An exhaust system component designed to reduce noise utilizes a circular housing containing a series of internal baffles or chambers. These chambers redirect and attenuate sound waves generated by the engine’s combustion process, effectively diminishing the overall noise level emitted from the vehicle. This particular type of noise reduction device is commonly found in automotive applications, ranging from passenger cars to light trucks, where a balance between performance and noise mitigation is desired.

The utilization of such a component offers several advantages. Primarily, it contributes to compliance with noise regulations and improves the overall driving experience by reducing unwanted auditory disturbances. Historically, the design has evolved to optimize the trade-off between noise reduction and exhaust flow, aiming to minimize backpressure and maintain engine efficiency. Its relative simplicity and cost-effectiveness have made it a prevalent choice in original equipment manufacturing and aftermarket exhaust systems.

The following sections will delve into the specific design characteristics, performance metrics, material considerations, and installation procedures associated with this type of exhaust component, providing a detailed understanding of its function and application within the broader context of automotive exhaust systems.

Tips for Maintaining and Optimizing an Exhaust Noise Reduction Device

The following recommendations aim to provide insights into the upkeep and performance enhancement of a specific component found within automotive exhaust systems. Adherence to these guidelines can extend the lifespan and maintain the effectiveness of this device.

Tip 1: Routine Inspection is Crucial: Regular visual checks for corrosion, leaks, or physical damage are paramount. Early detection of deterioration can prevent more extensive and costly repairs. Particular attention should be paid to weld points and areas exposed to road salt or other corrosive agents.

Tip 2: Address Exhaust Leaks Promptly: Any exhaust leak, regardless of size, can compromise the device’s ability to effectively mitigate noise. Furthermore, exhaust leaks can introduce harmful gases into the vehicle’s cabin. Repair or replacement should be undertaken immediately upon detection.

Tip 3: Consider Material Upgrades for Longevity: When replacement becomes necessary, exploring options with enhanced corrosion resistance, such as stainless steel, can significantly extend the component’s service life, particularly in regions with harsh climates.

Tip 4: Proper Installation is Essential: Ensure correct alignment and secure mounting during installation. Improper installation can introduce stress points, leading to premature failure and reduced performance. Use appropriate hardware and torque specifications.

Tip 5: Monitor Engine Performance: Changes in engine performance, such as reduced power or fuel economy, may indicate a blockage or internal damage within the device, even if external signs are not immediately apparent. A professional diagnostic assessment is advisable.

Tip 6: Regular Cleaning can Help: Debris and road grime can accumulate on the exterior surface, potentially accelerating corrosion. Periodic cleaning with appropriate cleaning agents can help maintain its structural integrity.

Consistent application of these tips will contribute to the prolonged functionality and optimal performance of this crucial exhaust system component, ensuring compliance with noise regulations and a more pleasant driving experience.

The subsequent sections will cover advanced troubleshooting techniques and performance modifications related to this device, offering a deeper understanding of its capabilities and limitations.

1. Noise Reduction

The primary function of a chambered exhaust component is noise reduction. Engine combustion generates high-amplitude sound waves that propagate through the exhaust system. A device employing internal chambers is specifically engineered to attenuate these waves before they exit the vehicle. The design redirects the sound waves through a series of strategically placed baffles, causing them to reflect and interfere with each other. This interference, both constructive and destructive, alters the frequency and amplitude of the sound, resulting in a lower overall noise level. Without such a device, the unmodified exhaust noise would exceed acceptable limits, potentially violating local regulations and contributing to environmental noise pollution.

