A device designed to capture audio signals in environments characterized by high levels of ambient noise. This specialized transducer mitigates unwanted sounds, focusing on specific acoustic sources. For example, technicians might employ one to isolate engine sounds during diagnostic procedures, effectively reducing interference from wind or other machinery.

The utilization of these instruments proves beneficial in diverse sectors. Its ability to enhance clarity in noisy settings is paramount in fields such as automotive repair, where accurate sound analysis is crucial for identifying mechanical issues. Furthermore, it has a historical precedent in situations where clear audio recording is essential despite challenging surroundings, evolving from basic noise reduction techniques to sophisticated signal processing methods.

The following sections will delve into the construction principles, operational characteristics, and practical applications of these noise-reducing audio devices. Furthermore, it explores the specific advantages they offer over conventional recording methods in various operational scenarios.

Optimizing Audio Capture in Noisy Environments

The subsequent guidelines aim to maximize the effectiveness of specialized audio recording equipment in challenging acoustic environments, ensuring accurate data acquisition and minimizing the influence of extraneous sounds.

Tip 1: Proper Positioning. Precise placement relative to the target sound source is crucial. Minimize the distance between the device and the source to enhance signal strength and diminish background interference.

Tip 2: Environmental Assessment. Before initiating recording, evaluate the surroundings for dominant noise sources. Adjust the device’s positioning or shielding to mitigate these sounds proactively.

Tip 3: Secure Mounting. Ensure stable installation to prevent unwanted vibrations from being transmitted to the audio recording. A robust mount minimizes handling noise and maintains recording integrity.

Tip 4: Cable Management. Implement organized cable routing to avoid signal interference from power lines or other electronic equipment. Shielded cables can further reduce electromagnetic interference.

Tip 5: Pre-Recording Sound Check. Conduct test recordings to verify optimal levels and sound isolation before committing to a full recording session. Analyze these test recordings for any residual noise requiring adjustment.

Tip 6: Wind Protection. When operating outdoors or in windy conditions, employ a windsock or windscreen to reduce wind-induced noise artifacts in the audio recording.

Tip 7: Post-Processing Techniques. Familiarize oneself with audio editing software capable of noise reduction and equalization to refine recorded audio further, enhancing clarity and intelligibility.

Implementing these guidelines will contribute significantly to achieving high-quality audio recordings, even in situations characterized by substantial ambient noise. Consistency in application is key to realizing the full potential of this specialized equipment.

The concluding section will provide a comprehensive overview of the applications of such devices across diverse industries and potential future developments within the field.

1. Noise Isolation

Noise isolation is a critical function inextricably linked to devices designed for capturing audio in challenging acoustic environments. It forms the foundational principle by which these specialized tools achieve accurate and intelligible sound recordings, particularly in settings where ambient sounds would otherwise obscure the target audio signal.

- Directional Sensitivity

Directional sensitivity pertains to the device’s capacity to selectively capture sound from a specific direction while attenuating sounds originating from other angles. This attribute minimizes the pick-up of extraneous noise, focusing on the primary sound source. An example is its use when analyzing engine components, where the tool is positioned to capture sounds emanating directly from the engine, reducing background sounds.

- Acoustic Shielding

Acoustic shielding involves physical barriers or materials employed to minimize the entry of unwanted sounds into the device. These shields deflect or absorb ambient noise, creating a localized zone of reduced acoustic interference around the transducer. This is similar to how windscreens mitigate wind noise, enabling clearer capture of targeted sounds.

- Frequency Filtering

Frequency filtering selectively attenuates or amplifies specific frequency ranges within the audio spectrum. This capability allows for the reduction of noise concentrated at certain frequencies, such as low-frequency rumble or high-pitched whine. For example, filtering can minimize the prominence of air hissing sounds, thus improving the clarity of lower-frequency sounds originating from mechanical processes.

- Signal Processing Algorithms

Signal processing algorithms are employed to further enhance noise isolation through computational means. These algorithms analyze the recorded audio signal, identifying and suppressing noise components based on their characteristics. Advanced noise cancellation techniques can adapt to changing noise profiles, providing real-time noise reduction.

The integration of these noise isolation techniques is essential for the reliable operation of equipment designed for capturing audio in noisy environments. These tools are not merely recording devices; they are precision instruments engineered to overcome acoustic challenges, enabling accurate analysis and diagnostics in various industries.

