This component is a critical part of the exhaust system for the Predator 212 engine, a popular small engine often used in go-karts, mini bikes, and other recreational vehicles. It serves the primary function of reducing noise generated by the engine’s combustion process and channeling exhaust gases away from the operator.

Properly functioning, this part contributes to a more pleasant operating experience by mitigating excessive noise. It can also improve engine performance and longevity by optimizing exhaust flow and backpressure. The design and materials used in its construction influence its durability, noise reduction effectiveness, and impact on engine power. Historically, various iterations of this part have been developed to address different performance and noise requirements.

The following discussion will delve into the different types available, their installation procedures, potential performance enhancements, and crucial maintenance considerations for optimal operation and longevity.

Tips for Predator 212 Muffler Management

Proper attention to the exhaust component of the Predator 212 engine is crucial for maintaining performance, ensuring safety, and adhering to noise regulations.

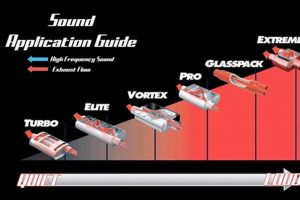

Tip 1: Selection Considerations: When choosing this component, evaluate the intended application. Racing engines benefit from performance-oriented designs that prioritize exhaust flow, while recreational applications often necessitate quieter, more restrictive options.

Tip 2: Installation Precautions: Always allow the engine to cool completely before installation. Use appropriate tools and torque specifications to prevent damage to the threads and ensure a secure, leak-free seal.

Tip 3: Regular Inspection: Conduct routine inspections for signs of damage, corrosion, or leaks. Cracks and excessive rust compromise performance and can pose safety hazards due to exhaust gas leakage.

Tip 4: Tightening Hardware: Periodically check the tightness of mounting bolts and fasteners. Vibrations from engine operation can loosen these components, leading to exhaust leaks and reduced performance.

Tip 5: Cleaning Procedures: Remove carbon buildup and debris from the exhaust port and surrounding areas. This helps maintain optimal exhaust flow and prevents overheating.

Tip 6: Modification Awareness: Understand the implications of modifying the exhaust system. Alterations can affect engine performance, fuel efficiency, and emissions compliance. Consult with experienced technicians before undertaking modifications.

Tip 7: Noise Level Monitoring: Be aware of local noise ordinances and regulations. Select this component that meets or exceeds these standards to avoid potential fines or legal issues.

Adhering to these maintenance and operational guidelines will contribute to the reliable and efficient operation of the Predator 212 engine.

The following sections will explore advanced topics related to performance optimization and troubleshooting common issues.

1. Noise Reduction

Noise reduction is a primary function of the exhaust component on the Predator 212 engine. The combustion process within small engines generates significant noise, and effective noise reduction is crucial for both operator comfort and compliance with noise regulations.

- Internal Baffling and Chamber Design

Internal baffles and strategically designed chambers within the exhaust component are engineered to disrupt sound waves. These features force exhaust gases to pass through complex paths, causing sound waves to collide and cancel each other out. The effectiveness of this design directly influences the overall noise level emitted by the engine. For instance, some designs incorporate multiple chambers of varying sizes to target a broader range of frequencies, resulting in a quieter operation.

- Material Composition and Density

The material from which the exhaust component is constructed significantly impacts its ability to dampen sound. Denser materials, such as heavier gauge steel, tend to be more effective at absorbing and dissipating sound energy compared to thinner, lighter materials. Some designs incorporate sound-absorbing materials, like fiberglass packing, within the component to further reduce noise levels.

- Exhaust Flow Restriction Considerations

While noise reduction is vital, it is often achieved by restricting exhaust flow. Excessive restriction can negatively impact engine performance, reducing horsepower and torque. Balancing noise reduction with maintaining adequate exhaust flow is a critical design consideration. Performance-oriented options often prioritize exhaust flow over maximum noise reduction, while stock mufflers typically prioritize noise suppression.

- Regulatory Compliance and Noise Standards

Many jurisdictions have noise level regulations that small engines must adhere to. The exhaust component plays a crucial role in ensuring compliance with these standards. Manufacturers often design and test components to meet specific noise level requirements, as measured in decibels (dB). Failure to comply with these regulations can result in fines or restrictions on engine usage.

In conclusion, noise reduction in Predator 212 engines is intricately linked to the design, materials, and construction of its exhaust components. Balancing noise suppression with performance requirements is a constant challenge, influencing the choice of materials, internal baffling configurations, and overall system design to meet both user expectations and regulatory mandates.

2. Exhaust Flow

Exhaust flow, the movement of combustion byproducts away from the engine’s cylinder, is a critical performance parameter intrinsically linked to the design and function of the Predator 212 muffler. The muffler acts as a gatekeeper, influencing the rate and efficiency of exhaust expulsion. Restriction in the muffler design directly impedes exhaust flow, leading to increased backpressure within the cylinder. This backpressure reduces the engine’s ability to efficiently expel spent gases, diminishing its capacity to draw in a fresh air-fuel mixture. Consequently, a restricted muffler hinders the engine’s volumetric efficiency and overall power output. Conversely, a muffler designed to facilitate unrestricted exhaust flow minimizes backpressure, promoting efficient scavenging of the cylinder and optimizing the engine’s power potential.

