An exhaust component configuration featuring a single outlet is a common design in automotive engineering. This setup channels exhaust gases from the engine through a system that culminates in one tailpipe. Vehicles employing this design often prioritize simplicity and cost-effectiveness in their exhaust systems. A compact car, for example, might utilize this configuration to manage emissions and noise levels efficiently.

This design offers certain advantages, including reduced manufacturing complexity and potentially lower weight compared to systems with multiple outlets. Historically, it has been prevalent in smaller vehicles and those where performance enhancement via exhaust modifications is not a primary concern. Its ubiquity stems from its balance of functionality and affordability, making it a practical choice for mass-produced automobiles.

The subsequent sections will delve into the specific considerations for selecting the appropriate component, discussing factors such as material choice, sound characteristics, and flow dynamics. Furthermore, installation procedures and maintenance recommendations will be addressed to ensure optimal performance and longevity.

Optimizing Performance

The following guidelines offer valuable insights for achieving optimal functionality and longevity from a system designed with a singular exhaust outlet.

Tip 1: Material Selection: Consider corrosion resistance. Stainless steel, for instance, provides enhanced durability in environments exposed to road salt and moisture, extending the service life of the component.

Tip 2: Diameter Considerations: The exhaust pipe diameter should be appropriately sized for the engine’s displacement and power output. An undersized diameter can restrict exhaust flow, impacting performance negatively.

Tip 3: Sound Attenuation: Evaluate the internal baffling design. Different configurations can significantly affect the exhaust note, allowing for customization of the vehicle’s sound characteristics.

Tip 4: Installation Precision: Ensure proper alignment and secure mounting. Misalignment can induce stress on the exhaust system, leading to premature failure.

Tip 5: Regular Inspections: Conduct periodic visual inspections for signs of damage, such as rust, cracks, or loose connections. Addressing these issues promptly can prevent more extensive repairs.

Tip 6: Consider Aftermarket Options: For certain applications, aftermarket components with optimized flow characteristics may offer performance improvements compared to stock designs.

Tip 7: Welding Quality: Examine the weld integrity, particularly in fabricated systems. Weak or improperly executed welds are prone to failure under thermal stress and vibration.

Adhering to these principles helps to ensure reliable operation, prolong component lifespan, and optimize the overall performance characteristics of the exhaust system.

The subsequent sections will address troubleshooting common issues and provide guidance on selecting a qualified technician for more complex repairs.

1. Efficiency

In the context of an exhaust system with a singular outlet, efficiency relates to the effectiveness with which exhaust gases are expelled from the engine. A highly efficient system minimizes restrictions, allowing for a more complete combustion cycle and improved engine performance. Reduced backpressure is a primary indicator of this efficiency. For instance, a properly designed component with a singular exit can facilitate better scavenging of exhaust gases from the cylinders, leading to a more powerful and responsive engine.

The internal design of the component is critical to achieving optimal efficiency. Straight-through designs, or those with minimal bends and obstructions, promote smoother exhaust flow. Conversely, complex baffling or restrictive passages can impede flow, increasing backpressure and diminishing engine performance. In practical applications, this translates to improved fuel economy and potentially increased horsepower and torque, particularly in performance-oriented vehicles. Selecting an appropriate size and design is thus essential.

In conclusion, the connection between efficiency and this exhaust system configuration centers on minimizing restrictions to exhaust flow. This translates into tangible benefits such as improved engine performance and fuel economy. While the single exit design is inherently simple, careful attention to internal design and system optimization is necessary to maximize its efficiency potential. Overlooking these factors can lead to compromised performance and negated advantages.

2. Backpressure

Backpressure, a critical consideration in exhaust system design, refers to the resistance encountered by exhaust gases as they flow through the system. Its relationship to an exhaust component featuring a singular outlet is significant, influencing engine performance, fuel efficiency, and component longevity. An understanding of backpressure dynamics is crucial for optimizing the overall effectiveness of this exhaust configuration.

- Factors Influencing Backpressure

Several design elements contribute to backpressure levels within a single-outlet system. These include the pipe diameter, the presence and nature of bends, and the internal structure of the muffler itself. Smaller diameter pipes, sharp bends, and restrictive muffler designs inherently increase backpressure. The cumulative effect of these factors determines the overall restriction imposed on the engine’s exhaust flow.

