A malfunctioning exhaust component, typically located underneath a vehicle, produces excessive sound. This situation often arises due to corrosion, physical damage from road debris, or internal degradation of the sound-dampening materials. As an example, a vehicle exhibiting a significantly louder-than-normal rumble, particularly during acceleration, is likely experiencing issues with its exhaust system’s sound reduction capability.

Addressing this condition is important for several reasons. Firstly, operating a vehicle that exceeds local noise ordinances can result in fines. Secondly, the increased volume can be disruptive to communities and contribute to noise pollution. Furthermore, a damaged component can indicate underlying issues with the vehicle’s emissions control system, potentially affecting fuel efficiency and increasing harmful pollutants. Historically, efforts to regulate vehicle sound levels have aimed to improve quality of life in urban environments and protect public health.

The following sections will examine common causes, diagnostic procedures, repair options, and preventative maintenance strategies related to exhaust system sound reduction, providing a comprehensive guide to understanding and resolving related issues.

Mitigating Excessive Vehicle Exhaust Noise

The following recommendations provide guidance on identifying, addressing, and preventing excessive exhaust system noise.

Tip 1: Periodic Visual Inspection: Regularly examine the exhaust system for signs of corrosion, holes, or physical damage. Early detection allows for timely repairs and prevents escalation of the problem.

Tip 2: Listen for Abnormal Sounds: Pay attention to any changes in the vehicle’s exhaust note, such as excessive rumbling, hissing, or rattling. These sounds can indicate a breach in the system.

Tip 3: Check for Leaks: If suspected, perform an exhaust leak test by carefully inspecting joints and seams while the engine is running. Use appropriate safety precautions to avoid burns.

Tip 4: Consider a Professional Inspection: If you are not comfortable performing visual inspections or suspect a problem but cannot locate it, seek professional assistance from a qualified mechanic.

Tip 5: Address Issues Promptly: Delaying repairs can lead to further damage, increased noise levels, and potential environmental violations. Timely maintenance is crucial.

Tip 6: Use Quality Replacement Parts: When replacing exhaust components, opt for reputable brands that meet or exceed original equipment manufacturer (OEM) specifications. This ensures optimal performance and longevity.

Tip 7: Understand Local Regulations: Familiarize yourself with local noise ordinances and vehicle inspection requirements to ensure compliance.

Adhering to these recommendations can contribute to reduced noise pollution, improved vehicle performance, and avoidance of costly repairs.

The subsequent sections will delve deeper into specific repair procedures and long-term maintenance strategies for vehicle exhaust systems.

1. Corrosion

Corrosion stands as a primary cause of exhaust system degradation, directly contributing to excessive noise production. The exhaust system, fabricated from metallic materials, is consistently exposed to high temperatures, combustion byproducts, and environmental moisture. This combination creates an environment conducive to oxidation and electrochemical reactions, weakening the metal structure over time. As corrosion progresses, small perforations and larger breaches form in the component’s outer shell and internal baffles. The intended sound-dampening function is subsequently compromised, resulting in amplified exhaust noise emanating from the vehicle. For example, vehicles operating in regions with frequent road salting during winter experience accelerated corrosion of their exhaust systems due to the increased exposure to corrosive agents.

The impact of corrosion extends beyond mere noise pollution. The structural integrity of the exhaust system is diminished, potentially leading to component failure and necessitating costly repairs. Furthermore, corrosion within the catalytic converter can impair its efficiency, increasing harmful emissions and potentially leading to non-compliance with emission standards. Recognizing the specific types of corrosion at play, such as galvanic corrosion at dissimilar metal junctions or pitting corrosion caused by localized environmental factors, is essential for implementing targeted preventative measures, such as applying corrosion-resistant coatings or utilizing stainless steel components in vulnerable areas.

In conclusion, corrosion is a critical factor in the development of excessive exhaust system noise. Understanding the mechanisms and environmental factors that promote corrosion allows for the implementation of proactive maintenance strategies, extending the lifespan of the exhaust system, reducing noise pollution, and mitigating the environmental impact of vehicle emissions. Therefore, regular inspection and preventative treatments are crucial for maintaining a properly functioning and quiet exhaust system.

2. Damage

Physical damage to an exhaust component directly correlates with elevated noise levels. Compromised structural integrity impairs its sound-dampening capabilities, resulting in increased vehicle noise pollution.

