An exhaust system component designed to reduce noise generated by an internal combustion engine, particularly those equipped with forced induction, often incorporates a specific design. This design focuses on managing the high-velocity, high-temperature exhaust gases produced by these engines. A common configuration features a series of internal baffles and expansion chambers that diffuse sound waves. As an example, certain vehicles utilize this device to meet noise regulations while maintaining engine performance.

Effective reduction of exhaust noise is critical for compliance with environmental standards and enhancing vehicle comfort. The engineering behind these systems impacts engine performance characteristics, including backpressure and exhaust flow. Historically, developments in this technology have strived to balance noise reduction with minimal restriction to the engine’s output, leading to improved fuel efficiency and power delivery.

The following sections will detail the construction, operational principles, performance characteristics, and selection criteria for such exhaust components. Furthermore, relevant considerations regarding installation, maintenance, and regulatory compliance will be addressed.

Turbo Tube Muffler

The following guidelines aim to provide insights for maximizing the performance and lifespan of an exhaust noise reduction device, commonly employed in turbocharged engine applications.

Tip 1: Material Selection Assessment: Prioritize components fabricated from high-grade stainless steel or aluminized steel for enhanced corrosion resistance, particularly in environments exposed to road salt or high humidity. This will extend service life and prevent premature failure.

Tip 2: Proper Installation Technique: Ensure secure and leak-free connections at all joints using appropriate clamps and gaskets. Improper installation can result in exhaust leaks, reduced performance, and potential safety hazards.

Tip 3: Regular Inspection Protocol: Conduct periodic visual inspections for signs of corrosion, damage, or loose connections. Address any identified issues promptly to prevent escalation and maintain optimal performance.

Tip 4: Engine Tuning Considerations: When modifying engine tuning parameters, ensure the devices flow capacity is sufficient to handle the increased exhaust volume. Insufficient flow can result in excessive backpressure and reduced engine output.

Tip 5: Minimizing Thermal Stress: Implement measures to mitigate excessive heat exposure, such as heat shields or exhaust wraps. This will protect the component from thermal degradation and extend its operational life.

Tip 6: Welding Integrity Verification: If welding is required, ensure that the welds are performed by a qualified technician using appropriate techniques and materials. Poorly executed welds are prone to failure and can compromise the system’s integrity.

Tip 7: Backpressure Monitoring: Track exhaust backpressure levels, particularly after modifications. Excessively high backpressure can indicate a restriction in the device or exhaust system, requiring investigation and remediation.

Adhering to these guidelines will contribute to sustained performance and prolonged service from the selected exhaust component. Careful attention to materials, installation, and maintenance is paramount.

The subsequent sections will explore advanced topics related to acoustic performance and emissions compliance.

1. Noise Reduction Effectiveness

The primary function of an exhaust noise reduction device is to mitigate the acoustic energy generated by the engine’s combustion process. Noise Reduction Effectiveness, therefore, represents the degree to which this device attenuates sound waves. In the context of turbocharged engines, these devices must address a broad spectrum of frequencies and amplitudes, as forced induction systems often amplify exhaust noise. A device with inadequate noise reduction capabilities fails to meet regulatory noise emission standards and compromises vehicle occupant comfort. As an example, failing this requirement would cause vehicles to be disallowed in residential areas due to a great level of noise produced.

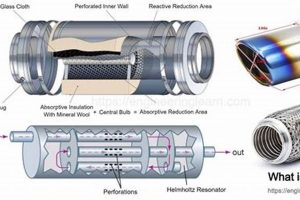

The Noise Reduction Effectiveness hinges on the muffler’s internal design, which typically incorporates a series of chambers, baffles, and sound-absorbing materials. These elements work in concert to reflect and dissipate sound waves, converting acoustic energy into thermal energy. The selection and arrangement of these components directly influence the frequency-specific noise reduction. The effectiveness must be assessed under various operating conditions to ensure consistent performance. Ineffective sound wave dispersion causes louder vehicle sound.