The internal structure of the muffler dictates its impact on exhaust flow. Stock mufflers, often prioritizing noise reduction, typically incorporate intricate baffling and restrictive passages. This design effectively suppresses noise but can significantly impede exhaust flow, reducing horsepower and throttle response. Aftermarket performance mufflers, on the other hand, are engineered with larger diameter passages, fewer baffles, or even straight-through designs to maximize exhaust flow. While these performance options often result in increased noise levels, they can unlock substantial gains in engine power, particularly in modified engines with performance-enhancing components like upgraded carburetors or camshafts. An example is the use of header systems coupled with free-flowing mufflers on racing karts utilizing the Predator 212 engine, demonstrating a direct correlation between improved exhaust flow and increased lap times.

Therefore, selecting the appropriate muffler for a Predator 212 engine requires careful consideration of the intended application and desired performance characteristics. A muffler designed solely for noise reduction may be suitable for recreational use, where minimizing disturbance is paramount. However, for applications where maximizing power output is the primary objective, a performance-oriented muffler that prioritizes exhaust flow is essential. Challenges lie in finding a balance between acceptable noise levels and optimal engine performance. Understanding the relationship between muffler design and exhaust flow is crucial for achieving the desired engine characteristics, ensuring efficient operation, and maximizing the Predator 212’s potential.

3. Durability

The durability of the exhaust component significantly affects the operational lifespan and overall value of the Predator 212 engine. This aspect encompasses the muffler’s resistance to physical damage, corrosion, and degradation under prolonged use and varying environmental conditions. Inferior materials or construction techniques invariably lead to premature failure, necessitating frequent replacements and increased maintenance costs. A robust muffler, conversely, withstands the rigors of continuous engine operation, extending its service life and minimizing downtime. Instances of thin-walled mufflers cracking under thermal stress or corroding rapidly due to exposure to moisture and exhaust gases are common indicators of inadequate durability. Selection of high-quality materials and meticulous manufacturing processes are essential for ensuring longevity.

The primary causes of muffler degradation include thermal cycling, vibration, and exposure to corrosive elements. Repeated heating and cooling cycles induce stress within the metal, potentially leading to fatigue cracking, particularly at welds or stress concentration points. Vibrations from engine operation exacerbate these stresses. Furthermore, exhaust gases contain corrosive compounds, such as sulfur dioxide and water vapor, which attack the metal, leading to rust and weakening of the structure. Some manufacturers employ coatings or specialized alloys to mitigate these effects. Examples include ceramic coatings that provide a thermal barrier and stainless steel alloys that offer superior corrosion resistance.

The practical significance of a durable muffler extends beyond simple replacement costs. A failing muffler can compromise engine performance, increase noise levels, and potentially pose safety hazards due to exhaust leaks. Ensuring the muffler’s longevity contributes to reliable engine operation, reduces environmental impact through minimized emissions, and safeguards the operator from potential harm. Therefore, durability is a critical consideration when selecting a muffler for the Predator 212, balancing initial cost with long-term performance and reliability.

4. Installation

Proper installation of the muffler is crucial to the performance, safety, and longevity of the Predator 212 engine. An incorrectly installed muffler can lead to exhaust leaks, reduced engine power, increased noise levels, and potential damage to the engine itself. The muffler’s secure attachment to the engine block’s exhaust port ensures a gas-tight seal, directing exhaust gases away from the operator and allowing the engine to function as designed. This process necessitates careful attention to torque specifications, gasket placement, and thread engagement. For example, overtightening mounting bolts can strip threads in the engine block, requiring costly repairs. Undertightening allows exhaust gases to escape, creating a noisy and potentially dangerous environment.

Installation procedures typically involve removing the existing muffler (if applicable), cleaning the exhaust port surface, installing a new gasket (if required), aligning the new muffler, and tightening the mounting bolts to the manufacturer’s specified torque. The correct gasket type is paramount; using the wrong gasket can result in exhaust leaks even if the bolts are properly torqued. Additionally, ensuring proper thread engagement is essential to prevent stripping. Some installations may require heat shields or other protective components to prevent burns or damage to nearby parts. A real-world example includes instances where individuals neglect to replace a damaged gasket, resulting in significant power loss and excessive noise, necessitating a complete re-installation with the correct components.

In summary, a correctly executed muffler installation is not merely an assembly task, but a critical step in ensuring the Predator 212 engine operates efficiently and safely. Attention to detail, adherence to torque specifications, and the use of correct components are paramount. The challenges often encountered during installation highlight the need for clear instructions and the proper tools. Understanding the direct link between installation quality and engine performance underscores the practical significance of this often-overlooked aspect of engine maintenance.