2. Audio Clarity

Audio clarity represents a cornerstone in the functionality of specialized audio transducers designed for noisy environments. It encompasses the faithful reproduction of target sounds while minimizing the intrusion of extraneous noise, directly impacting the accuracy and reliability of acoustic analysis.

- Signal-to-Noise Ratio (SNR) Optimization

Enhancing the signal-to-noise ratio involves maximizing the amplitude of the desired signal relative to the background noise floor. A higher SNR translates to improved sound distinction and reduced masking of subtle acoustic features. In automotive diagnostics, optimizing SNR enables the detection of faint engine anomalies amidst louder operational noises.

- Harmonic Distortion Reduction

Harmonic distortion introduces spurious frequencies into the recorded signal, compromising its fidelity. Minimizing harmonic distortion ensures that the captured sound accurately reflects the original waveform, preventing misinterpretations during analysis. This is particularly crucial when analyzing complex waveforms such as those generated by mechanical vibrations.

- Frequency Response Flatness

Maintaining a flat frequency response signifies that the transducer accurately reproduces all frequencies within its operational range without undue emphasis or attenuation. This ensures that the spectral content of the recorded sound remains faithful to the original, allowing for accurate analysis of tonal characteristics. In industrial settings, frequency response flatness facilitates the precise identification of machine malfunctions based on their sonic signatures.

- Transient Response Accuracy

Transient response refers to the ability of the transducer to accurately capture sudden changes in sound amplitude, such as impacts or sharp percussive sounds. A fast and accurate transient response preserves the temporal characteristics of the audio signal, preventing smearing or distortion of transient events. This is vital when analyzing the timing of mechanical events within complex systems.

The attributes of signal-to-noise ratio optimization, harmonic distortion reduction, frequency response flatness, and transient response accuracy converge to define the overall audio clarity achieved by specialized recording equipment. These factors are not merely specifications; they are critical determinants of the instrument’s ability to deliver precise and reliable acoustic data in demanding operational contexts.

3. Engine Diagnostics

The application of specialized audio recording technology within engine diagnostics represents a significant advancement in identifying and resolving mechanical issues. The ability to isolate specific sounds within the complex acoustic environment of an operating engine facilitates a more precise assessment of its condition. This intersection of technology and diagnostic practice allows for non-invasive monitoring and targeted troubleshooting.

- Acoustic Anomaly Detection

Acoustic anomaly detection relies on the capability to discern irregular sounds indicative of mechanical faults. By comparing captured audio signatures against established baselines for normal engine operation, deviations can be identified and categorized. Examples include detecting valve train noise, piston slap, or bearing failures, each characterized by distinct acoustic signatures. The proper functioning of specialized transducers is paramount in isolating these anomalies from general engine noise.

- Cylinder Misfire Identification

Cylinder misfires, often arising from faulty ignition systems, fuel delivery issues, or compression leaks, generate unique acoustic events that can be detected and isolated. The precise timing and spectral characteristics of these sounds provide crucial information for pinpointing the affected cylinder. The ability of specialized audio equipment to accurately capture these transient events is essential for effective misfire diagnosis.

- Turbocharger Assessment

Turbochargers, critical components in forced induction systems, are prone to developing issues such as bearing wear, impeller damage, or boost leaks. These malfunctions produce distinct acoustic signatures that can be identified through careful audio analysis. A transducer capable of capturing high-frequency sounds and filtering out engine noise is essential for accurately assessing turbocharger health.

- Exhaust System Leak Detection

Exhaust system leaks, often manifesting as hissing or rattling sounds, can compromise engine performance and emissions control. Locating these leaks through traditional methods can be challenging, particularly in confined engine bays. Acoustic leak detection utilizes sensitive microphones to pinpoint the source of escaping exhaust gases, streamlining the repair process.

The utilization of specialized recording devices significantly enhances the efficacy and accuracy of engine diagnostics. By facilitating the detection and isolation of subtle acoustic anomalies, these tools empower technicians to perform targeted repairs, reducing downtime and minimizing unnecessary component replacements. The precise and reliable data acquired through this technology contribute to a more comprehensive understanding of engine health and performance.

