An aftermarket automotive component modifies the exhaust note produced by a vehicle. This device typically installs inline with the existing exhaust system, altering the sound characteristics without necessitating a complete system overhaul. For instance, a unit could be employed to deepen the exhaust tone of a car, providing a more aggressive sound profile without sacrificing factory exhaust components.

The utilization of such a component offers several advantages. It allows customization of a vehicle’s auditory signature, enabling drivers to tailor the sound to their preferences. It can also be a more cost-effective alternative to replacing the entire exhaust system. Historically, modifications to exhaust sounds were often achieved through complex and expensive custom fabrication. This product provides a simpler, more accessible means of achieving a similar result.

The subsequent sections will delve into the specific types available, their installation procedures, and the potential effects on vehicle performance. Furthermore, factors to consider when selecting and using such a component, including legality and potential impact on emissions, will be discussed in detail.

Selecting and Utilizing Exhaust Sound Modification Devices

The selection and proper implementation of devices designed to alter exhaust sound requires careful consideration. Neglecting crucial aspects can lead to undesirable outcomes, including reduced performance, legal complications, and system damage.

Tip 1: Research Compatibility: Before purchasing, confirm the device is compatible with the specific vehicle make, model, and year. Incompatible components can lead to improper fitment, reduced performance, or even damage to the existing exhaust system. Consult the manufacturer’s specifications or a qualified mechanic to verify compatibility.

Tip 2: Understand Local Regulations: Familiarize yourself with local noise ordinances and emission regulations. Modifying exhaust sound can sometimes violate these regulations, resulting in fines or required remediation. Check with local authorities or consult automotive experts on compliance.

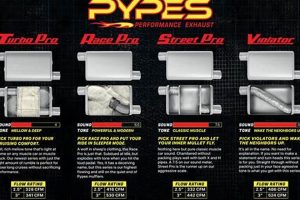

Tip 3: Consider Acoustic Properties: Evaluate the intended sound characteristics. Different devices produce varying sound profiles, ranging from subtle enhancements to aggressive tones. Listen to sound samples or consult reviews to determine if the product aligns with your desired auditory outcome.

Tip 4: Prioritize Quality Materials: Opt for devices constructed from durable, corrosion-resistant materials, such as stainless steel. Low-quality materials can degrade rapidly, leading to premature failure and potential exhaust leaks. Consider the environmental conditions in which the vehicle operates when selecting materials.

Tip 5: Ensure Proper Installation: Proper installation is critical to ensure optimal performance and prevent leaks. If lacking experience, seek professional installation to avoid damaging the existing exhaust system or compromising the effectiveness of the device. Torque specifications and sealant usage are crucial.

Tip 6: Evaluate Potential Performance Impacts: While some devices solely alter the exhaust note, others may impact engine performance. Research potential effects on horsepower, torque, and fuel efficiency. Consider dyno testing after installation to assess actual performance changes.

Tip 7: Regular Inspection and Maintenance: Routinely inspect the device and surrounding exhaust components for signs of wear, corrosion, or leaks. Address any issues promptly to prevent further damage or performance degradation. Tighten clamps and inspect welds periodically.

By adhering to these recommendations, individuals can effectively select and utilize exhaust sound modification devices to achieve their desired acoustic enhancements while mitigating potential risks and ensuring compliance with applicable regulations.

The following section will discuss the legal considerations surrounding exhaust modifications, emphasizing the importance of adhering to local and national laws.

1. Compatibility

The relationship between an aftermarket exhaust sound modification device and vehicle compatibility is a critical determinant of successful installation and functional performance. Incompatibility can result in a range of adverse consequences, including improper fitment, reduced operational efficiency, and potential damage to existing exhaust components. For instance, a device designed for a V6 engine cannot be effectively or safely installed on an inline-4 engine due to differing exhaust manifold configurations and pipe diameters. This physical mismatch prevents secure attachment and compromises the device’s ability to properly alter the exhaust note.