- Impact on Engine Performance

Excessive backpressure can impede the engine’s ability to effectively expel exhaust gases, leading to reduced volumetric efficiency. This can manifest as diminished horsepower and torque, particularly at higher RPMs. Conversely, insufficient backpressure can also be detrimental, leading to reduced low-end torque in some engine designs. The optimal level of backpressure is therefore dependent on the specific engine characteristics and intended application.

- Design Considerations for Minimizing Backpressure

To mitigate the negative effects of excessive backpressure, various design strategies can be employed. Larger diameter piping, mandrel bends (smoothly curved pipes), and straight-through muffler designs are commonly used to minimize flow restriction. The selection of appropriate components and their arrangement within the exhaust system is paramount in achieving the desired backpressure characteristics.

- Consequences of Incorrect Backpressure Management

Failure to properly manage backpressure can result in a range of adverse consequences. Increased fuel consumption, reduced engine lifespan, and elevated emissions are all potential outcomes. Moreover, excessive backpressure can lead to overheating and potential damage to other engine components. Regular monitoring and maintenance of the exhaust system are essential for detecting and addressing backpressure-related issues.

In summary, backpressure is a key parameter in the design and function of exhaust systems with single outlets. Careful consideration of design factors, coupled with regular inspection and maintenance, is essential for optimizing engine performance, ensuring longevity, and minimizing environmental impact. Ignoring the principles of backpressure management can lead to significant compromises in vehicle performance and reliability.

3. Sound Control

Sound control is a significant function of any exhaust system, directly affecting vehicle noise levels and driver/passenger comfort. In designs incorporating a single outlet, the muffler plays a pivotal role in achieving desired sound characteristics. The design and construction of this component dictate the level of noise reduction achieved.

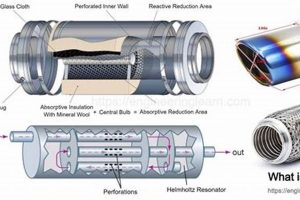

- Muffler Design and Sound Attenuation

The internal configuration of the muffler directly determines its sound attenuation capabilities. Baffled designs, absorption designs (using fiberglass or other sound-deadening materials), and resonator-equipped mufflers each offer distinct sound control properties. Baffled designs redirect sound waves, causing them to cancel each other out. Absorption designs convert sound energy into heat. Resonators target specific frequencies to eliminate drone. The selection of a particular muffler design depends on the desired balance between noise reduction and exhaust flow.

- Material Selection and Sound Characteristics

The materials used in the construction of the muffler also influence the sound produced. Stainless steel, for example, tends to produce a brighter, more resonant sound compared to aluminized steel. The thickness of the metal also affects sound characteristics, with thicker materials generally resulting in a deeper, more subdued tone. Material selection, therefore, is a crucial aspect of tailoring the exhaust sound to specific preferences.

- Resonator Integration for Drone Reduction

Droning, a low-frequency resonant sound often experienced at certain engine speeds, can be particularly noticeable in single-outlet exhaust systems. Resonators, strategically placed along the exhaust path, are designed to counteract these specific frequencies. They function by creating destructive interference, effectively canceling out the droning sound. The effectiveness of a resonator depends on its size, shape, and placement within the exhaust system.

- Regulatory Compliance and Noise Limits

Vehicle noise emissions are subject to regulatory limits in many jurisdictions. Exhaust systems must comply with these regulations to be legally operated on public roads. Single-outlet systems, in particular, must be carefully designed to meet these requirements. Sound control strategies, such as the use of effective mufflers and resonators, are essential for ensuring compliance with noise regulations.

The effectiveness of sound control measures in a system with a single exit depends on the combined effect of muffler design, material selection, and the integration of resonators. Careful consideration of these factors allows for the tailoring of exhaust sound characteristics to meet specific performance goals, aesthetic preferences, and regulatory requirements. While a single outlet design inherently limits the potential for complex sound tuning, a well-engineered system can effectively balance noise reduction with performance optimization.

4. Installation

The installation process for an exhaust system component featuring a solitary outlet is a critical factor influencing its long-term performance and reliability. Proper installation techniques are essential for ensuring optimal exhaust flow, preventing leaks, and minimizing stress on the system.