Understanding the relationship between design parameters and Noise Reduction Effectiveness is critical for engineering exhaust systems that meet stringent noise regulations without sacrificing engine performance. Challenges lie in achieving a balance between noise reduction and exhaust flow restriction. Improvements in material science and acoustic modeling are continuously enhancing the noise reduction capabilities of these devices. The long-term performance of the device, its contribution to emissions control, and vehicle operation are all significantly influenced by effective sound reduction.

2. Exhaust Flow Optimization

Exhaust Flow Optimization is a critical factor in the performance and efficiency of internal combustion engines, particularly those equipped with turbochargers. The ability of the exhaust system, including the noise reduction device, to efficiently evacuate exhaust gases directly impacts engine power, fuel economy, and overall operational characteristics. A device that unduly restricts exhaust flow can negate the benefits of forced induction.

- Backpressure Minimization

Excessive backpressure, caused by a poorly designed noise reduction device, hinders the engine’s ability to expel exhaust gases, leading to reduced volumetric efficiency. This results in decreased power output and increased fuel consumption. Minimizing backpressure within the exhaust system is paramount for maximizing engine performance. The design of the noise reduction device significantly influences the overall backpressure of the system.

- Turbine Efficiency

In turbocharged engines, the turbine’s performance is directly linked to exhaust flow. A noise reduction device that restricts flow can reduce turbine speed and responsiveness, resulting in turbo lag and diminished boost pressure. Optimizing exhaust flow through the device is essential for maintaining turbine efficiency and maximizing the benefits of turbocharging. Proper airflow promotes quicker turbine response.

- Scavenging Effect

Optimized exhaust flow contributes to the scavenging effect, where the outflow of exhaust gases from one cylinder aids in drawing in the intake charge for the next cylinder. This improves cylinder filling and combustion efficiency. A well-designed noise reduction device facilitates the scavenging effect by promoting smooth and unrestricted exhaust flow. Efficient scavenging is crucial for maximizing engine power and reducing emissions.

- Pulse Management

Managing exhaust pulses is essential for preventing unwanted pressure waves that can disrupt exhaust flow. The internal design of the noise reduction device can either promote or hinder the efficient dissipation of these pulses. Effective pulse management contributes to smoother exhaust flow and improved engine performance. Poorly managed pulses can lead to resonance and increased noise levels.

The aforementioned facets illustrate the intricate relationship between Exhaust Flow Optimization and the device used for noise reduction. Effective design and implementation of such components are crucial for maximizing engine performance, fuel efficiency, and overall vehicle operation. Trade-offs between noise reduction and flow optimization must be carefully considered to achieve the desired balance. Improperly executed device can impede engine operations and lower output.

3. Backpressure Considerations

Backpressure, in the context of an exhaust system incorporating a noise reduction device, is a critical parameter influencing engine performance. This parameter is defined as the resistance encountered by exhaust gases as they flow through the system, particularly within the confines of a component designed to attenuate sound. Its management is paramount for optimized engine operation and longevity.

- Engine Power and Torque:

Excessive backpressure impedes the efficient expulsion of exhaust gases from the combustion chamber. This restriction diminishes the engine’s ability to draw in a fresh air-fuel mixture, reducing volumetric efficiency and, consequently, power and torque output. For example, an engine experiencing high backpressure due to a poorly designed device might exhibit sluggish acceleration and reduced top-end performance. The effect is more pronounced in turbocharged engines.

- Fuel Efficiency:

Increased backpressure compels the engine to work harder to expel exhaust gases, leading to elevated fuel consumption. A compromised device, causing undue restriction, increases the energy required to overcome exhaust resistance. The subsequent result is a reduction in fuel efficiency. In practical terms, a vehicle with high exhaust backpressure might exhibit a noticeable decrease in miles per gallon.

