The auditory characteristic produced by a specific type of automotive exhaust component is the focus of this discussion. These components are designed to alter the noise profile of an engine’s combustion process. The resulting acoustic signature is often described as a deep, resonant tone, distinct from other muffler types. An example would be the subjective assessment of a vehicle’s exhaust, noting its louder and more aggressive sound when equipped with this particular component, compared to a stock or quieter aftermarket alternative.

The significance of this particular sonic characteristic lies in its association with performance modifications and perceived engine power. In automotive culture, the modification of exhaust systems is a common practice to both enhance engine output and create a desired auditory experience. The historical context of this practice involves the evolution of automotive technology, where early exhaust systems focused primarily on functionality. Over time, the demand for customizability and distinctive sound profiles led to the development of specialized components capable of altering an engine’s acoustic output.

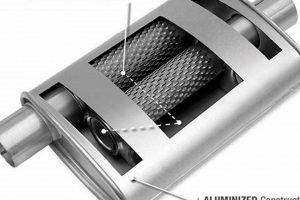

The remainder of this discussion will delve into the specific design features that contribute to this unique auditory outcome, examining the materials used, the internal construction, and the resulting impact on vehicle performance. Furthermore, consideration will be given to the legal implications and potential drawbacks associated with exhaust system modifications.

Optimization Strategies for Systems Utilizing Specific Exhaust Components

The following guidelines address considerations related to optimizing vehicle performance and ensuring compliance when employing specific exhaust components known for a characteristic sound profile.

Tip 1: Material Selection: Evaluate the material composition of the exhaust component. Stainless steel offers superior corrosion resistance and longevity compared to aluminized steel, particularly in regions with harsh climates.

Tip 2: System Compatibility: Ensure the selected exhaust component is compatible with the vehicle’s existing exhaust system and engine specifications. Mismatched components can negatively impact engine performance.

Tip 3: Professional Installation: Engage a qualified automotive technician for installation. Proper installation ensures optimal performance, prevents leaks, and minimizes the risk of damage to the vehicle.

Tip 4: Noise Level Compliance: Verify that the resulting exhaust sound levels comply with local noise ordinances and regulations. Excessive noise can result in fines and legal repercussions.

Tip 5: Backpressure Management: Monitor exhaust backpressure after installation. Excessive backpressure can reduce engine performance. Optimize exhaust system design to minimize backpressure while maintaining desired sound characteristics.

Tip 6: Periodic Inspection: Conduct regular inspections of the exhaust system, including welds and connections. Address any signs of corrosion, leaks, or damage promptly to prevent further degradation and maintain optimal performance.

Tip 7: Heat Shielding: Consider incorporating heat shielding around the exhaust component, particularly in areas where it may be in close proximity to sensitive components. This can help prevent heat damage and improve overall system reliability.

Adhering to these strategies contributes to maximizing the operational effectiveness and lifespan of exhaust systems while mitigating potential issues related to compliance and performance.

The subsequent sections will address specific scenarios and troubleshooting techniques related to utilizing these components in various vehicle applications.

1. Auditory signature

The auditory signature emanating from a thrush muffler is its defining characteristic. It’s not simply “loud” or “quiet,” but a specific tonal quality a deep, resonant rumble often described as aggressive or throaty. The creation of this signature is a direct result of the muffler’s internal design, which manipulates the flow of exhaust gases. Without this distinct auditory signature, the component would not be recognized as possessing the intended function.

For example, consider a vehicle equipped with a stock exhaust system, characterized by a muted and relatively quiet sound profile. Replacing this with an exhaust system incorporating the specific component immediately alters the acoustic experience. This change is noticeable both inside the vehicle cabin and externally. The resulting auditory profile is frequently used to evoke a perception of increased power, even if the actual engine performance gains are marginal. Consequently, the precise control and predictable reproduction of this sound are central to the component’s market value and brand identity. It is used, and perceived, as an upgrade.