- Component Alignment and Fitment

Correct alignment is paramount for preventing premature wear and potential exhaust leaks. The exhaust component should be carefully aligned with the exhaust manifold and downstream components. Ensuring proper fitment minimizes stress on joints and hangers, contributing to the longevity of the system. Using appropriate mounting hardware and gaskets is crucial for achieving a secure and leak-free installation.

- Welding and Clamping Techniques

When welding is required, employing proper welding techniques is essential for creating strong and durable joints. The welds must be free of porosity and cracks to prevent leaks. Alternatively, using high-quality clamps ensures a secure connection between exhaust components. Clamps should be tightened to the manufacturer’s specifications to prevent slippage or damage to the piping. Applying exhaust sealant to the joints can further enhance leak prevention.

- Hanger Placement and Support

Adequate hanger placement is critical for supporting the weight of the exhaust system and minimizing vibration. Hangers should be strategically positioned to prevent sagging or excessive movement of the exhaust piping. Using rubber isolators in the hangers helps to dampen vibrations, reducing noise and preventing stress cracks in the exhaust system. Inspecting and replacing worn or damaged hangers is an important maintenance task.

- Clearance and Heat Shielding

Maintaining adequate clearance between the exhaust system and surrounding components, such as fuel lines and wiring harnesses, is crucial for preventing heat damage. Heat shields can be used to protect sensitive components from excessive heat exposure. Insufficient clearance can lead to fuel vaporization, wiring damage, and potentially dangerous situations. Regularly inspecting the clearance and heat shielding is necessary to ensure continued safety and reliability.

The installation of a system featuring a single exhaust outlet, while seemingly straightforward, requires attention to detail and adherence to best practices. Proper alignment, secure connections, adequate support, and sufficient clearance are all essential for maximizing the performance and lifespan of the exhaust system. Neglecting these aspects can lead to premature failures, reduced engine performance, and potential safety hazards. Therefore, a thorough and meticulous approach to installation is paramount.

5. Cost-effective

The cost-effectiveness inherent in an exhaust system configuration with a single outlet stems from several factors. Fewer components, simplified manufacturing processes, and reduced material usage contribute directly to lower production expenses. The absence of a need for complex routing or balancing between multiple outlets translates into savings across the manufacturing pipeline. This makes this configuration a financially attractive option, particularly for budget-conscious vehicle models or applications where performance enhancements are not a primary concern.

The long-term cost implications extend beyond the initial purchase price. The relative simplicity of the system often results in reduced maintenance requirements and lower repair costs compared to more complex setups. A fewer parts and easier accessibility mean that diagnostics and repairs are often less time-consuming and less expensive. For instance, replacement of a component in a single-outlet system will typically be more economical than addressing a similar issue in a dual-outlet system due to part costs and labor involved. This cost advantage becomes particularly significant over the vehicle’s lifespan, impacting the overall cost of ownership.

The financial advantages of the setup translate into real-world benefits for vehicle manufacturers and owners. By minimizing production costs, manufacturers can offer more competitively priced vehicles. Consumers benefit from lower purchase prices, as well as reduced operating and maintenance expenses. The designs simplicity promotes greater reliability and durability, minimizing the likelihood of costly repairs over time. Although performance may be compromised compared to more complex designs, the lower total cost often renders this choice a viable and appealing compromise. The pursuit of cost-effectiveness does not preclude responsible engineering; a well-designed, affordable system provides reliable service and meets the needs of a substantial portion of the automotive market.

6. Weight Saving

Weight reduction is a persistent goal in automotive engineering, directly influencing vehicle performance, fuel efficiency, and handling characteristics. The implementation of an exhaust system ending with a single outlet can contribute to overall weight savings, albeit often marginally. This configuration inherently requires fewer components and less material compared to more complex, multi-outlet systems. Consequently, this weight reduction, while potentially incremental, can positively impact the vehicle’s dynamics.

- Reduced Component Count

A primary contribution to weight savings stems from the decreased number of components. Single-outlet systems eliminate the need for a second muffler, associated piping, and potentially additional hangers. This simplification translates directly into less material used in the exhaust system’s construction. The removal of these elements reduces the vehicle’s overall mass, impacting acceleration, braking, and cornering performance.

- Minimized Material Usage

The reduced complexity of the exhaust routing contributes to a decrease in the quantity of materials required. Shorter and simpler piping runs, coupled with the elimination of redundant components, minimize the overall mass of the exhaust system. This material reduction, however small, adds to the cumulative effect of other weight-saving measures employed throughout the vehicle.