- Impact Damage from Road Debris

Strikes from rocks, potholes, or other road debris can create punctures, dents, or fractures in the exhaust system. These breaches allow exhaust gases to escape prematurely, bypassing the internal baffles designed to attenuate sound. The resulting effect is a significant increase in exhaust noise, often characterized by a rattling or hissing sound. For instance, a vehicle driven frequently on unpaved roads is at higher risk of sustaining this type of damage, leading to increased noise levels and potential regulatory violations.

- Joint and Connection Failure

The exhaust system comprises several connected sections held together by clamps, flanges, or welds. The constant thermal cycling and vibration inherent in vehicle operation can weaken these connections over time. Failed welds, loosened clamps, or corroded flanges create exhaust leaks, resulting in a noticeable increase in exhaust noise. This noise often manifests as a high-pitched whistling or buzzing sound, particularly during acceleration. Neglecting these connection failures can lead to further damage to adjacent components and exacerbate noise pollution.

- Internal Baffle Degradation

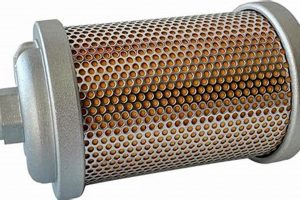

The internal structure contains a series of baffles designed to redirect and dampen sound waves. Physical damage, often in conjunction with corrosion, can cause these baffles to collapse, fracture, or become dislodged. The compromised internal structure loses its ability to effectively attenuate sound, leading to a significant increase in exhaust noise. This type of damage often results in a deep, rumbling exhaust note that is disproportionate to the vehicle’s engine size.

- Catalytic Converter Damage

While primarily responsible for emissions control, the catalytic converter also contributes to sound dampening. Physical damage, such as internal substrate fractures caused by overheating or impact, can reduce its ability to attenuate exhaust noise. Damaged catalytic converters often produce a rattling or buzzing sound, particularly at idle or low engine speeds. Furthermore, damage to the catalytic converter can lead to reduced emissions control effectiveness, potentially resulting in regulatory violations and environmental consequences.

In summary, physical damage, regardless of its source or location within the exhaust system, invariably leads to increased noise levels. Addressing this damage promptly is essential for mitigating noise pollution, maintaining vehicle compliance with noise regulations, and preventing further damage to the exhaust system and its associated components. Regular inspection and timely repairs are crucial for ensuring a quiet and efficient vehicle operation.

3. Regulations

Regulations play a crucial role in governing vehicle noise emissions, directly impacting the acceptability of exhaust systems. These legal frameworks aim to mitigate noise pollution and maintain acceptable sound levels within communities. The enforcement of these regulations has a direct bearing on the legality of vehicles operating with excessively loud exhaust systems.

- Noise Emission Standards

Local, state, and federal authorities establish specific noise emission standards for vehicles, typically measured in decibels (dB) at a specified distance and under defined operating conditions. Vehicles exceeding these limits are in violation of noise pollution regulations. A vehicle equipped with an exhaust component that produces sound levels above the permissible threshold is considered non-compliant. Enforcement can range from warnings to fines and mandatory repairs to bring the vehicle into compliance. For example, many municipalities have ordinances that restrict vehicle noise levels during nighttime hours to further protect residential areas.

- Vehicle Inspections and Enforcement

Many jurisdictions incorporate noise level testing into their routine vehicle inspection programs. During these inspections, exhaust systems are evaluated for excessive noise. Non-compliant vehicles may fail the inspection, requiring repair or replacement of the offending components to pass subsequent inspections. Law enforcement officers also have the authority to issue citations for vehicles operating with excessively noisy exhaust systems based on subjective judgment or objective sound level measurements. For example, some states require vehicles to undergo annual or biennial safety and emissions inspections, including an assessment of the exhaust system’s condition and noise output.

- Aftermarket Exhaust System Restrictions

Regulations also govern the sale and use of aftermarket exhaust systems. Certain aftermarket components marketed for increased performance may be designed to bypass or eliminate sound-dampening features, leading to excessive noise. These components may be deemed illegal for street use and restricted to off-road or track applications. Manufacturers and retailers of aftermarket exhaust systems are often required to comply with noise emission standards and provide documentation certifying compliance. For example, some states have laws that prohibit the installation of aftermarket exhaust systems that are louder than the original equipment manufacturer (OEM) system.