The challenges with the auditory signature lie in balancing the desired sound quality with regulatory compliance regarding noise levels. Overly aggressive sound profiles may exceed legal limits, leading to fines or restrictions on vehicle operation. Therefore, careful engineering and design are required to achieve the targeted sound while adhering to legal requirements. The understanding of these sonic characteristics impacts product design and consumer purchasing decisions. The practical significance resides in satisfying customer expectations for both performance enhancement and an enhanced auditory experience.

2. Resonance Frequency

Resonance frequency, a fundamental property of oscillating systems, directly influences the characteristic sound produced by a thrush muffler. The internal structure of these mufflers is engineered to create specific resonant cavities. These cavities amplify certain frequencies within the exhaust stream while attenuating others. The effect is that they filter the sound. The specific frequencies that are amplified determine the perceived tone and depth of the exhaust note. For instance, if a muffler is designed to resonate at lower frequencies, the resulting sound will be a deeper, more bass-heavy rumble. Conversely, a muffler designed for higher resonance frequencies would produce a higher-pitched, raspier sound. Therefore, resonance frequency is not merely a characteristic, but a design criterion that directly dictates the component’s auditory outcome.

The tuning of resonance frequency within a thrush muffler can be achieved through variations in internal chamber size, baffle placement, and the types of materials used. Changes to these physical parameters shift the frequencies at which the muffler resonates. In the design process, engineers use computational fluid dynamics (CFD) and acoustic modeling software to predict and optimize the resonant frequencies. These tools allow engineers to fine-tune the sound profile without relying solely on trial-and-error methods. For example, altering the length of an internal tube within the muffler directly impacts the wavelengths that it encourages to resonate, thereby modifying the resulting sound spectrum. The practical application here is in enabling manufacturers to offer products that meet diverse customer preferences, from those seeking a subtle enhancement to those desiring a pronounced, aggressive sound.

In summary, resonance frequency is an integral element of the specific audio qualities, acting as a sound characteristic. It is essential to the definition of this sound, since design of the internal geometries dictates which frequencies are amplified and which are suppressed. The challenges lie in managing the trade-offs between desired sound characteristics, backpressure levels, and regulatory compliance. A holistic understanding of resonance frequency, combined with advanced engineering techniques, allows for the creation of this kind of product.

3. Exhaust Velocity

Exhaust velocity, the speed at which exhaust gases exit an engine, is intrinsically linked to the acoustic properties of a thrush muffler. The rate of gas flow interacts with the muffler’s internal structure, thereby influencing the generated sound profile. This interaction is fundamental to understanding the specific auditory characteristics associated with this type of exhaust component.

- Influence on Sound Pressure Level

Higher exhaust velocity typically correlates with increased sound pressure levels. The rapid expulsion of gases creates more intense pressure waves. This effect is amplified within a thrush muffler’s resonant chambers, resulting in a louder and more aggressive sound. For example, an engine operating at high RPMs will generate a greater exhaust velocity, leading to a correspondingly louder and more pronounced sound emanating from the muffler. Lower exhaust velocity provides less sound, even if the internal design of the muffler can amplify the existing sound.

- Impact on Frequency Spectrum

Exhaust velocity influences the frequency spectrum of the emitted sound. Faster gas flow can excite higher-frequency components within the muffler, potentially resulting in a raspier or more metallic tone. Slower flow favors the amplification of lower frequencies, contributing to a deeper, more resonant rumble. The design of the muffler, specifically the size and shape of its internal passages, is optimized to interact with specific velocity ranges to achieve the desired frequency response.

- Effect on Flow-Induced Noise

Flow-induced noise, generated by the turbulent movement of exhaust gases, is significantly affected by exhaust velocity. As the velocity increases, turbulence intensifies, leading to a greater contribution of broadband noise to the overall sound profile. A thrush muffler is designed to manage and shape this turbulence, channeling it through specific pathways to create a controlled, desirable sound rather than simply emitting chaotic noise.