- Turbocharger Performance:

In turbocharged applications, backpressure exerts a direct influence on turbine efficiency. Elevated backpressure downstream of the turbine impedes its ability to effectively extract energy from the exhaust stream, reducing boost pressure and increasing turbo lag. Consequently, the engine’s responsiveness suffers. A well-designed device minimizes backpressure to optimize turbine performance.

- Engine Health and Longevity:

Sustained exposure to high backpressure can lead to premature engine wear and component failure. The increased strain on the engine’s internal components, such as pistons and valves, accelerates degradation and reduces overall engine lifespan. Moreover, high backpressure can contribute to increased engine operating temperatures, further exacerbating wear. Over time, this can lead to significant maintenance costs and reduced reliability.

These interconnected elements illustrate the critical importance of managing backpressure. A well-designed and properly maintained device minimizes exhaust restriction, thereby promoting optimal engine performance, fuel efficiency, and longevity. Conversely, a device that induces excessive backpressure compromises engine health and reduces overall vehicle performance. A delicate balance must be achieved to meet noise reduction targets without negatively impacting engine operation.

4. Material Durability

Material Durability, referring to the capacity of a component to withstand wear, corrosion, and other forms of degradation over an extended service life, is of paramount importance for components integrated within exhaust systems. This consideration is particularly relevant for noise reduction devices operating in turbocharged engine environments, where extreme temperatures, corrosive gases, and mechanical stresses are prevalent. Material failure directly impacts performance, reliability, and regulatory compliance.

- Corrosion Resistance

The exhaust stream contains corrosive compounds, including acids and water vapor, generated during combustion. Materials utilized in the construction of noise reduction devices must exhibit high resistance to corrosion to prevent premature failure. For instance, stainless steel alloys are commonly employed due to their superior corrosion resistance compared to mild steel. The selection of appropriate materials directly influences the longevity of the device and its ability to maintain performance standards over time.

- Thermal Stability

Exhaust gases from turbocharged engines can reach extremely high temperatures, potentially exceeding the melting points of certain materials. Therefore, the materials used must possess adequate thermal stability to withstand these temperatures without undergoing significant deformation or degradation. Inadequate thermal stability can lead to structural failure and loss of noise reduction effectiveness. Materials like Inconel are used in high-performance applications due to their high thermal stability.

- Mechanical Strength

The exhaust system is subjected to mechanical stresses resulting from engine vibrations, road impacts, and thermal expansion. The materials employed in the device must possess sufficient mechanical strength to withstand these stresses without cracking or fracturing. Fatigue resistance is also crucial to prevent failure due to cyclic loading. Reinforcements are often needed to improve the overall material mechanical strength.

- Erosion Resistance

The high velocity of exhaust gases, particularly in turbocharged engines, can lead to erosion of the internal surfaces of the noise reduction device. The choice of materials with high erosion resistance is essential to prevent premature wear and maintain consistent performance. Hardened alloys and surface coatings are sometimes utilized to enhance erosion resistance. Erosion resistance contributes to the long-term performance and reliability of the component.

Collectively, these facets underscore the critical role of Material Durability in the overall performance and lifespan of the noise reduction component, commonly employed in turbocharged engine applications. Selection of appropriate materials, coupled with proper design and manufacturing processes, is essential to ensure the device meets stringent performance requirements, maintains compliance with regulatory standards, and provides reliable operation over an extended service life. Improper material choices can quickly degrade performance.

5. Installation Integrity

Installation Integrity, in the context of a noise reduction device, directly dictates its operational effectiveness and longevity. Proper installation ensures the component functions as designed, effectively mitigating exhaust noise and minimizing any negative impact on engine performance. Conversely, compromised installation integrity can lead to a cascade of adverse effects, ranging from reduced noise attenuation to catastrophic component failure. Specific to turbocharged systems, the elevated pressures and temperatures necessitate meticulous attention to installation procedures.