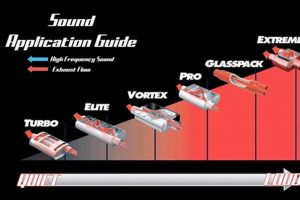

The degree of noise reduction achieved is directly influenced by the internal configuration of the chambers. Factors such as chamber volume, baffle shape, and the number of chambers significantly impact the effectiveness of sound wave attenuation. For instance, a system with a larger chamber volume and a greater number of baffles will generally provide more effective noise reduction than one with a smaller volume and fewer baffles. However, increasing the complexity of the chamber design can also increase backpressure within the exhaust system, potentially impacting engine performance. Consequently, optimizing the chamber design requires a careful balance between noise reduction and exhaust flow.

In summary, noise reduction is the core purpose of an exhaust component incorporating chambers. Its effectiveness is determined by the device’s internal design, which aims to attenuate sound waves through interference. Achieving optimal noise reduction necessitates a trade-off with exhaust flow considerations to minimize any adverse effects on engine performance, highlighting the critical engineering challenges in designing such systems.

2. Flow Restriction

The presence of internal chambers and baffles within an exhaust component invariably introduces flow restriction. This restriction stems from the redirection and impedance of exhaust gases as they traverse the internal pathways of the device. The greater the complexity and number of chambers, the higher the level of flow restriction generally becomes. This phenomenon is not merely a theoretical concern; it directly impacts engine performance, as increased backpressure can hinder the efficient expulsion of exhaust gases from the engine cylinders. A poorly designed or excessively restrictive device can lead to reduced horsepower, diminished fuel economy, and potentially increased engine wear due to elevated operating temperatures. For instance, a chambered system optimized primarily for maximum noise reduction, without adequate consideration for flow dynamics, could significantly stifle engine output in a high-performance application.

The magnitude of flow restriction varies depending on the specific design parameters of the component. Some designs incorporate larger chamber volumes and strategically placed perforations to minimize backpressure while still achieving adequate noise reduction. Others utilize smoother internal surfaces and carefully engineered baffle shapes to promote laminar flow and reduce turbulence, thereby minimizing flow resistance. Real-world examples demonstrate this variability: a mass-produced exhaust component designed for a fuel-efficient passenger vehicle will typically exhibit higher flow restriction than a performance-oriented aftermarket device intended for a sports car. This difference reflects the varying priorities of noise reduction versus performance enhancement in different vehicle categories.

In conclusion, flow restriction is an inherent characteristic of chambered exhaust systems and represents a critical design consideration. Understanding the trade-offs between noise reduction and flow restriction is paramount for engineers and vehicle owners alike. Balancing these competing demands requires careful optimization of chamber geometry, baffle design, and material selection to ensure that the component effectively mitigates noise without unduly compromising engine performance. Addressing the challenges of flow restriction is integral to maximizing the overall efficiency and longevity of both the exhaust system and the engine it serves.

3. Chamber Design

Chamber design is a defining characteristic that dictates the performance and acoustic properties of a cylindrical exhaust component. The arrangement, size, and internal geometry of the chambers directly influence its ability to reduce noise and manage exhaust flow. A thorough understanding of these design elements is critical for optimizing the effectiveness of this type of component.

- Baffle Configuration

The arrangement of baffles within the cylindrical housing is fundamental to its function. Baffles redirect sound waves, causing destructive interference that diminishes noise. Different configurations, such as straight-through, offset, or perforated baffles, yield varying degrees of noise reduction and flow restriction. For instance, a straight-through design with perforations offers minimal flow restriction but less noise reduction compared to an offset baffle system, which creates more significant sound wave interference but also increases backpressure.

- Chamber Volume and Shape

The volume and shape of individual chambers are key parameters influencing sound attenuation. Larger chamber volumes generally allow for lower frequency sound waves to be effectively dampened, whereas smaller chambers are more effective at attenuating higher frequencies. The shape of the chamber, whether cylindrical, elliptical, or irregular, affects the reflection and diffusion of sound waves. A carefully designed combination of chamber volumes and shapes can achieve a broad spectrum of noise reduction across the engine’s operating range.