- Relationship to Engine Performance

Exhaust velocity, in conjunction with muffler design, affects engine performance parameters such as backpressure and scavenging efficiency. A thrush muffler designed with minimal flow restriction will allow for higher exhaust velocity, potentially improving engine horsepower and torque. However, excessively high velocities, coupled with improper muffler design, can lead to increased noise levels and potential regulatory non-compliance. Engine performance dictates overall flow volume.

In summary, exhaust velocity is not merely a byproduct of engine operation, but an active element shaping the unique sound of a thrush muffler. Its influence spans from sound pressure level to frequency spectrum, and flow-induced noise. Balancing exhaust velocity and muffler design is crucial to achieving the desired auditory experience, regulatory compliance, and optimal engine performance.

4. Backpressure effect

Backpressure, the resistance to exhaust gas flow within an exhaust system, exerts a significant influence on the sound characteristics associated with a thrush muffler. The degree of backpressure created by a muffler directly affects the tonal qualities and overall loudness perceived by the listener. The cause-and-effect relationship is as follows: a higher level of backpressure typically results in a reduction in sound volume and a shift towards lower frequencies. Conversely, lower backpressure allows for increased sound volume and the potential for higher-frequency components to become more prominent. Therefore, the backpressure effect is not merely a byproduct of muffler design, but an active element shaping the final auditory experience.

The importance of understanding the backpressure effect lies in optimizing engine performance while achieving the desired sound profile. In some instances, minimizing backpressure is prioritized to maximize engine power output. However, a completely unrestricted exhaust system may produce undesirable noise levels and frequencies. A thrush muffler, in this context, represents a compromise: its internal design aims to create a distinctive sound while also managing backpressure to maintain acceptable engine performance. For example, a thrush muffler installed on a high-performance vehicle might be designed to provide a moderate level of backpressure, balancing the need for power with the desire for an aggressive sound. The practical significance lies in enabling automotive enthusiasts to customize their vehicle’s exhaust system to suit their specific performance and sound preferences.

In conclusion, the backpressure effect is an inseparable component of the acoustic profile associated with a thrush muffler. Managing this effect is crucial for achieving the desired balance between sound quality, engine performance, and regulatory compliance. Challenges arise in designing mufflers that provide both a distinctive sound and minimal backpressure. A comprehensive understanding of fluid dynamics and acoustic principles is necessary for overcoming these challenges. The ability to accurately predict and control the backpressure effect is essential for creating thrush mufflers that meet the diverse needs of the automotive market.

5. Material Composition

The selection of materials in the construction of a thrush muffler significantly influences its acoustic properties and overall durability. The density, stiffness, and damping characteristics of the materials directly contribute to the sound profile and the muffler’s ability to withstand high temperatures and corrosive exhaust gases. The interrelationship is therefore intrinsic to the functionality and longevity of the component.

- Steel Alloys and Resonant Frequency

Different steel alloys exhibit varying degrees of stiffness and density, directly affecting the resonant frequencies within the muffler. Thicker, denser alloys tend to produce lower resonant frequencies, resulting in a deeper, more bass-heavy sound. For example, a muffler constructed from heavy-gauge steel will generally have a lower tone than one made from a thinner gauge. Furthermore, the alloy composition can impact the material’s ability to dampen vibrations. Lower damping characteristics can lead to a “ringing” or metallic sound, while higher damping reduces unwanted noise and contributes to a cleaner tone.

- Stainless Steel and Acoustic Longevity

The use of stainless steel offers superior corrosion resistance, ensuring long-term acoustic performance. Unlike aluminized steel, stainless steel is less susceptible to rust and degradation from exposure to moisture and exhaust byproducts. This is crucial because corrosion can alter the internal geometry of the muffler, thereby affecting its resonant frequencies and overall sound profile. A stainless steel muffler maintains its intended sound characteristics for a longer period, providing a more consistent auditory experience over the vehicle’s lifespan. The corrosion resistance will help the sound last for the long term.