4. Acoustic Analysis

Acoustic analysis, the study of sound properties and behavior, constitutes a fundamental component in the design and utilization of specialized audio devices. The connection is intrinsically linked; the efficacy of the transducer in capturing specific sounds relies directly on a thorough understanding of acoustic principles. Specifically, the device’s ability to isolate and record engine sounds, depends on applying acoustic analysis techniques. The device’s design incorporates elements that leverages the understanding of sound waves, frequency ranges, and sound propagation patterns to effectively mitigate unwanted noise. A real-life illustration is its use in automotive engine diagnostics, where acoustic analysis of captured engine sounds allows for identification of specific mechanical problems, even in noisy environments.

Further, the practical application of these tools extends beyond simple audio recording. Acoustic analysis of the sound signature allows for comparison against baseline data, detecting anomalies indicative of mechanical stress or failure. For instance, an alteration in frequency characteristics of a bearing sound reveals signs of wear. Similarly, a change in the amplitude profile of the sound can indicate a fuel injector malfunction. In each case, the tool serves as a sensor, acquiring the data that is then processed using acoustic analysis to extract useful information.

In summary, acoustic analysis forms an integral link in the operational chain of this specialized recording equipment. Its integration enables focused and reliable data capture in challenging conditions, opening avenues for detailed insights and decision-making in various applications. However, the practical use of these devices is not without challenges. Accurately interpreting acoustic data requires specialized knowledge. Ultimately, the value lies in its ability to translate raw sound into actionable intelligence, aiding in effective problem-solving across diverse fields.

5. Signal Integrity

Signal integrity, in the context of specialized audio transducers, is paramount to ensuring the reliability and accuracy of acquired data. It refers to the preservation of the audio signal’s characteristicsamplitude, frequency, and timingthroughout the recording and transmission process. When the device is used in high-noise settings, maintaining signal integrity becomes especially critical, as extraneous noise can easily corrupt the desired audio information. Factors influencing signal integrity include cable quality, connector types, and the impedance matching between the transducer and the recording device. Any degradation in signal integrity can lead to inaccurate diagnoses or flawed analysis. For example, if the audio signal from an engine is significantly attenuated or distorted, identifying subtle mechanical faults becomes challenging, if not impossible.

Practical implications of signal integrity extend to the selection and implementation of audio recording equipment. Shielded cables are often necessary to minimize electromagnetic interference (EMI) from surrounding machinery, which can introduce noise into the signal. Careful attention must also be given to grounding techniques to prevent ground loops, which can generate unwanted hum or buzzing sounds. Moreover, the use of high-quality connectors ensures a secure and reliable connection between the transducer and the recording device, preventing signal loss due to loose or corroded contacts. Regular calibration of the recording system is also crucial to verify that the audio signal is being accurately captured and processed. The adherence to best practices contributes directly to the reliability of data used for engine diagnostics and acoustic analysis.

In conclusion, signal integrity is a crucial component of effective audio capture, particularly within noisy environments. Maintaining it minimizes data errors, supports precise problem identification, and facilitates dependable performance analysis. Overcoming these challenges necessitates a multi-pronged strategy encompassing equipment selection, best practices, and continuous verification. It is essential to prioritize signal integrity to leverage fully the potential of specialist audio instruments.

6. Industrial Applications

The utility of specialized audio recording technology extends beyond automotive diagnostics to encompass a wide range of industrial applications. Its capacity to isolate and analyze sound in noisy environments renders it indispensable for preventative maintenance, quality control, and safety monitoring across diverse sectors. The value lies in its capacity to capture acoustic signals amidst considerable background noise, enabling assessment and troubleshooting not feasible through conventional methods.

- Predictive Maintenance of Machinery

In manufacturing plants and processing facilities, rotating machinery such as pumps, motors, and compressors are critical assets. The specialized audio device can facilitate predictive maintenance by detecting subtle changes in the acoustic signature of these machines. Early detection of bearing wear, imbalance, or cavitation allows for timely repairs, preventing catastrophic failures and minimizing downtime. For example, analyzing the spectral content of a pump’s sound can reveal the onset of cavitation long before it becomes visually apparent, enabling proactive intervention.

- Leak Detection in Compressed Air and Gas Systems

Compressed air and gas systems are ubiquitous in industrial settings. Leaks in these systems represent a significant source of energy waste and can pose safety hazards. The tool is used to identify and pinpoint the location of leaks by detecting the ultrasonic sound waves generated by escaping gas. This enables targeted repairs, reducing energy consumption and enhancing workplace safety. The acoustic signature of the escaping gas is identified, regardless of audible noise present at the facility.