Furthermore, even within the same engine configuration, variations in vehicle model years can introduce incompatibility. Minor changes in exhaust system routing, hanger locations, or pipe diameters from one year to the next may necessitate specific device designs. An aftermarket component intended for a 2018 model might not fit correctly on a 2020 version of the same vehicle, even if the engine remains unchanged. This is because manufacturers occasionally make subtle modifications to exhaust systems during model refreshes. Therefore, precise matching of the device to the vehicle’s specific make, model, and year is paramount. Some manufacturers offer detailed compatibility charts or databases to guide consumers in selecting the appropriate component.

In summary, compatibility is not merely a desirable feature, but a foundational requirement for the safe and effective use of exhaust sound modification devices. Failure to ensure compatibility can lead to wasted resources, compromised vehicle performance, and potential system damage. Prioritizing thorough compatibility checks and consulting manufacturer specifications are vital steps in avoiding these negative outcomes and ensuring a successful modification.

2. Sound Customization

Sound Customization, in the context of aftermarket automotive modification, refers to the ability to modify the auditory characteristics of a vehicle’s exhaust note. Devices designed for this purpose offer a degree of control over the perceived sound profile, allowing drivers to tailor the sound to their preferences. This adjustment is achieved without necessarily altering the fundamental performance characteristics of the exhaust system.

- Frequency Tuning

Frequency tuning involves manipulating the dominant frequencies present in the exhaust sound. Some devices incorporate resonators or baffles designed to attenuate specific frequencies, resulting in a deeper or more aggressive sound. Adjusting these components can selectively reduce high-pitched frequencies, enhancing the lower frequencies that contribute to a more robust sound profile. Different designs cater to different frequency preferences.

- Volume Adjustment

Volume adjustment focuses on controlling the overall sound pressure level (SPL) emitted by the exhaust. This can be accomplished through variable baffles or electronically controlled valves that regulate the flow of exhaust gases. Higher flow rates typically correspond to increased volume. Such adjustments must be balanced against local noise ordinances, which often impose limitations on maximum permissible sound levels.

- Harmonic Enhancement

Harmonic enhancement involves selectively amplifying or creating specific harmonics in the exhaust sound. Harmonics are multiples of the fundamental frequency and contribute to the richness and complexity of the auditory experience. Devices employing specific chamber designs or internal geometries can selectively enhance certain harmonics, producing a unique and distinctive sound signature.

- Resonance Control

Resonance control aims to manage unwanted vibrations and drone within the exhaust system. Specific frequencies can cause resonance, resulting in unpleasant noise within the vehicle cabin, particularly at certain engine speeds. Devices incorporating resonators or Helmholtz chambers can effectively dampen these resonant frequencies, improving the overall driving experience and refining the sound quality.

The application of these methods allows a targeted approach to altering a vehicle’s exhaust sound. The selection and adjustment of a specific mechanism must be considered to obtain an exhaust note that is both aesthetically pleasing and compliant with relevant regulatory requirements, optimizing the balance between subjective preference and objective performance.

3. Installation Method

The installation method of a muffler sound adapter directly impacts its effectiveness, longevity, and compliance with safety standards. Incorrect installation can lead to diminished sound alteration, exhaust leaks, structural damage, and potentially hazardous operating conditions. The process is not merely affixing a component; it is integrating a modification into a complex system, where precision and adherence to specifications are paramount. A clamp-on adapter, for instance, requires proper tightening torque to ensure a secure seal without crushing the existing exhaust pipe. Welding, if required, demands expertise to prevent burn-through or compromised weld integrity, which could lead to premature failure due to corrosion or vibration.

Real-world examples underscore the importance of correct installation. A slip-on adapter secured with insufficient clamping force will likely exhibit exhaust leaks, negating the intended sound modification and introducing potentially harmful exhaust gases into the vehicle’s environment. Conversely, excessive force can deform the existing exhaust pipe, creating stress points that eventually lead to cracks and leaks. Similarly, improperly welded adapters can introduce turbulence into the exhaust flow, negatively impacting engine performance and fuel efficiency. The selection of appropriate welding techniques and materials is also crucial to prevent galvanic corrosion between dissimilar metals.

