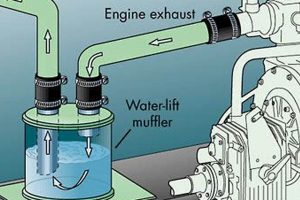

A device used to reduce the noise emitted by an internal combustion engine, specifically tailored and installed by qualified technicians, is critical for vehicle operation. These components, often part of an exhaust system, minimize sound pollution through a series of chambers and baffles that attenuate pressure waves. The installation of such a component, performed by trained specialists, ensures optimal functionality and compliance with noise regulations.

The advantages of employing expert service for exhaust sound reduction extend beyond mere decibel reduction. Proper installation can enhance engine performance and fuel efficiency. Furthermore, these specialized professionals ensure compliance with local and federal emission standards. Historically, these components have evolved from simple noise suppressors to complex systems integrating catalytic converters and sensors, necessitating specialized knowledge for their correct fitting and maintenance.

The subsequent sections will delve into the specific materials used in its construction, the range of services offered by qualified installers, and the criteria for selecting the appropriate system for a particular vehicle and its intended use.

Guidance from Exhaust System Specialists

Effective sound reduction in vehicles requires attention to detail and expert knowledge. The following recommendations, derived from experienced exhaust system installers, are designed to optimize performance and longevity.

Tip 1: Select Components Designed for the Vehicle. Ensuring compatibility is essential. Refer to manufacturer specifications or consult with an expert to avoid performance degradation or system damage. Incompatible parts can lead to increased backpressure, reduced fuel efficiency, and potential engine problems.

Tip 2: Inspect for Damage Prior to Installation. A thorough examination for dents, rust, or structural weaknesses is vital. Installing a compromised component can lead to premature failure and increased noise levels.

Tip 3: Use Appropriate Mounting Hardware. Securing the system with the correct hangers and clamps is critical for preventing vibrations and stress on the exhaust system. Incorrect hardware can lead to premature wear and breakage.

Tip 4: Seal Connections Effectively. Exhaust leaks compromise sound reduction and pose a safety risk. Employ proper gaskets and sealant to ensure a gas-tight seal at all connections.

Tip 5: Address Underlying Engine Issues. Excessive noise may indicate deeper engine problems. Misfires or worn components can contribute to abnormal exhaust sounds. Addressing these issues can improve overall vehicle performance and reduce stress on the exhaust system.

Tip 6: Perform Regular Inspections. Periodic visual checks can identify potential problems before they escalate. Examine the system for rust, leaks, or damaged components.

Adherence to these guidelines ensures optimal performance, reduces noise pollution, and extends the lifespan of the vehicle’s exhaust system. Implementing these steps can contribute to a safer and more enjoyable driving experience.

The article will now proceed to the discussion of materials used in sound-reducing systems and their impact on performance and durability.

1. Precise Installation

Precise installation is paramount for the effective operation of any exhaust sound reduction device. Suboptimal fitting can negate the intended sound-dampening characteristics, compromise vehicle performance, and potentially create safety hazards. The following facets highlight key considerations in this process.

- Optimal Alignment and Positioning

Correct alignment within the exhaust system is crucial. Misalignment can induce stress points, leading to premature component failure and exhaust leaks. Professional installers utilize specialized tools and techniques to ensure the device is positioned according to manufacturer specifications, minimizing vibration and maximizing sound absorption.

- Leak-Proof Sealing

Gas-tight seals at all connection points are imperative. Improper sealing allows exhaust gases to escape, diminishing sound reduction and potentially introducing harmful emissions into the vehicle cabin. Qualified technicians employ appropriate gaskets, sealants, and torque specifications to guarantee a secure and leak-free connection, thereby maintaining system integrity.

- Secure Mounting and Support

Adequate mounting hardware and support are essential to prevent excessive movement and vibration. Insufficient or improperly installed supports can cause the device to detach or develop cracks, resulting in increased noise and potential damage to other exhaust system components. Professionals utilize appropriate hangers and brackets, ensuring the device is securely mounted and able to withstand the stresses of daily driving.

- Compatibility with Vehicle Systems

Integration with existing vehicle systems, such as catalytic converters and oxygen sensors, is critical. Incorrect installation can interfere with these systems, leading to reduced engine performance and increased emissions. Skilled installers possess the knowledge to properly integrate the device without compromising the functionality of other vehicle components.

These facets underscore the importance of entrusting exhaust system modifications to qualified professionals. Precise installation, encompassing alignment, sealing, mounting, and system compatibility, ensures optimal performance, minimizes safety risks, and maximizes the lifespan of the sound-reducing device.

2. Material Selection

Material selection is a foundational element in the creation and performance of an effective exhaust sound reduction device. The properties of the chosen materials directly influence the component’s durability, sound attenuation capabilities, and overall longevity. Professional installers must consider factors such as corrosion resistance, thermal expansion coefficients, and acoustic damping characteristics when recommending and installing systems. For example, a system constructed from aluminized steel offers a cost-effective balance of corrosion resistance and heat tolerance for standard applications. However, in environments with high road salt exposure or for high-performance vehicles, stainless steel provides superior protection and longevity, justifying the increased cost. The installer’s expertise lies in matching material properties to the specific operating conditions and vehicle requirements, thereby mitigating premature failure and ensuring sustained performance.