5. Compatibility

Compatibility, in the context of the Predator 212 muffler, refers to the ability of a specific muffler model to correctly and effectively integrate with the Predator 212 engine. This encompasses physical fitment, functional performance, and adherence to intended operational parameters. Improper compatibility leads to performance degradation, potential engine damage, and safety risks. The following facets explore key elements that define compatibility within this context.

- Mounting Interface

The mounting interface defines the physical connection between the muffler and the engine’s exhaust port. Compatibility here involves precise alignment of bolt holes, correct thread size and pitch, and proper gasket sealing surface. Incompatible mounting interfaces prevent secure attachment, leading to exhaust leaks, vibration-induced failures, and compromised engine performance. Examples include mufflers designed for different engine models being mistakenly installed on a Predator 212, resulting in improper sealing and exhaust backpressure issues.

- Exhaust Port Diameter

The exhaust port diameter of the muffler must correspond to the diameter of the Predator 212 engine’s exhaust port. A mismatch in diameters creates flow restrictions or turbulence, hindering efficient exhaust expulsion and potentially overheating the engine. Real-world scenarios include using a muffler with a significantly smaller diameter port, leading to increased backpressure and reduced horsepower output.

- Engine Configuration (Stock vs. Modified)

Muffler compatibility is influenced by the engine’s configuration. Stock engines typically require mufflers designed for specific backpressure characteristics, whereas modified engines may necessitate high-flow mufflers to accommodate increased exhaust volume. A muffler designed for a stock engine installed on a heavily modified engine might create excessive backpressure, negating the benefits of other performance upgrades.

- Clearance and Fitment within Chassis

Compatibility extends beyond the engine itself to the surrounding chassis or vehicle frame. The muffler must physically fit within the available space without interfering with other components, such as fuel tanks, wiring harnesses, or body panels. Lack of clearance can lead to vibration-induced damage, overheating, and potential fire hazards. Examples include installing oversized mufflers on go-karts, which then rub against the tires or chassis, creating safety concerns.

These facets highlight the multi-dimensional nature of compatibility concerning the Predator 212 muffler. Correct compatibility ensures optimal engine performance, safety, and longevity. Deviations from these parameters inevitably lead to compromised operation and potential engine damage, reinforcing the importance of selecting a muffler specifically designed and validated for use with the Predator 212 engine and its intended application.

Frequently Asked Questions

This section addresses common inquiries regarding the exhaust component for the Predator 212 engine, offering concise and fact-based answers to promote understanding and informed decision-making.

Question 1: What constitutes an acceptable noise level for a Predator 212 engine equipped with an aftermarket exhaust component?

Acceptable noise levels are determined by local ordinances and regulations. Consult local authorities for specific decibel (dB) limits in the operating area. Aftermarket components should be selected to comply with these regulations.

Question 2: How does the selection of an incorrect exhaust component affect Predator 212 engine performance?

An incorrectly matched component creates excessive backpressure or inadequate exhaust scavenging, reducing horsepower, torque, and fuel efficiency. Damage to engine components can result from prolonged operation with an improperly matched exhaust system.

Question 3: Is regular maintenance of the Predator 212 exhaust system essential?

Periodic inspection for corrosion, leaks, and damage is essential. Loose bolts and deteriorated gaskets compromise performance and safety. Timely replacement of worn components prevents further engine damage and ensures compliance with noise regulations.

Question 4: What are the implications of removing the exhaust component from a Predator 212 engine?

Removal results in significantly increased noise levels, exceeding most legal limits. It also exposes the operator to hot exhaust gases and potential engine damage due to lack of backpressure. Such a modification is generally not recommended.

Question 5: How does altitude influence exhaust component selection for the Predator 212 engine?

At higher altitudes, reduced air density impacts engine performance. Adjustments to carburetor settings may be necessary, potentially requiring a different exhaust component to optimize exhaust flow and maintain power output.

Question 6: What is the recommended torque specification for exhaust component mounting bolts on a Predator 212 engine?

Torque specifications vary depending on the specific engine and component model. Consult the engine manufacturer’s documentation or a qualified technician for precise torque values to prevent damage to threads and ensure a secure seal.

These responses underscore the importance of proper exhaust system management for the Predator 212 engine. A proactive approach to selection, installation, and maintenance ensures optimal performance, safety, and compliance.

The following section explores advanced troubleshooting techniques for common Predator 212 engine issues.

Conclusion

This exploration has elucidated the multifaceted significance of the “predator 212 muffler.” From noise reduction and exhaust flow optimization to durability, proper installation, and compatibility, each attribute contributes to the efficient, safe, and regulation-compliant operation of the Predator 212 engine. The correct selection, meticulous installation, and conscientious maintenance of this crucial component are not merely procedural steps, but rather, essential practices that directly impact engine performance and longevity.

Given the critical role the Predator 212 muffler plays, understanding its function and proper management is paramount. Further research into specific applications, advanced performance modifications, and evolving regulatory standards is encouraged to ensure continued optimal utilization of the Predator 212 engine. Prioritizing knowledge and responsible practices will safeguard engine integrity, enhance operational safety, and promote adherence to environmental standards.