In conclusion, the installation method is an integral component of the muffler sound adapter’s functionality and safety. A proper installation ensures that the adapter performs as intended, maintains the integrity of the exhaust system, and avoids potential hazards. While seemingly straightforward, the process necessitates careful attention to detail, adherence to manufacturer specifications, and, in many cases, professional expertise. The challenges associated with improper installation highlight the broader theme of responsible vehicle modification, where safety and performance are inextricably linked. Choosing a suitable installation method and understanding each process are important for best use of Muffler Sound Adapter.

4. Material Durability

Material durability is a primary factor governing the long-term performance and reliability of any exhaust modification component. Exhaust systems are subject to extreme conditions, including high temperatures, corrosive gases, and constant vibration. The choice of materials directly dictates the component’s ability to withstand these conditions, thereby affecting its lifespan and overall value.

- Corrosion Resistance

Exhaust gases contain various corrosive compounds, including sulfur dioxide and water vapor, which can rapidly degrade certain metals. Stainless steel alloys, particularly 304 and 409 grades, exhibit superior corrosion resistance compared to mild steel or aluminized steel. The presence of chromium in stainless steel forms a protective oxide layer that inhibits rust formation. In the context of the exhaust modification component, the selection of a corrosion-resistant material is critical for preventing premature failure and maintaining structural integrity.

- Thermal Stability

Exhaust temperatures can fluctuate dramatically, ranging from ambient temperatures during startup to several hundred degrees Celsius during operation. Materials must possess adequate thermal stability to withstand these temperature variations without undergoing significant expansion, contraction, or degradation. Excessive thermal stress can lead to cracking, warping, or weld failures. Alloys with low coefficients of thermal expansion and high melting points are generally preferred for exhaust applications. Material selection directly influences the component’s ability to maintain its shape and functionality under extreme thermal conditions.

- Vibration Resistance

Exhaust systems are subjected to constant vibration from the engine and road conditions. This vibration can induce fatigue in materials, leading to cracking or joint failures over time. High tensile strength and fatigue resistance are essential properties for materials used in exhaust modification components. Reinforcement strategies, such as thicker gauge materials or strategic bracing, can further enhance vibration resistance. The material’s ability to withstand prolonged vibration significantly affects its service life and reliability.

- Weld Integrity

Many exhaust modification components require welding during manufacturing or installation. The chosen material must exhibit good weldability to ensure strong and durable joints. Incompatible filler metals or improper welding techniques can compromise weld integrity, creating weak points that are susceptible to failure. Post-weld heat treatment may be necessary to relieve residual stresses and further enhance weld strength. The quality of welds directly affects the component’s ability to withstand mechanical stresses and maintain its structural integrity under demanding operating conditions.

In conclusion, material durability represents a multifaceted consideration that profoundly affects the performance and longevity of exhaust modification components. The selection of materials with adequate corrosion resistance, thermal stability, vibration resistance, and weldability is essential for ensuring reliable operation and preventing premature failure. These factors contribute to the overall value and customer satisfaction with the product.

5. Regulatory Compliance

Regulatory compliance regarding muffler sound adapters centers on adherence to noise emission standards established by various governmental bodies. These standards are typically implemented to mitigate noise pollution within communities and protect public health. The use of a muffler sound adapter that exceeds permissible decibel levels can result in fines, vehicle impoundment, or mandatory modifications to restore compliance. For example, the Society of Automotive Engineers (SAE) has established J1169 standard, Measurement of Light Vehicle Exhaust Sound Level Under Stationary Conditions, that some states and municipalities reference. Exceeding these limits, after installing a muffler sound adapter leads to non-compliance. The severity of the consequences is often dependent on the jurisdiction and the extent of the violation.

The importance of regulatory compliance as a component of muffler sound adapter usage stems from the potential negative impacts of excessive noise. Prolonged exposure to high decibel levels can lead to hearing loss, stress, and other health problems. Furthermore, non-compliant vehicles contribute to a general degradation of the quality of life in residential areas. Some states mandate periodic vehicle inspections, including noise level checks, to ensure continued compliance. Adapters that bypass or disable factory-installed noise reduction systems are typically illegal. This reinforces the emphasis on responsible aftermarket modifications that stay within established legal boundaries.

In conclusion, the connection between regulatory compliance and muffler sound adapters is a critical consideration for vehicle owners. Failing to adhere to noise emission standards can lead to legal repercussions and contribute to noise pollution. Understanding and respecting these regulations is essential for promoting responsible vehicle modification practices and ensuring a healthy auditory environment for the public.