The internal construction of the device also relies heavily on material selection. The baffles, chambers, and packing material employed to attenuate sound waves must withstand high temperatures and exposure to corrosive exhaust gases. Fiberglass packing, commonly used for its sound-absorbing properties, can degrade over time due to thermal cycling and chemical attack. More advanced materials, such as stainless steel wool or ceramic fibers, offer enhanced durability and performance in demanding applications. Improper material selection within the device can lead to reduced sound attenuation, increased backpressure, and accelerated component degradation. Therefore, a professional assessment of vehicle usage and environmental factors is crucial in determining the optimal materials for both the external housing and internal components.

In summary, material selection is an inextricable component of an exhaust sound reduction device’s performance and lifespan. Expertise in this area allows professionals to balance cost considerations with the need for durability and effective sound attenuation. The challenge lies in adapting material choices to specific vehicle applications and environmental conditions, ensuring long-term reliability and compliance with noise regulations. The subsequent sections will examine the aspects of performance optimization and emission compliance and their relationship to a suitable exhaust system.

3. Performance Optimization

Performance optimization, in the context of exhaust systems, involves achieving a balance between sound reduction, exhaust flow efficiency, and engine power output. A device designed by certified specialists can significantly impact a vehicle’s overall performance characteristics. Alterations or replacements undertaken without proper consideration can inadvertently hinder engine function.

- Backpressure Management

Backpressure, the resistance to exhaust flow, directly influences engine efficiency. An improperly designed component can create excessive backpressure, reducing engine power and fuel economy. Professionals select systems that provide sufficient sound attenuation while minimizing restrictions to exhaust flow, thus optimizing engine performance. This frequently involves matching pipe diameter, chamber design, and baffle configuration to the engine’s specific needs.

- Exhaust Gas Scavenging

Scavenging refers to the efficient removal of exhaust gases from the combustion chamber. A well-designed system can enhance scavenging, promoting a more complete combustion cycle. Qualified technicians consider the exhaust system’s length, diameter, and resonance characteristics to optimize scavenging effects. This can result in increased horsepower and improved throttle response.

- Torque Curve Shaping

The exhaust system’s design can influence the engine’s torque curve, affecting its power delivery across the RPM range. Professional installers can tailor the system to emphasize either low-end torque or high-end horsepower, depending on the vehicle’s intended use. Modifications to the exhaust manifold, catalytic converter, and tailpipe can be employed to achieve the desired torque characteristics.

- Resonance Tuning

Resonance, the amplification of sound waves within the exhaust system, can be harnessed to both reduce noise and improve performance. Professionals can strategically position resonators and chambers to cancel out specific sound frequencies while optimizing exhaust flow. Careful tuning of these resonant frequencies can minimize drone and improve the overall driving experience.

These considerations illustrate the complexities inherent in optimizing an exhaust system for both sound reduction and performance. Professionals possess the knowledge and tools necessary to navigate these trade-offs, ensuring that any modifications enhance rather than hinder the vehicle’s overall capabilities. The subsequent discourse will delve into the crucial role of emission compliance in the selection and installation process.

4. Emission compliance

Emission compliance is inextricably linked to exhaust system components, including sound-reducing devices. Government regulations mandate specific emission standards for vehicles, and any alteration to the exhaust system must not compromise its ability to meet those standards. Sound-reducing devices are integrated into the exhaust system, which also houses catalytic converters, oxygen sensors, and other emission control components. Incorrect installation or the use of non-compliant parts can result in increased emissions, potentially leading to legal penalties and vehicle failure during inspection.

The professional installation of a sound-reducing device necessitates careful consideration of its impact on the vehicle’s emission control systems. For example, if the alteration increases backpressure significantly, it can negatively affect the catalytic converter’s efficiency, resulting in elevated levels of hydrocarbons, carbon monoxide, and nitrogen oxides in the exhaust. Experienced technicians understand these potential consequences and ensure that any modifications maintain the required emission control functionality. They select components that are certified to meet or exceed emission standards and employ installation techniques that avoid disrupting the operation of other emission-related devices. For instance, aftermarket systems often incorporate oxygen sensor bungs in the correct locations to maintain feedback to the engine control unit, preventing incorrect fuel trim and subsequent emission increases.

In conclusion, emission compliance is not merely an ancillary consideration but rather an integral aspect of professional exhaust system service. A failure to uphold emission standards can lead to environmental damage, regulatory penalties, and diminished vehicle performance. A competent technician understands the interconnectedness of the exhaust system’s components and takes proactive steps to ensure that any modifications adhere to applicable regulations, contributing to both environmental responsibility and vehicle longevity.

5. Diagnostic Expertise

Diagnostic expertise is a critical component of professional exhaust system service, playing a pivotal role in identifying and resolving issues related to sound reduction and overall system performance. Accurate diagnosis ensures that repairs are targeted and effective, preventing unnecessary replacements and minimizing vehicle downtime.

