The exhaust component designed for the specified model year vehicle serves a critical role in reducing engine noise and directing exhaust gases away from the passenger compartment. It is typically positioned along the exhaust system, downstream from the catalytic converter. A properly functioning unit contributes to a quieter and more comfortable driving experience.

This component is essential for compliance with noise regulations and contributes to overall vehicle emissions control. Replacement may become necessary due to corrosion, physical damage from road debris, or internal degradation that diminishes its sound-dampening capabilities. Maintaining its integrity is crucial for optimal vehicle performance and adherence to environmental standards.

Considerations for this component include material construction (typically steel or stainless steel), compatibility with existing exhaust system components, and availability of aftermarket or original equipment manufacturer (OEM) replacements. Understanding the specific design and performance characteristics is important when evaluating replacement options or diagnosing potential issues.

Maintenance and Longevity Tips

Proper care and attention to the exhaust system can extend the lifespan of its key components, ensuring optimal vehicle performance and minimizing repair costs.

Tip 1: Routine Inspection: Regularly examine the component for signs of corrosion, rust, or physical damage. Early detection of these issues can prevent more extensive and costly repairs.

Tip 2: Avoid Short Trips: Frequent short trips can lead to moisture buildup inside the component, accelerating corrosion. Ensure that the vehicle is driven for longer periods occasionally to burn off accumulated moisture.

Tip 3: Salt Exposure Mitigation: In regions with salted roads during winter, frequent washing of the vehicle’s undercarriage is crucial. Salt can significantly accelerate corrosion; therefore, its prompt removal is essential.

Tip 4: Secure Mounting: Inspect the mounting hardware (hangers, brackets, and rubber isolators) regularly. Damaged or missing mounting hardware can cause excessive vibration, leading to premature failure of the component and other exhaust system parts.

Tip 5: Exhaust Leaks: Address any exhaust leaks promptly. Leaks not only affect performance and fuel economy but can also lead to increased noise and potentially dangerous exposure to exhaust fumes.

Tip 6: Professional Assessment: Periodic inspections by a qualified mechanic are highly recommended. A professional can identify potential issues that may not be readily apparent during a visual inspection.

Tip 7: Consider Material Upgrades: When replacing the component, consider upgrading to a stainless-steel version. Stainless steel offers superior corrosion resistance compared to traditional steel, extending the lifespan of the replacement part.

Adhering to these maintenance practices contributes to the overall health and longevity of the exhaust system, reducing the likelihood of premature failure and ensuring continued compliance with noise and emissions regulations.

Effective maintenance safeguards vehicle performance and minimizes long-term costs.

1. Corrosion Resistance

Corrosion resistance is a critical factor influencing the lifespan and performance of the exhaust component in a 2009 Nissan Sentra. The exhaust system, particularly the terminal sound dampening device, is subjected to extreme temperature fluctuations, exposure to moisture, road salts, and other corrosive elements. Consequently, the material composition and protective coatings significantly determine its longevity and functionality.

- Material Composition and Degradation

The original equipment component typically comprises aluminized steel, offering a moderate degree of corrosion protection. However, exposure to road salts and prolonged moisture can lead to rust formation, weakening the structural integrity of the component. Aftermarket options may offer enhanced corrosion resistance through the use of stainless steel alloys, significantly extending the service life, particularly in regions with harsh winter conditions.

- Impact on Exhaust System Functionality

Corrosion can compromise the sound-dampening capabilities of the component. Rust-induced perforations create exhaust leaks, increasing noise levels and potentially leading to exhaust gas intrusion into the passenger compartment. Furthermore, structural weakening can cause the component to detach from its mounting points, resulting in increased vibration and further damage to the exhaust system.

- Protective Coatings and Their Limitations

Protective coatings, such as aluminization or ceramic coatings, are applied to mitigate corrosion. However, these coatings can be damaged by physical impacts or prolonged exposure to extreme temperatures. Once the protective layer is breached, the underlying steel becomes vulnerable to corrosion. Regular inspection and maintenance are essential to identify and address any breaches in the protective coating before significant corrosion occurs.

- Environmental Considerations

Corrosion not only affects the performance and longevity of the component but also has environmental implications. Exhaust leaks caused by corrosion can lead to increased emissions and reduced fuel efficiency. Replacing a corroded component with a more durable, corrosion-resistant alternative minimizes the frequency of replacements, reducing waste and promoting sustainability.

The corrosion resistance characteristics directly impact the cost of ownership and environmental footprint of a 2009 Nissan Sentra. Selecting a replacement component with superior corrosion resistance represents a long-term investment, minimizing repair expenses and contributing to a more sustainable vehicle operation.

