This automotive component is designed to reduce engine noise emanating from the exhaust system. The internal construction often utilizes baffles and chambers to attenuate sound waves. For example, a vehicle experiencing excessive exhaust noise could be fitted with this component to achieve a more subdued sound profile.

The implementation of this device offers several advantages, including compliance with noise regulations and improved driving comfort. Historically, its development has been driven by both legal mandates concerning noise pollution and consumer demand for quieter vehicles. This technology represents a balance between engine performance and acoustic control.

Understanding the function and attributes of this device is crucial when discussing exhaust system design, noise reduction techniques, and automotive performance optimization.

Tips Regarding Exhaust Noise Attenuation Devices

The following suggestions are pertinent for professionals and enthusiasts working with or considering the implementation of an exhaust noise attenuation device.

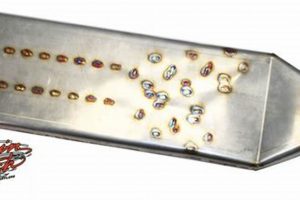

Tip 1: Material Selection: When selecting an exhaust noise attenuation device, consider the vehicle’s operating environment. Stainless steel construction offers superior corrosion resistance compared to aluminized steel, particularly in regions with harsh weather conditions.

Tip 2: Internal Design: Analyze the internal design of the device. A chambered design may provide different noise reduction characteristics than a baffled design. Understanding these differences is critical to achieving the desired sound profile and performance.

Tip 3: Installation Procedures: Adhere strictly to the manufacturer’s installation instructions. Improper installation can compromise the device’s performance, lead to premature failure, and potentially void any warranty.

Tip 4: Welding Techniques: When welding the device into the exhaust system, employ appropriate welding techniques to ensure a secure and leak-free connection. Utilize a welding process compatible with the device’s material composition.

Tip 5: Regulatory Compliance: Verify that the selected device meets all applicable local and federal noise regulations. Failure to comply with these regulations can result in fines and penalties.

Tip 6: Performance Considerations: Be aware that alterations to the exhaust system, including the installation of an exhaust noise attenuation device, can affect engine performance. Consider consulting with a qualified technician to assess potential impacts on horsepower and torque.

Tip 7: Periodic Inspection: Conduct regular inspections of the device for signs of wear, corrosion, or damage. Address any issues promptly to maintain optimal performance and prevent more significant problems.

By implementing these suggestions, professionals and enthusiasts can ensure the proper selection, installation, and maintenance of exhaust noise attenuation devices, leading to optimal performance, regulatory compliance, and extended service life.

The subsequent sections will delve further into specific applications and troubleshooting techniques related to exhaust systems.

1. Sound Attenuation

Sound attenuation, the reduction of noise levels, is a primary function of the thrush rattler muffler. This device utilizes specific internal designs to minimize the intensity of sound waves generated by engine combustion. Baffles, chambers, and resonating structures within the muffler disrupt and redirect sound waves, causing them to interfere with each other and thereby reducing overall noise emissions. A thrush rattler muffler experiencing internal damage, such as a collapsed baffle, will exhibit diminished sound attenuation capabilities, resulting in a noticeably louder exhaust note. This direct cause-and-effect relationship underscores the importance of the muffler’s structural integrity for effective sound control.

The specific design of the thrush rattler mufflers internal components directly dictates its sound attenuation performance. A straight-through design, while often maximizing exhaust flow for performance gains, typically offers less sound attenuation than a chambered design. Conversely, a multi-chambered design, employing multiple baffles and expansion chambers, provides superior sound dampening but may impose a slight restriction on exhaust flow. The selection of an appropriate muffler design, therefore, requires a careful balance between desired noise levels and acceptable performance tradeoffs. For instance, a vehicle operating in a noise-sensitive environment, such as a residential area, would benefit from a chambered design to minimize noise pollution, even at the potential expense of marginal horsepower reduction.