Faulty installation practices, such as improper alignment, inadequate clamping force, or the use of incompatible hardware, can result in exhaust leaks. These leaks not only diminish the device’s noise reduction capabilities but also introduce potentially hazardous exhaust gases into the vehicle’s cabin. Furthermore, misalignment can induce undue stress on the component’s structure, accelerating fatigue and potentially leading to cracking or complete failure. In a real-world scenario, a misaligned device may experience premature weld failure due to excessive vibration and stress concentration, rendering it ineffective and requiring costly repairs. Correct tightening torque prevents exhaust leakages that causes unwanted engine noises.

Ensuring installation integrity requires adherence to manufacturer specifications, utilization of appropriate tools and hardware, and meticulous inspection of all connections. The consequences of neglecting these principles extend beyond mere inconvenience, potentially impacting vehicle safety, performance, and regulatory compliance. A properly installed device not only fulfills its intended function but also contributes to the overall reliability and efficiency of the vehicle’s exhaust system. Prioritizing installation quality is essential for realizing the full benefits of such exhaust components, especially in demanding turbocharged applications. Over time, the effects are noticeable and prevent further damage.

6. Thermal Management

Thermal Management is intrinsically linked to the operational effectiveness and longevity of an exhaust noise reduction device, particularly in turbocharged engine applications. These systems generate high exhaust gas temperatures, placing significant thermal stress on components. Effective thermal management mitigates the adverse effects of this heat, preventing premature degradation and ensuring consistent performance. Without adequate thermal control, the noise reduction devices materials can weaken, leading to structural failure and diminished acoustic performance. For example, prolonged exposure to high temperatures can cause oxidation and cracking of metallic components, rendering them brittle and ineffective.

The design of the noise reduction device directly influences its thermal characteristics. Heat shields, insulation wraps, and strategically placed air gaps can reduce heat transfer to surrounding components and maintain optimal operating temperatures. Material selection plays a crucial role; high-temperature alloys, such as stainless steel and Inconel, offer superior resistance to thermal degradation. Moreover, the device’s internal configuration affects airflow and heat dissipation. A properly designed device facilitates convective heat transfer, preventing localized hot spots and maintaining a more uniform temperature distribution. Effective heat dissipation maximizes component lifespan.

In conclusion, Thermal Management is not merely an ancillary consideration but an essential element in the design and operation of exhaust noise reduction devices. Proper thermal management safeguards the structural integrity of the device, preserves its acoustic performance, and extends its operational lifespan. Neglecting thermal considerations can lead to costly repairs, reduced engine efficiency, and potential safety hazards. Therefore, a comprehensive approach to thermal management is paramount for ensuring the reliable and efficient operation of a turbocharged engine system. Consistent monitoring promotes system health.

7. Emission Compliance

Emission Compliance, pertaining to adherence to legally mandated limits on exhaust pollutants, constitutes a critical performance parameter for all vehicles, including those equipped with turbocharged engines and associated noise reduction devices. Regulations governing exhaust emissions are increasingly stringent, necessitating careful design and integration of exhaust components to minimize the release of harmful substances. This exploration examines the critical facets of emission compliance as they relate to the functionality and design considerations of noise reduction devices installed in exhaust systems.

- Catalytic Converter Integration

The positioning and effectiveness of the catalytic converter are directly influenced by the flow characteristics of the exhaust system, including the noise reduction device. Excessive backpressure created by the device can negatively impact the converter’s efficiency in oxidizing hydrocarbons, carbon monoxide, and nitrogen oxides. Proper integration ensures the converter operates within its optimal temperature range and achieves maximum conversion rates. For example, a device that generates turbulent flow may hinder the catalytic converter’s ability to function effectively. Effective catalytic converer integration can have a good environment impact.

- Particulate Matter Filtration

Diesel engines, often utilizing turbochargers, require particulate filters to capture soot and other particulate matter. The noise reduction device must not impede the performance of the particulate filter by generating excessive backpressure or altering the exhaust gas flow characteristics. A well-designed device minimizes disruption to the particulate filter’s operation, ensuring effective trapping of particulate matter and compliance with emission standards. Proper installation helps filtration operations.