6. Performance Impact

The performance impact of a muffler sound adapter is a complex consideration, often exhibiting a nuanced relationship between sound modification and engine output. While the primary purpose of these adapters is to alter the exhaust note, their design and integration can inadvertently influence various performance parameters. The effect may be positive, negative, or negligible, depending on several factors, including the adapter’s internal geometry, the overall exhaust system design, and the engine’s characteristics. A poorly designed adapter can create excessive backpressure, impeding exhaust gas flow and reducing engine horsepower and torque, particularly at higher RPMs. Conversely, a well-designed adapter, especially when integrated into a complete performance exhaust system, can optimize exhaust scavenging, potentially leading to modest gains in power and fuel efficiency. For example, a straight-through adapter design, with minimal flow restriction, might enhance high-end horsepower in a turbocharged engine, while a baffled design could reduce noise levels at the expense of some performance.

Real-world examples illustrate the varying effects of such modifications. Vehicles fitted with restrictive adapters have exhibited noticeable reductions in throttle response and overall acceleration, particularly in dyno tests measuring power output across the RPM range. Conversely, vehicles with free-flowing adapters, coupled with ECU tuning, have demonstrated marginal improvements in horsepower and torque. It is essential to note that perceived performance changes may not always correlate with actual measured data. The enhanced auditory experience provided by a louder or deeper exhaust note can create a subjective impression of increased power, even when objective measurements indicate little or no change. The significance of the performance impact also depends on the vehicle’s intended use. A slight reduction in horsepower might be inconsequential for a daily driver, whereas it could be a critical concern for a performance-oriented vehicle used in racing or competitive events.

In summary, the performance impact associated with muffler sound adapters is multifaceted and context-dependent. While their primary function is sound alteration, these devices can influence engine output, both positively and negatively. Careful consideration of the adapter’s design, the existing exhaust system, and the vehicle’s intended application is crucial to minimize potential performance losses and maximize any potential gains. A balanced approach, combining objective performance measurements with subjective sound preferences, is recommended for making informed decisions regarding exhaust modification.

7. System Integrity

System integrity, in the context of automotive exhaust modification through the use of a muffler sound adapter, refers to the preservation of the exhaust system’s operational effectiveness, structural soundness, and environmental compliance after the installation of the component. Compromising system integrity can manifest in several detrimental ways, including exhaust leaks, reduced engine performance, increased emissions, and accelerated component wear. For example, an improperly installed or mismatched adapter can create stress points in the exhaust piping, leading to cracks and leaks that disrupt the intended exhaust flow and introduce harmful gases into the environment.

The importance of system integrity as a component of muffler sound adapter usage stems from the interconnected nature of the exhaust system and its role in engine operation and emissions control. A properly functioning exhaust system is essential for efficient combustion, optimal engine performance, and adherence to environmental regulations. A muffler sound adapter that compromises these functions can have cascading effects, impacting not only the vehicle’s performance but also its environmental footprint. Real-life instances of system integrity failures resulting from poorly chosen or installed adapters include catalytic converter damage due to increased backpressure, engine misfires caused by exhaust leaks near oxygen sensors, and non-compliance with emissions testing requirements. The practical significance of understanding this connection lies in the ability to make informed decisions about exhaust modifications, selecting components and installation methods that prioritize both desired sound characteristics and the continued health and functionality of the overall exhaust system.

Furthermore, maintaining system integrity requires ongoing monitoring and maintenance after the adapter is installed. Regular inspections for leaks, corrosion, and loose connections are essential for identifying and addressing potential problems before they escalate. The selection of high-quality adapters constructed from durable materials also contributes significantly to system integrity by minimizing the risk of premature failure or degradation. Challenges in preserving system integrity often arise from a lack of understanding of the exhaust system’s intricacies or a prioritization of sound modification over long-term system health. Addressing these challenges requires a commitment to responsible modification practices and a willingness to seek professional advice when needed. In summary, upholding system integrity is paramount when incorporating a muffler sound adapter, ensuring that the desired sound modification does not come at the expense of the vehicle’s performance, reliability, or environmental responsibility.