In conclusion, sound attenuation is an integral and defining characteristic of the thrush rattler muffler. Its effectiveness is fundamentally linked to the device’s internal construction and condition. Understanding the relationship between design choices, structural integrity, and sound attenuation capabilities enables informed selection and maintenance practices, ensuring both regulatory compliance and a comfortable driving experience. Degradation or modification can drastically affect the exhaust system, and must be taken seriously.

2. Exhaust Flow

Exhaust flow represents the rate at which combustion gases are evacuated from an engine’s cylinders through the exhaust system. The thrush rattler muffler, as an integral component of this system, directly influences exhaust flow characteristics. Internal designs of mufflers, such as baffle arrangements and chamber configurations, create varying degrees of resistance to the flow of exhaust gases. A more restrictive muffler design impedes exhaust flow, potentially increasing backpressure within the system. Conversely, a less restrictive, straight-through design promotes higher exhaust flow rates, minimizing backpressure. For example, a high-performance engine application may benefit from a straight-through muffler design to maximize power output by reducing exhaust flow restrictions, even if it results in a louder exhaust note.

The relationship between exhaust flow and muffler design is further complicated by the trade-off between performance and noise reduction. While a highly restrictive muffler provides superior noise attenuation, it can also reduce engine efficiency and power output by increasing backpressure. The choice of muffler, therefore, represents a compromise. Understanding the cause and effect of different muffler designs on exhaust flow is critical when selecting a muffler for a specific application. The internal diameter of the mufflers inlet and outlet also directly influences flow rates. Smaller diameter openings create bottlenecks, restricting gas passage and increasing backpressure, while larger diameter openings facilitate improved flow. An inappropriately sized muffler can impede an engine’s ability to expel exhaust gasses efficiently, which can hinder performance.

In summary, the thrush rattler muffler profoundly affects exhaust flow within an engine’s exhaust system. Internal designs, including baffles, chambers, and inlet/outlet diameters, determine the level of flow restriction imposed. The ultimate selection of a muffler type necessitates a careful consideration of the desired balance between noise reduction, engine performance, and regulatory compliance. Optimizing exhaust flow, in conjunction with appropriate muffler selection, is vital for achieving peak engine performance and minimizing potential for engine damage. The consideration of optimal flow can lead to a more informed decision.

3. Material Durability

Material durability is a critical factor influencing the lifespan and performance of an automotive exhaust component. The harsh operating environment, characterized by high temperatures, corrosive gases, and exposure to road debris, necessitates the use of robust materials in its construction.

- Corrosion Resistance

The primary threat to an exhaust component is corrosion, caused by the acidic compounds present in exhaust gases and environmental exposure to moisture and road salts. Stainless steel alloys, such as 304 and 409, offer superior corrosion resistance compared to aluminized steel. This resistance mitigates the formation of rust and degradation, extending the component’s operational life.

- Thermal Stability

Exhaust gases can reach extremely high temperatures, particularly near the engine. Material selection must consider thermal stability to prevent warping, cracking, or weakening of the exhaust component. Materials with high melting points and resistance to thermal fatigue are essential for maintaining structural integrity under extreme heat cycling. Titanium alloys, while expensive, offer exceptional thermal stability and strength-to-weight ratios.

- Mechanical Strength

The exhaust system is subjected to mechanical stresses from engine vibrations, road impacts, and thermal expansion and contraction. Materials used must possess adequate tensile strength, yield strength, and fatigue resistance to withstand these forces. Inadequate mechanical strength can lead to premature failure, such as cracks or weld fractures, compromising exhaust system performance and potentially causing safety hazards.

- Weldability

The fabrication of exhaust components typically involves welding various sections and components together. The chosen materials must exhibit good weldability to ensure strong, durable joints. Poor weldability can lead to weak welds susceptible to cracking or corrosion, reducing the overall lifespan of the exhaust component.

The selection of materials directly correlates to the long-term reliability and performance of the exhaust component. Utilizing materials with superior corrosion resistance, thermal stability, mechanical strength, and weldability ensures that the component can withstand the rigors of its operating environment, providing reliable service and minimizing the need for premature replacement.