2. Sound Attenuation

Sound attenuation, as a function of the exhaust system’s terminal device, is crucial for minimizing engine noise and ensuring compliance with noise regulations in the 2009 Nissan Sentra. The component’s design directly affects the reduction of sound pressure levels emitted by the vehicle.

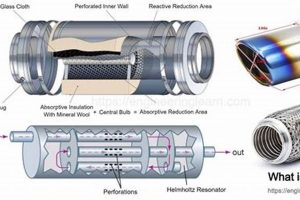

- Internal Chamber Design

The internal configuration incorporates chambers and baffles designed to disrupt sound waves through reflection and absorption. The number, size, and arrangement of these chambers significantly influence the frequency and amplitude of sound that is attenuated. A well-designed internal structure minimizes the transmission of undesirable frequencies, resulting in a quieter exhaust note. Deviations from the original design or degradation due to corrosion can compromise the component’s effectiveness.

- Material Properties and Absorption

The materials used in construction contribute to sound absorption. Typically, fiberglass or other sound-absorbing materials are packed within the chambers. These materials convert acoustic energy into heat, further reducing noise levels. Over time, these materials can degrade due to heat and exhaust gas exposure, diminishing their sound-absorbing capabilities and requiring replacement. The packing density and type of material are key determinants of performance.

- Resonator Integration

In some designs, a resonator is integrated upstream of the main device. The resonator is a specifically tuned chamber designed to cancel out specific frequencies of exhaust noise. Its effectiveness relies on precise dimensions and placement within the exhaust system. The absence of a functional resonator or damage to its structure will negatively affect sound attenuation.

- Exhaust Gas Flow Dynamics

The internal structure must balance sound attenuation with minimal restriction to exhaust gas flow. Excessive backpressure can negatively impact engine performance and fuel economy. A compromised internal design, whether due to corrosion or modification, can impede exhaust flow, negating the benefits of sound reduction. The component must effectively manage both sound and gas flow to maintain optimal vehicle operation.

The efficiency of sound attenuation directly impacts the driving experience and the vehicle’s compliance with environmental regulations. Understanding the various design elements and their impact on sound reduction is crucial for proper maintenance and selection of replacement components for a 2009 Nissan Sentra.

3. Exhaust Flow

Exhaust flow through the terminal sound-dampening component directly influences engine performance and efficiency in the 2009 Nissan Sentra. Restriction within this component can create backpressure, impeding the expulsion of exhaust gases and negatively affecting engine operation.

- Internal Design and Backpressure

The internal structure, including baffle design and chamber size, dictates the resistance to gas flow. Excessive baffles or undersized chambers increase backpressure, leading to reduced horsepower and torque. A properly designed component optimizes flow without compromising sound attenuation. Replacing the original component with one that significantly alters the internal design can have detrimental effects on engine performance.

- Material Degradation and Obstruction

Corrosion or internal degradation of the component can lead to obstructions within the exhaust pathway. Rust flakes or collapsed internal structures can impede gas flow, increasing backpressure. Regular inspection for signs of internal degradation is crucial to prevent performance loss. In extreme cases, complete blockage can occur, causing severe engine damage.

- Diameter and Pipe Configuration

The inlet and outlet diameters, as well as the internal pipe configuration, influence the flow rate. Significant reductions in diameter or sharp bends can create turbulence and increase resistance. Maintaining the original dimensions and configuration is essential for preserving optimal exhaust flow. Modifications to the exhaust system, such as installing an undersized component, should be carefully considered to avoid performance penalties.

- Catalytic Converter Integration (if applicable)

Some integrated designs incorporate a catalytic converter within the same unit as the sound-dampening device. A clogged or malfunctioning catalytic converter significantly restricts exhaust flow, creating substantial backpressure. Proper maintenance of the catalytic converter is essential for ensuring optimal engine performance. Diagnosing and addressing catalytic converter issues promptly can prevent further damage to the exhaust system and engine.

Maintaining proper exhaust flow through the terminal component is crucial for preserving the performance and efficiency of the 2009 Nissan Sentra. Identifying and addressing any flow restrictions caused by internal design, material degradation, or catalytic converter issues ensures optimal engine operation and prevents potential damage. Neglecting exhaust flow can lead to reduced fuel economy, diminished power output, and increased emissions.

4. Material Durability

Material durability is a paramount consideration in the design and longevity of the terminal sound-dampening component for the 2009 Nissan Sentra. The component’s exposure to corrosive elements, extreme temperatures, and physical stress necessitates robust materials capable of withstanding degradation over an extended service life.