- Legal Consequences and Penalties

Operating a vehicle with an exhaust system that violates noise regulations can result in various legal consequences. These may include fines, court appearances, mandatory vehicle repairs, and even vehicle impoundment in severe cases. Repeat offenders may face escalating penalties. Furthermore, violations of noise regulations can impact vehicle registration renewal and insurance premiums. For example, a driver repeatedly cited for excessive vehicle noise may face increased insurance rates due to the perceived higher risk associated with their driving behavior.

In conclusion, the regulations governing vehicle noise emissions directly influence the acceptability and legality of exhaust systems. These regulations, encompassing noise emission standards, vehicle inspections, aftermarket exhaust system restrictions, and legal consequences, aim to mitigate noise pollution and ensure compliance with community standards. Operating a vehicle with an excessively loud exhaust component not only creates a public nuisance but also carries significant legal and financial risks. Therefore, maintaining a properly functioning and compliant exhaust system is essential for responsible vehicle operation.

4. Emissions

Vehicle emissions and exhaust system integrity are inextricably linked. A compromised exhaust component, leading to excessive noise, often signifies underlying issues that affect the control and release of pollutants. This relationship underscores the importance of maintaining a properly functioning exhaust system to ensure environmental compliance.

- Catalytic Converter Efficiency

A damaged or deteriorated catalytic converter, frequently a consequence of exhaust system leaks or corrosion, experiences a reduced capacity to convert harmful pollutants, such as hydrocarbons, carbon monoxide, and nitrogen oxides, into less harmful substances. This reduction in efficiency contributes to increased emissions, potentially exceeding regulatory limits. For instance, an exhaust component breach upstream of the catalytic converter introduces excess oxygen, disrupting the chemical reactions essential for pollutant conversion.

- Exhaust Leaks and Unmetered Air

Exhaust leaks, which often manifest as increased noise levels, introduce unmetered air into the exhaust stream. This excess air can disrupt the air-fuel ratio monitored by the engine’s sensors, leading to inefficient combustion and increased emissions of various pollutants. The engine control unit (ECU) may attempt to compensate for the unmetered air, potentially resulting in further inefficiencies and elevated emissions. This is particularly relevant in vehicles with oxygen sensors positioned downstream of exhaust leaks.

- Oxygen Sensor Functionality

The functionality of oxygen sensors, critical components in the engine’s feedback control system, can be adversely affected by exhaust leaks. Leaks near oxygen sensors can lead to inaccurate readings, causing the ECU to make incorrect adjustments to the air-fuel mixture. This can result in increased fuel consumption and higher emissions levels. For example, a small exhaust leak near an oxygen sensor might trick the ECU into thinking the engine is running lean, prompting it to enrich the fuel mixture and increase emissions of hydrocarbons and carbon monoxide.

- Backpressure and Engine Performance

A compromised exhaust system, characterized by excessive noise, can disrupt the proper exhaust backpressure. Altered backpressure can negatively impact engine performance, leading to reduced fuel efficiency and increased emissions. Deviations from the designed backpressure parameters can affect the scavenging of exhaust gases from the cylinders, resulting in incomplete combustion and elevated levels of pollutants. This is especially critical in turbocharged engines, where exhaust backpressure plays a vital role in turbocharger performance and overall engine efficiency.

These interconnected factors highlight the crucial link between exhaust system integrity and vehicle emissions. Addressing exhaust system issues promptly not only reduces noise pollution but also contributes to improved emissions control, reduced environmental impact, and enhanced vehicle performance.

5. Performance

A direct correlation exists between exhaust system condition and vehicle performance. An exhaust component experiencing degradation, manifesting as excessive noise, invariably influences engine efficiency and overall vehicle operation. The intended flow of exhaust gases is disrupted, leading to suboptimal engine function. Performance implications range from reduced power output to diminished fuel economy, directly affecting the vehicle’s capabilities and operational costs. For instance, a severely corroded exhaust, generating a loud rumbling sound, can restrict exhaust flow, increasing backpressure and reducing engine horsepower.