- Packing Materials and Sound Absorption

Some thrush muffler designs incorporate packing materials, such as fiberglass or steel wool, to absorb high-frequency sound waves. These materials effectively dampen unwanted noise and contribute to a smoother, more refined sound profile. The type and density of the packing material directly influence the amount of sound absorption. Over time, packing materials can degrade and become less effective, leading to a change in the muffler’s sound. Therefore, the choice of packing material and its resistance to heat and chemical degradation are crucial considerations.

- Welding Techniques and Structural Integrity

Welding techniques and the weld material itself play a crucial role in maintaining structural integrity and preventing leaks, both of which influence sound quality. Poorly executed welds can create stress points and lead to premature failure, resulting in exhaust leaks that alter the intended sound profile. Furthermore, the weld material must be compatible with the base materials to prevent corrosion and ensure a strong, durable bond. High-quality welding techniques and materials are essential for preserving the muffler’s structural integrity and maintaining its intended acoustic characteristics.

Consequently, material composition is not simply a manufacturing consideration but a fundamental factor in determining the distinctive “thrush muffler sound.” The choice of materials, from steel alloys to packing materials, directly influences the muffler’s resonant frequencies, sound absorption properties, and overall durability. Selecting appropriate materials and employing proper manufacturing techniques are essential for achieving the desired acoustic performance and ensuring long-term customer satisfaction.

6. Sound alteration

The design of a thrush muffler centers on sound alteration. The components primary function is to modify the sound produced by an engine’s exhaust. Stock exhaust systems are generally designed to minimize noise. The thrush muffler, conversely, seeks to transform the exhaust note into a specific, often louder, and more aggressive acoustic profile. The sound alteration is not merely an increase in volume, but a targeted reshaping of the frequency spectrum. This involves attenuating certain frequencies and amplifying others to create the desired auditory signature. Thus, the cause of a thrush muffler’s existence is to effect a specific and intentional alteration of the exhaust sound.

The importance of sound alteration as a component of the thrush muffler lies in its association with perceived performance and vehicle identity. For example, a driver may seek to enhance their vehicle’s perceived power by replacing a factory muffler with a thrush muffler. This modification creates a more resonant and aggressive sound. The act of replacing a stock muffler with an aftermarket model is a practical application of deliberate sound alteration. By modifying a vehicle’s exhaust system, a desired auditory experience is made, often associated with an impression of enhanced performance. The understanding of sound alteration principles enables manufacturers to create products targeting specific acoustic profiles, catering to varied customer preferences. Sound profiles affect customers willingness to pay for a component.

Sound alteration, therefore, is central to the thrush muffler’s functionality and market value. The understanding of how internal components contribute to sound alteration enables efficient design and production of an effective thrush muffler. Challenges arise in balancing the desired sound with regulatory compliance and managing backpressure. In summary, an understanding of sound alteration principles is crucial for anyone involved in the design, manufacture, or utilization of this type of automotive component.

7. Noise regulation

Noise regulation constitutes a significant constraint on the design and application of thrush mufflers. These regulations, enacted at various levels of government, establish permissible sound limits for motor vehicles. Non-compliance results in penalties, ranging from fines to vehicle impoundment. The inherent characteristic of a thrush muffler, which amplifies and modifies exhaust sound, directly clashes with the intent of noise regulations. The cause-and-effect relationship is evident: a thrush muffler designed without consideration for these regulations is likely to exceed permissible sound levels. The importance of noise regulation as a component of thrush muffler sound lies in its role as a legal boundary. A thrush muffler, irrespective of its performance benefits or auditory appeal, is rendered unusable if it violates established noise limits. For example, many jurisdictions have specific decibel limits for vehicle exhaust systems, often measured at a specific distance from the vehicle. If a thrush muffler increases the exhaust sound level beyond this limit, it becomes illegal to operate the vehicle on public roads. The practical significance of this understanding resides in the need for manufacturers to design thrush mufflers that provide a desirable sound profile while remaining within legal sound limits.