- Acoustic Signature Analysis

This involves interpreting the sounds emanating from the exhaust system to pinpoint the source of noise irregularities. Experienced technicians can differentiate between normal exhaust sounds and indicators of problems such as leaks, damaged baffles, or catalytic converter failure. For example, a hissing sound often signifies an exhaust leak, while a rattling noise may indicate a detached internal component. Correct interpretation of these acoustic signatures allows for targeted repairs and prevents misdiagnosis.

- Exhaust Pressure Testing

Monitoring exhaust backpressure provides insights into the system’s overall health. Elevated backpressure can indicate a clogged muffler, a collapsed pipe, or a restricted catalytic converter. A technician uses a pressure gauge to measure backpressure at various points in the system, comparing the readings against manufacturer specifications. Deviations from the norm can point to specific areas requiring attention, ensuring that sound reduction efforts do not compromise engine performance.

- Visual Inspection and Component Assessment

A thorough visual examination of the exhaust system can reveal physical damage, corrosion, or improper installation. Technicians assess the condition of mufflers, pipes, hangers, and clamps, identifying potential failure points before they lead to significant problems. Rust, cracks, or loose connections can be indicators of underlying issues affecting sound attenuation and exhaust flow. Addressing these physical deficiencies proactively extends the system’s lifespan and maintains optimal performance.

- Emissions Monitoring and Diagnostic Code Interpretation

Modern vehicles incorporate sensors that monitor exhaust gas composition and trigger diagnostic codes when emissions exceed acceptable levels. Technicians use diagnostic scan tools to retrieve these codes and interpret them in relation to potential exhaust system malfunctions. For instance, a P0420 code indicates a catalytic converter inefficiency, which may be related to a faulty muffler design or exhaust leaks. Integration of emissions data with other diagnostic findings provides a comprehensive understanding of the vehicle’s exhaust system performance.

The facets of diagnostic expertise detailed above enable professionals to accurately assess the condition of sound-reducing devices and their impact on the overall exhaust system and engine operation. This comprehensive approach ensures that repairs are targeted, effective, and aligned with the vehicle’s performance and emissions requirements, ultimately enhancing the reliability and longevity of the system.

Frequently Asked Questions Regarding Professional Muffler Services

The following addresses prevalent inquiries concerning the selection, installation, and maintenance of devices intended for exhaust sound reduction, commonly referred to as mufflers, by qualified automotive professionals.

Question 1: What constitutes a ‘professional muffler’ installation?

A professional installation entails adherence to manufacturer specifications, gas-tight sealing of all connections, secure mounting to prevent vibration, and verification of compatibility with existing vehicle emission control systems.

Question 2: How does the selection of materials impact the longevity of a muffler?

Material composition directly affects resistance to corrosion and thermal stress. Stainless steel typically offers superior durability compared to aluminized steel, particularly in regions with high road salt usage. The selection must align with the vehicle’s operational environment.

Question 3: Can modifications to a muffler system negatively impact engine performance?

Improperly designed or installed systems can create excessive backpressure, thereby reducing engine power and fuel efficiency. A professional ensures that the selected component minimizes restriction to exhaust flow while achieving desired sound attenuation.

Question 4: What role does emission compliance play in muffler selection?

Replacement or modification of a muffler must not compromise the vehicle’s ability to meet emissions standards. Non-compliant components can lead to increased emissions, legal penalties, and potential vehicle inspection failure. Adherence to regulations is paramount.

Question 5: How frequently should a muffler be inspected for potential issues?

Periodic visual inspections, ideally during routine vehicle maintenance, are recommended. Attention should be given to signs of rust, leaks, or physical damage. Early detection of problems can prevent more extensive and costly repairs.

Question 6: What diagnostic procedures are employed to assess the health of a muffler system?

Diagnostic methods include acoustic signature analysis to identify noise irregularities, exhaust pressure testing to detect restrictions, visual inspection for physical damage, and interpretation of emissions diagnostic codes to assess catalytic converter performance.

In summary, the selection, installation, and maintenance of a professional muffler system require specialized knowledge and adherence to established standards. Proper execution ensures optimal sound reduction, vehicle performance, emission compliance, and long-term reliability.

The subsequent section will explore case studies illustrating the benefits of professional muffler services and the potential consequences of neglecting proper maintenance.

Conclusion

This exploration has underscored the multifaceted nature of sound reduction components for vehicle exhaust systems. From material selection and precise installation to performance optimization, diagnostic expertise, and adherence to emission compliance standards, the application of specialized knowledge by qualified technicians is crucial. A “professional muffler” service, therefore, extends beyond mere component replacement; it encompasses a holistic approach to ensure optimal functionality, longevity, and regulatory adherence.

Neglecting the expertise associated with exhaust sound reduction can result in compromised engine performance, increased emissions, and costly repairs. The long-term benefits of employing a qualified professional demonstrably outweigh the perceived cost savings of less informed alternatives, contributing to both environmental responsibility and sustained vehicle value. Prioritizing professional service ensures the continued integrity of the vehicle and adherence to noise and emission regulations.