Specific performance impacts vary depending on the nature and extent of the damage. Exhaust leaks introduce unmetered air into the system, altering the air-fuel ratio and impacting combustion efficiency. This can lead to hesitant acceleration, rough idling, and a general decrease in responsiveness. A malfunctioning catalytic converter, often indicated by rattling noises or decreased emissions control, can significantly reduce engine power and fuel economy. Furthermore, the improper flow of exhaust gases can affect the turbocharger’s operation in turbocharged engines, resulting in diminished boost pressure and reduced performance gains. Consider a scenario where a vehicle’s exhaust manifold gasket fails, creating a noticeable hissing sound; this leak not only increases noise but also reduces the pressure available to drive the turbocharger, leading to a perceptible drop in acceleration.

In summary, the presence of excessive noise emanating from the exhaust indicates an underlying issue that compromises vehicle performance. These performance reductions can manifest as decreased power, reduced fuel economy, and impaired responsiveness. Addressing exhaust system problems promptly not only mitigates noise pollution and environmental concerns but also restores the vehicle’s intended performance characteristics, ensuring efficient and reliable operation. The proper maintenance and repair of the exhaust system are therefore crucial for maximizing both vehicle performance and operational longevity.

6. Cost

The expense associated with a malfunctioning exhaust component is multifaceted, extending beyond the immediate repair or replacement costs. The long-term financial implications, coupled with potential secondary damages, warrant careful consideration.

- Initial Repair or Replacement Expenses

The direct cost of addressing a noisy muffler varies significantly based on the vehicle model, the extent of the damage, and the chosen repair method. A simple weld repair might represent a minimal expense, whereas a complete replacement of the component can incur substantial costs, including parts and labor. Selecting aftermarket parts versus original equipment manufacturer (OEM) components also influences the price, with OEM parts generally commanding a higher premium. The complexity of the vehicle’s exhaust system further affects labor costs, as certain systems require more intricate disassembly and reassembly procedures. For instance, a high-performance vehicle with a complex exhaust design could result in significantly higher replacement expenses compared to a standard passenger vehicle.

- Potential Fines and Legal Penalties

Operating a vehicle with an excessively loud exhaust system can lead to fines and legal penalties, depending on local noise ordinances and enforcement policies. These fines represent an additional expense associated with neglecting the noisy component. Repeat offenders may face escalating penalties, potentially including mandatory vehicle repairs and court appearances. Furthermore, a vehicle failing a noise inspection may incur additional costs related to re-inspection fees and lost time. The cumulative effect of these penalties can substantially increase the overall cost of neglecting a damaged component.

- Fuel Efficiency Reduction

A compromised exhaust system, often signified by excessive noise, can negatively impact fuel efficiency. Exhaust leaks and altered backpressure can disrupt the engine’s optimal combustion process, resulting in increased fuel consumption. This gradual decrease in fuel economy translates to higher fuel costs over time. While the individual impact may seem marginal, the cumulative effect over months or years can represent a significant financial burden. For example, a persistent exhaust leak can cause a decrease in fuel efficiency by several miles per gallon, adding significantly to the annual fuel expenses.

- Secondary Damage and Accelerated Wear

Neglecting a damaged exhaust component can lead to secondary damage to other vehicle systems. Exhaust leaks can expose adjacent components to high temperatures and corrosive gases, accelerating wear and tear. Furthermore, altered engine backpressure can strain other engine components, potentially shortening their lifespan. The cost of repairing these secondary damages adds to the overall financial burden of neglecting the initial problem. A leaking exhaust manifold gasket, for instance, can lead to overheating and damage to nearby sensors and wiring harnesses, resulting in additional repair costs.

In summary, the financial implications of a noisy muffler extend beyond the immediate repair costs. Potential fines, reduced fuel efficiency, and secondary damage contribute significantly to the overall financial burden. Addressing the issue promptly not only mitigates noise pollution and environmental concerns but also prevents the accumulation of additional expenses associated with long-term neglect.

7. Safety

A compromised exhaust system, often indicated by excessive noise, presents distinct safety concerns that warrant careful consideration. The integrity of the exhaust system is crucial for directing harmful combustion byproducts away from the vehicle’s occupants and the surrounding environment. A damaged exhaust component can lead to the leakage of these gases into the passenger cabin, posing a significant health risk. The potential consequences range from mild discomfort to severe health complications. For instance, carbon monoxide, an odorless and colorless gas present in exhaust fumes, can accumulate within the vehicle, leading to carbon monoxide poisoning. This condition can cause symptoms such as headache, dizziness, nausea, and, in severe cases, loss of consciousness and death. Furthermore, exhaust leaks can create fire hazards if flammable materials come into contact with hot exhaust gases. Consider a scenario where a corroded exhaust pipe allows exhaust gases to vent near the vehicle’s fuel lines, creating a potential ignition source.