Frequently Asked Questions

The following questions and answers address common concerns and misconceptions regarding muffler sound adapters and their application in automotive exhaust systems. The information presented aims to provide clarity and promote informed decision-making.

Question 1: What precisely is a muffler sound adapter and how does it function?

A muffler sound adapter is an aftermarket automotive component designed to modify the exhaust note produced by a vehicle. Its functionality typically involves altering the flow of exhaust gases through the existing exhaust system, which can result in changes to the sound’s volume, pitch, and overall character. The adapter might achieve this through baffles, resonators, or alterations to the exhaust pipe diameter.

Question 2: Does the installation of a muffler sound adapter void a vehicle’s warranty?

The installation of an aftermarket component such as a muffler sound adapter may, under certain circumstances, affect the vehicle’s warranty coverage. It is generally the case that the vehicle manufacturer warranty will not cover parts that failed because of improper installation of, or modifications to, original parts. A failure related to the muffler sound adapter is unlikely to void the entire vehicle warranty, but it may void the warranty of components directly affected by the modification.

Question 3: Are there legal restrictions regarding the use of muffler sound adapters?

Yes, legal restrictions pertaining to muffler sound adapters vary depending on jurisdiction. Many regions have noise ordinances that establish maximum permissible sound levels for vehicles. Adapters that cause a vehicle to exceed these limits may be illegal to use on public roads. It is crucial to consult local regulations before installing any such device.

Question 4: Can a muffler sound adapter improve a vehicle’s performance?

While the primary function of a muffler sound adapter is to alter sound characteristics, some models might offer marginal performance gains, particularly when integrated within a complete performance exhaust system. However, it is important to note that restrictive adapters could impede exhaust flow, potentially reducing engine output. The selection of an adapter that balances sound modification with minimal flow restriction is paramount.

Question 5: What materials are commonly used in the construction of muffler sound adapters and what are the implications for durability?

Common materials include stainless steel (various grades), aluminized steel, and, less frequently, mild steel. Stainless steel offers superior corrosion resistance and is generally considered the most durable option. Aluminized steel provides a balance between cost and corrosion protection. Mild steel is the least expensive but also the most susceptible to rust. The choice of material significantly impacts the adapter’s lifespan and resistance to environmental degradation.

Question 6: How can potential exhaust leaks be prevented when installing a muffler sound adapter?

Preventing exhaust leaks necessitates careful attention to installation procedures. Ensuring proper sealing at all connection points is critical, potentially involving the use of high-temperature sealants or gaskets. Clamping force must be adequate to create a tight seal without deforming the exhaust pipes. Welding, when required, should be performed by a qualified technician using appropriate techniques and materials.

In summary, muffler sound adapters present a complex landscape of considerations, ranging from legal compliance and warranty implications to performance effects and material durability. A thorough understanding of these factors is essential for making responsible and informed decisions.

The next section will address specific installation considerations and best practices for ensuring optimal results when using muffler sound adapters.

Conclusion

This exploration of the muffler sound adapter has traversed numerous facets of its application, from compatibility and sound customization to regulatory compliance and potential performance impacts. The analysis underscores the importance of a comprehensive understanding of this device, extending beyond mere acoustic alteration to encompass critical considerations of system integrity and legal adherence. The preceding discussion also highlights the nuanced interplay between desired sound characteristics, engineering constraints, and responsible vehicle modification practices.

The effective implementation of a muffler sound adapter hinges on informed decision-making and meticulous execution. As technology evolves and regulatory landscapes shift, ongoing vigilance and a commitment to best practices will remain paramount. The responsible use of this technology necessitates a continuous pursuit of knowledge, balancing the allure of customized sound with the imperative of preserving vehicle performance, environmental responsibility, and legal compliance. Further research and responsible practices are always encouraged.

![Fix: Why Does One of My AirPods Sound Muffled? [SOLVED] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: Why Does One of My AirPods Sound Muffled? [SOLVED] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-396-300x200.jpg)

![Fix: Samsung TV Sound Is Muffled? [Solutions & Tips] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: Samsung TV Sound Is Muffled? [Solutions & Tips] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-328-300x200.jpg)