- Impact on Fuel Efficiency

A lighter vehicle requires less energy to accelerate and maintain speed. This reduction in weight directly translates into improved fuel efficiency. While the contribution of a single-outlet exhaust system to fuel economy may be modest, it is a factor contributing to the vehicle’s overall efficiency rating. Over the vehicle’s lifespan, this incremental improvement in fuel economy can result in substantial cost savings.

- Influence on Vehicle Dynamics

Lowering a vehicle’s weight improves its handling characteristics. Reduced mass results in increased responsiveness and agility. While the weight savings associated with a single-outlet system may not be transformative, it contributes to a more balanced and responsive driving experience. This improvement is most noticeable in smaller, lighter vehicles where even small weight reductions can have a tangible impact on performance.

The weight savings associated with a single-outlet exhaust system configuration are generally modest but nevertheless contribute to overall vehicle efficiency and performance. While not a primary driver of weight reduction initiatives, this simplified design offers an incremental advantage in minimizing mass, which benefits fuel economy, handling, and overall vehicle dynamics. These savings should be weighed against any potential performance disadvantages relative to dual-outlet systems, aligning the exhaust design with the intended application and performance objectives.

Frequently Asked Questions

The following addresses common inquiries and misconceptions pertaining to exhaust systems featuring a single outlet.

Question 1: What is the typical application for an exhaust system featuring a single exit muffler?

Single-outlet systems are commonly found on economy vehicles, compact cars, and those where maximizing performance gains from exhaust modifications is not a primary objective. They prioritize cost-effectiveness and simplicity over peak power enhancements.

Question 2: How does a single exit muffler affect exhaust backpressure?

The impact on backpressure depends largely on the internal design of the muffler and the diameter of the exhaust piping. A poorly designed system, even with a single exit, can create excessive backpressure, hindering engine performance. Conversely, a well-designed system can minimize restriction.

Question 3: Are single exit mufflers necessarily quieter than dual exit mufflers?

Not necessarily. The sound level is dictated by the muffler’s internal baffling and sound-deadening materials, not the number of outlets. A single exit muffler can be designed to be either quiet or relatively loud, depending on the specific requirements.

Question 4: Can a single exit muffler be upgraded for improved performance?

Yes, upgrading to an aftermarket muffler with a less restrictive design and larger diameter piping can enhance exhaust flow and potentially improve engine performance. However, the gains may be limited compared to more comprehensive exhaust system modifications.

Question 5: How does the material of a single exit muffler affect its durability?

Stainless steel offers superior corrosion resistance and typically lasts longer than aluminized steel, particularly in regions with harsh climates or road salt exposure. The material choice significantly impacts the muffler’s lifespan.

Question 6: Is a single exit muffler system more fuel-efficient than a dual exit system?

The potential for fuel efficiency improvements depends on the overall exhaust system design and engine characteristics. The weight savings associated with a single-outlet system can contribute marginally to fuel efficiency, but other factors, such as engine tuning and driving habits, play a more significant role.

The key takeaway is that the functionality and characteristics of an exhaust system featuring a single outlet depend heavily on the specific design and materials employed. Generalizations should be avoided.

The subsequent section will discuss methods for diagnosing common issues and troubleshooting exhaust system problems.

Conclusion

This exploration has illuminated the multifaceted aspects of exhaust systems incorporating a single exit muffler. From its inherent cost-effectiveness and potential for weight savings to the critical considerations of backpressure, sound control, and installation nuances, the single exit muffler configuration presents a unique set of engineering trade-offs. The effectiveness of this system hinges on meticulous design and material selection, emphasizing the need for informed decision-making when considering or implementing such a setup.

As automotive technology progresses, the optimization of exhaust systems will continue to play a crucial role in balancing performance, emissions, and cost. The enduring presence of the single exit muffler design underscores its continued relevance in a segment of the market where practicality and value remain paramount. Continued research and development are essential to further refine the performance and efficiency of this ubiquitous system, ensuring its sustained contribution to the automotive landscape.

![Best Kinney Muffler: Reviews & Alternatives [Year] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Best Kinney Muffler: Reviews & Alternatives [Year] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-52-300x200.jpg)