Beyond the direct health risks associated with exhaust leaks, a noisy muffler can also indicate structural weaknesses in the vehicle. Severely corroded or damaged components may detach from the vehicle while in motion, creating a road hazard for other drivers. A detached exhaust component can cause significant damage to other vehicles or contribute to accidents. Moreover, the noise itself can be a distraction to the driver, impairing their ability to concentrate on the road and increasing the risk of accidents. The link between noise-induced stress and decreased driving performance is well-documented, highlighting the importance of maintaining a quiet and functional vehicle.

In summary, the connection between safety and a noisy muffler is significant and multifaceted. The potential for carbon monoxide poisoning, fire hazards, and the creation of road hazards underscores the importance of maintaining a properly functioning exhaust system. Addressing exhaust system problems promptly not only mitigates noise pollution and environmental concerns but also ensures the safety of the vehicle’s occupants and other road users. Regular inspection and timely repairs are therefore essential for promoting responsible vehicle operation and preventing potentially life-threatening situations.

Frequently Asked Questions Regarding Excessive Exhaust System Noise

The following addresses common inquiries and clarifies misunderstandings surrounding the causes, consequences, and remedies associated with an exhaust component producing excessive sound.

Question 1: What constitutes an “excessively loud” exhaust system?

An exhaust system is deemed excessively loud when it exceeds established noise emission standards, as defined by local, state, or federal regulations. These standards typically specify a maximum decibel level measured under controlled conditions. Subjective assessment by law enforcement can also determine excessive noise, even if objective measurements are not immediately available.

Question 2: What are the primary causes of a noisy muffler?

The most prevalent causes include corrosion, physical damage from road debris, internal baffle degradation, and joint/connection failures. These factors compromise the sound-dampening capabilities of the component, resulting in amplified exhaust noise.

Question 3: What are the potential legal ramifications of operating a vehicle with a noisy muffler?

Operating a vehicle exceeding established noise emission standards can result in fines, court appearances, mandatory vehicle repairs, and, in severe cases, vehicle impoundment. Repeat offenders may face escalating penalties and increased insurance premiums.

Question 4: Can a noisy muffler affect vehicle performance?

Yes, a compromised exhaust system can negatively impact engine performance. Exhaust leaks and altered backpressure disrupt the optimal combustion process, potentially leading to reduced power output, diminished fuel economy, and impaired engine responsiveness.

Question 5: Is a noisy muffler a safety concern?

A damaged exhaust system can present safety hazards. Exhaust leaks can allow harmful gases, such as carbon monoxide, to enter the passenger cabin, posing a health risk. Furthermore, detached components can create road hazards for other drivers.

Question 6: What are the recommended steps for addressing a noisy muffler?

A thorough inspection by a qualified mechanic is recommended to diagnose the cause of the noise. Repair or replacement of the damaged component is typically required to restore the exhaust system to a compliant and safe operating condition. Preventative maintenance, such as regular visual inspections and corrosion protection, can help extend the lifespan of the exhaust system.

Proper maintenance and prompt repairs are crucial for ensuring a safe, environmentally compliant, and legally sound vehicle operation.

The subsequent section will explore diagnostic procedures and repair options in greater detail, providing practical guidance for addressing related issues.

Conclusion

The preceding analysis has comprehensively examined the causes, consequences, and ramifications associated with a vehicle exhibiting a “noisy muffler.” Corrosion, physical damage, regulatory compliance, emissions control, vehicle performance, financial costs, and safety considerations were identified as interconnected and critical elements. The presence of excessive exhaust system noise serves as a clear indicator of underlying problems requiring prompt attention.

Neglecting the issues surrounding a “noisy muffler” carries significant risks, ranging from environmental pollution and legal penalties to compromised vehicle safety and escalating repair expenses. Therefore, proactive maintenance, regular inspections, and timely repairs are essential for responsible vehicle ownership and the preservation of community well-being. Adherence to established noise regulations, coupled with a commitment to proper vehicle maintenance, contributes to a safer and more environmentally sound transportation ecosystem.