4. Vehicle Compatibility

The successful integration of an aftermarket exhaust component hinges critically on its compatibility with the target vehicle. This compatibility encompasses multiple facets, including physical dimensions, inlet/outlet configurations, exhaust pipe diameter, and mounting point locations. Mismatched dimensions prevent proper installation, potentially causing exhaust leaks, reduced performance, and even damage to surrounding vehicle components. The vehicle’s engine displacement and horsepower also influence the selection of an appropriate muffler; installing a muffler designed for a smaller engine on a larger one can lead to excessive backpressure and reduced engine efficiency. For example, fitting a thrush rattler muffler intended for a four-cylinder engine onto a V8 engine would likely result in a noticeable reduction in horsepower and torque.

Furthermore, vehicle compatibility extends beyond mere physical fitment. The acoustic properties of a thrush rattler muffler must be considered in relation to the vehicle’s intended use and the driver’s preferences. A muffler designed to produce a loud, aggressive exhaust note may be unsuitable for a luxury sedan where a quiet and refined driving experience is desired. Conversely, a muffler that overly dampens exhaust noise may detract from the driving experience in a performance-oriented sports car. The vehicle’s emissions control system represents another critical area of consideration; modifications to the exhaust system, including the installation of a thrush rattler muffler, must not compromise the vehicle’s ability to meet applicable emissions regulations. Failure to adhere to these regulations can result in fines and penalties.

In conclusion, verifying vehicle compatibility represents a non-negotiable step in the selection and installation process. Addressing physical fitment, acoustic properties, and emissions compliance concerns is essential for ensuring optimal performance, regulatory adherence, and a satisfactory driving experience. Ignoring the intricate relationship between the muffler and the target vehicle can lead to costly mistakes and unsatisfactory results.

5. Installation Method

The installation method directly influences the performance and longevity of the thrush rattler muffler. Improper installation techniques can negate the benefits of even the highest-quality component. Exhaust leaks stemming from inadequate welding or improperly tightened clamps compromise sound attenuation and negatively affect engine performance. Such leaks, for example, disrupt exhaust gas scavenging, diminishing power output and potentially triggering error codes within the vehicle’s engine management system. The alignment of the muffler within the exhaust system is crucial. Misalignment induces stress on the muffler’s internal components and connecting pipes, leading to premature fatigue and failure. The installation process itself represents a critical factor.

Welding, a common method for securing the thrush rattler muffler, necessitates expertise and precision. Insufficient weld penetration creates weak points susceptible to cracking under thermal stress and vibration. Conversely, excessive heat input during welding can distort the muffler’s body or damage its internal baffling. Clamp-based installations demand properly sized clamps and meticulous tightening procedures. Over-tightening deforms the exhaust pipes, creating leaks, while under-tightening results in slippage and separation. The use of antiseize compound on threaded fasteners facilitates future maintenance and prevents corrosion-induced seizing, contributing to the muffler’s serviceability over time. Ignoring the installation of rubber hangers for exhaust systems cause vibrations. This damages and potentially completely separate exhaust components that are not designed for high vibrations.

In summation, the installation method is inextricably linked to the thrush rattler muffler’s overall effectiveness. Diligent adherence to established best practices, coupled with the use of appropriate tools and techniques, ensures optimal performance, extended service life, and minimizes the risk of costly repairs. The quality of installation is as vital as the component’s inherent design and materials. A well-executed installation mitigates potential problems.

6. Performance Impact

The thrush rattler mufflers design and condition significantly influence the overall performance characteristics of a vehicle. The following points elucidate the key facets of this relationship, emphasizing the implications for engine efficiency, power output, and drivability.

- Backpressure Modulation

The internal construction of the muffler, including baffle arrangements and chamber dimensions, directly affects backpressure within the exhaust system. Excessive backpressure impedes exhaust gas evacuation from the cylinders, reducing volumetric efficiency and diminishing power output, particularly at higher engine speeds. Conversely, insufficient backpressure can negatively affect low-end torque and fuel economy by disrupting exhaust gas scavenging. The selection of a thrush rattler muffler that strikes a balance between backpressure reduction and adequate exhaust gas velocity is critical for optimizing engine performance across the RPM range. Aftermarket performance mufflers are designed with this effect in mind.