- Internal Passage Geometry

The geometry of the internal passages connecting the chambers influences the flow of exhaust gases. Smooth, gradual transitions between chambers minimize turbulence and reduce backpressure. Sharp angles and constrictions create turbulence, increasing flow restriction and potentially impacting engine performance. The design of these passages must balance the need for efficient exhaust flow with the requirement to redirect sound waves for effective noise reduction. Examples include the use of converging-diverging nozzles to manage gas velocity and the incorporation of Helmholtz resonators to target specific frequencies.

- Resonance Tuning

The design can be tuned to exploit acoustic resonance principles. By carefully selecting chamber dimensions and passage lengths, specific frequencies can be amplified or dampened. This tuning can be used to target undesirable frequencies, such as engine drone, while minimizing the impact on other frequencies. For example, a quarter-wave resonator can be integrated into the chamber design to cancel out a specific frequency associated with engine operation at a particular RPM.

The aforementioned facets of chamber design are integral to optimizing the performance of a cylindrical exhaust component. The interplay between baffle configuration, chamber volume and shape, internal passage geometry, and resonance tuning determines the device’s effectiveness in reducing noise and managing exhaust flow. Effective design requires a holistic approach that balances these competing demands to achieve optimal performance characteristics for the intended application.

4. Material Selection

The selection of materials is paramount in the design and functionality of an exhaust component with a cylindrical housing containing internal chambers. The harsh operating environment, characterized by high temperatures, corrosive exhaust gases, and exposure to road debris, necessitates careful consideration of material properties. The choice directly influences the component’s lifespan, performance, and overall reliability. For example, using low-grade steel in a region with significant road salting during winter will invariably lead to rapid corrosion and premature failure. Conversely, employing high-grade stainless steel, while more expensive, offers superior corrosion resistance and extends the component’s service life considerably.

Several materials are commonly employed in the construction of such components, each possessing distinct advantages and disadvantages. Aluminized steel provides a cost-effective balance of corrosion resistance and heat tolerance, making it a prevalent choice in original equipment manufacturing. Stainless steel, particularly grades like 304 and 409, offers superior resistance to corrosion and oxidation, extending the component’s lifespan in demanding environments. Titanium, although less common due to its higher cost, provides exceptional strength-to-weight ratio and corrosion resistance, making it suitable for high-performance applications. The selection process also considers the welding characteristics of the chosen material, as robust and durable welds are essential for structural integrity. For instance, exhaust systems intended for off-road vehicles often utilize thicker gauge stainless steel and reinforced welding techniques to withstand the rigors of harsh terrain and potential impacts. The effect of material selection is a cascade of consequences on the component’s durability and performance.

In conclusion, material selection for an exhaust noise reduction device is a critical engineering decision with far-reaching implications. The interplay between cost, corrosion resistance, heat tolerance, and structural integrity must be carefully evaluated to ensure the component meets the demands of its intended application. A well-informed material selection strategy results in a more durable, reliable, and cost-effective exhaust system. Ignoring this aspect can lead to premature failure, increased maintenance costs, and compromised vehicle performance, underscoring the practical significance of a thorough understanding of material properties in the design and manufacturing of these components.

5. Installation Geometry

The correct positioning and orientation of a cylindrical exhaust component, referred to as installation geometry, is a crucial factor affecting its performance and longevity within the exhaust system. Installation geometry encompasses the angles of connection to adjacent exhaust piping, the overall alignment relative to the vehicle chassis, and the support mechanisms used to secure the device. Improper installation geometry can introduce undue stress on the component’s welds and body, leading to premature failure due to fatigue or corrosion. For instance, if the component is installed with excessive bending stress, vibrations from the engine and road conditions will concentrate stress at weld points, accelerating crack formation and ultimately resulting in exhaust leaks. Similarly, misalignment can induce strain on the connection points, causing distortion and potential separation.