- Steel Composition and Corrosion Resistance

The gauge and type of steel employed in the component’s construction directly correlate with its resistance to corrosion. Lower-grade steels are susceptible to rapid oxidation when exposed to moisture and road salts, leading to structural weakening and eventual failure. Higher-grade alloys, such as stainless steel, offer superior corrosion resistance, significantly extending the component’s lifespan. The initial manufacturing process, including the application of protective coatings, further contributes to long-term durability.

- Weld Integrity and Fatigue Resistance

The quality of welds joining the various sections of the component is critical for structural integrity. Weak or poorly executed welds are prone to cracking under cyclical stress and vibration, leading to exhaust leaks and premature failure. The welding process must ensure adequate penetration and fusion of the materials to withstand the mechanical stresses encountered during vehicle operation. Post-weld treatments can further enhance fatigue resistance and prevent crack propagation.

- Mounting Hardware and Vibration Dampening

The durability of the mounting hardware, including hangers and brackets, is essential for maintaining secure attachment to the vehicle chassis. These components are subjected to constant vibration and must withstand fatigue and corrosion. Rubber isolators are incorporated to dampen vibration and prevent stress transfer to the component body. Degradation of the mounting hardware can lead to excessive vibration, accelerating the wear and tear on the entire exhaust system. Neglecting worn or damaged mounting hardware can compromise the integrity of the component itself.

- Internal Baffle Design and Thermal Stress

The internal baffle design influences the component’s ability to withstand thermal stress. Inadequate baffle support or poorly designed expansion joints can lead to cracking and deformation under extreme temperature fluctuations. The selection of materials and manufacturing processes must account for the thermal expansion and contraction characteristics of the steel to prevent structural failure. Incorporating flexible elements within the internal structure can mitigate thermal stress and improve long-term durability.

The material durability of the terminal exhaust component is intrinsically linked to its service life and overall performance. Selecting a replacement component constructed from high-quality materials with robust welds and durable mounting hardware is a prudent investment. Prioritizing material durability reduces the frequency of replacements and contributes to a more reliable and cost-effective vehicle operation for the 2009 Nissan Sentra.

5. OEM Compatibility

Original Equipment Manufacturer (OEM) compatibility signifies the degree to which a replacement terminal sound-dampening device adheres to the specifications and performance standards established by Nissan for the 2009 Sentra. It extends beyond mere physical fitment and encompasses considerations of backpressure, sound attenuation characteristics, material composition, and mounting point geometry. Deviations from OEM specifications, even seemingly minor ones, can result in compromised engine performance, altered exhaust tone, or difficulties during installation.

The importance of OEM compatibility stems from the integrated nature of the vehicle’s exhaust system. The engine control unit (ECU) relies on specific exhaust characteristics to optimize fuel delivery, ignition timing, and emissions control. A non-OEM device that alters the exhaust flow or backpressure may trigger diagnostic trouble codes (DTCs), illuminate the check engine light, and potentially reduce fuel economy. For example, a replacement device with insufficient backpressure could lead to lean fuel mixtures and potential engine damage over time. Conversely, excessive backpressure might result in reduced power output and increased fuel consumption. Moreover, mismatched mounting points can necessitate modifications to the vehicle’s chassis or exhaust system, potentially compromising structural integrity and invalidating warranties. Cases have been documented where aftermarket components, despite being advertised as compatible, exhibited significant performance discrepancies compared to the OEM part, leading to customer dissatisfaction and additional expenses for rework.

In summary, OEM compatibility is a critical factor to consider when replacing the terminal sound-dampening component on a 2009 Nissan Sentra. Adherence to OEM specifications ensures proper engine performance, emissions compliance, and ease of installation. While aftermarket alternatives may offer cost savings, prioritizing OEM compatibility mitigates the risk of unforeseen complications and preserves the vehicle’s original design intent. Challenges in achieving perfect OEM compatibility often arise from variations in manufacturing processes and material sourcing. However, diligent research and selecting reputable suppliers who prioritize OEM standards can minimize these risks.

6. Mounting Integrity

Mounting integrity is a critical aspect influencing the performance, longevity, and safety of the exhaust system terminal device on the 2009 Nissan Sentra. Secure and properly installed mounting hardware prevents excessive vibration, stress, and potential detachment, all of which can lead to premature component failure and potential safety hazards.

- Hanger Condition and Exhaust System Support

Exhaust hangers, typically constructed of metal and rubber, are responsible for supporting the weight of the terminal device and absorbing vibrations. Deterioration of the rubber isolators due to age, exposure to heat, and road contaminants can compromise their ability to dampen vibration. Corroded or broken metal hangers can lead to excessive stress on the exhaust piping and welds, potentially causing cracks and leaks. Replacing worn hangers ensures proper support and reduces the risk of component detachment, preserving the exhaust system’s integrity and minimizing noise from vibration.

