the muffler end cap is not merely a matter of vehicle upkeep, but a commitment to responsible automotive stewardship. Further research and development in materials science and design innovation will undoubtedly lead to advancements in its durability and performance, ensuring quieter, more efficient, and environmentally sound transportation for the future.

![Best Kinney Muffler: Reviews & Alternatives [Year] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Best Kinney Muffler: Reviews & Alternatives [Year] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-52-300x200.jpg)