The correct installation geometry ensures that the cylindrical device is supported adequately, preventing excessive movement and vibration. Mounting brackets should be positioned to distribute the weight of the component evenly and dampen vibrations transmitted from the engine and chassis. The use of flexible hangers or rubber isolators can further minimize the transmission of vibrations, extending the lifespan of both the device and the surrounding exhaust components. Practical examples include the use of adjustable hangers to accommodate variations in vehicle chassis design and the implementation of heat shields to protect the component from excessive thermal stress. An understanding of installation geometry also includes ensuring sufficient clearance between the component and other vehicle components, preventing heat transfer and potential damage. A real-world scenario includes installing an exhaust system on a lowered vehicle. In such cases, additional considerations are given to ground clearance, as the exhaust system may be more prone to damage when driving over speed bumps or uneven road surfaces.

In summary, installation geometry plays a critical role in maximizing the performance and durability of a cylindrical, chambered exhaust component. Proper alignment, support, and clearance are essential for preventing stress, minimizing vibration, and ensuring optimal operating conditions. Careful attention to installation geometry not only extends the component’s lifespan but also contributes to overall vehicle reliability and performance. Neglecting these considerations can result in premature failure, increased maintenance costs, and potentially compromised vehicle safety.

Frequently Asked Questions

The following questions address common inquiries and misconceptions regarding exhaust system components incorporating a circular housing and internal chambers for noise attenuation. The information provided aims to offer clarity and enhance understanding of these devices.

Question 1: What is the primary function?

The core purpose is to mitigate exhaust noise generated by the engine’s combustion process. Internal chambers and baffles are engineered to redirect and attenuate sound waves, reducing the overall noise level emitted from the vehicle.

Question 2: Does such a device negatively impact engine performance?

The introduction of internal chambers and baffles inevitably creates some level of flow restriction, which can potentially affect engine performance. However, well-designed devices strive to minimize backpressure while still effectively reducing noise. Performance impacts depend on the specific design and application.

Question 3: What materials are typically used in construction?

Common materials include aluminized steel, stainless steel (various grades), and, in some high-performance applications, titanium. The choice of material depends on factors such as cost, corrosion resistance requirements, and operating temperatures.

Question 4: How does chamber design influence performance?

The size, shape, and configuration of the internal chambers and baffles directly impact noise reduction and flow restriction. Strategic design optimizes sound wave attenuation while minimizing backpressure. Variations in chamber volume and baffle placement target specific noise frequencies.

Question 5: What are the signs of a failing or degraded device?

Common indicators include increased exhaust noise, reduced engine performance (e.g., decreased power or fuel economy), visible corrosion or physical damage, and exhaust leaks. A professional inspection is recommended to accurately diagnose the condition of the component.

Question 6: Is it possible to modify an existing component for improved performance?

Modifying an existing component may offer potential performance gains, but it can also compromise noise reduction and potentially violate noise regulations. Alterations should be undertaken with caution and a thorough understanding of the potential consequences. Consultation with a qualified exhaust system specialist is advisable.

In summary, cylindrical, chambered exhaust components serve a critical role in noise reduction, and their design and material composition significantly impact performance and durability. Regular inspection and maintenance are essential for optimal functionality.

The subsequent sections will explore advanced customization options and delve into specific diagnostic procedures for identifying and resolving common issues associated with these devices.

Round Chambered Muffler

The preceding discussion has illuminated the multifaceted aspects of the round chambered muffler, a critical component in automotive exhaust systems. The examination encompassed its fundamental function in noise reduction, the inherent trade-offs with exhaust flow, the importance of chamber design and material selection, and the influence of installation geometry on performance and longevity. The provided information underscores the complex engineering considerations involved in optimizing these devices for diverse applications.

The pursuit of quieter and more efficient vehicles necessitates a continued focus on advancements in exhaust system technology. Further research and development in materials science, acoustic engineering, and fluid dynamics will be instrumental in refining the design and performance of the round chambered muffler. Understanding these elements ensures informed decision-making regarding vehicle maintenance, modification, and overall environmental responsibility.