- Lambda Sensor Feedback

The lambda sensor, also known as an oxygen sensor, provides critical feedback to the engine control unit (ECU) regarding the air-fuel ratio. The noise reduction device must not interfere with the accurate measurement of exhaust gas composition by the lambda sensor. Obstruction of the sensor or creation of localized exhaust pockets can lead to inaccurate readings and compromised engine management, resulting in increased emissions. Sensor accuracy ensures precise readings.

- Noise Reduction Device Materials

The materials used in the construction of the noise reduction device must be compatible with the exhaust gas stream and not contribute to increased emissions. Certain materials can release volatile organic compounds (VOCs) or other pollutants when exposed to high temperatures, compromising emission compliance. The selection of appropriate materials is crucial for ensuring the device does not introduce unintended emissions into the exhaust stream. Compatibility with the surrounding system is important.

These components, and the intricacies of their integration, directly correlate with achieving and maintaining Emission Compliance. Thorough design and validation are necessary to ensure that noise reduction strategies do not compromise the ability of the vehicle to meet increasingly stringent emission standards. Attention to flow characteristics, material selection, and system integration is paramount. Neglecting these elements can lead to regulatory penalties and environmental consequences.

Frequently Asked Questions

The following questions address common concerns and misconceptions regarding turbo tube muffler systems, offering concise and informative answers.

Question 1: What constitutes a turbo tube muffler?

A turbo tube muffler is an exhaust system component designed to reduce noise generated by an internal combustion engine, particularly those equipped with turbochargers. Its design typically incorporates chambers and baffles to attenuate sound waves while minimizing backpressure.

Question 2: How does a turbo tube muffler differ from a standard muffler?

While both reduce exhaust noise, turbo tube mufflers are specifically engineered to handle the higher exhaust flow and temperatures associated with turbocharged engines. They often feature larger internal passages and more robust construction to withstand the increased demands.

Question 3: Does a turbo tube muffler affect engine performance?

A properly designed turbo tube muffler minimizes backpressure, thereby mitigating negative impacts on engine performance. However, a poorly designed unit can restrict exhaust flow, leading to reduced power and fuel efficiency.

Question 4: What materials are commonly used in turbo tube muffler construction?

Stainless steel and aluminized steel are commonly employed due to their corrosion resistance and ability to withstand high temperatures. The specific alloy and gauge of the material influence the muffler’s durability and lifespan.

Question 5: How does one determine the appropriate turbo tube muffler size for a given application?

The size of the turbo tube muffler should be matched to the engine’s displacement and horsepower output. Consulting with a qualified exhaust system specialist or referencing manufacturer specifications is recommended to ensure proper sizing.

Question 6: What maintenance procedures are recommended for a turbo tube muffler?

Regular inspections for corrosion, leaks, and damage are crucial. Promptly addressing any identified issues can prevent further degradation and extend the muffler’s service life. Periodic cleaning may also be necessary to remove accumulated debris.

In summary, selecting and maintaining an appropriate turbo tube muffler is essential for optimizing exhaust noise reduction without compromising engine performance.

The subsequent section will delve into the regulatory aspects of exhaust systems and noise emissions.

Turbo Tube Muffler

The preceding analysis has elucidated the multi-faceted considerations inherent in the design, selection, and maintenance of the turbo tube muffler. From optimizing exhaust flow and minimizing backpressure to ensuring material durability and emission compliance, the effective deployment of this component demands a comprehensive understanding of its functional parameters and its impact on overall vehicle performance. A properly implemented device represents a crucial intersection of noise reduction and engine efficiency.

As regulatory standards continue to evolve and engine technologies advance, the turbo tube muffler remains a critical component in achieving both environmental responsibility and optimal vehicle operation. Continued research and development in materials science and acoustic engineering are essential to further refine its capabilities and ensure its sustained relevance in the automotive landscape. The careful application of this technology is fundamental to responsible vehicle engineering and operation.