- Exhaust Gas Velocity

Maintaining adequate exhaust gas velocity is crucial for efficient cylinder scavenging, which refers to the removal of spent combustion gases and the intake of fresh air/fuel mixture. The thrush rattler muffler’s design influences exhaust gas velocity. A muffler with excessive internal restrictions slows down exhaust flow, hindering scavenging and reducing engine efficiency. A well-designed muffler optimizes gas velocity to promote effective scavenging, improving combustion efficiency and power output. Exhaust systems with properly sized mufflers will produce greater overall engine horsepower.

- Sound Wave Interference

The thrush rattler muffler utilizes specific internal designs to cancel out unwanted sound frequencies through destructive interference. This process inevitably creates some degree of flow restriction, influencing overall exhaust system performance. A muffler designed primarily for maximum noise reduction may introduce significant flow restrictions, negatively impacting engine power and efficiency. A performance-oriented muffler prioritizes minimizing flow restrictions while still providing acceptable noise levels, balancing performance and sound control. This design represents a delicate balance.

- Catalytic Converter Compatibility

The catalytic converter, a crucial component of the vehicle’s emissions control system, operates optimally within a specific temperature range. An improperly designed or damaged thrush rattler muffler can affect exhaust gas temperature, potentially compromising the catalytic converter’s efficiency and longevity. Excessive backpressure, for example, can lead to increased exhaust gas temperatures, overheating and damaging the catalytic converter. Ensuring compatibility between the thrush rattler muffler and the catalytic converter is essential for maintaining emissions compliance and preventing costly repairs. Without a properly installed and functioning catalytic converter, a vehicle is unable to meet compliance regulations for emissions standards.

These facets underscore the complex relationship between the thrush rattler muffler and overall vehicle performance. The selection of an appropriate muffler, considering backpressure modulation, exhaust gas velocity, sound wave interference, and catalytic converter compatibility, is paramount for optimizing engine efficiency, power output, and emissions compliance. A poorly chosen or maintained muffler can negatively impact these parameters, resulting in reduced performance, increased fuel consumption, and potential damage to other engine components. It is important to always have a skilled mechanic handle the installation and maintenance of thrush rattler mufflers, especially when performance is a top priority.

7. Regulatory Compliance

Regulatory compliance mandates adherence to established laws and standards governing vehicle noise emissions. The thrush rattler muffler, as a component directly influencing exhaust sound levels, is subject to these regulations. Non-compliance can result in fines, vehicle impoundment, and legal liabilities. Therefore, understanding and adhering to these regulations is critical for both manufacturers and vehicle owners.

- Federal Noise Standards

The U.S. Environmental Protection Agency (EPA) establishes federal noise emission standards for motor vehicles. These standards define the permissible noise levels at specific speeds and operating conditions. A thrush rattler muffler failing to meet these standards renders the vehicle non-compliant. Enforcement mechanisms include vehicle inspections and manufacturer audits. Tampering with or removing emission control devices such as the muffler and catalytic converter is prohibited.

- State and Local Ordinances

In addition to federal regulations, state and local governments often enact their own noise ordinances, which may be stricter than federal standards. These ordinances can vary significantly between jurisdictions. For example, some cities implement nighttime noise restrictions, further limiting permissible exhaust sound levels. A thrush rattler muffler that complies with federal regulations may still violate local noise ordinances, resulting in fines or other penalties. Vehicle modifications that alter or change noise output can be measured and ticketed.

- Aftermarket Compliance

Manufacturers of aftermarket thrush rattler mufflers must ensure their products meet applicable noise regulations. Some aftermarket mufflers are specifically designed and labeled as “street legal” or “noise compliant” to indicate adherence to established standards. However, it is the vehicle owner’s responsibility to verify that the selected muffler complies with the regulations in their jurisdiction. Modifying a muffler that results in a louder exhaust than what the vehicle was originally equipped with could trigger a compliance check. The aftermarket installer can also be held accountable for the improper change.