Real-world examples of the interaction between noise regulation and thrush mufflers are abundant. Many aftermarket exhaust manufacturers now offer “street legal” versions of their thrush mufflers. These designs incorporate features, such as additional sound dampening or optimized internal geometries, to reduce the overall sound output while maintaining the desired tonal qualities. Automotive enthusiasts often face the dilemma of wanting a louder, more aggressive exhaust sound, but needing to comply with local noise ordinances. This necessitates a careful selection process, often involving sound level testing to ensure compliance. Enforcement of noise regulations varies widely, with some jurisdictions actively targeting vehicles with excessively loud exhaust systems. These areas often see a reduced prevalence of thrush mufflers lacking adequate sound control measures. The legal implications are broad. For example, in certain areas, a vehicle failing a sound level test may be required to be brought into compliance before its registration can be renewed.

The intersection of noise regulation and the thrush muffler sound presents ongoing challenges for manufacturers and consumers alike. Developing thrush mufflers that meet both consumer demand for enhanced sound and regulatory requirements for noise reduction requires a combination of advanced engineering techniques and innovative design approaches. As noise regulations become more stringent, the ability to effectively manage and control exhaust sound becomes increasingly crucial. The broader theme relates to balancing individual vehicle customization with community expectations for noise control and environmental quality.

Frequently Asked Questions

The following questions address common concerns and misconceptions regarding the auditory characteristics and practical implications of using exhaust components known for a specific “thrush” sound profile.

Question 1: What defines the auditory qualities?

The sound possesses a distinct, deep, and resonant tone, often described as a throaty rumble. This sonic signature is generally louder and more aggressive than that of a stock muffler, making the overall effect more noticeable.

Question 2: What design aspects determine sound and performance?

Internal chamber design, baffle configuration, and the selection of materials play a significant role. Optimal design balances desirable sound with potential negative impacts on engine backpressure.

Question 3: Does installation of these components always increase engine output?

While these systems can contribute to increased horsepower and torque, this result is not guaranteed. Engine performance changes vary based on vehicle type, existing exhaust system configuration, and compatibility of the installed component.

Question 4: Are there specific requirements?

Most municipalities enforce noise restrictions. Confirm that modifications comply with applicable laws to avoid fines or legal repercussions.

Question 5: What are the longevity and sustainability elements?

Material composition affects corrosion resistance and long-term acoustic performance. Stainless steel options offer increased lifespan. It’s most efficient to choose high quality material.

Question 6: Is professional installation essential?

Professional installation is recommended. Competent technicians ensure proper installation, system performance and prevention of damage. Damage can reduce the sound quality.

In summary, a comprehensive understanding is essential for responsible implementation. Knowledge of its defining sound and its practical effects is crucial. Proper installation and legal compliance are most important.

The subsequent section will address key purchasing considerations and maintenance best practices for systems known for a low frequency signature.

Conclusion

The preceding analysis has elucidated the multifaceted nature of the thrush muffler sound, extending beyond a simple auditory phenomenon. This exploration encompassed the physical principles governing its generation, the design considerations influencing its characteristics, and the regulatory constraints shaping its application. The auditory signature, influenced by exhaust velocity and backpressure, originates from carefully manipulated resonance frequencies within the muffler’s internal architecture. The material composition impacts the quality, and installation requirements also impact the sound. The pursuit of this specific sonic profile exists in a delicate equilibrium with noise ordinances.

Ultimately, the responsible implementation of any exhaust modification necessitates a comprehensive understanding of its technical intricacies and its potential consequences. Further research and development remain critical in refining the acoustic properties of exhaust systems while minimizing their environmental impact. A continued commitment to balancing auditory preferences with regulatory compliance will ensure the sustainable evolution of automotive soundscapes. Future designs should consider the environment with sustainability.

![Fix: Why Do My Audio Messages Sound Muffled? [Quick Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Fix: Why Do My Audio Messages Sound Muffled? [Quick Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/01/th-508-300x200.jpg)