- Quality Control of Manufacturing Processes

In manufacturing environments, acoustic analysis can be employed to monitor the quality of processes such as welding, machining, and assembly. Deviations from normal operating parameters often manifest as changes in the sound produced during these processes. By analyzing the acoustic signature, defects or inconsistencies can be detected in real-time, allowing for immediate corrective action. For instance, during a welding operation, changes in the arc sound can indicate porosity or incomplete fusion, enabling adjustments to welding parameters to ensure product quality.

- Monitoring of High-Voltage Equipment

High-voltage equipment, such as transformers and switchgear, can generate partial discharge activity, which is often indicative of insulation degradation. The device, in conjunction with specialized acoustic sensors, can detect the faint ultrasonic sounds produced by partial discharge, providing an early warning of potential equipment failure. The location and intensity of the discharge can be determined, facilitating targeted maintenance and preventing costly outages. This helps maintain the functionality of essential electrical systems.

The multifaceted nature of these tools renders them invaluable across the industrial landscape. From ensuring the longevity of vital machinery to enhancing the precision of manufacturing processes, it serves as a versatile tool for monitoring, detecting, and diagnosing issues that might otherwise go unnoticed. The continued development and application of this technology promises further advancements in industrial efficiency, safety, and reliability.

Frequently Asked Questions

This section addresses common inquiries regarding the design, operation, and application of specialized audio recording equipment employed in challenging acoustic environments.

Question 1: What distinguishes this kind of microphone from conventional recording devices?

The primary distinction lies in its enhanced noise reduction capabilities. It is engineered to attenuate ambient sounds, focusing on isolating specific acoustic signals amidst high levels of environmental noise, unlike standard microphones optimized for broader sound capture.

Question 2: In what specific industries or sectors is this specialized audio instrument most applicable?

These instruments find applications across diverse sectors, including automotive diagnostics, industrial maintenance, aerospace engineering, and environmental monitoring. Their utility stems from the need for accurate sound analysis in noisy operational settings.

Question 3: How does the positioning of this noise-reducing microphone affect recording quality?

Optimal positioning is crucial. Minimizing the distance between the microphone and the target sound source, while strategically orienting it to reduce the pick-up of extraneous noise, maximizes the signal-to-noise ratio and improves overall recording clarity.

Question 4: What types of environmental factors can negatively impact the performance of this kind of microphone?

Adverse environmental factors include wind, vibration, extreme temperatures, and electromagnetic interference. These factors can introduce unwanted noise or distort the audio signal, compromising the accuracy of the recording.

Question 5: Are specific training or skills required to effectively operate and interpret data from these specialized audio tools?

Yes, proficiency in acoustic principles, signal processing techniques, and the specific application domain is generally required. Accurate interpretation of the data necessitates an understanding of sound characteristics and potential sources of error.

Question 6: What are some common maintenance procedures for these sensitive audio instruments?

Regular maintenance includes cleaning the microphone element, inspecting cables for damage, and periodically calibrating the device to ensure accurate performance. Proper storage in a protective case also contributes to its longevity.

These questions aim to clarify the key aspects of these kinds of recording tools, providing a concise overview of their capabilities and limitations.

The subsequent section will explore potential future developments and emerging trends within the field of acoustic analysis using specialized recording equipment.

Conclusion

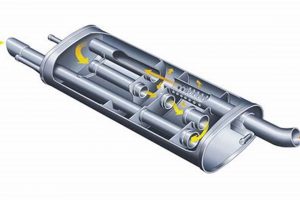

Throughout this exploration, the capabilities of the “muffler microphone” in addressing the challenges of audio capture in environments with high ambient noise levels has been thoroughly examined. Its utility in a spectrum of applications, from automotive diagnostics to industrial maintenance, underscores its significance. The design features that contribute to effective noise isolation and accurate signal acquisition have also been explored.

As technology continues to advance, further refinements in its design and signal processing techniques will inevitably broaden its applicability. Continued investment in research and development is critical to unlock further potential. The pursuit of enhanced clarity in acoustic data will ensure its ongoing relevance in data driven decisions across a number of sectors.