- Enforcement and Penalties

Enforcement of noise regulations typically involves vehicle inspections, sound level testing, and visual inspections of exhaust systems. Law enforcement officers may issue warnings or citations for vehicles exceeding permissible noise levels. Penalties for non-compliance can range from monetary fines to vehicle impoundment. Repeat offenders may face more severe consequences, including license suspension. Drivers should keep this in mind.

These points emphasize the importance of regulatory compliance concerning thrush rattler mufflers. Manufacturers, installers, and vehicle owners must remain informed about applicable noise regulations to avoid potential legal and financial repercussions. Selecting and maintaining a compliant thrush rattler muffler is a vital aspect of responsible vehicle ownership. These considerations will improve regulatory compliance and greatly lessen the chance of receiving tickets.

Frequently Asked Questions

The following questions and answers address common inquiries regarding the thrush rattler muffler, its function, application, and regulatory considerations.

Question 1: What is the primary function of a thrush rattler muffler?

The primary function is the reduction of exhaust noise generated by the internal combustion engine. The device employs internal baffles and chambers to attenuate sound waves, mitigating noise pollution.

Question 2: How does the internal design of a thrush rattler muffler impact its performance?

The internal design, specifically the arrangement of baffles and chambers, affects exhaust flow and sound attenuation. A more restrictive design reduces noise but may increase backpressure, while a less restrictive design enhances flow but offers diminished noise reduction.

Question 3: What materials are commonly used in the construction of thrush rattler mufflers, and what are their respective advantages?

Common materials include aluminized steel and stainless steel. Stainless steel provides superior corrosion resistance compared to aluminized steel, extending the lifespan of the component, particularly in corrosive environments.

Question 4: How can one determine if a specific thrush rattler muffler is compatible with a particular vehicle?

Compatibility depends on several factors, including physical dimensions, inlet/outlet configurations, exhaust pipe diameter, and engine displacement. Consulting the manufacturer’s specifications and verifying these parameters ensures proper fitment and performance.

Question 5: What are the potential consequences of installing a thrush rattler muffler that does not comply with local noise regulations?

Non-compliance with noise regulations can result in fines, vehicle impoundment, and legal liabilities. It is the vehicle owner’s responsibility to ensure that the selected muffler meets all applicable standards.

Question 6: Does the installation of a thrush rattler muffler affect the vehicle’s engine performance?

Yes, the muffler can affect engine performance by influencing backpressure and exhaust gas velocity. Selecting an appropriate muffler design, considering these factors, is crucial for optimizing engine efficiency and power output. A modified system may experience different output compared to factory settings.

In summary, the thrush rattler muffler plays a crucial role in noise reduction and exhaust system performance. Understanding its function, design, material composition, compatibility, and regulatory implications is essential for informed decision-making.

The subsequent section will explore advanced topics related to exhaust system diagnostics and troubleshooting.

Concluding Remarks on Exhaust Noise Attenuation

This discourse has illuminated the function, attributes, and implications of the thrush rattler muffler within the automotive landscape. From its role in mitigating noise pollution and complying with regulatory standards to its impact on engine performance and exhaust system dynamics, this component embodies a complex interplay of engineering considerations. The selection, installation, and maintenance of a thrush rattler muffler demand a comprehensive understanding of its inherent characteristics and its interaction with the vehicle’s overall design.

The efficacy of noise attenuation technology is continuously evolving. It is imperative that professionals and enthusiasts remain informed about advancements in materials, designs, and regulatory requirements. Understanding these aspects ensures optimal implementation of the thrush rattler muffler, achieving a balance between performance, environmental responsibility, and legal compliance. This commitment fosters a more sustainable and harmonious automotive ecosystem.

![Loudest Flowmaster Mufflers: Find Your Sound [Guide] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Loudest Flowmaster Mufflers: Find Your Sound [Guide] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-109-300x200.jpg)

![Find The Best Muffler Tape: [Brand] Lasts Longer Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Find The Best Muffler Tape: [Brand] Lasts Longer | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-102-300x200.jpg)