- Bracket Security and Chassis Attachment

Brackets secure the exhaust system to the vehicle’s chassis, providing a stable mounting platform. Loose or corroded brackets allow excessive movement of the terminal device, accelerating wear and tear on the exhaust system. Securely fastened brackets prevent stress concentration points and minimize the likelihood of damage from road debris or impact. Regular inspection and tightening of bracket fasteners are essential for maintaining proper exhaust system alignment and stability.

- Hardware Corrosion and Component Detachment

Corrosion of mounting hardware, including bolts, nuts, and clamps, can weaken their structural integrity and lead to component detachment. Salt exposure and moisture accelerate corrosion, particularly in regions with harsh winter conditions. Applying anti-seize compound to threaded fasteners during installation can prevent corrosion and facilitate future maintenance. Regular inspection and replacement of corroded hardware ensure secure attachment of the terminal device and minimize the risk of it separating from the vehicle.

- Alignment and Stress Distribution

Proper alignment of the exhaust system during installation is crucial for distributing stress evenly across the mounting points. Misalignment can create stress concentration points, leading to premature failure of the hangers, brackets, and exhaust piping. Ensuring correct alignment during installation and subsequent maintenance minimizes stress and prolongs the lifespan of the entire exhaust system. A properly aligned system also prevents contact between the exhaust components and the vehicle’s chassis, reducing noise and preventing potential damage.

Maintaining mounting integrity is paramount for the reliable operation and safety of the 2009 Nissan Sentra’s exhaust system terminal device. Regular inspection and maintenance of hangers, brackets, and hardware, coupled with proper alignment during installation, minimize vibration, stress, and the risk of component detachment. Addressing any mounting issues promptly prevents more extensive and costly repairs to the exhaust system and contributes to a safer and more comfortable driving experience.

Frequently Asked Questions

The following addresses common inquiries concerning the terminal sound-dampening device on the specified vehicle.

Question 1: How frequently should the exhaust component be inspected for potential issues?

A visual inspection is recommended during each oil change or approximately every 5,000 to 7,500 miles. A more thorough inspection by a qualified technician is advised annually, particularly in regions with harsh winter conditions where road salts are prevalent.

Question 2: What are the primary indicators of a failing exhaust component?

Increased exhaust noise, a rattling sound originating from underneath the vehicle, noticeable rust or corrosion, and reduced fuel efficiency may indicate component failure. A visual inspection may reveal holes or cracks in the component body.

Question 3: Is it permissible to drive with a damaged exhaust component?

Operating a vehicle with a damaged exhaust component is not recommended. Exhaust leaks can expose occupants to harmful gases and may violate local noise ordinances. Furthermore, a damaged component can negatively impact engine performance and fuel economy.

Question 4: Are aftermarket exhaust components suitable replacements for the original equipment part?

Aftermarket components may offer cost savings; however, ensure the replacement part meets or exceeds OEM specifications for fit, performance, and durability. Non-compliant components may negatively affect engine performance, emissions, and noise levels.

Question 5: Can a damaged exhaust component affect vehicle emissions testing?

Yes, a damaged component that causes an exhaust leak can result in a failed emissions test. Exhaust leaks allow uncombusted hydrocarbons to escape into the atmosphere, exceeding permissible emission levels. Addressing exhaust system issues is essential for passing emissions testing.

Question 6: What is the typical lifespan of the exhaust component on a 2009 Nissan Sentra?

The lifespan varies depending on driving conditions, climate, and the quality of the component. Under typical conditions, a properly maintained component may last between 5 to 7 years. Exposure to road salts and aggressive driving habits can shorten its lifespan.

Proper maintenance and timely replacement of the exhaust component ensure optimal vehicle performance, regulatory compliance, and a safe driving experience.

The subsequent section will address diagnostic procedures for identifying common exhaust system issues.

Conclusion

The preceding exploration of the nissan sentra 2009 muffler has highlighted its crucial role in vehicle operation, emissions control, and noise reduction. Factors such as corrosion resistance, sound attenuation, exhaust flow, material durability, OEM compatibility, and mounting integrity directly influence its performance and longevity. Proper maintenance, regular inspection, and the selection of compatible replacement parts are essential for ensuring continued functionality.

Neglecting the condition of this component can lead to diminished engine performance, increased emissions, regulatory non-compliance, and potential safety hazards. Therefore, due diligence in maintaining and addressing any issues related to the nissan sentra 2009 muffler is paramount for responsible vehicle ownership and environmental stewardship. Prioritizing its integrity safeguards vehicle reliability and minimizes long-term costs.